Construction method for crossing construction waste rotary excavating pile

A construction method and technology of construction waste, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the difficulty of installing steel casings for super-thick construction waste backfill layers, poor construction waste backfill layer effects, and inability to excavate construction waste Clear and other problems to achieve the effect of solving the collapsed hole situation, improving the quality of pile forming, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

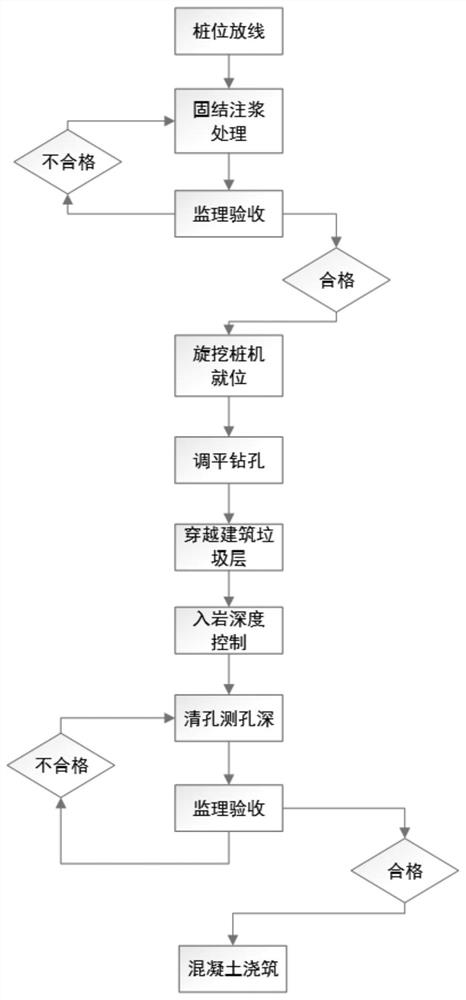

[0027] A construction method for rotary excavation piles passing through construction waste, referring to figure 1 , the construction method comprises the following steps:

[0028] S1. Pile position setting out: locate and measure the pile position according to the construction drawing, level the surrounding site, check the pile number and the surrounding environment of the site location, and mark the pile position with short steel bars; the measurement work should be reviewed and recorded to ensure accuracy ;

[0029] S2. Consolidation grouting treatment: Arrange consolidation grouting points within 3m around the support piles, the distance between the consolidation grouting points and the support piles is 600×600mm, and the high-pressure rotary grouting pile machine is in place and leveled , penetrate the injection pipe to the bottom of the construction waste, use 42.5 Portland cement, cement slurry with a water-cement ratio of 1.0, double-pipe method for side grouting, sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com