A method for predicting formation collapse pressure and fracture pressure under the drill bit while drilling

A technology of rupture pressure and collapse pressure, which is used in the field of predicting the collapse pressure and rupture pressure of the stratum under the drill bit by using seismic records while drilling, and can solve the problems of prone to accidents, complicated downhole operations, and rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0108] The following reference is attached Figure 23 The method of using seismic records to predict the collapse pressure and rupture pressure of the section to be drilled in the present invention will be described in detail. The method mainly includes the following steps:

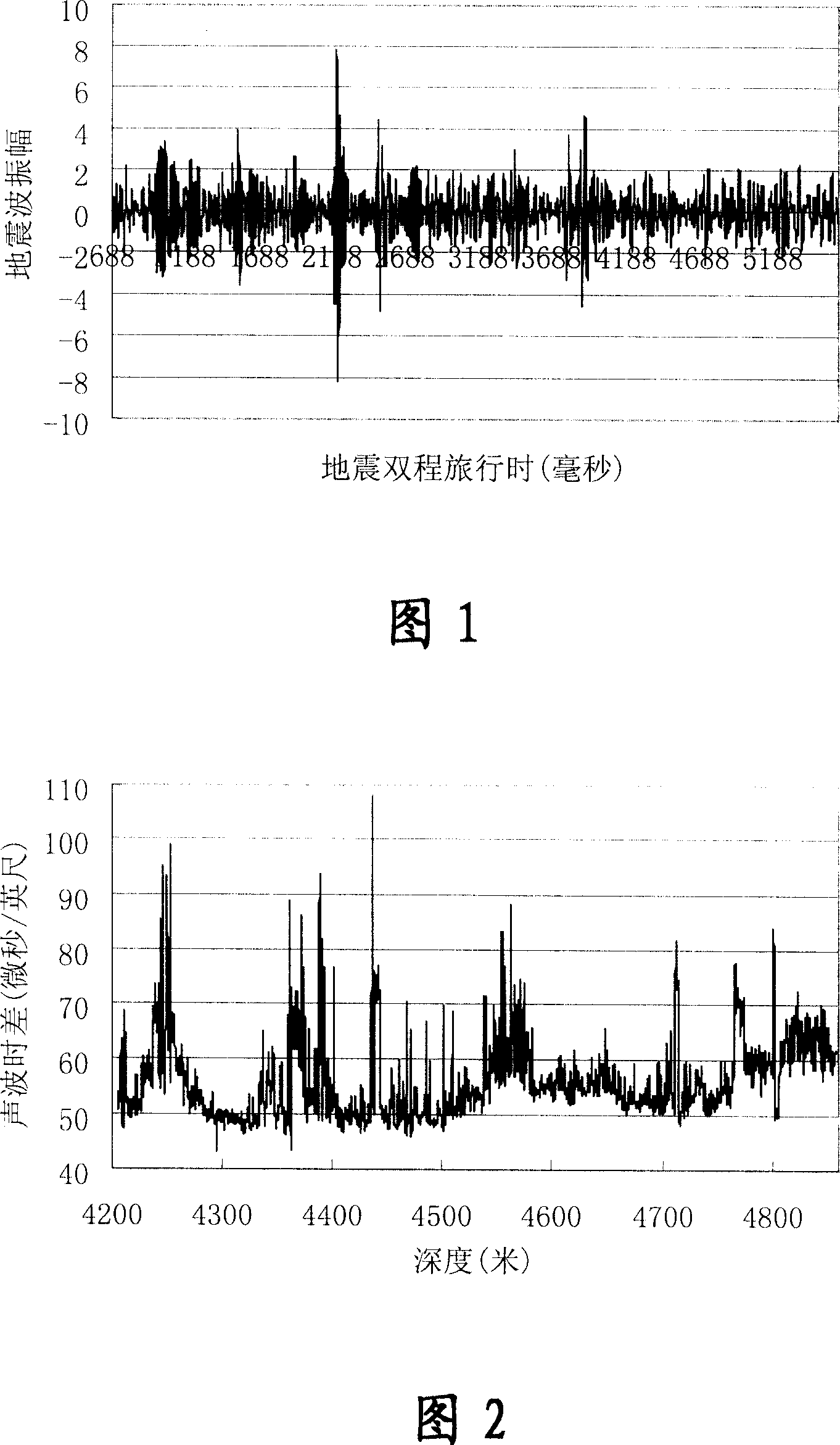

[0109] Step 1. Extract several seismic records beside each well for the well-drilled and to-be-drilled seismic records, and perform weighting processing to obtain the well-drilled and to-be-drilled seismic records, such as figure 1 with Picture 12 Shown

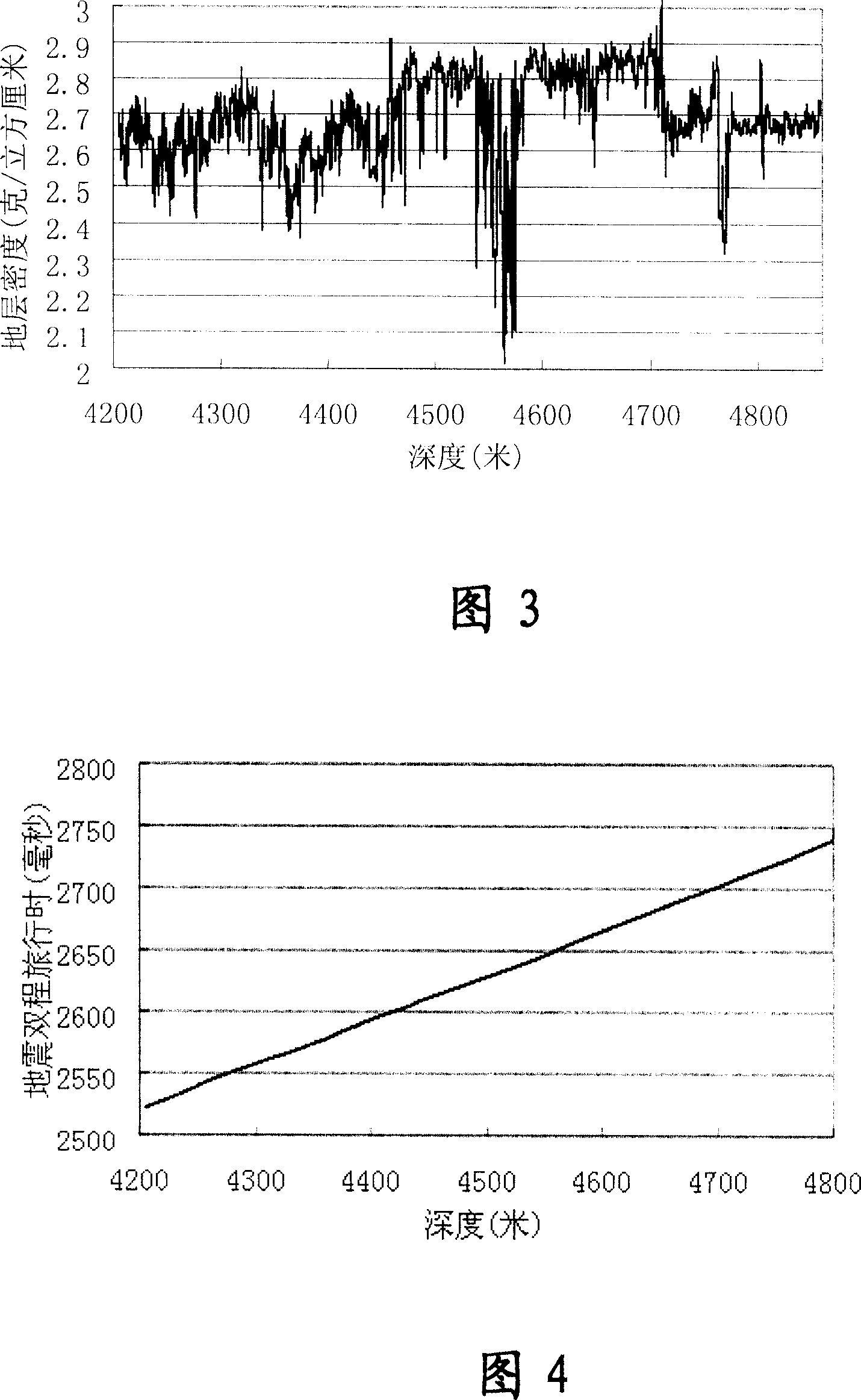

[0110] Step 2: Perform sonic time difference and density logging on the well drilled, and obtain sonic time difference logging data and formation density logging data of the different layers that have been drilled; thereby obtaining sonic time difference logging curves and formation density logging curves, Such as figure 2 , image 3 Shown

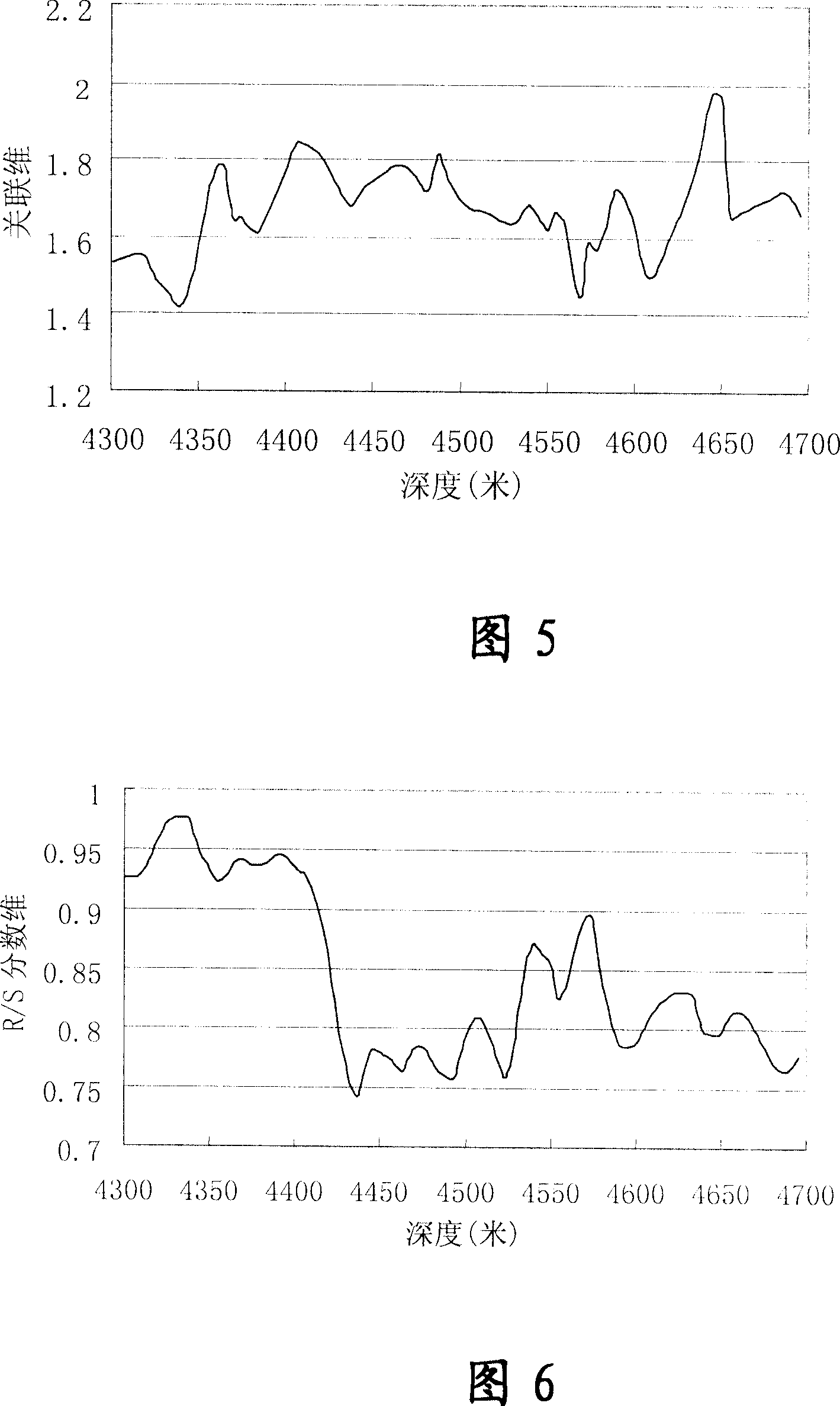

[0111] Step 3. Use the logging data and seismic records of the different layers that have been drilled to establish a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com