Method for predicting pore pressure of regional high-pressure saltwater layer by utilizing curvature of face of geologic structure

A technology of pore pressure and area prediction, which is applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problems of drilling manpower, material loss, contaminated drilling fluid, irregular regional distribution, etc., to prevent downhole complex situations, The effect of preventing well wall collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

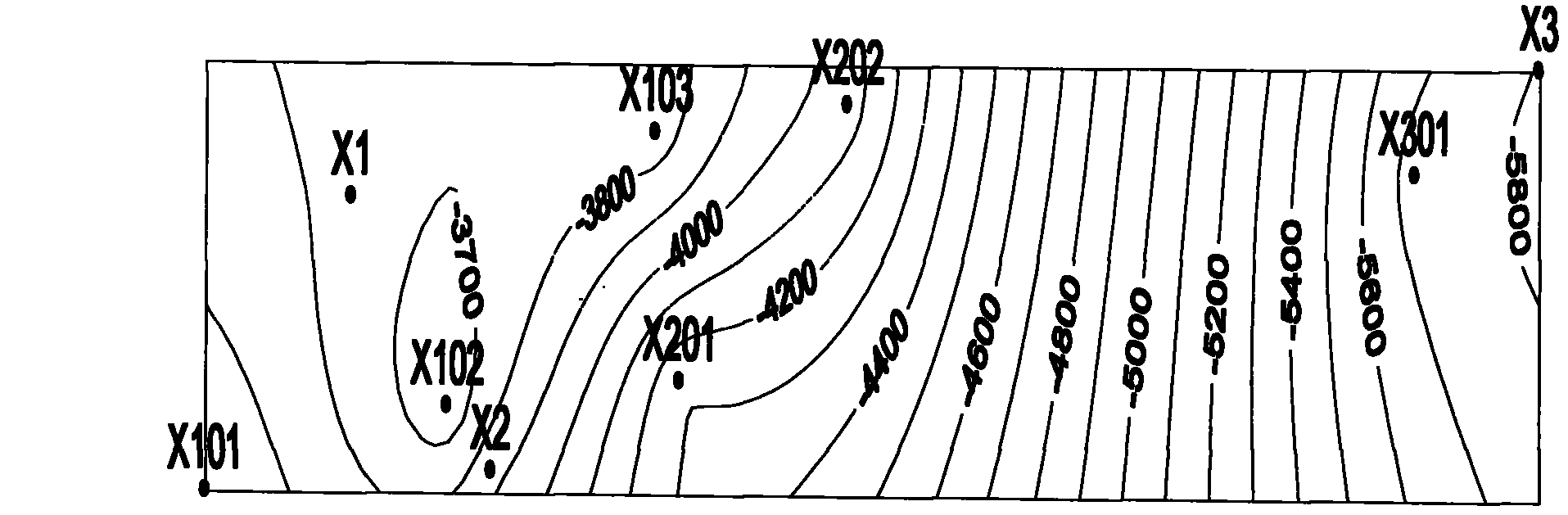

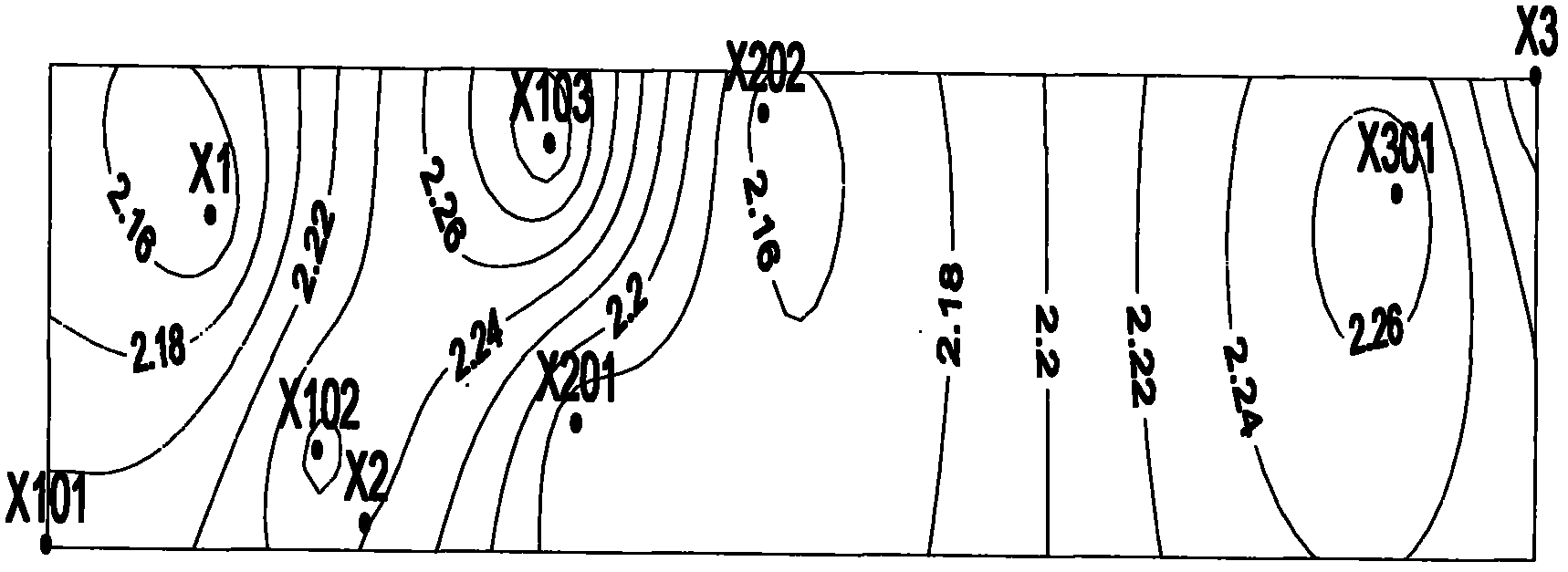

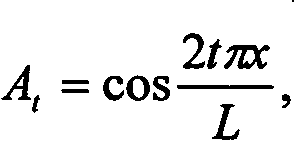

[0018] In the long geological time, due to the folding movement of the earth's crust, the salt layer is bent, or the salt layer is arched due to the uplift of the basement, and the closed salt water layer between salts is anomalously formed due to structural compression, uplift and plastic flow of salt rock. The degree of high pressure and structural deformation is related to the abnormal pressure of the saline layer. Generally speaking, the more severe the structural deformation, the greater the pore pressure of the abnormally high-pressure brine layer. The degree of structural deformation can be described by the curvature of any point on the structural surface, and the curvature is inherently related to the mechanical constitutive deformation of rocks. The constitutive relationship of rock is a quantitative description that revea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com