Anti-collapse plugging agent for drilling fluid and preparation method and application thereof

A plugging agent and anti-slump technology, applied in the fields of mining, oil and natural gas exploration, can solve the problems of easy foaming, can not meet the anti-slump drilling fluid, and the viscosity of the drilling fluid increases, and achieves good effect, good plugging performance, The effect of low fluorescence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

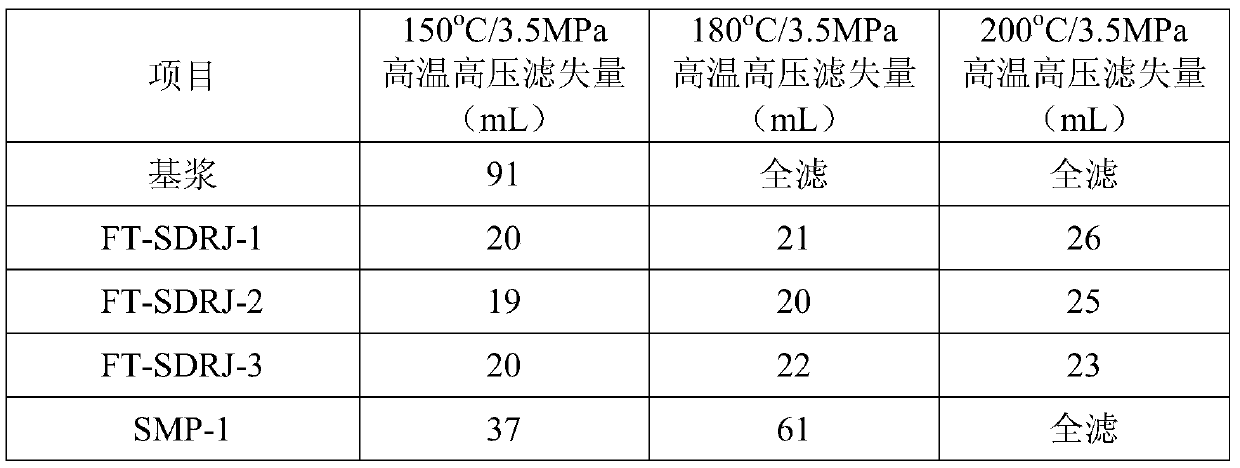

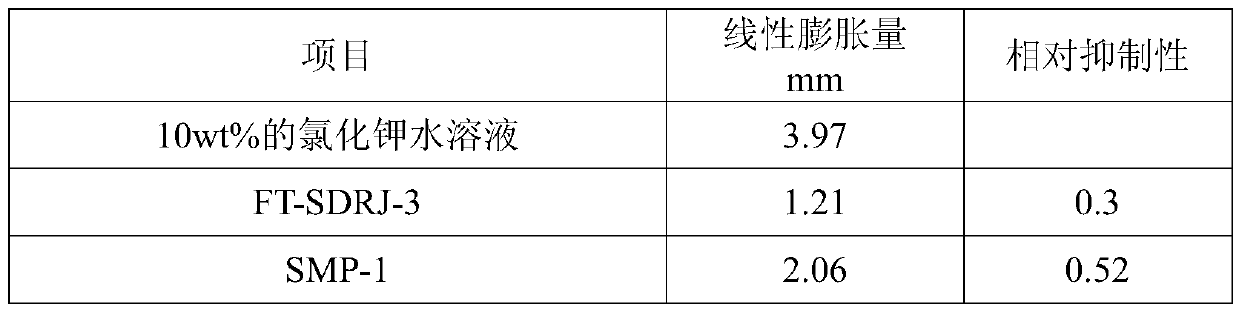

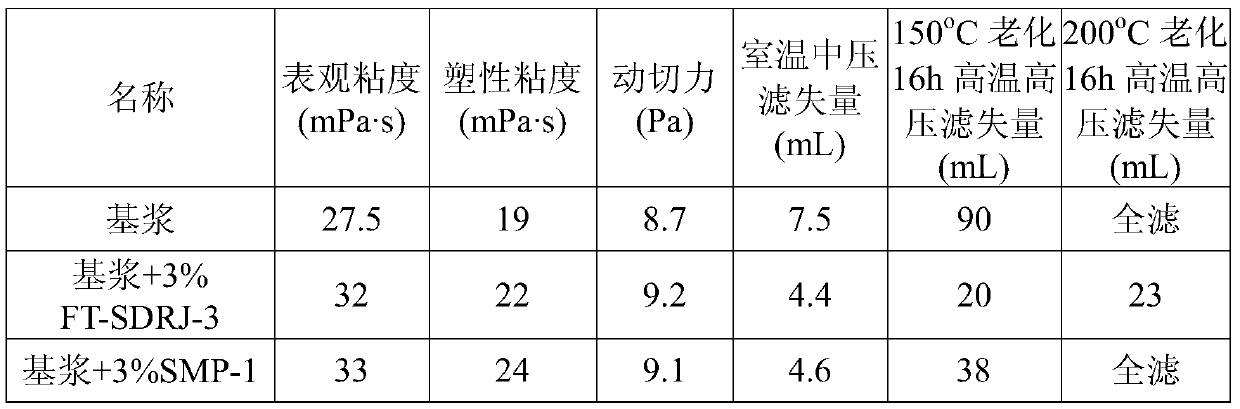

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing an anti-collapse plugging agent for drilling fluid, wherein the method specifically includes the following steps:

[0033] a. Add 0.3 mole of sodium sulfite to 60 mL of water to dissolve completely, add 0.5 mole of dimethylamine and 1 mole of formaldehyde to the aqueous solution, and react at 80°C for 120 minutes to obtain the addition product;

[0034] b. Add 1 mole of phenol and 0.05 mole of formaldehyde into the reaction kettle, heat up to 90°C and react for 180 minutes;

[0035] C, add the alkaline catalyst sodium hydroxide of 0.001 mole in reactor;

[0036] d. Add 0.05 moles of the addition product described in step a to the reactor, and keep the temperature at 90°C for 200 minutes;

[0037] e. After the reaction, cool down and discharge, dry at 50°C, and pulverize to obtain an anti-slump plugging agent for drilling fluid with a particle size of 80 mesh, which is designated as FT-SDRJ-1.

Embodiment 2

[0039] This embodiment provides a method for preparing an anti-collapse plugging agent for drilling fluid, wherein the method specifically includes the following steps:

[0040] a. Add 1 mole of potassium sulfite to 200 mL of water to dissolve completely, add 0.8 mole of dimethylamine, 1 mole of a mixture of formaldehyde and acetaldehyde to the aqueous solution, and react at 100°C for 100 minutes to obtain an addition product;

[0041] b. Add 1 mole of a mixture of phenol and cresol, and 0.9 moles of a mixture of formaldehyde and acetaldehyde into the reaction kettle, raise the temperature to 150°C and react for 120 minutes;

[0042] C, add the alkaline catalyst potassium hydroxide of 0.6 mole in reactor;

[0043] d. Add 1 mole of the addition product described in step a to the reactor, and keep the temperature at 150°C for 150 minutes;

[0044] e. After the reaction, cool down and discharge the material, dry at 100°C, and pulverize to obtain an anti-slump plugging agent for ...

Embodiment 3

[0046] This embodiment provides a method for preparing an anti-collapse plugging agent for drilling fluid, wherein the method specifically includes the following steps:

[0047] a. Add 1.6 moles of sodium sulfite, potassium sulfite, and sodium bisulfite to 320 mL of water to dissolve completely, add 1.2 moles of dimethylamine, 1 mole of paraformaldehyde and furfural to the aqueous solution, and react at 90°C for 110 minutes. Addition products are obtained;

[0048] b. Add 1 mole of a mixture of xylenol and resorcinol and 1.5 moles of acetaldehyde into the reaction kettle, heat up to 120°C and react for 150 minutes;

[0049] C, add the mixture of the alkali catalyst ammoniacal liquor of 1.2 moles and barium hydroxide in reactor;

[0050] d. Add 1.5 moles of the addition product described in step a to the reactor, and keep the temperature at 120°C for 180 minutes;

[0051] e. After the reaction, cool down and discharge the material, dry at 80°C, and pulverize to obtain an anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com