Patents

Literature

204 results about "Abnormal pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Abnormal Pressure lies either below or above the normal pressure gradient and thus can be over pressured or subnormal. The mechanism that generates the Abnormal Pressure can be complicated and can vary from one region to another. The pressure is the hydrodynamic phenomena where time has a great role.

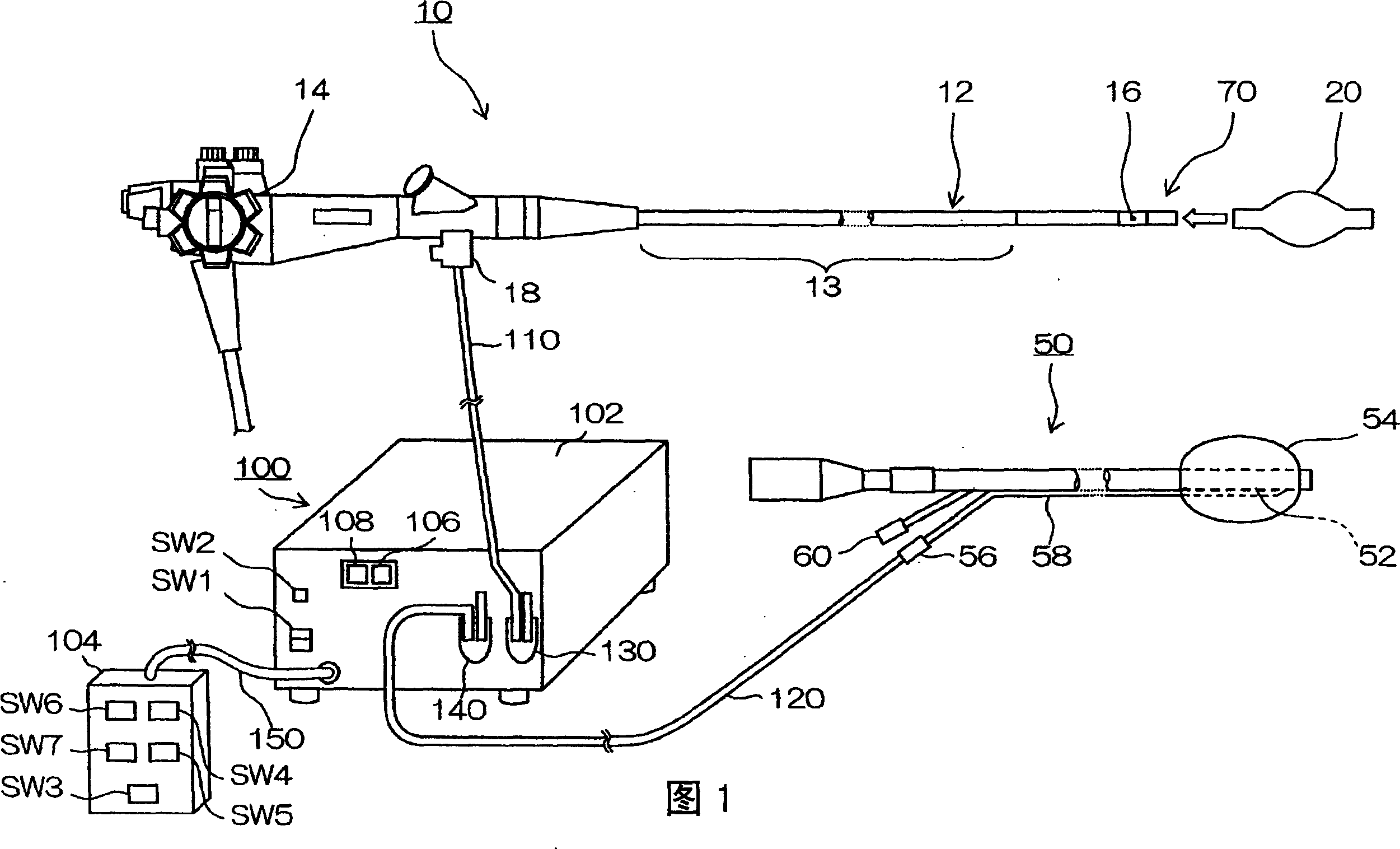

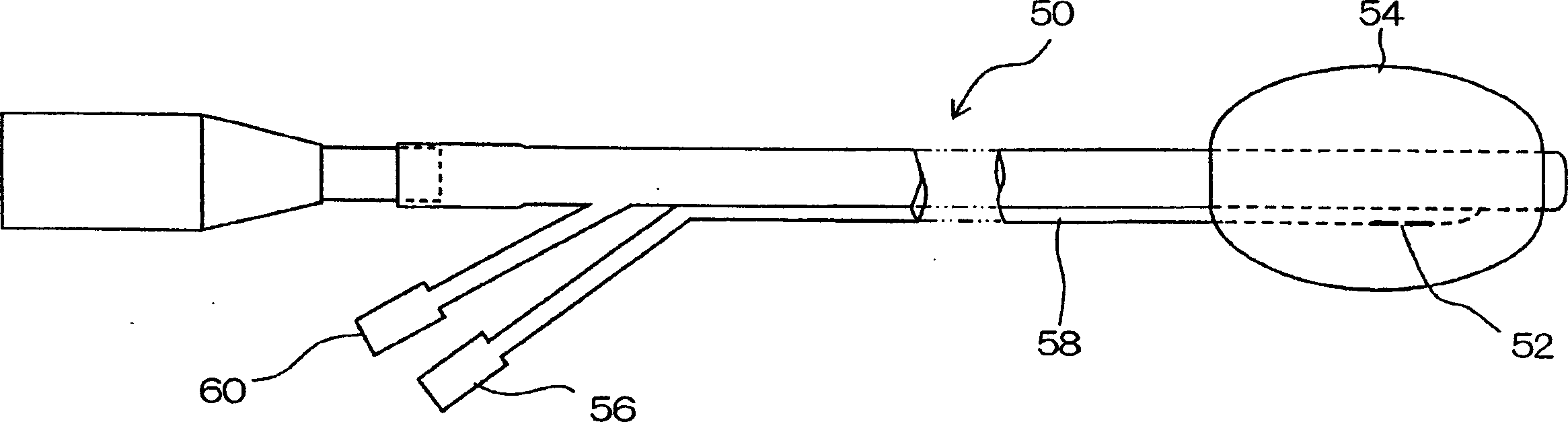

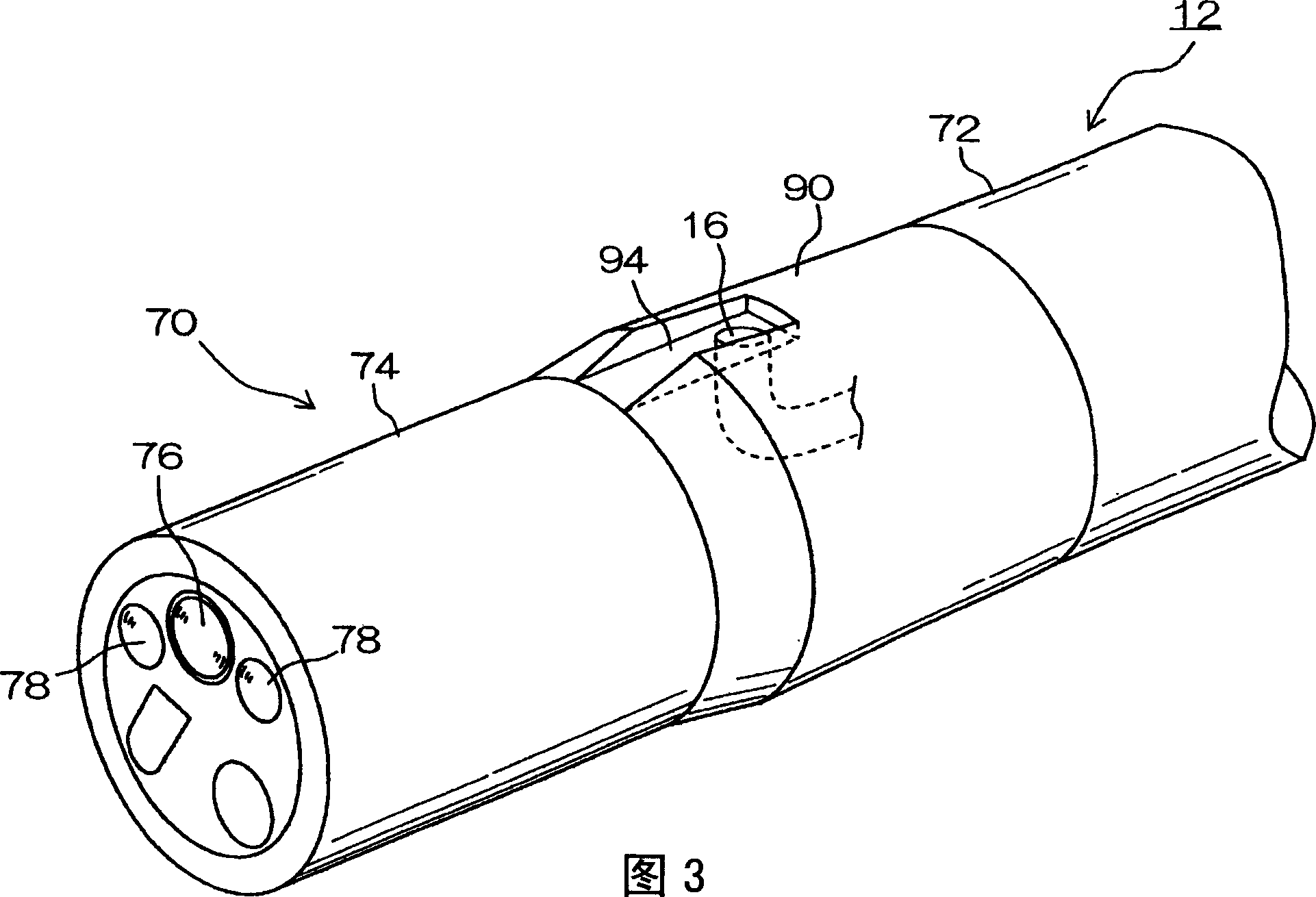

Airbag type endoscope

A warning unit outputs an alert when a first abnormality detector and a second abnormality detector determine detachment or loosening of a tube (110) that can cause abnormal pressure in each balloon (20,54).

Owner:FUJIFILM CORP +1

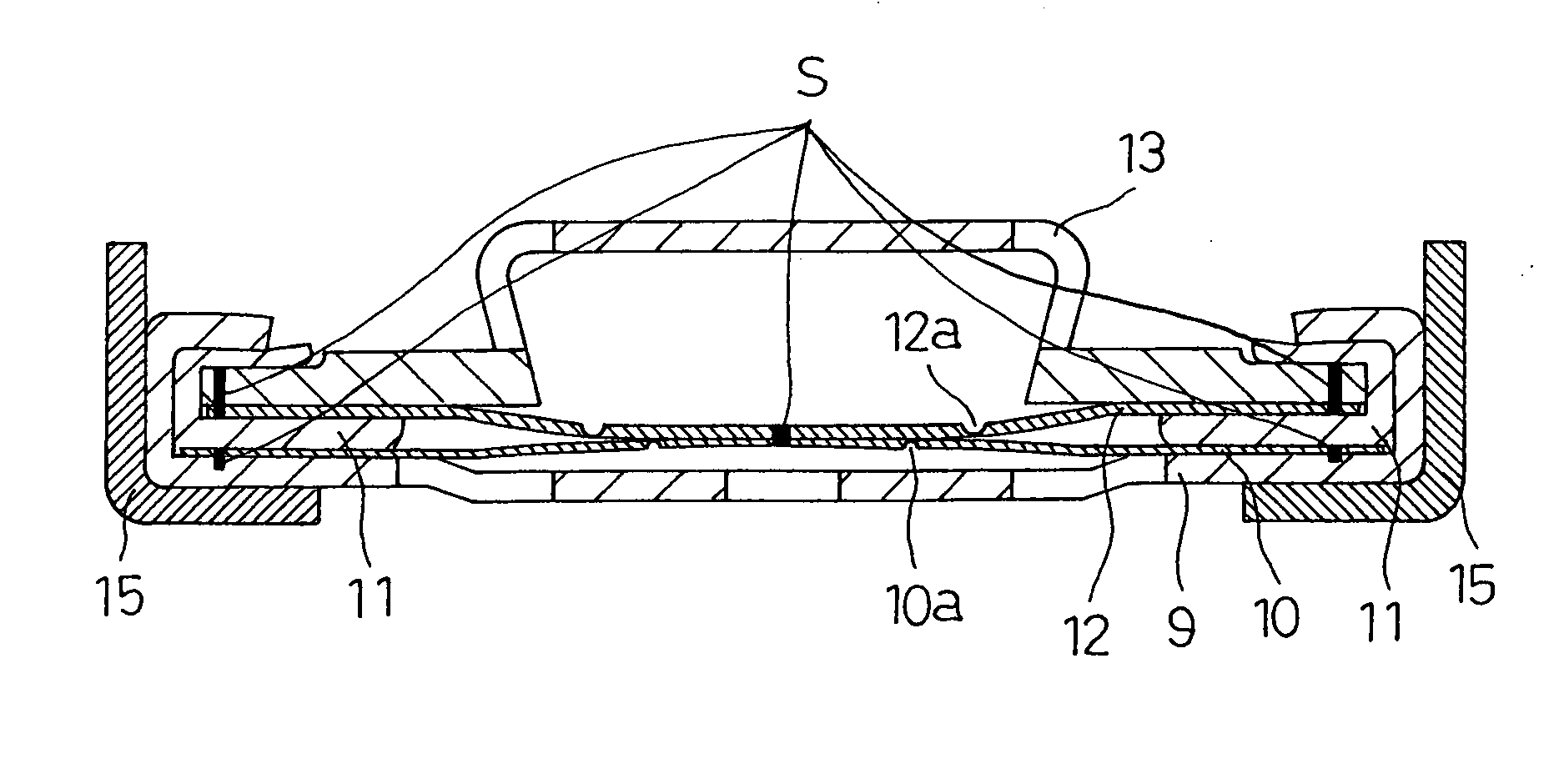

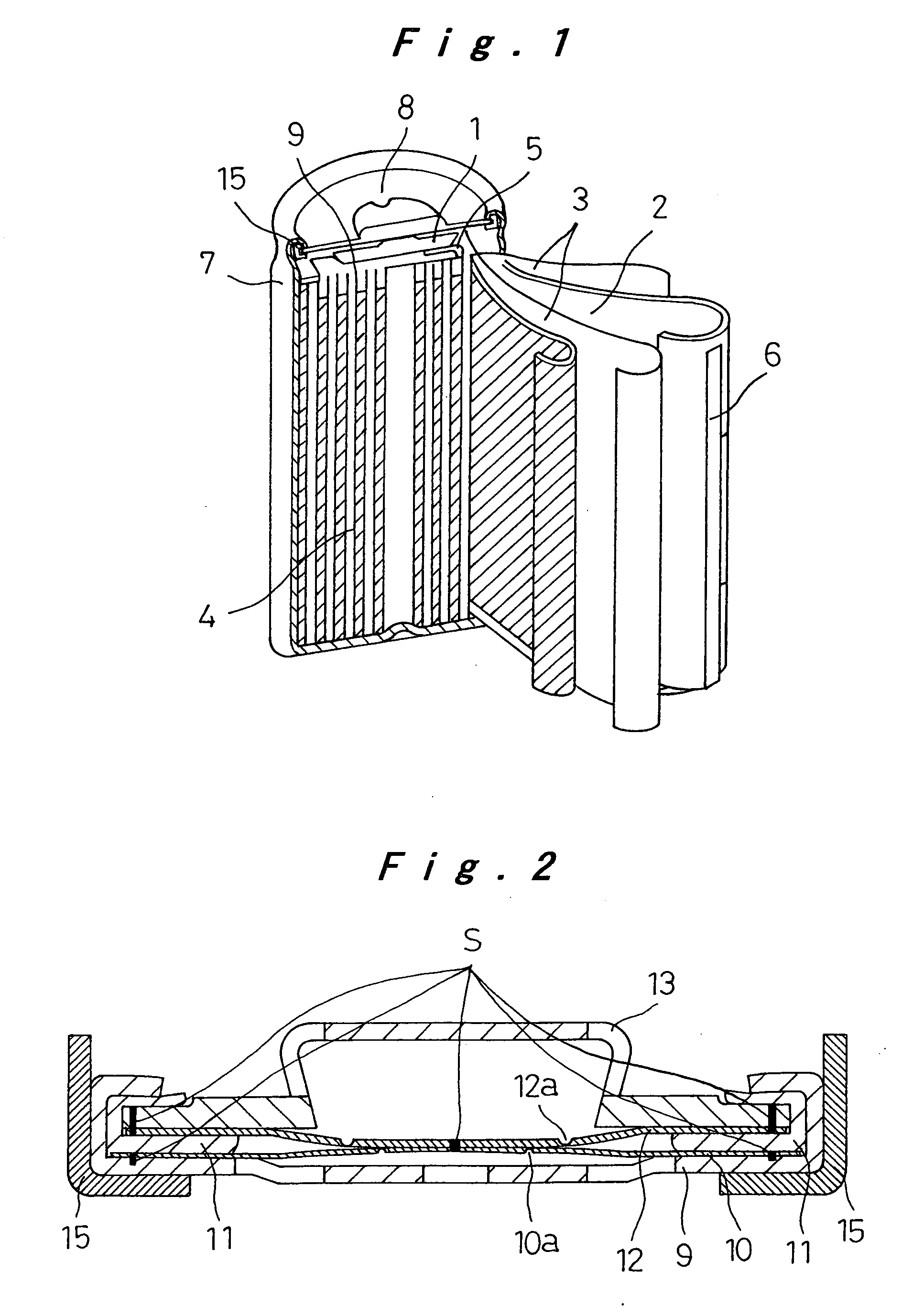

Sealed rechargeable battery and manufacturing method of the same

A sealed rechargeable battery containing an electrode unit and a liquid electrolyte in a metallic case with a bottom that is sealed with a closure assembly. The electrode unit includes a positive electrode and a negative electrode, each made up of a collector and electrode material paste coated thereon, wound around with a separator interposed therebetween. The closure assembly includes a metallic filter that forms an internal terminal and accommodates a safety mechanism provided in case of abnormal pressure rise caused by overcharging etc, a resin inner gasket, and a metallic cap that forms an external terminal superposed upon one another. A resin inner gasket is attached to the metallic filter and the end edge of the metallic filter is crimped to provide a seal. The metallic filter and all the metallic parts encased in the metallic filter are joined together by welding. This closure assembly design enables high power output and high-current discharge of the battery with low resistance.

Owner:PANASONIC CORP

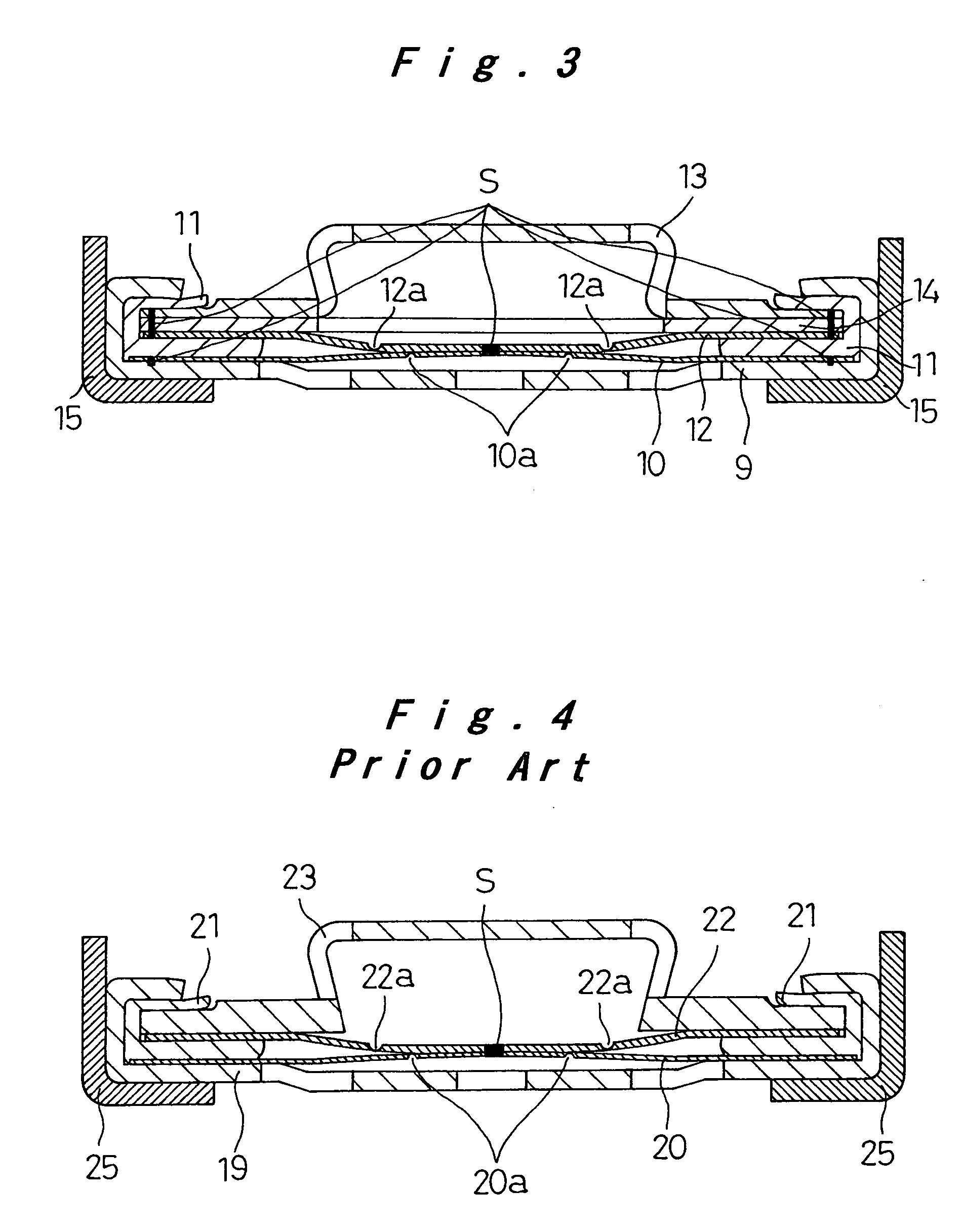

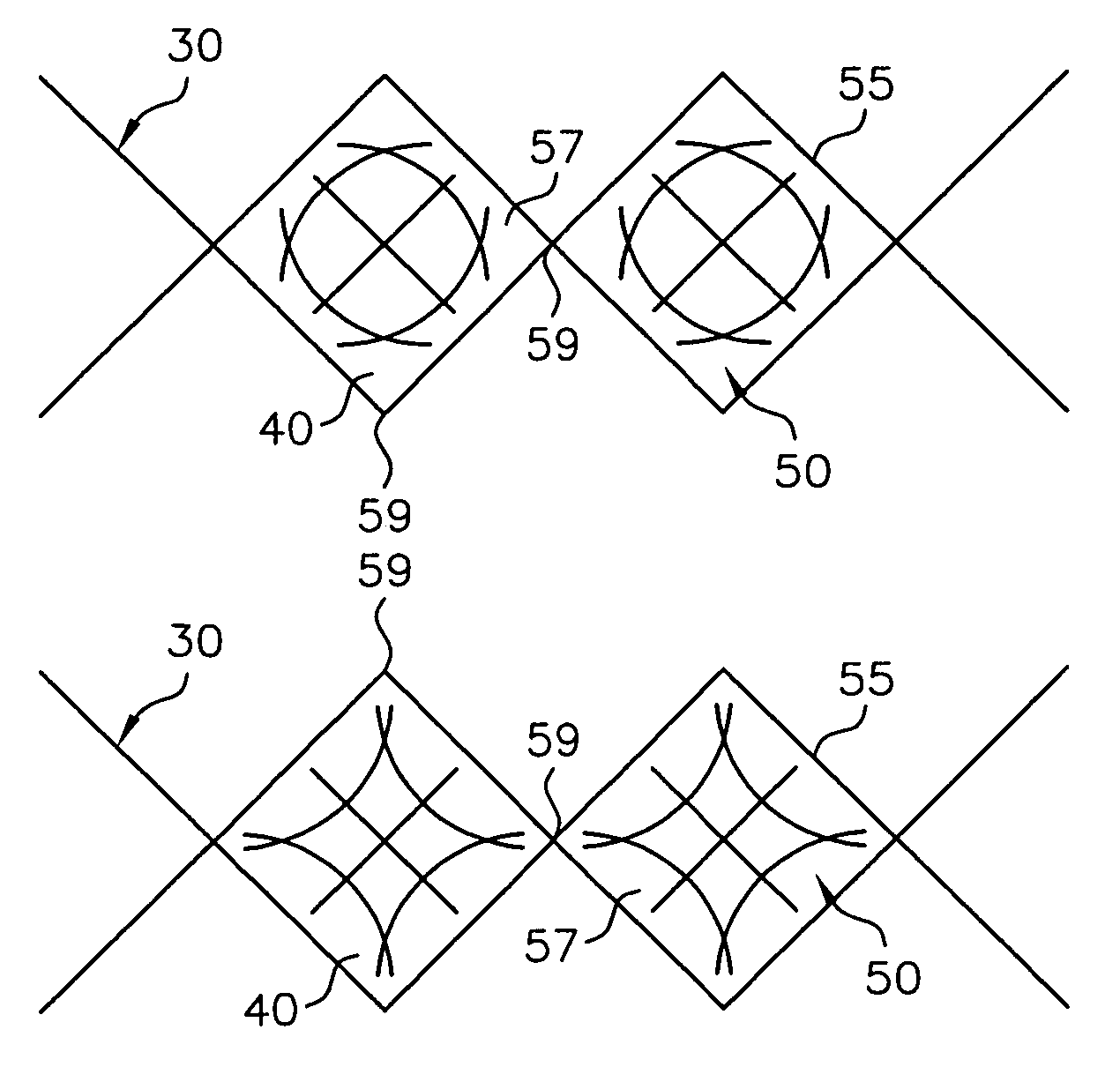

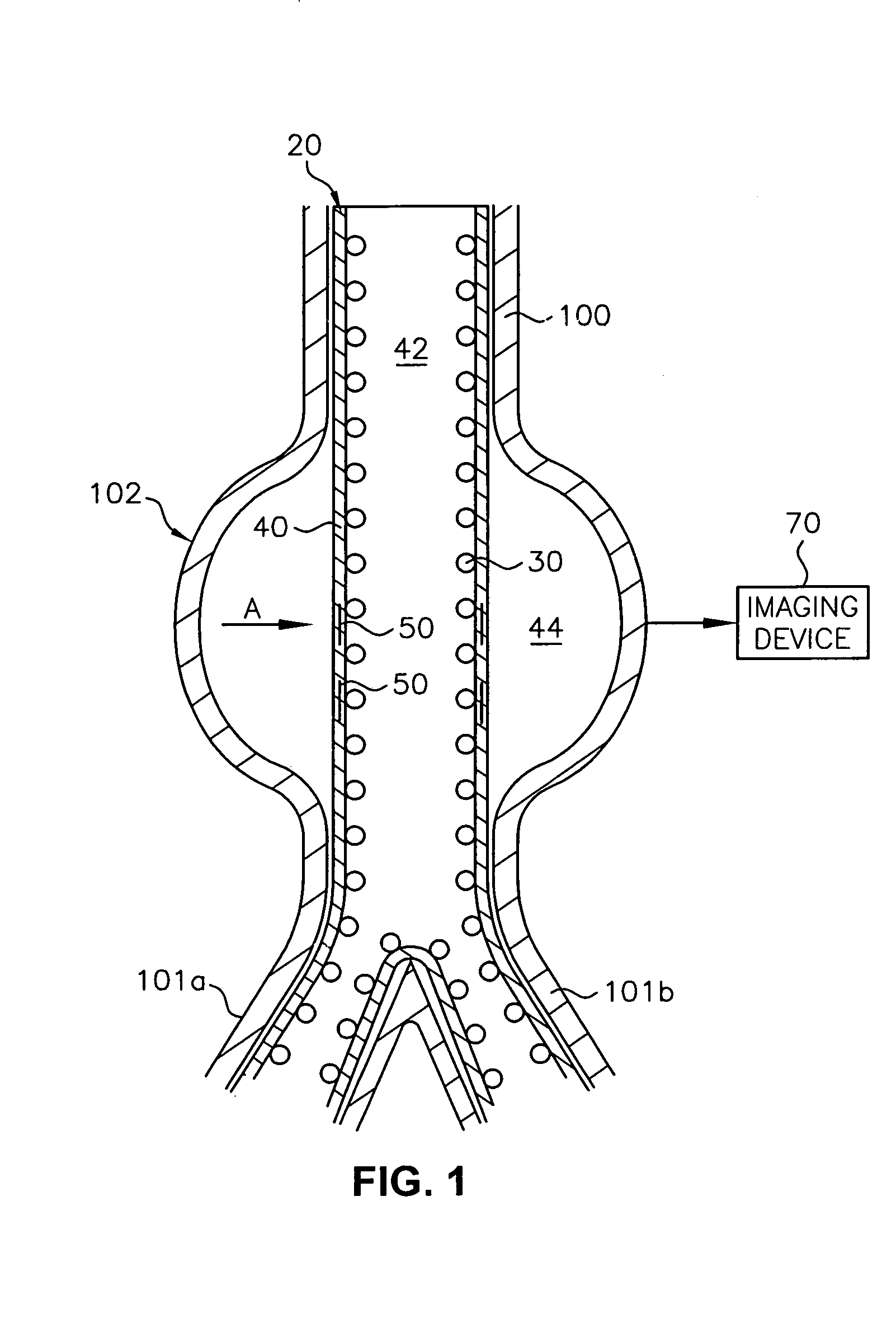

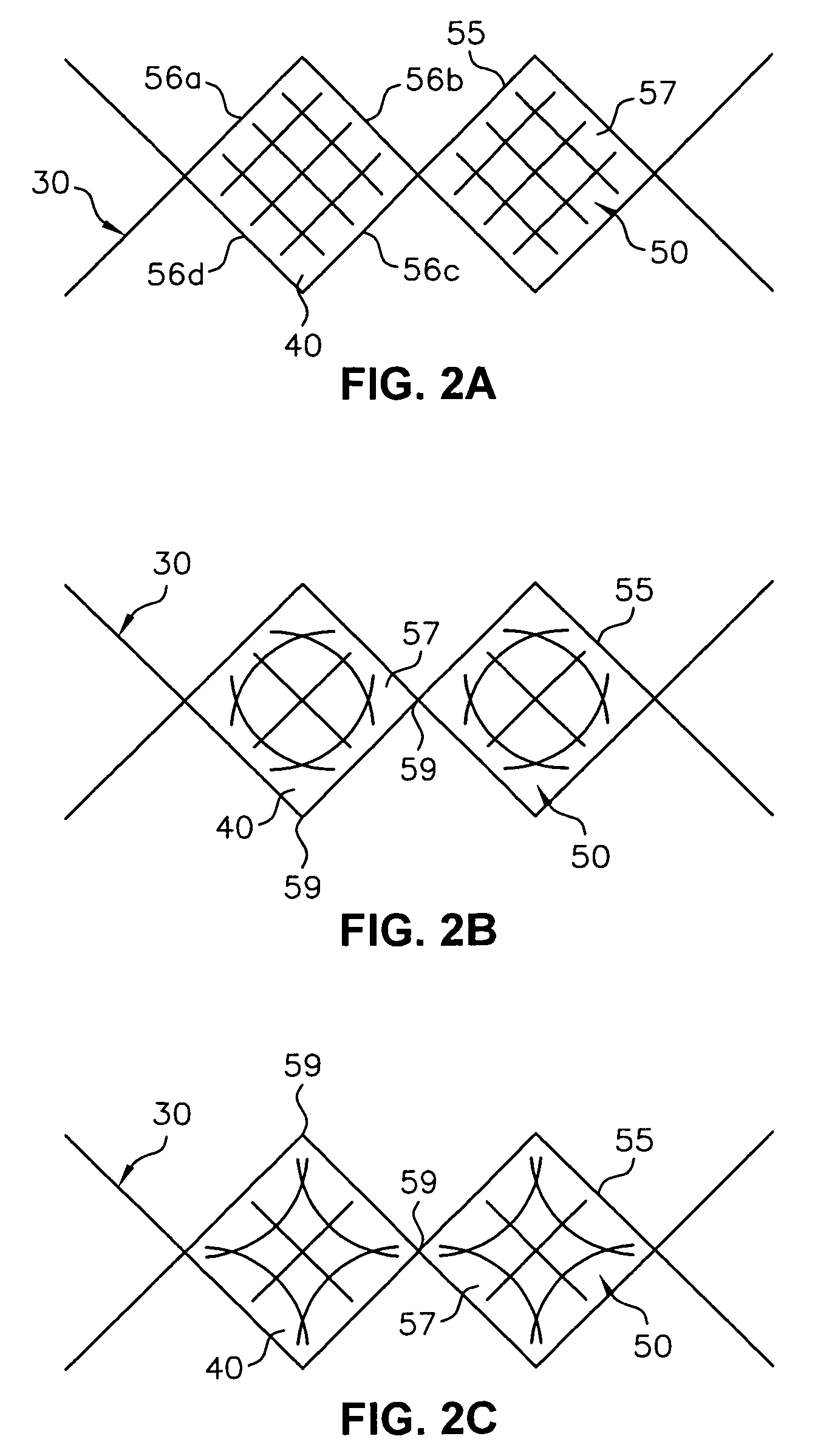

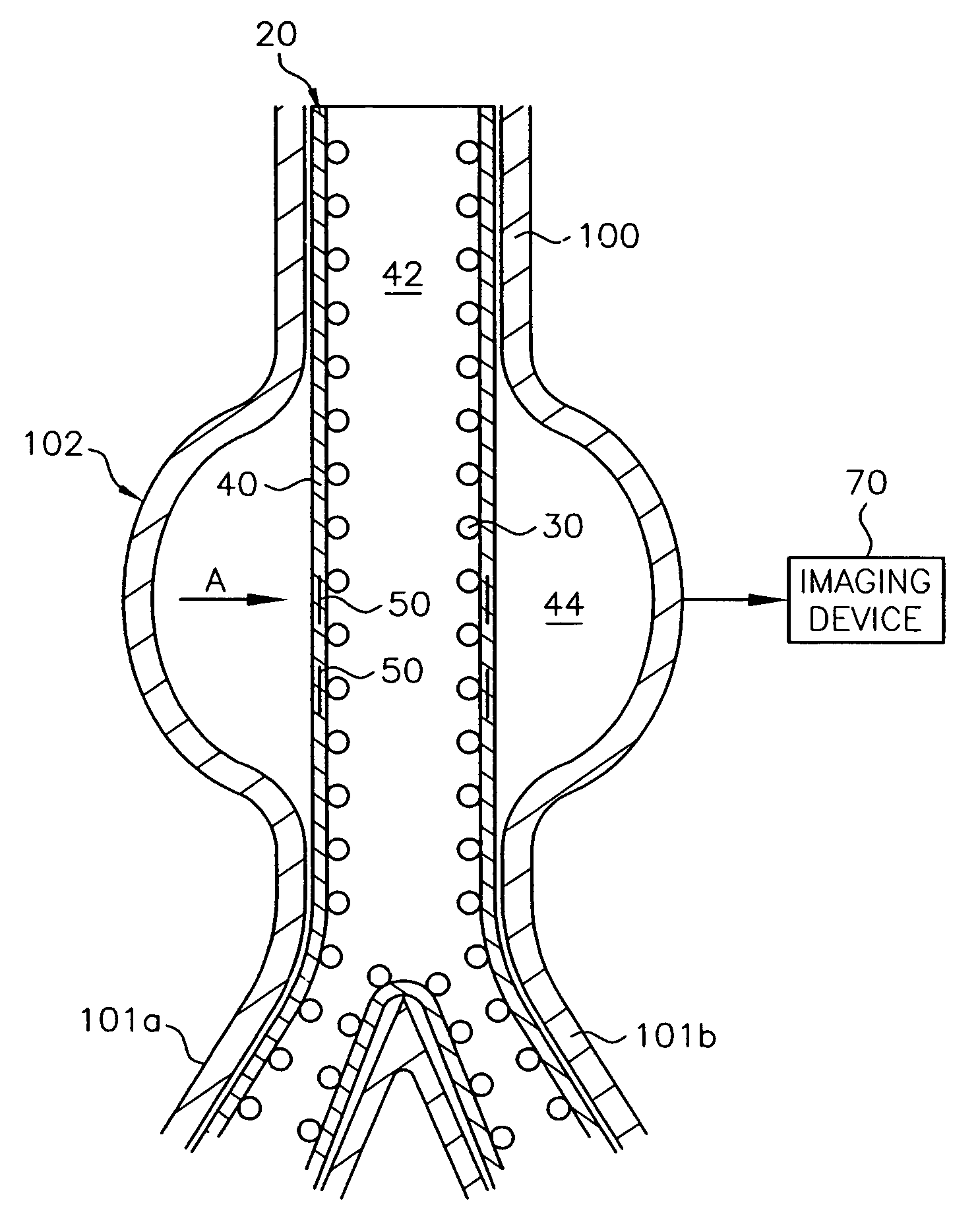

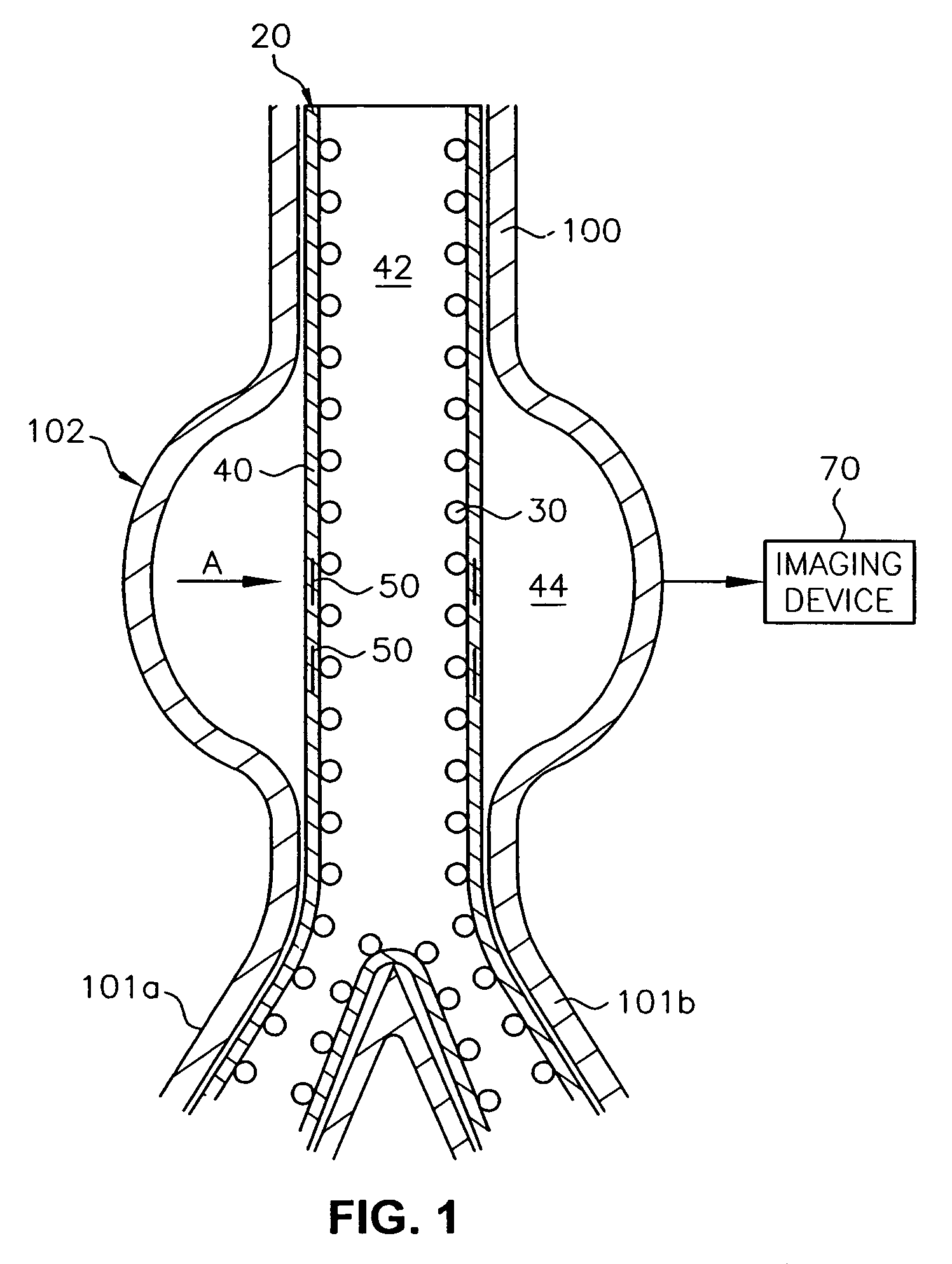

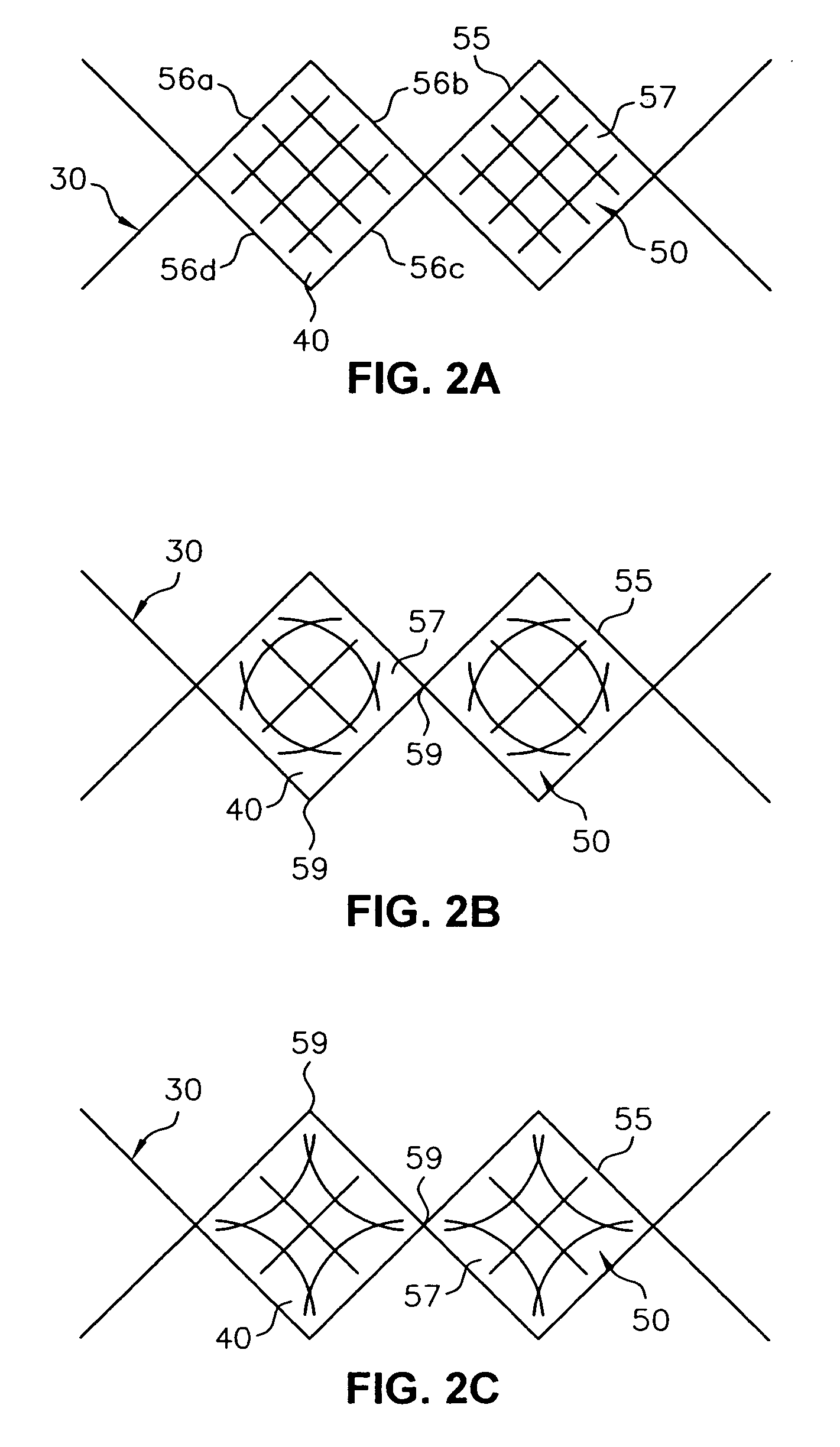

Endoluminal device and system and method for detecting a change in pressure differential across an endoluminal device

An endoluminal device for deployment in a body lumen includes a radially expandable stent, a graft attached to the stent, and a plurality of indicator members affixed to the graft and adapted to form a normal pattern in response to a normal pressure differential and an abnormal pattern in response to an abnormal pressure differential across the graft. By forming different patterns at different pressure differentials, the indicator members enable the detection of a change in pressure which could be evidence of a leak. A system for detecting a change in pressure differential includes the endoluminal device and an imaging system for displaying the indicator members. A method for detecting a change in pressure includes the steps of identifying the normal pattern, implanting the device, imaging the indicator members, and comparing the imaged pattern with the normal pattern to determine whether the normal pressure or an abnormal pressure differential exists.

Owner:LIFESHIELD SCI

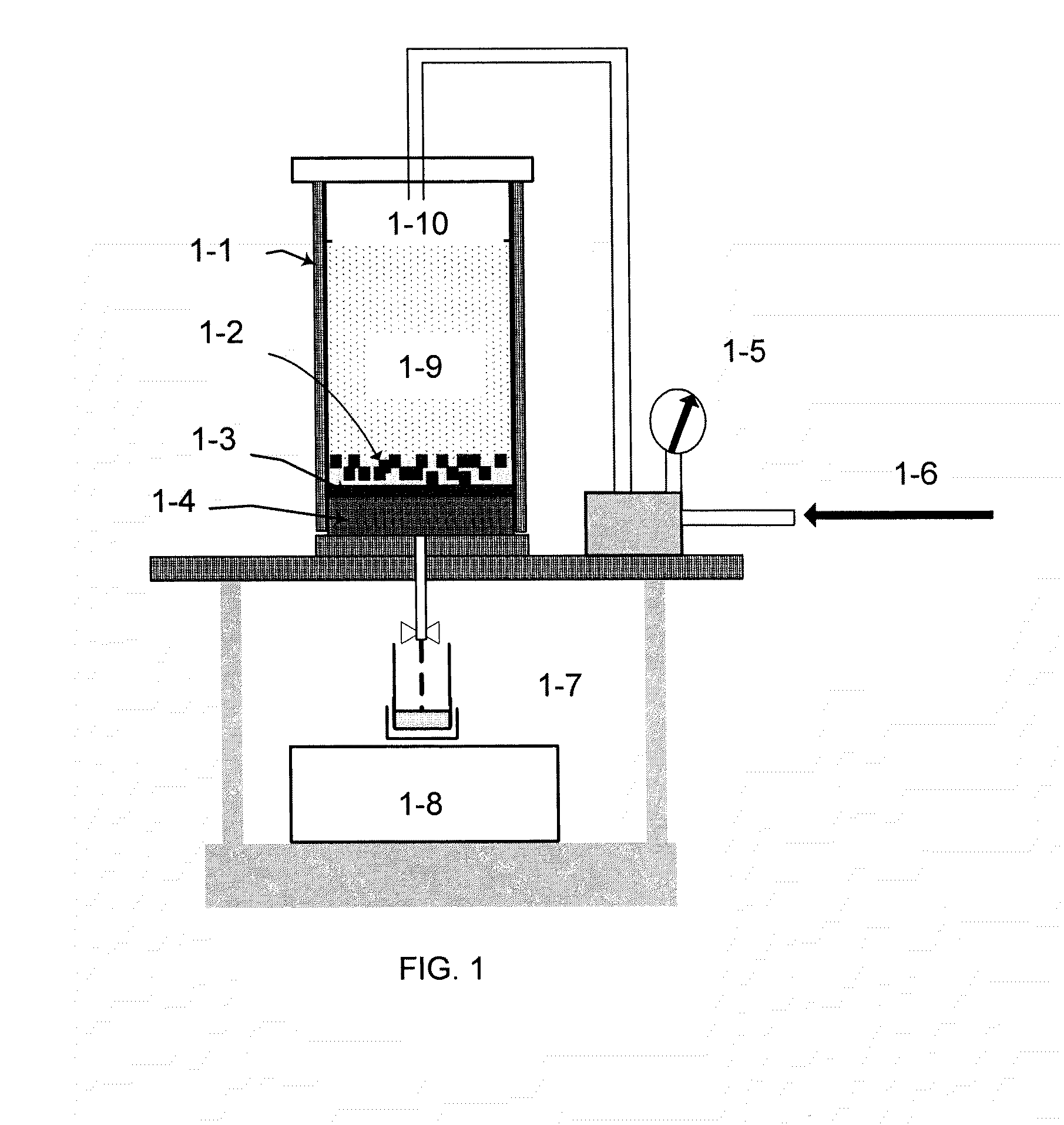

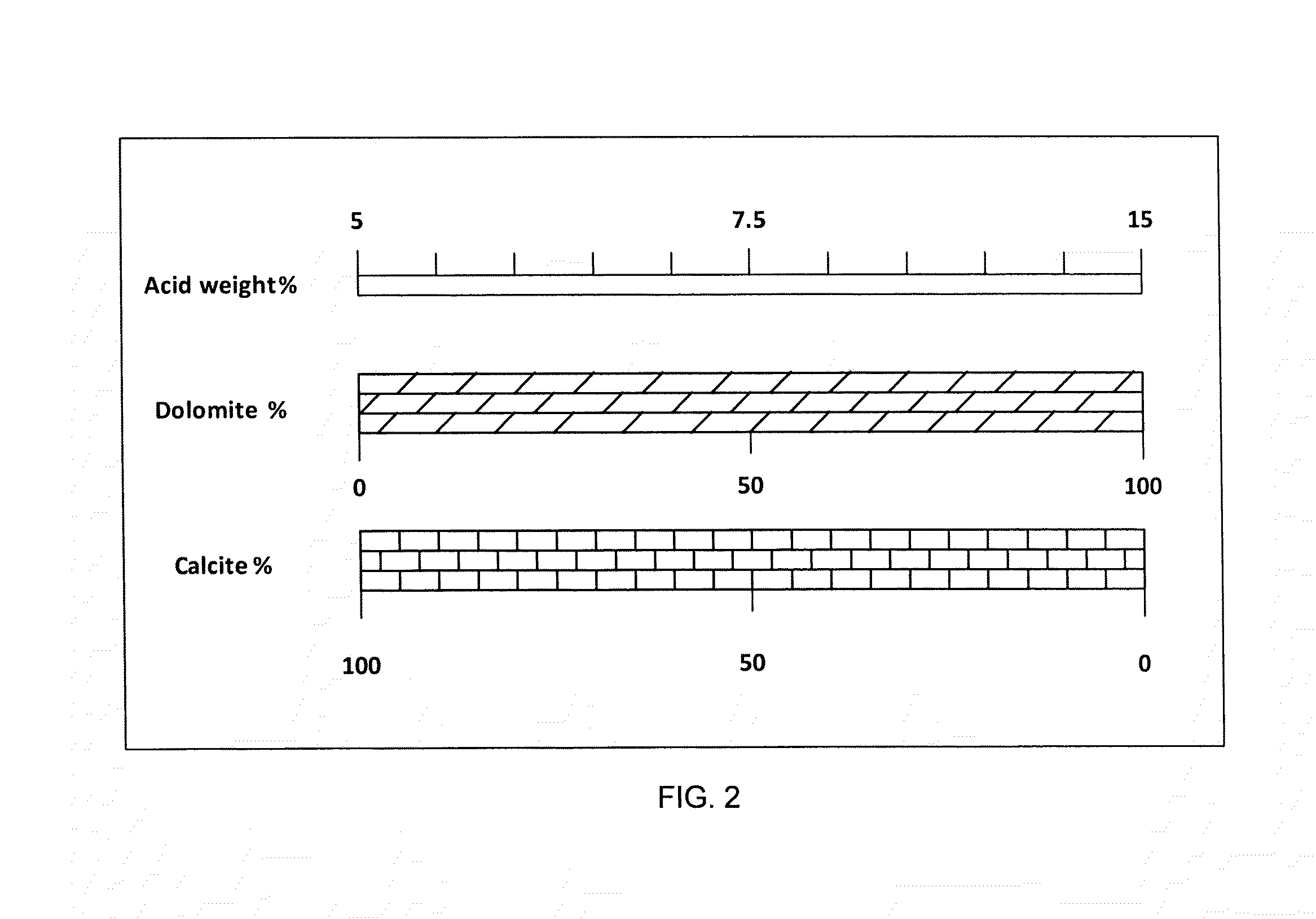

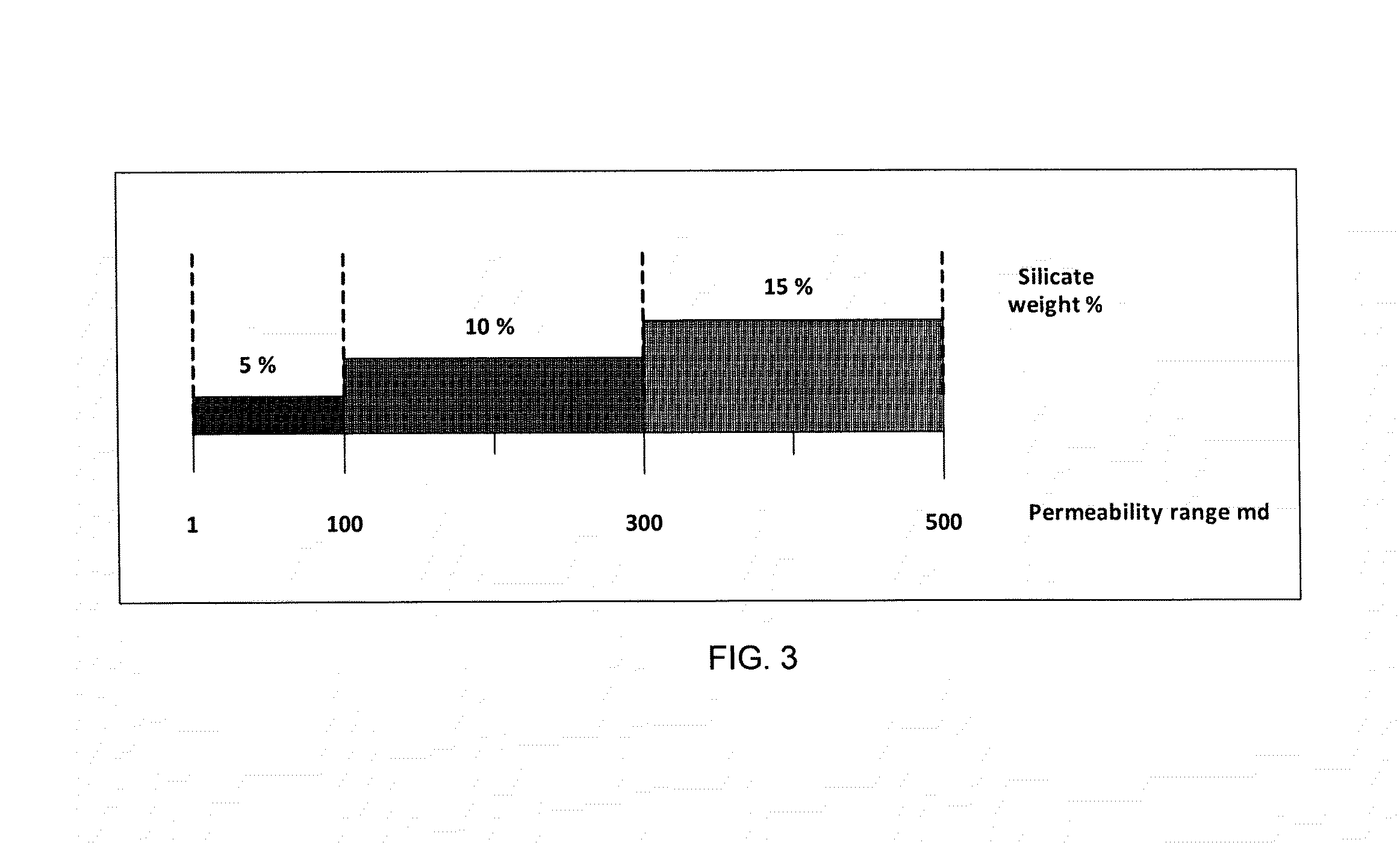

Zero-invasion acidic drilling fluid

A drilling fluid system using retarded acid systems such as gelled acid (VES or polymer) and / or emulsified acid to drill carbonate formations (calcite and dolomite). Foamed acid may be used in low abnormal pressure carbonate reservoirs. The drilling fluid system permits drilling a target hydrocarbon-producing formation with zero-invasion of the drilling fluid system. A method for using the drilling fluid system for fluid loss control during drilling operations.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

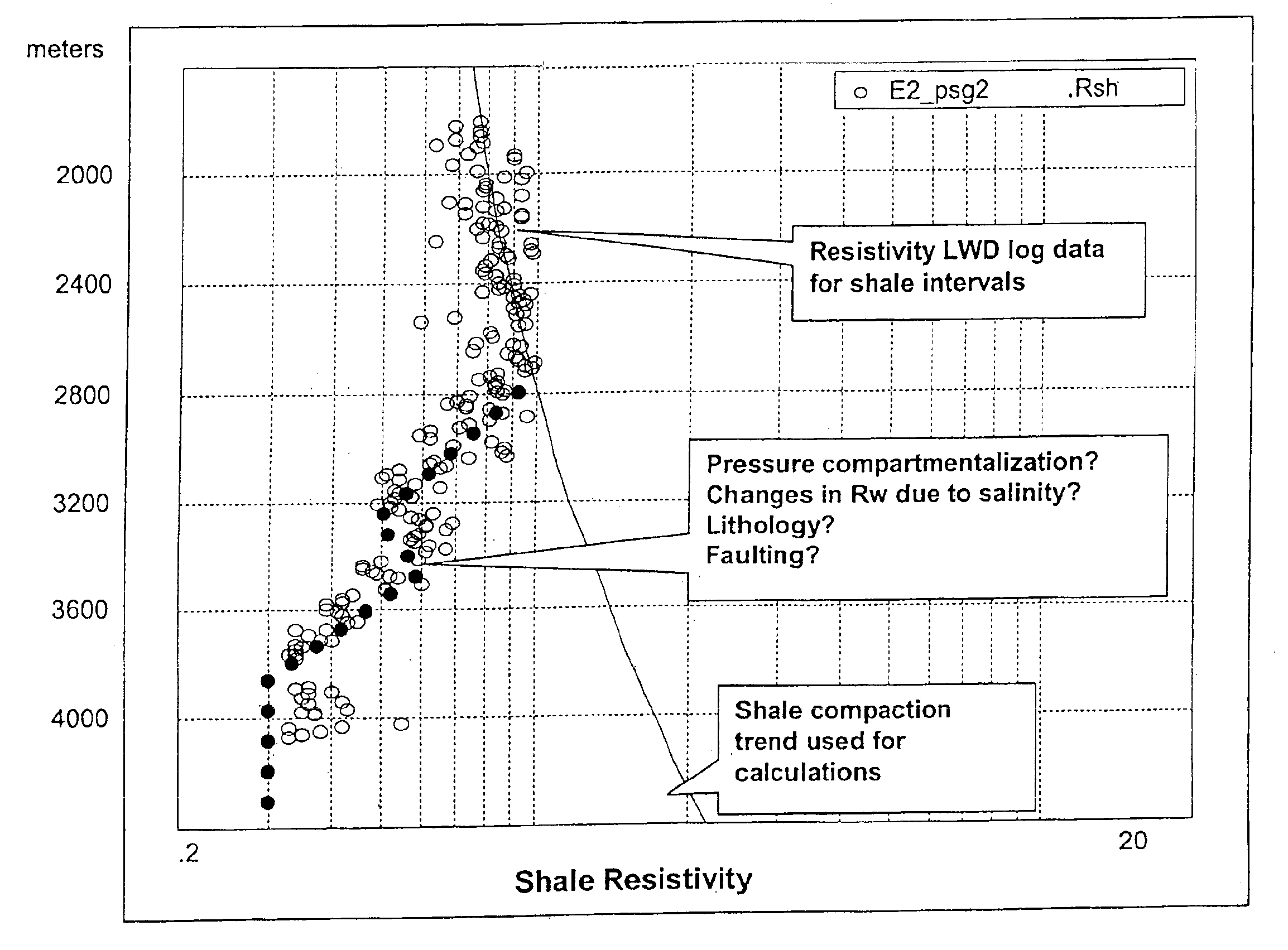

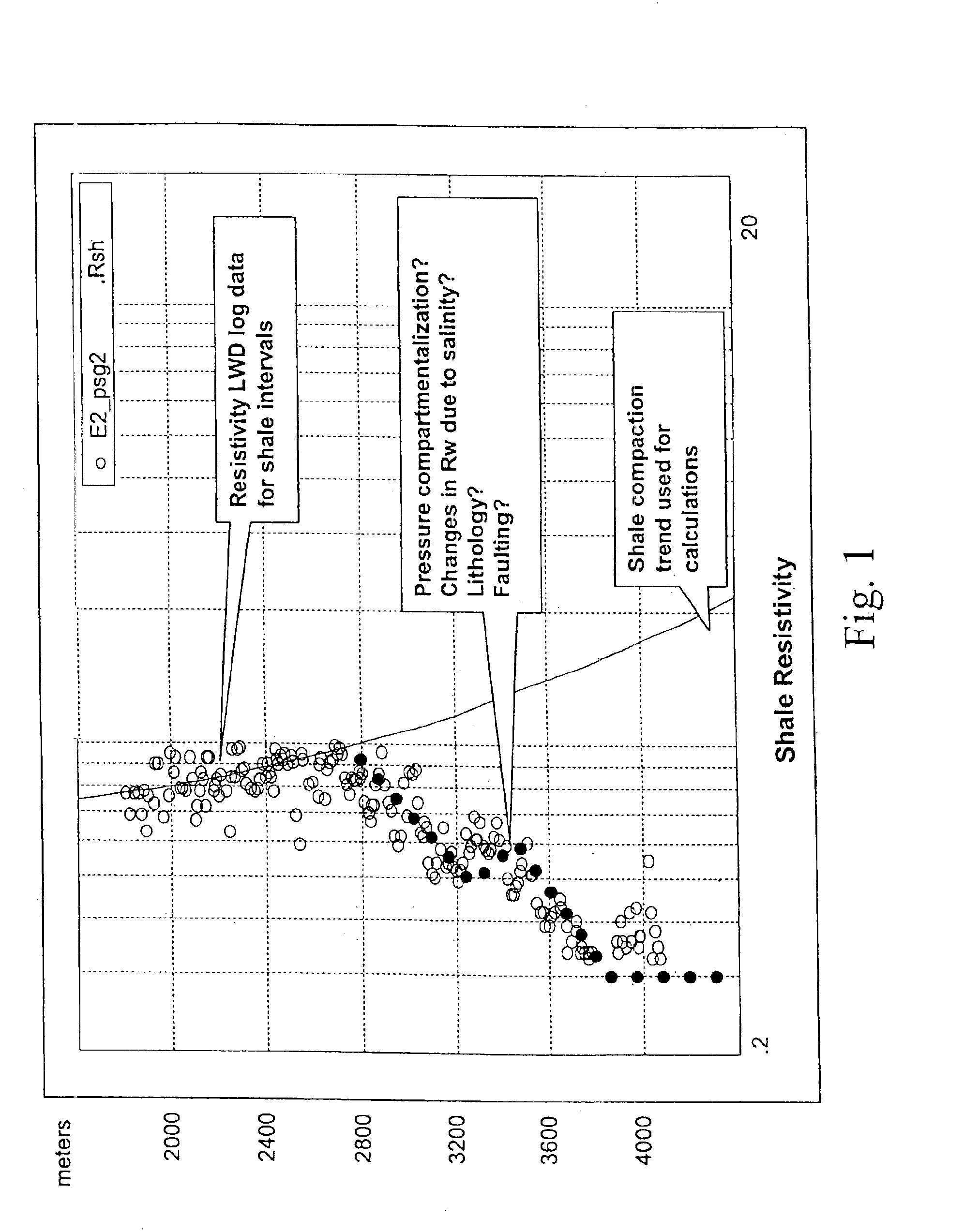

Abnormal pressure determination using nuclear magnetic resonance logging

ActiveUS6954066B2Accurate porosityResolution problemElectric/magnetic detection for well-loggingWater resource assessmentPorosityBound water

A method and apparatus for determining abnormal pressure zones of a geologic formation using NMR measurements, preferably for logging-while-drilling applications. In a preferred embodiment, a normal compaction trend is constructed using NMR-derived clay bound water volume (CBW) content for non-consolidated subsurface formations or bulk volume irreducible (BVI) and CBW for consolidated formations versus depth. Deviations from this normal compaction trend are used to indicate the presence of shale sections with higher porosity that directly corresponds to an overpressured top seal or transitional zone.

Owner:HALLIBURTON ENERGY SERVICES INC

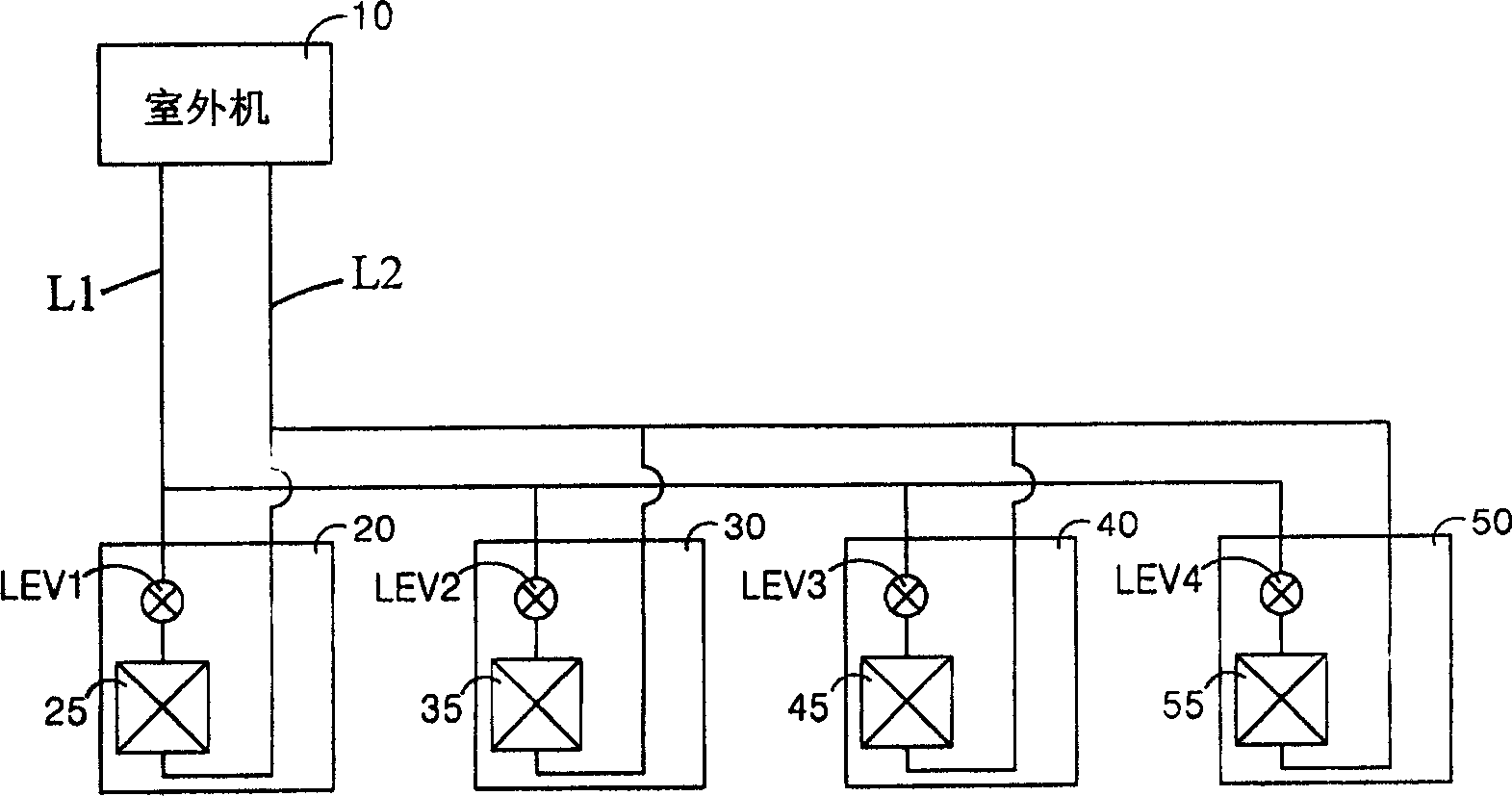

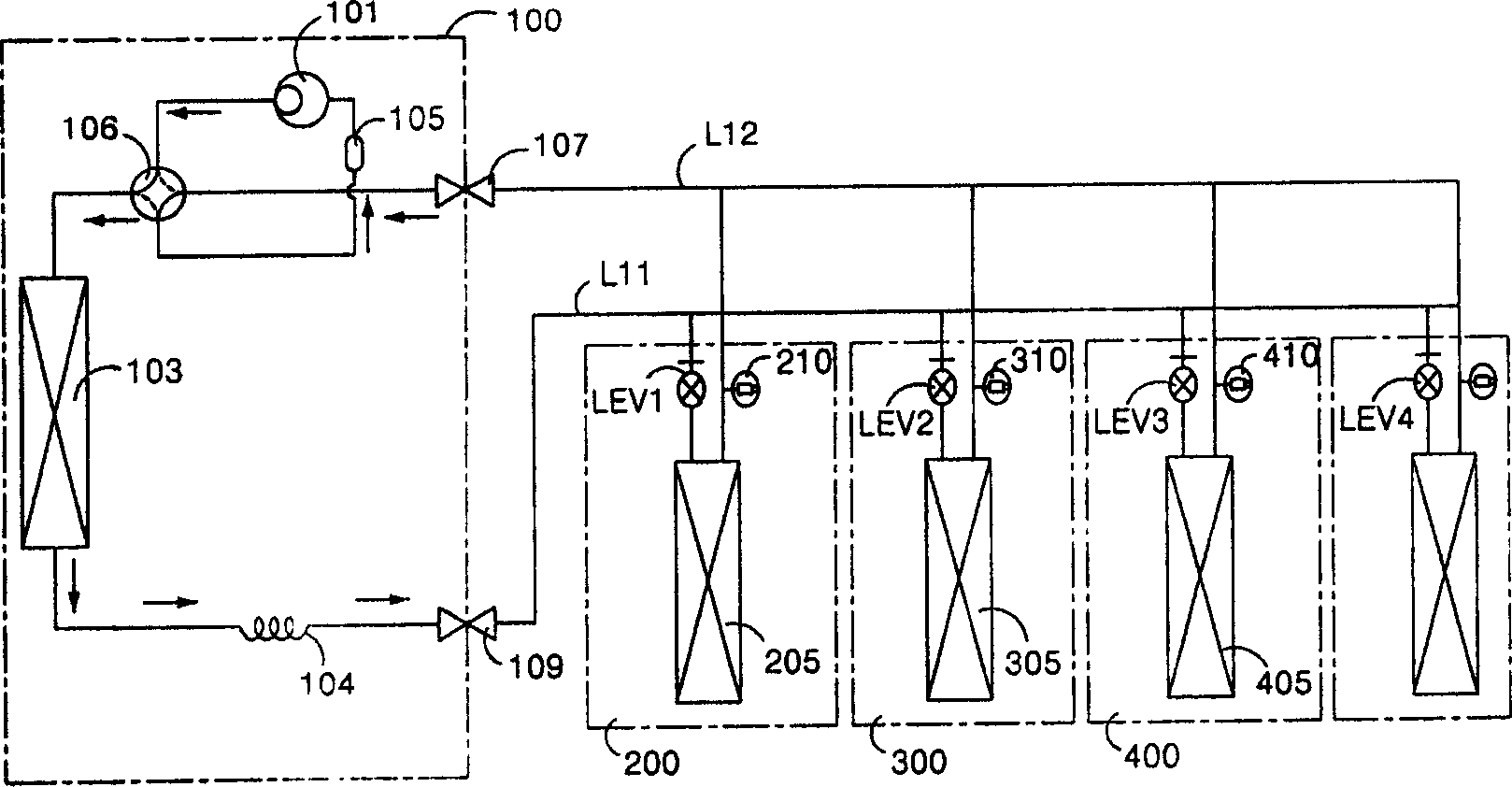

Air-conditioner with one outdoor set and multiple indoor sets and its control method

InactiveCN1566826AAvoid harmReduce leakageSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringAbnormal pressure

The invention discloses a one-mainframe-multi-evaporator air conditioner and a control method therefore. The air conditioner comprises a detection device for detecting refrigerant pressure, a refrigerant cutoff device for cutting off refrigerant flow and a refrigerant recovery device. The control method mainly includes stage of detecting abnormal pressure value because of refrigerant leakage, stage of cutting off refrigerant flowing in multi indoor set from an outdoor set when pressure change being detected, and stage of recovering residual refrigerant in the indoor sets after refrigerant flow being cut off. The invention can reduce refrigerant leakage of the one-mainframe-multi-evaporator air conditioner.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

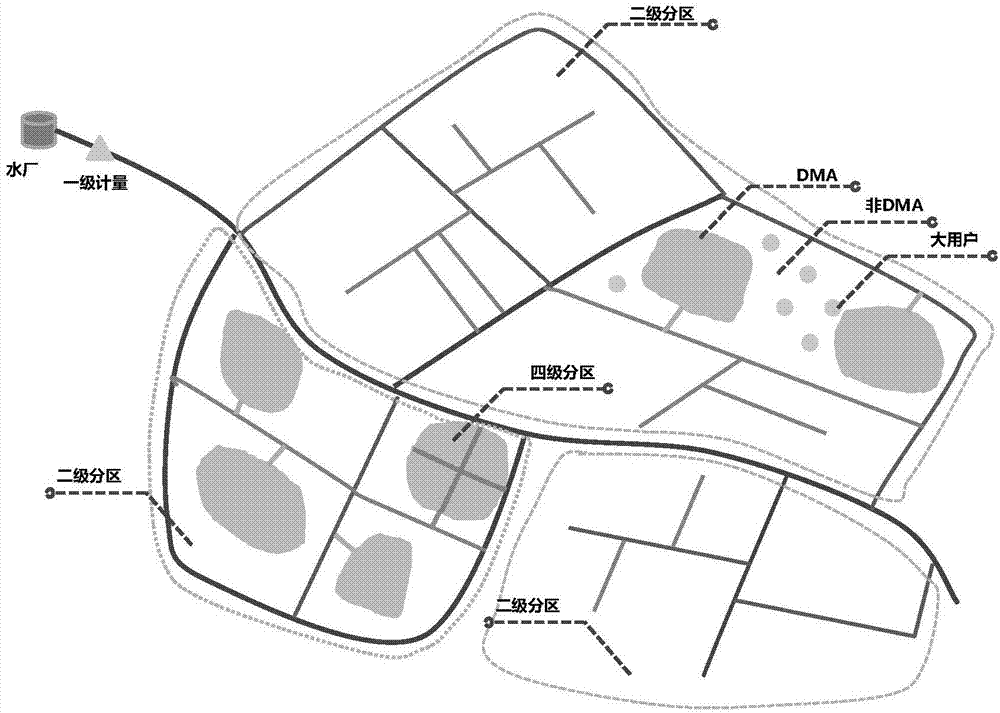

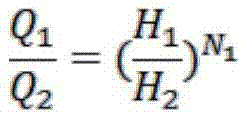

LeakView leakage control and management system for urban water supply pipe network

ActiveCN107355688AImprove hydraulic conditionsPressure balanceData processing applicationsPipeline systemsNoise monitoringUrban water supply

The invention discloses a LeakView leakage control and management system for an urban water supply pipe network. The control and management system comprises a partitioned management system, a leakage noise online monitoring system and a water hammer early warning and monitoring system, the partitioned management system makes the water supply pipe network to form a partitioned management mode from the factory-leaving water yield, first-level partition, second-level partition, DMA to user terminal multi-level water units, all the water units are scientifically managed through a water balance test, a pressure control strategy with the optimal water saving effect and the optimal economic matching performance is made through a response mechanism of the leakage of the water supply pipe network to the pressure, leakage noise is monitored on line by using terminal noise monitoring equipment instead of leakage detection by manual listening, the noise is displayed in the form of data, a region where the leakage is suspected to exist is found through comparative analysis of the key data, the water hammer early warning and monitoring system adopts a transient flow pressure fluctuation situation of a network system to be combined with a big data technology, and therefore the rapid change of the pressure of the pipe network system can be monitored on line, an alarm for the abnormal pressure change situation can be given in real time, on-line early warning can be realized, the data can be deeply excavated and analyzed, and water hammer protection can be made.

Owner:水联网技术服务中心(北京)有限公司

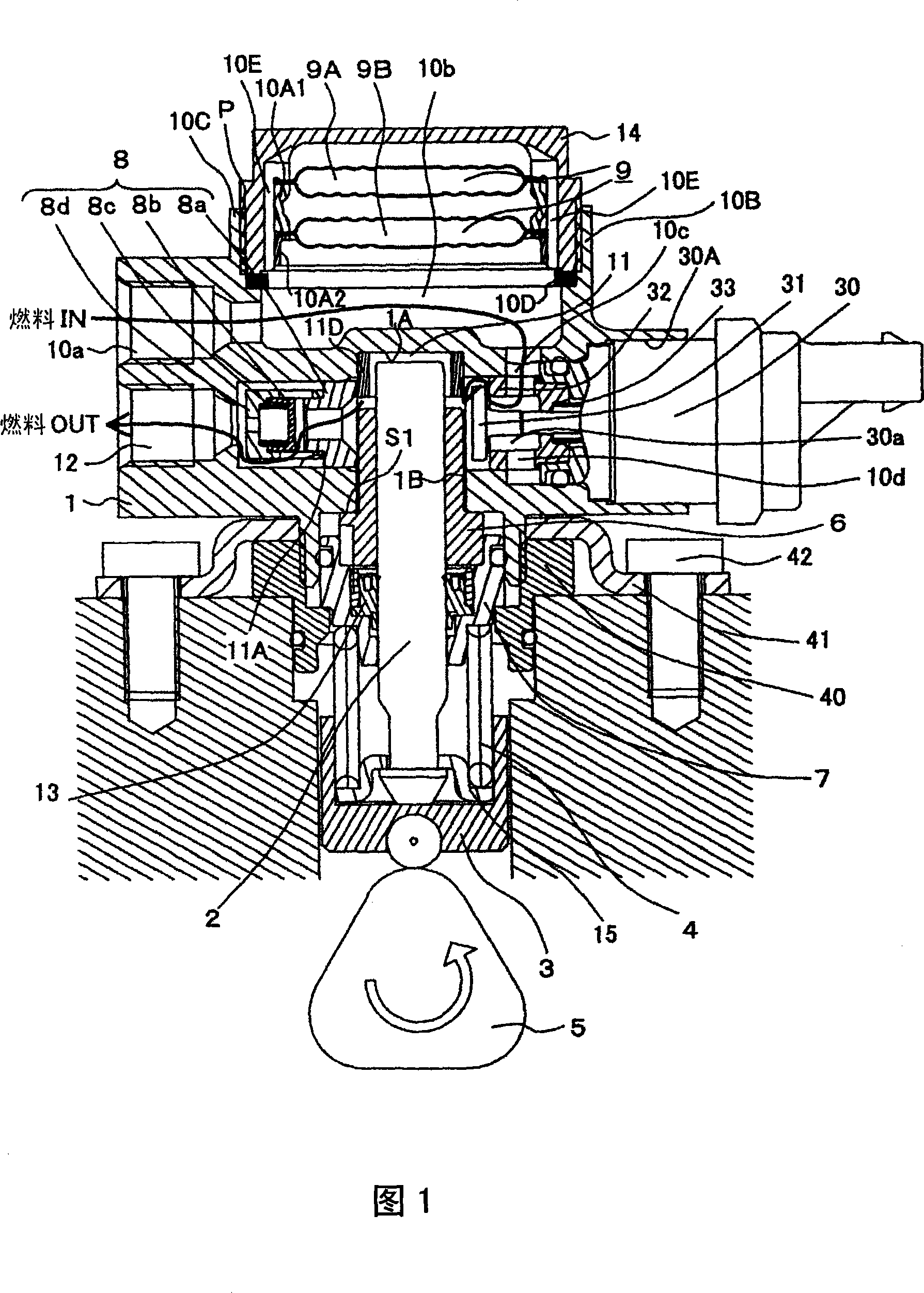

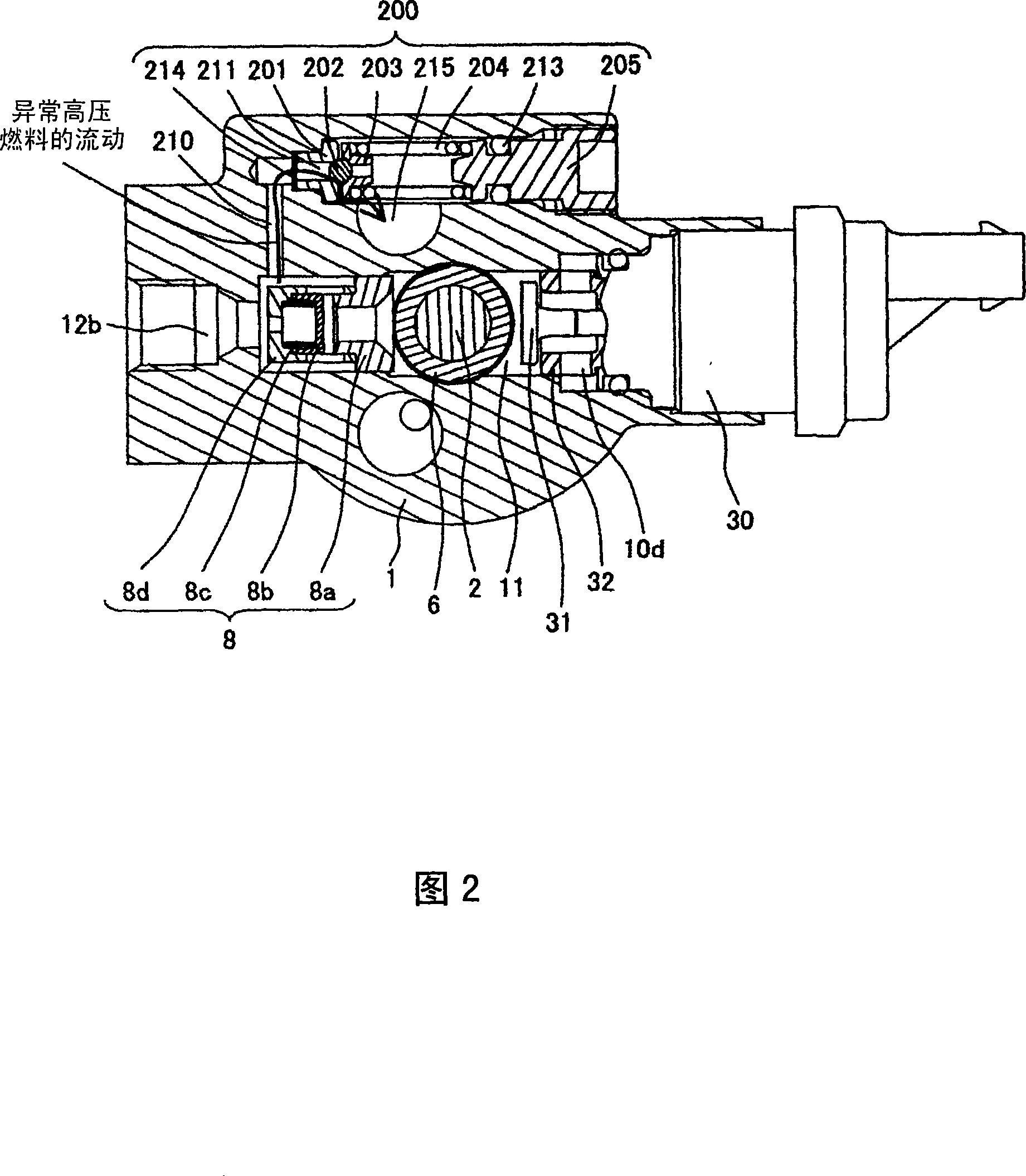

High-pressure fuel supply pump

ActiveCN101135283AIncrease the compression ratioImprove energy efficiencyMachines/enginesFuel injecting pumpsTransient statePressure rise

The present invention provides a high-pressure fuel supply pump, when ejecting value is open and under transient state of high-pressure fuel pump pressing fuel, even though the pressure of instant ejecting fuel increase to become abnormal pressure, the safety value will not be open. In the fuel ejecting path of upstream side (that is ejecting value side) of the safety value within the fuel safety path, setting a mechanism for preventing the pressure generated instantly within the path to enter the safety value. More specifically, setting alveolus in the safety path, which reduces the acting energy to the safety value of the pressure due to opening high-pressure fuel pump value; or setting mechanism for cutting off the transmission of anormal pressure in the safety path.

Owner:HITACHI ASTEMO LTD

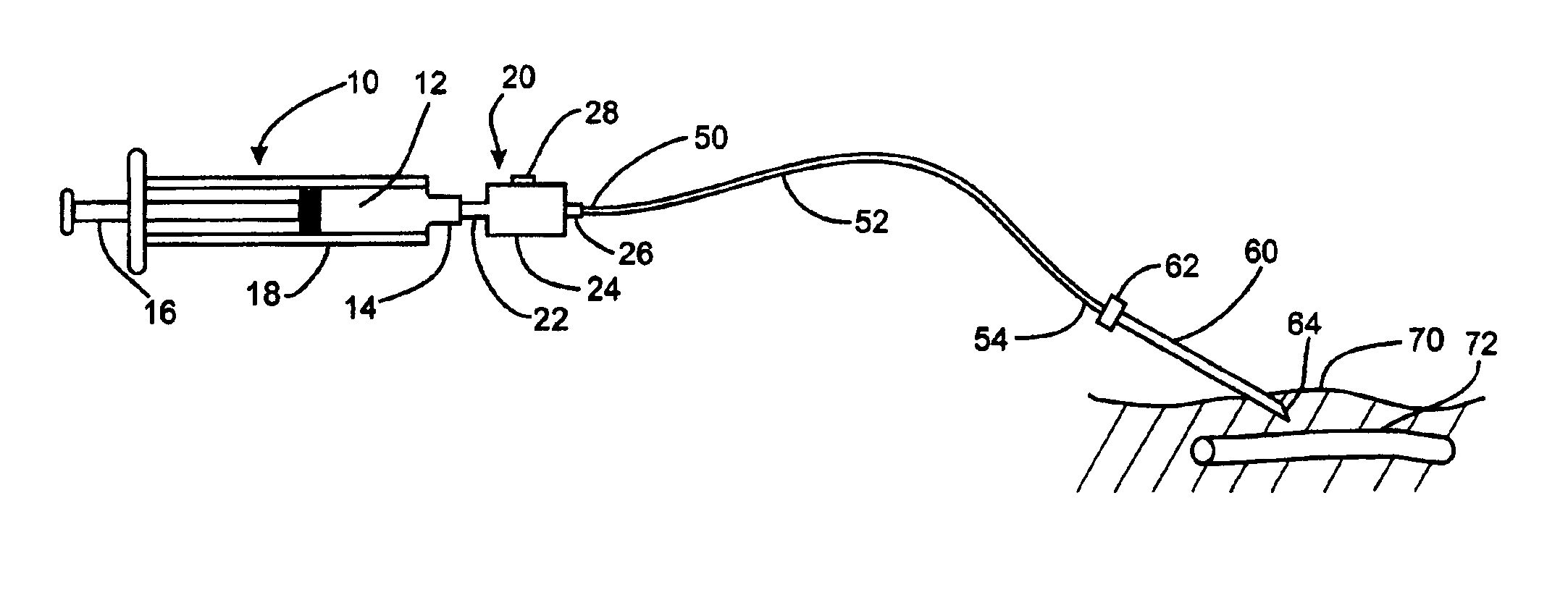

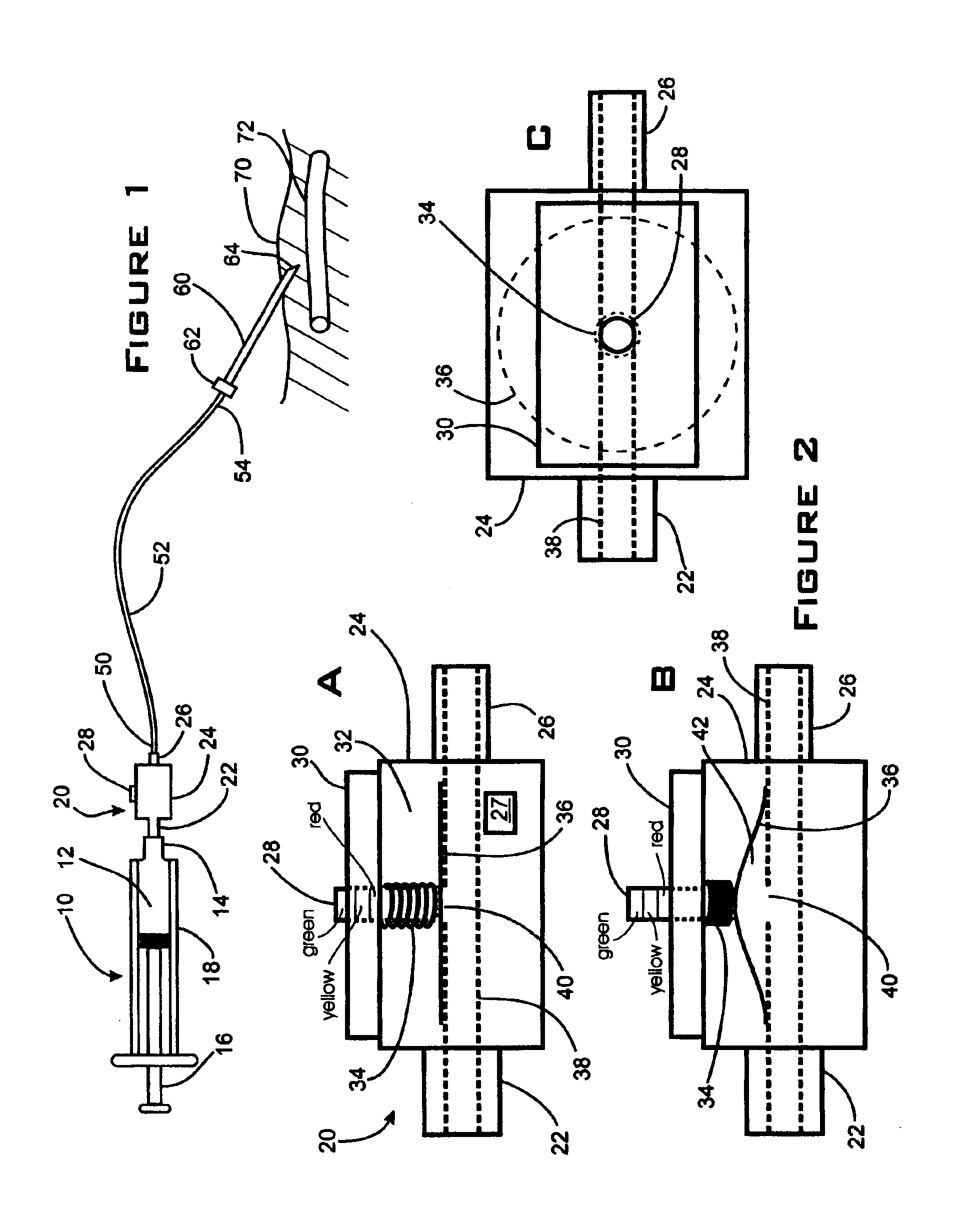

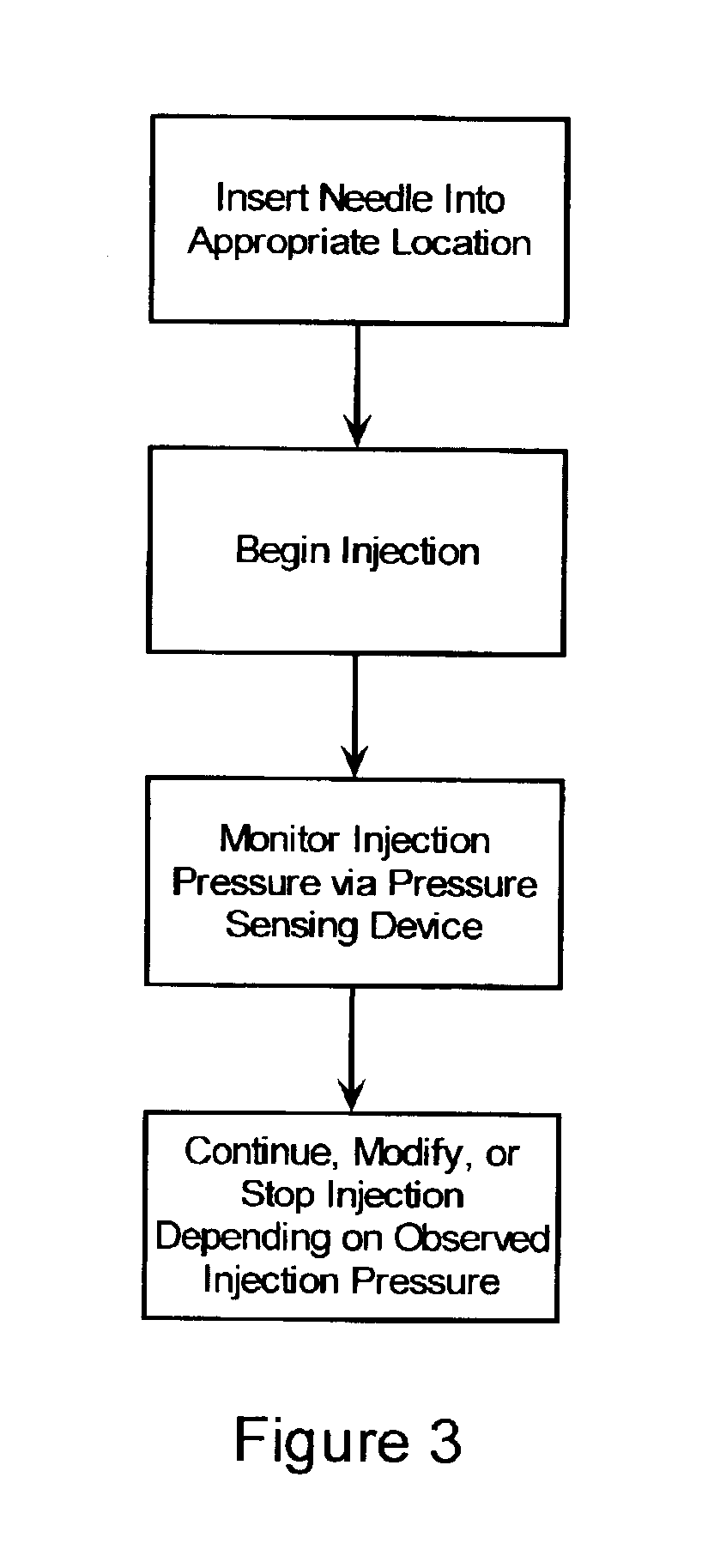

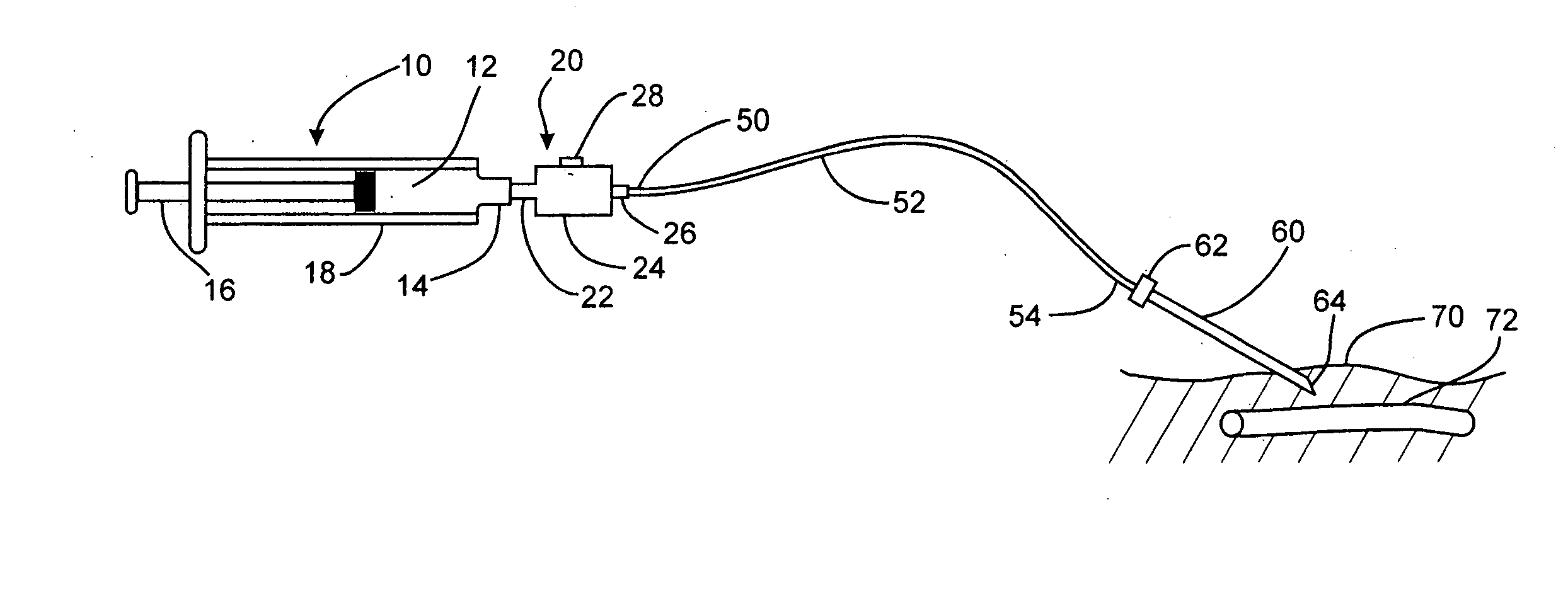

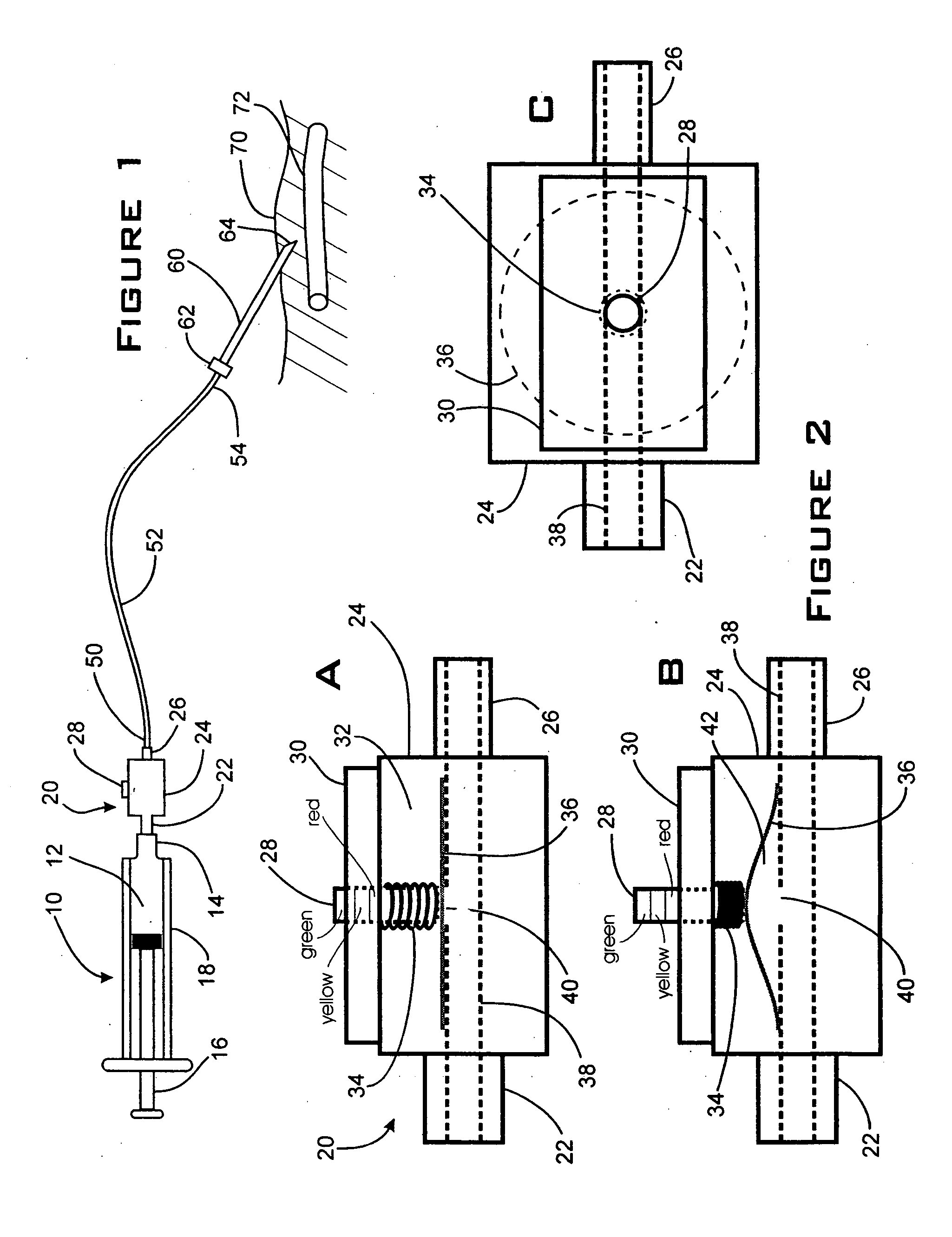

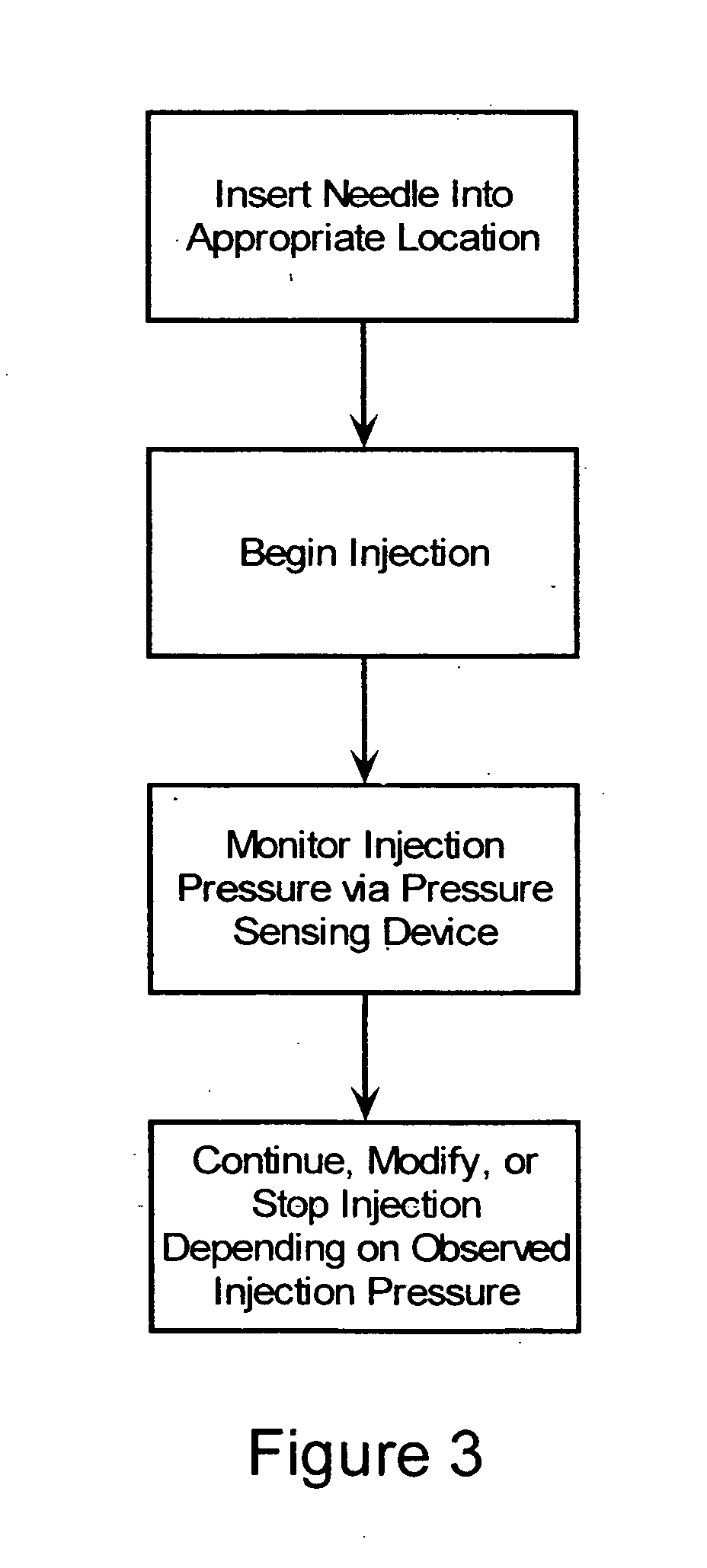

Method and apparatus to decrease the risk of intraneuronal injection during administration of nerve block anesthesia

InactiveUS6866648B2Reduce the possibilityEasily and objectively monitoredAnaesthesiaInfusion syringesInjection pressurePressure sense

An objective and reproducible system for, and method of, monitoring and / or controlling the pressure during nerve blockage injection, especially by less experienced personnel, is provided in order to decrease the possibility of intraneuronal injection. More specifically, the present invention employs a pressure sensing and / or limiting device located between an injection device (typically a syringe) and a nerve block needle whereby injection pressure during a nerve block injection can be easily and objectively monitored, thereby allowing the operator to monitor the injection pressure and / or injection speed during a nerve blockage injection procedure and to take appropriate corrective actions if abnormal pressure conditions are observed.

Owner:B BRAUN MELSUNGEN AG

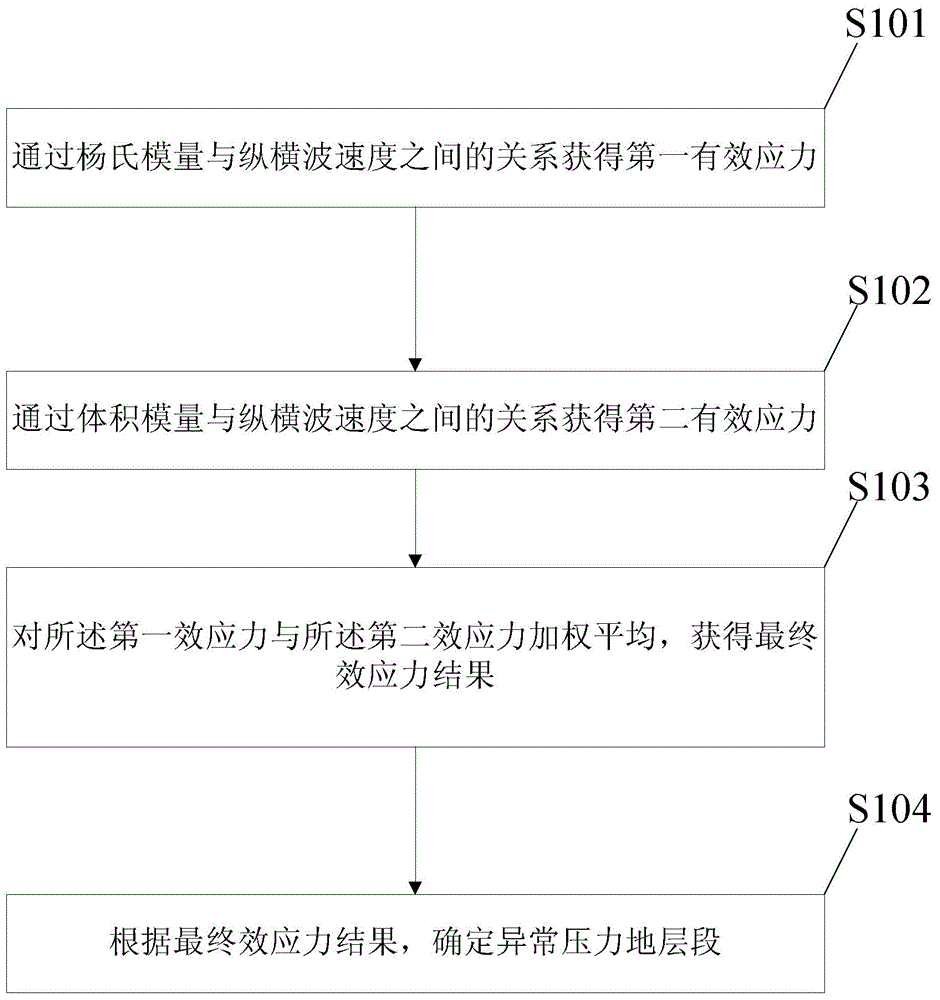

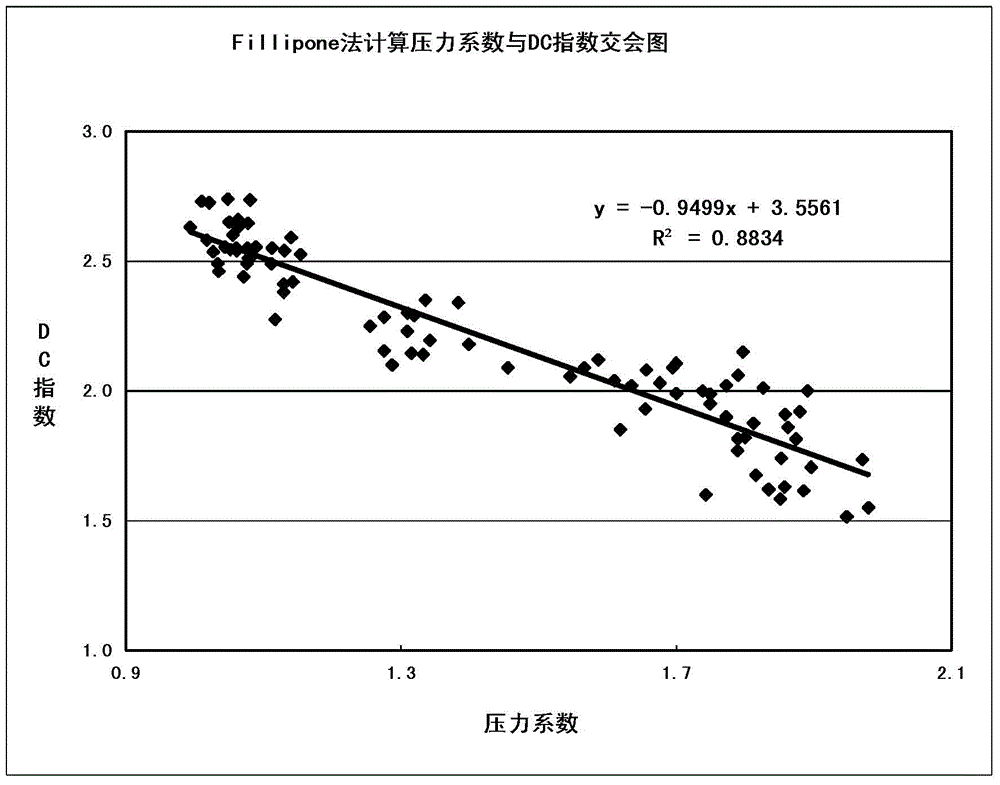

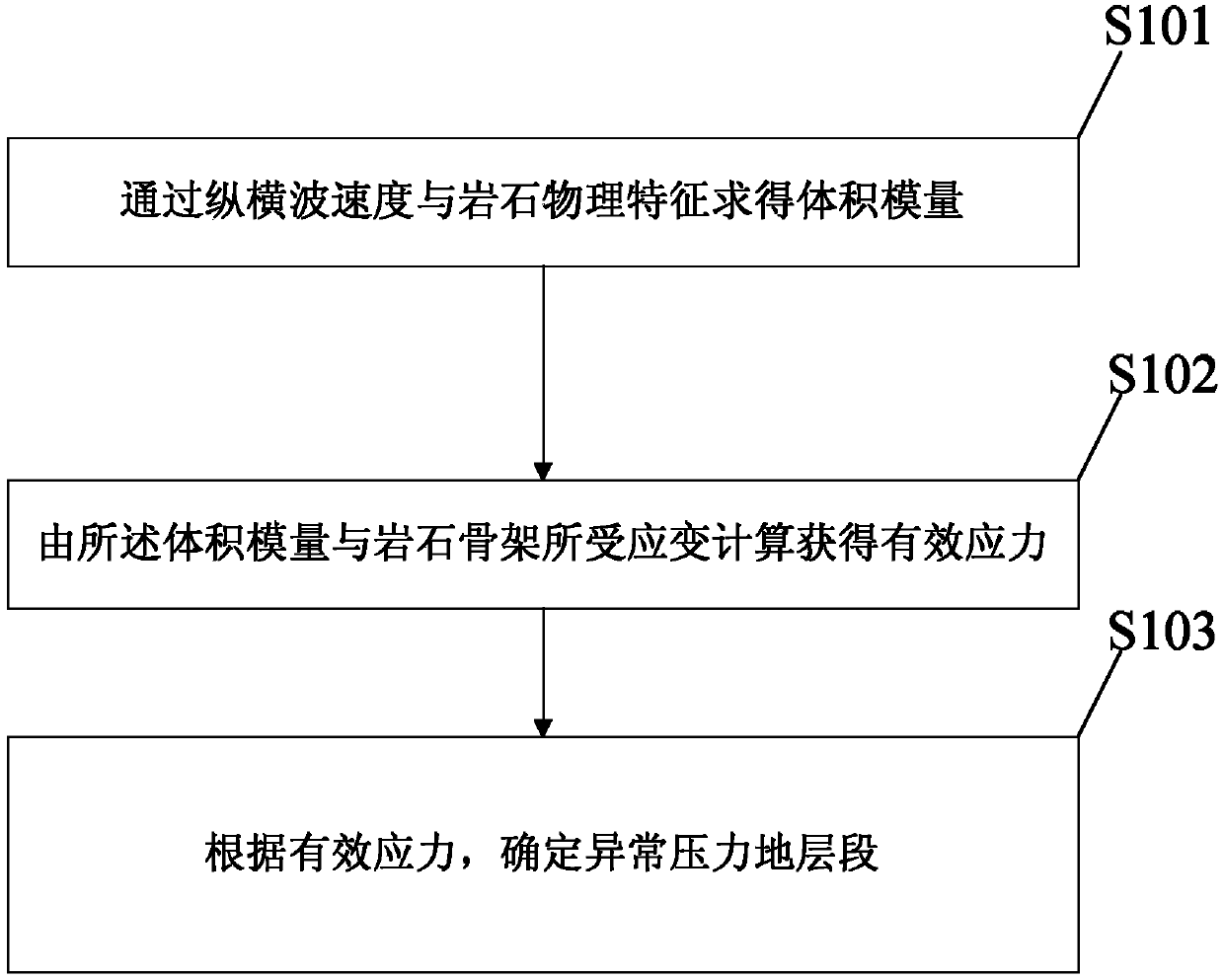

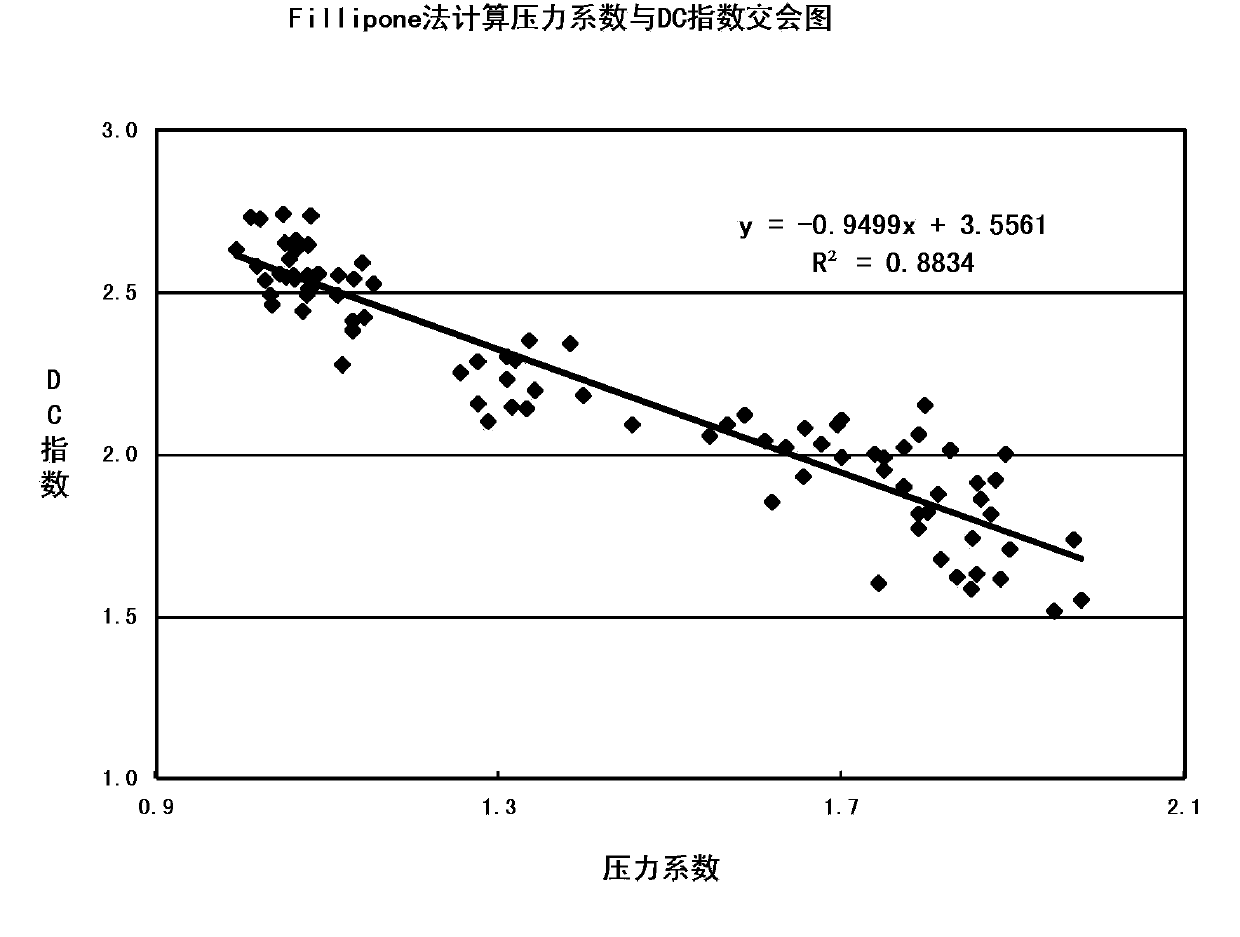

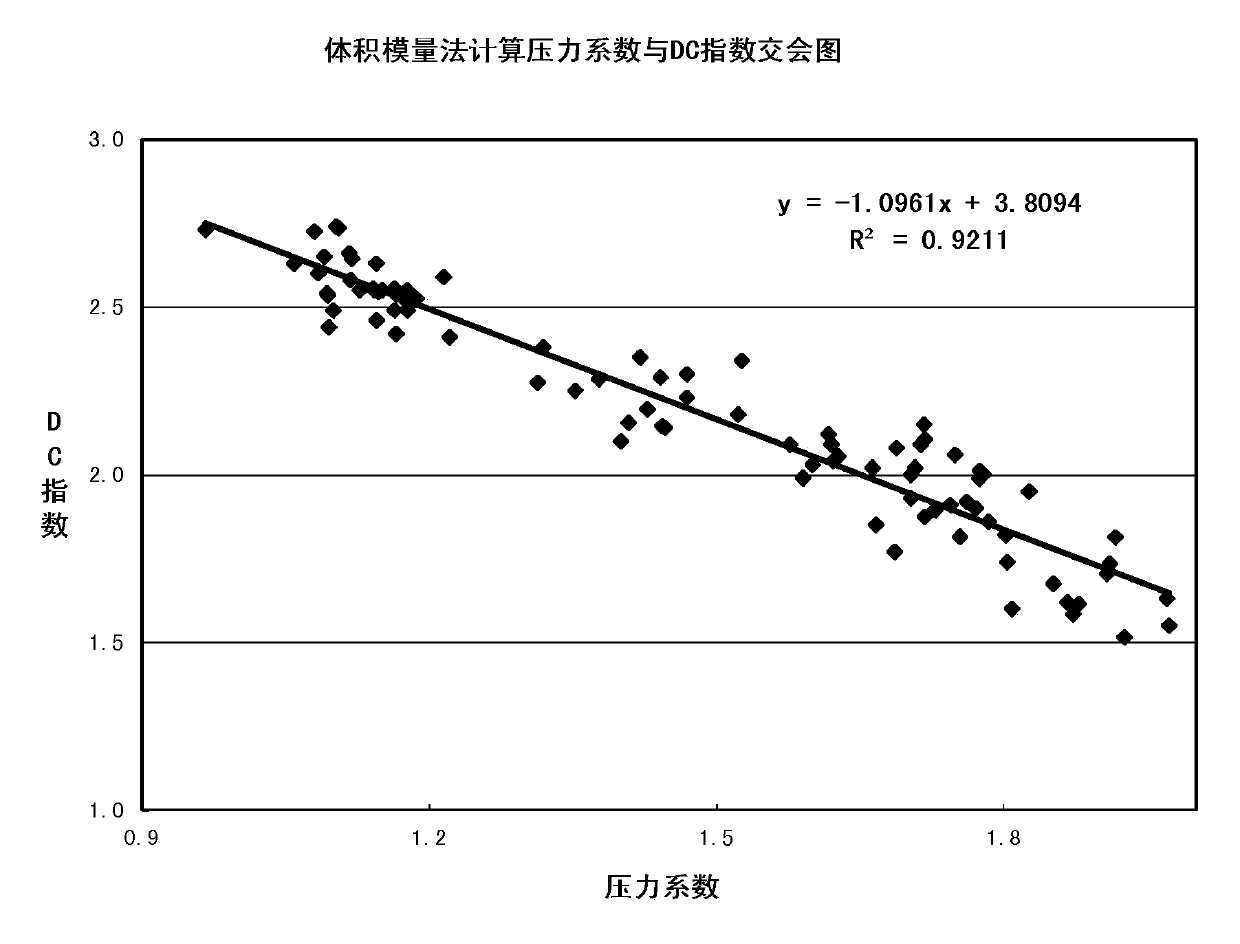

Abnormal formation pressure calculation method

ActiveCN104698492AHigh precisionEliminate the effects ofSeismic signal processingMedicineYoung's modulus

The invention discloses an abnormal formation pressure calculation method. The method includes: acquiring first effective stress through the relation between Young modulus and longitudinal and transverse wave velocity; acquiring second effective stress through the relation between bulk modulus and the longitudinal and transverse velocity; subjecting the first effective stress and the second effective stress to weighted average to acquire a final effective stress result; according to the final effective stress result, determining abnormal formation pressure sections by the aid of the effective stress theory. With the method, precision in predicting formation pressure is improved, influence of containing gas in the formation on formation velocity is eliminated, a high-precision model is established between the formation velocity and the effective stress, and an elastic modulus weighing method is developed to have the formation pressure predicated.

Owner:PETROCHINA CO LTD

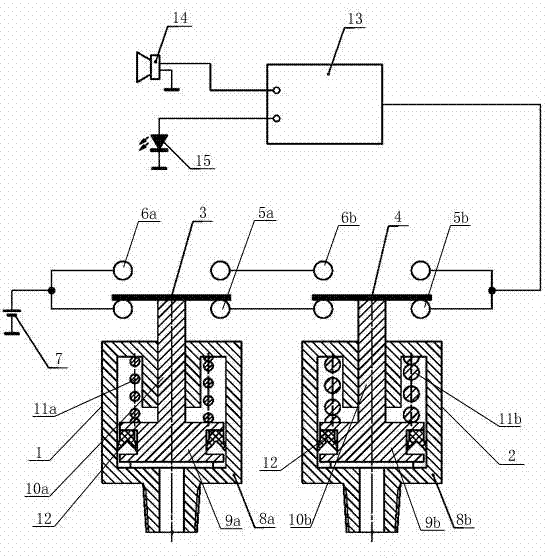

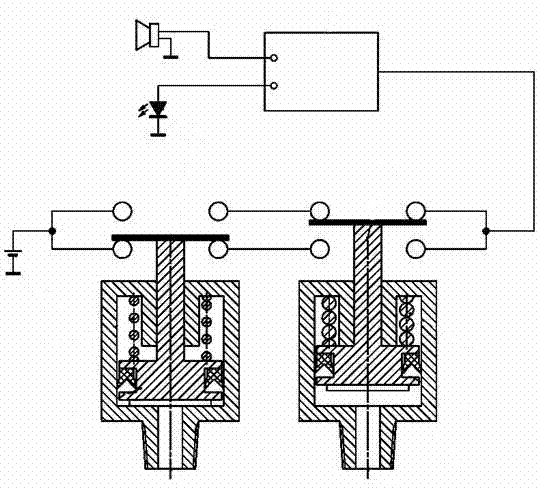

Air brake fault alarm device for railway vehicle

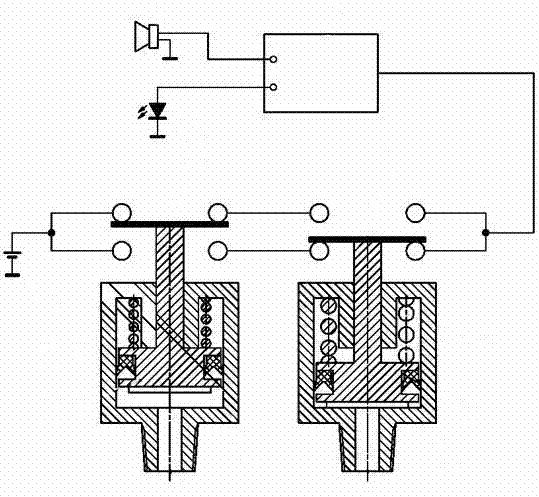

The invention discloses an air brake fault alarm device for a railway vehicle, which comprises a brake cylinder pressure sensor communicated with a brake cylinder, a train pipe pressure sensor connected with a train pipe, and an alarm system. A brake cylinder pressure switch and a train pipe pressure switch are arranged on the brake cylinder pressure sensor and the train pipe pressure sensor respectively, and can be contacted with corresponding normally closed joints A and B or normally open joints A and B respectively under the actions of the brake cylinder pressure sensor and the train pipe pressure sensor; and the alarm system, the train pipe pressure switch, the brake cylinder pressure switch, and a power supply form a loop. In the invention, the brake cylinder pressure sensor and the train pipe pressure sensor are used to detect the pressure when the air brake is in a working state, in the case of an abnormal pressure, an alarm circuit is powered on to give out an acoustic and optical alarm. Therefore, a train examiner is reminded of the fault and safe train traveling is ensured.

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

Method and apparatus to decrease the risk of intraneuronal injection during administration of nerve block anesthesia

InactiveUS20050043710A1Reduce the possibilityEasily and objectively monitoredAnaesthesiaInfusion syringesInjection pressurePressure sense

An objective and reproducible system for, and method of, monitoring and / or controlling the pressure during nerve blockage injection, especially by less experienced personnel, is provided in order to decrease the possibility of intraneuronal injection. More specifically, the present invention employs a pressure sensing and / or limiting device located between an injection device (typically a syringe) and a nerve block needle whereby injection pressure during a nerve block injection can be easily and objectively monitored, thereby allowing the operator to monitor the injection pressure and / or injection speed during a nerve blockage injection procedure and to take appropriate corrective actions if abnormal pressure conditions are observed.

Owner:MACOSTA MEDICAL US

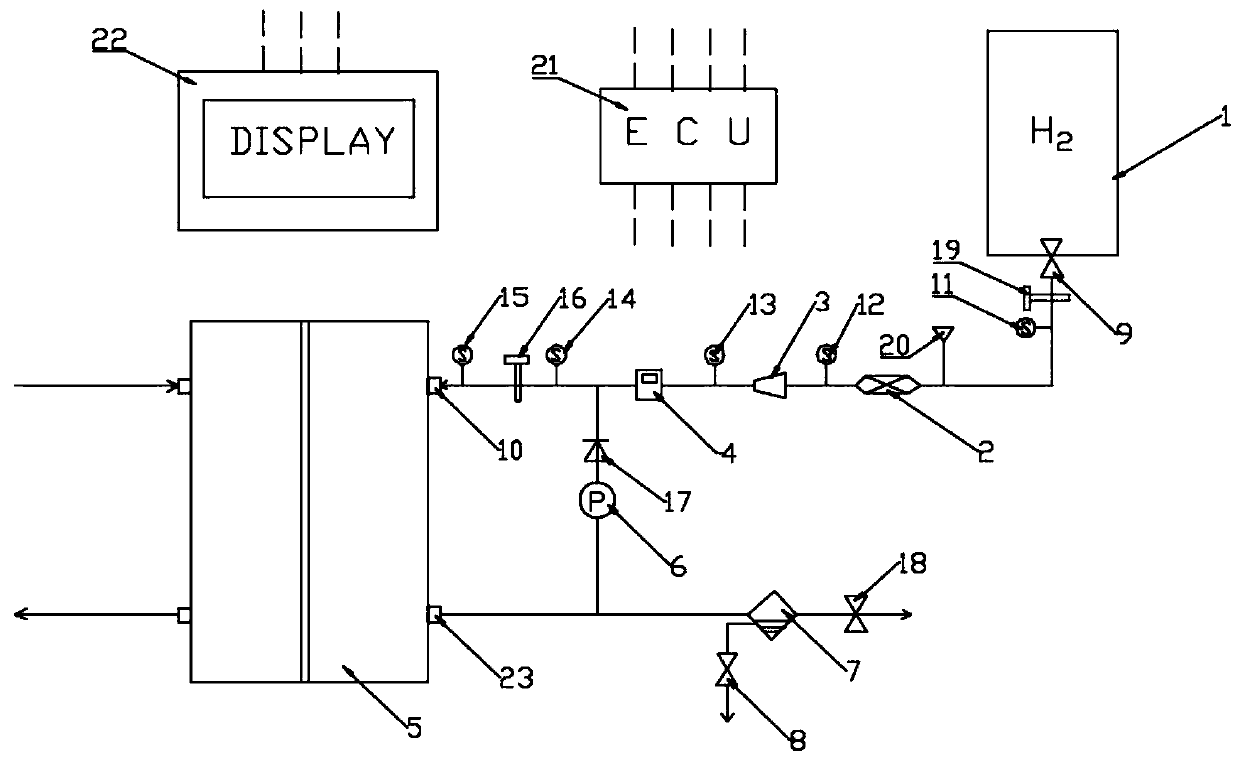

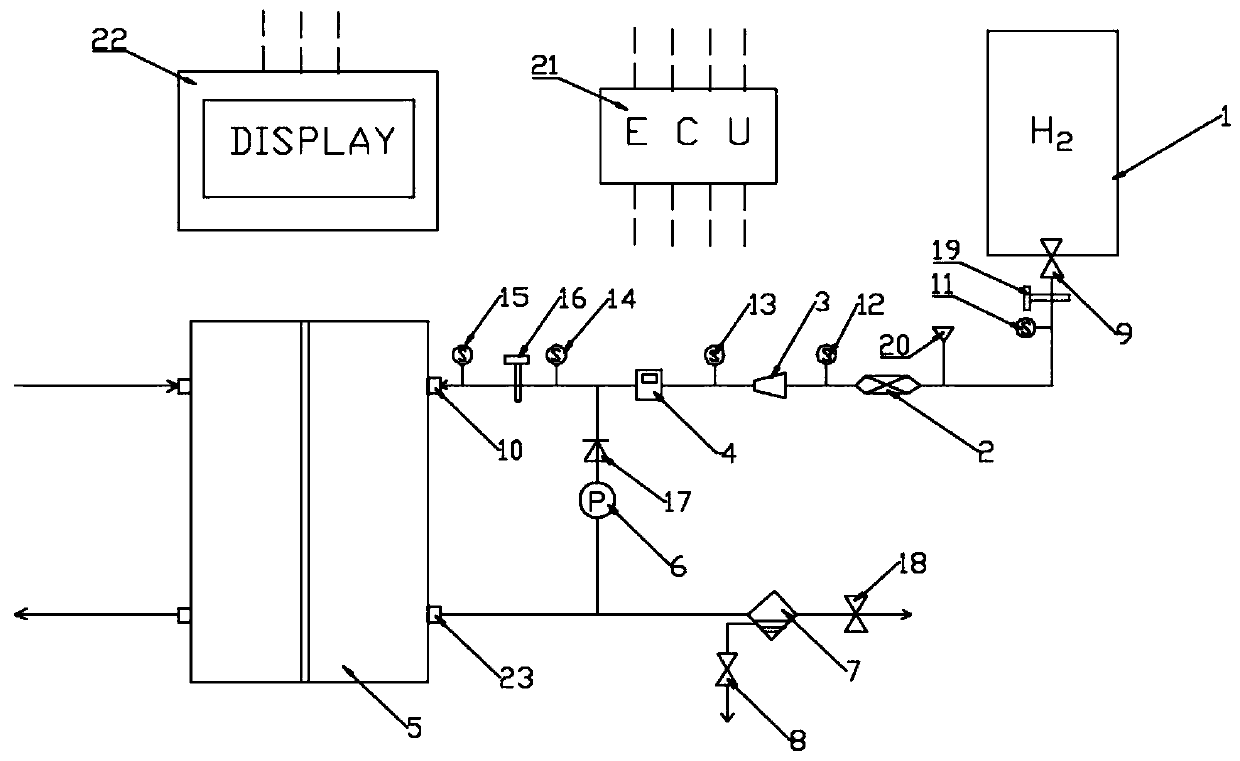

Hydrogen supply system for rapidly judging hydrogen leakage part

PendingCN109860663ASatisfy the needs of safe useReal-time monitoring of working statusFuel cellsBlowoff valveExhaust valve

The invention discloses a hydrogen supply system for rapidly judging a hydrogen leakage part. The hydrogen supply system for rapidly judging the hydrogen leakage part mainly comprises a hydrogen storage tank, an overflowing valve, a pressure reducing valve, an electromagnetic valve, a fuel cell stack, a hydrogen circulating pump, a moisture separator, a drainage valve, a high pressure cylinder valve, a hydrogen inlet, a hydrogen outlet, pressure sensors, a low pressure stop valve, a one-way valve, an exhaust valve, a high pressure stop valve, a blowoff valve, a vehicle-mounted computer, a hydrogen supply system state display and the like. According to the hydrogen supply system for rapidly judging the hydrogen leakage part, a self-inspection state when the system is started can be comparedwith a signal and a safety value of the vehicle-mounted computer fed back by the pressure sensors during normal work to judge whether hydrogen leaks or not, and assemblies with the problem can be rapidly positioned according to the sensors with abnormal pressure. The hydrogen supply system for rapidly judging the hydrogen leakage part is applied to hydrogen fuel cell passenger vehicles and hydrogen fuel cell commercial vehicles, a working state of the hydrogen supply system can be monitored in real time and the problem assemblies can be rapidly positioned, and the safety of the vehicles in the use process is improved.

Owner:FAW JIEFANG AUTOMOTIVE CO

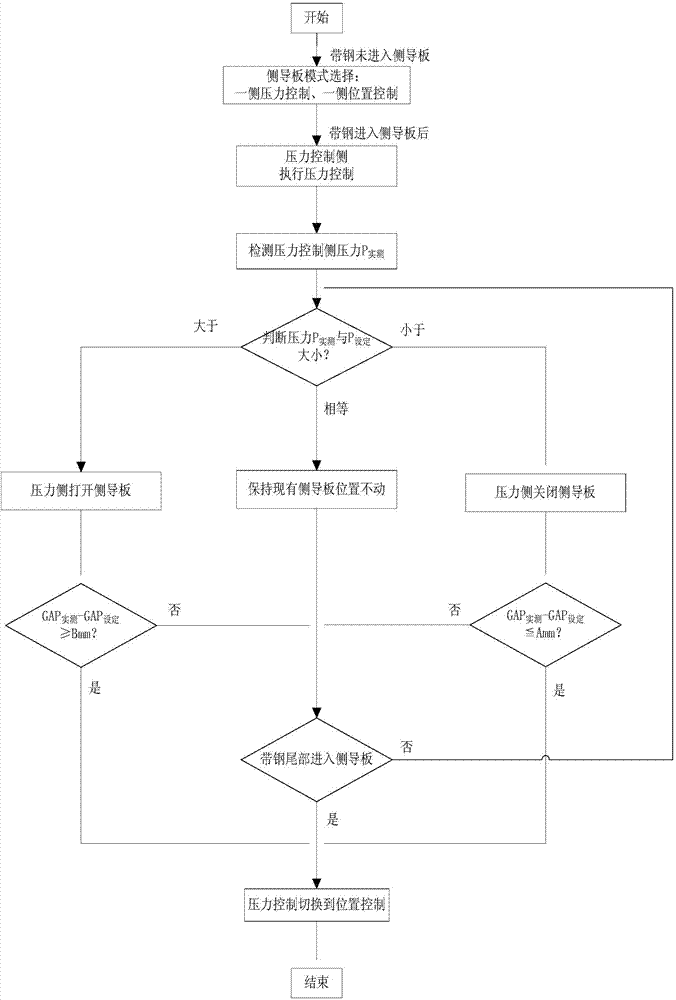

Pressure control method for coiling machine side guide plate

ActiveCN104267753AAvoid quality problemsAvoid control confusionMechanical pressure/force controlPlate pressureControl disorders

The invention discloses a pressure control method for a coiling machine side guide plate and belongs to the technical field of coiling machines. According to the selection of the pressure control method for the coiling machine side guide plate, pressure control is adopted in one side, and position control is adopted in the other side; after strip steel enters the coiling side guide plate, the side guide plate pressure control side executes pressure control, and real-time judgment is carried out on actual measurement of actual measurement pressure P and setting of a set pressure value P of the side guide plate pressure control side; judgment is carried out according to the position motion situation of the side guide plate pressure control side; finally, judgment is carried out according to the size of the actual measurement of the actual measurement pressure P and the size of setting of the set pressure value P of the side guide plate pressure control side, and the size of the actual measurement of the opening degree GAP and the size of setting of the set opening degree GAP of the two sides of the side guide plate, and the situation of the tail of the strip steel entering the side guide plate. According to the pressure control method for the coiling machine side guide plate, the problem of the steel roll tower shape caused by the fact that the side guide plate pushes the strip steel in a deviating mode can be prevented, the problem of the control disorder caused by abnormal pressure control under the circumstance of the pressure sensor failure is avoided, and layer staggering and edge cracking of steel rolls are effectively avoided.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

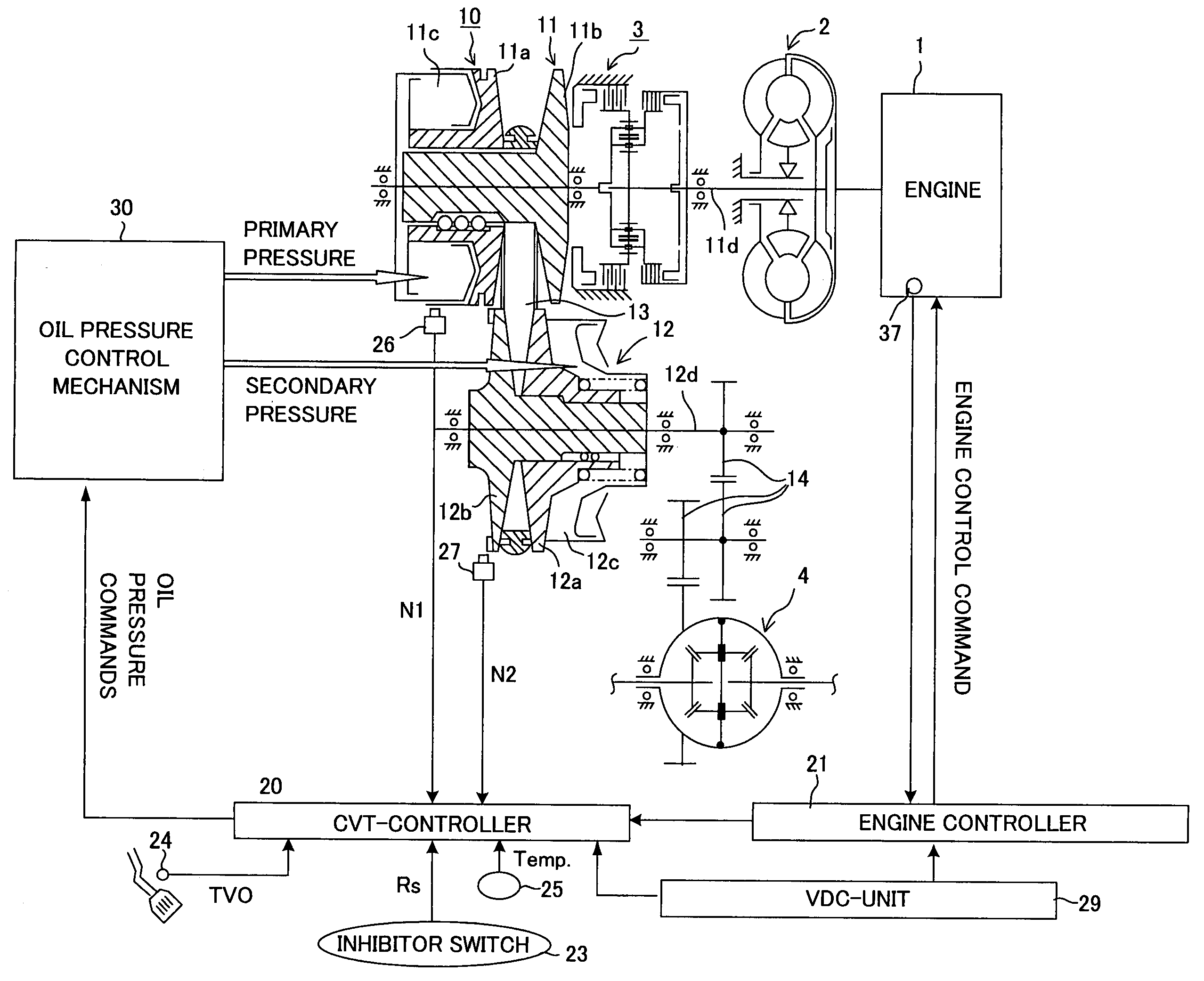

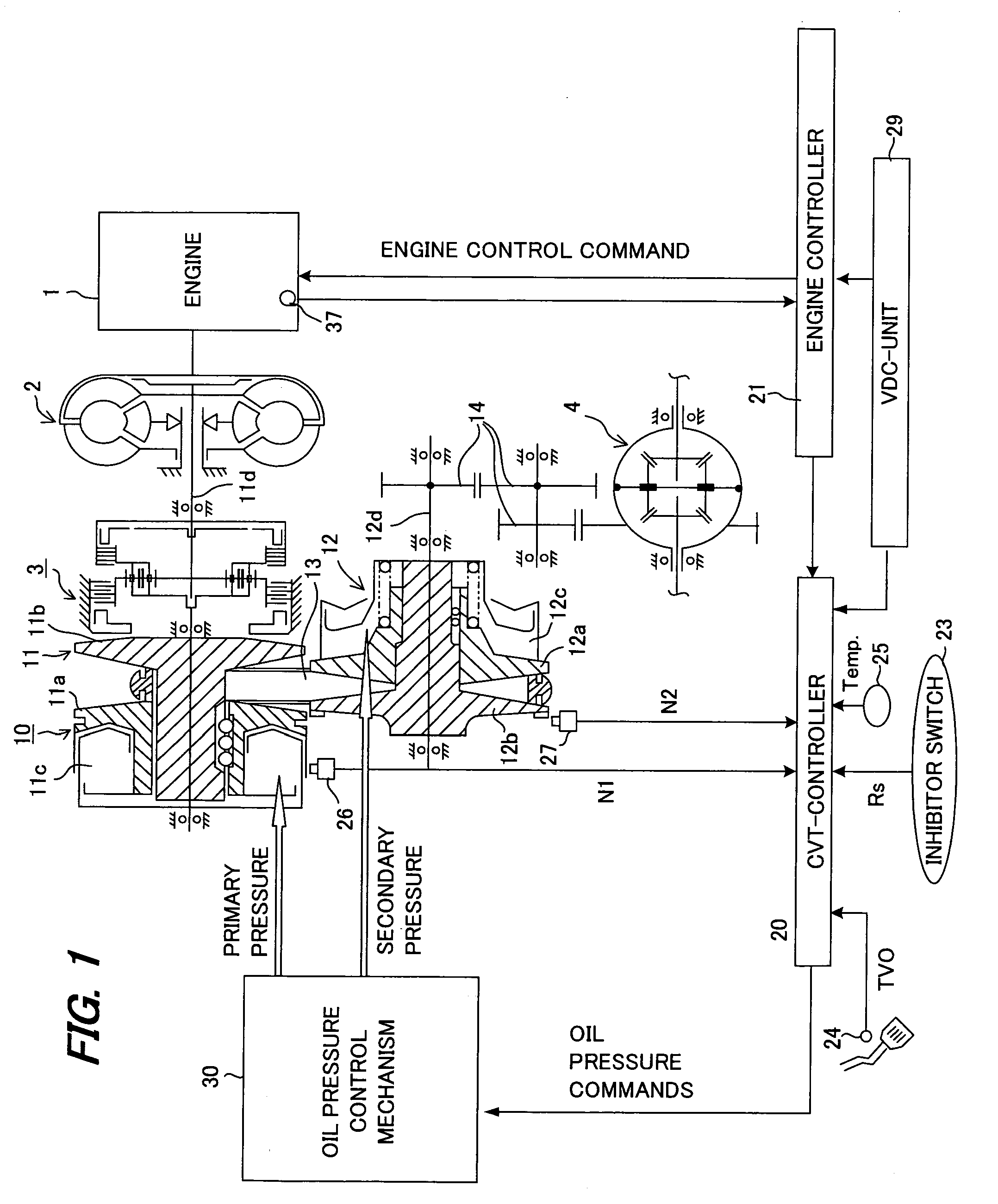

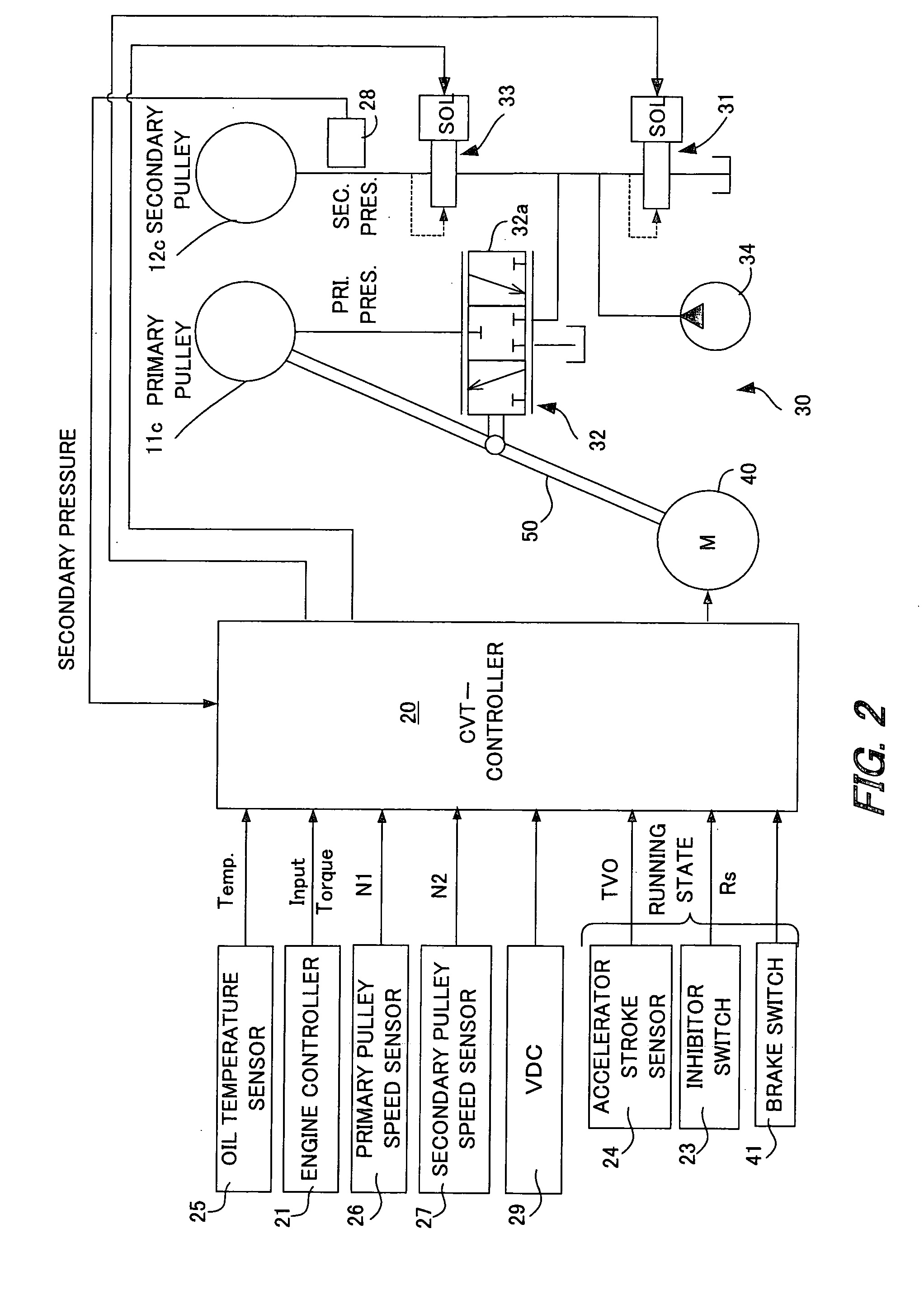

Abnormal oil pressure reduction determination device for vehicle transmission

ActiveUS7222005B2Reduce oil pressureVehicle testingRegistering/indicating working of vehiclesLower limitPressure difference

An abnormal oil pressure reduction determining device has an oil pressure sensor which detects a real oil pressure, a sensor which detects a vehicle running state, and a controller which sets an oil pressure command value for an oil pressure control mechanism. The controller computes the lower limiting oil pressure which is possible in the present vehicle running state, and when the real oil pressure is less than this lower limiting oil pressure and the pressure difference between the real oil pressure and oil pressure command value exceeds a reference value, determines that there is an abnormal pressure reduction due to a fault in the oil pressure control mechanism. Even if the oil pressure of the transmission has dropped abnormally due to some reason, the abnormal oil pressure reduction determining device determines the situation without fail.

Owner:JATCO LTD

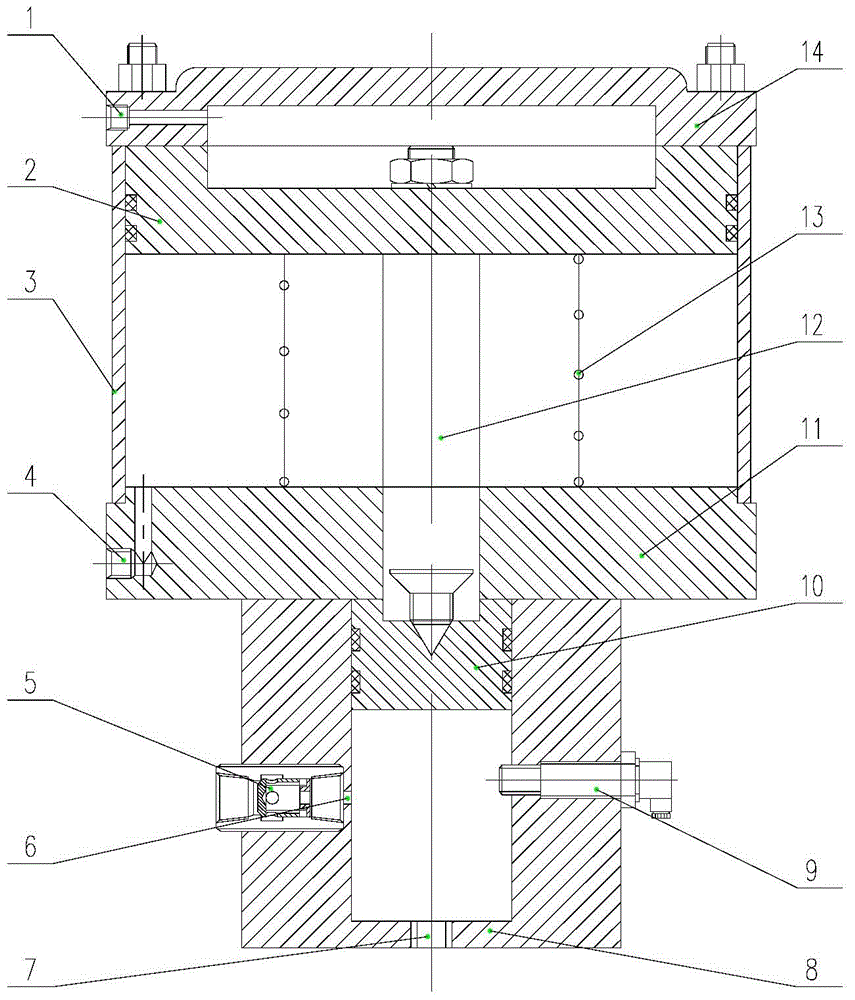

Gas-liquid pressure cylinder

InactiveCN104314912ACompact structureEasy maintenanceFluid-pressure actuator testingServometer circuitsLow speedFuel tank

The invention discloses a gas-liquid pressure cylinder. The gas-liquid pressure cylinder is not provided with an oil storage cavity and is simple and compact in structure, convenient to maintain, high in efficiency, and saves energy. An oil inlet is formed in a liquid cylinder body and communicated with an oil storage tank of a braking system through a one-way valve. When the pressure cylinder does not have pressure air, the one-way valve is opened, and the oil storage tank is communicated with the pressure cylinder. After the pressure cylinder is filled with compressed air, due to the pressure action, the one-way valve is closed, and the passage between the oil storage tank and the pressure cylinder is cut off. The gas-liquid pressure cylinder can realize automatic oil supplement, lowers the labor intensity, and is low in maintenance cost. As a hydraulic sensor is arranged in the liquid cylinder body, the gas-liquid pressure cylinder has a real-time pressure monitoring function, can quickly and accurately feedback and display hydraulic pressure information, can carry out an early-warning prompt for abnormal pressure, and is convenient for a hydraulic system to maintain and find faults. The gas-liquid pressure cylinder is convenient to add oil and can monitor and feedback the hydraulic pressure in real time, all the operations are automatically completed during working, and the practicality is strong. The gas-liquid pressure cylinder is used together with low-speed and middle-speed maglev train braking systems, lowers the labor intensity of workers, and is convenient to maintain and reliable in work.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

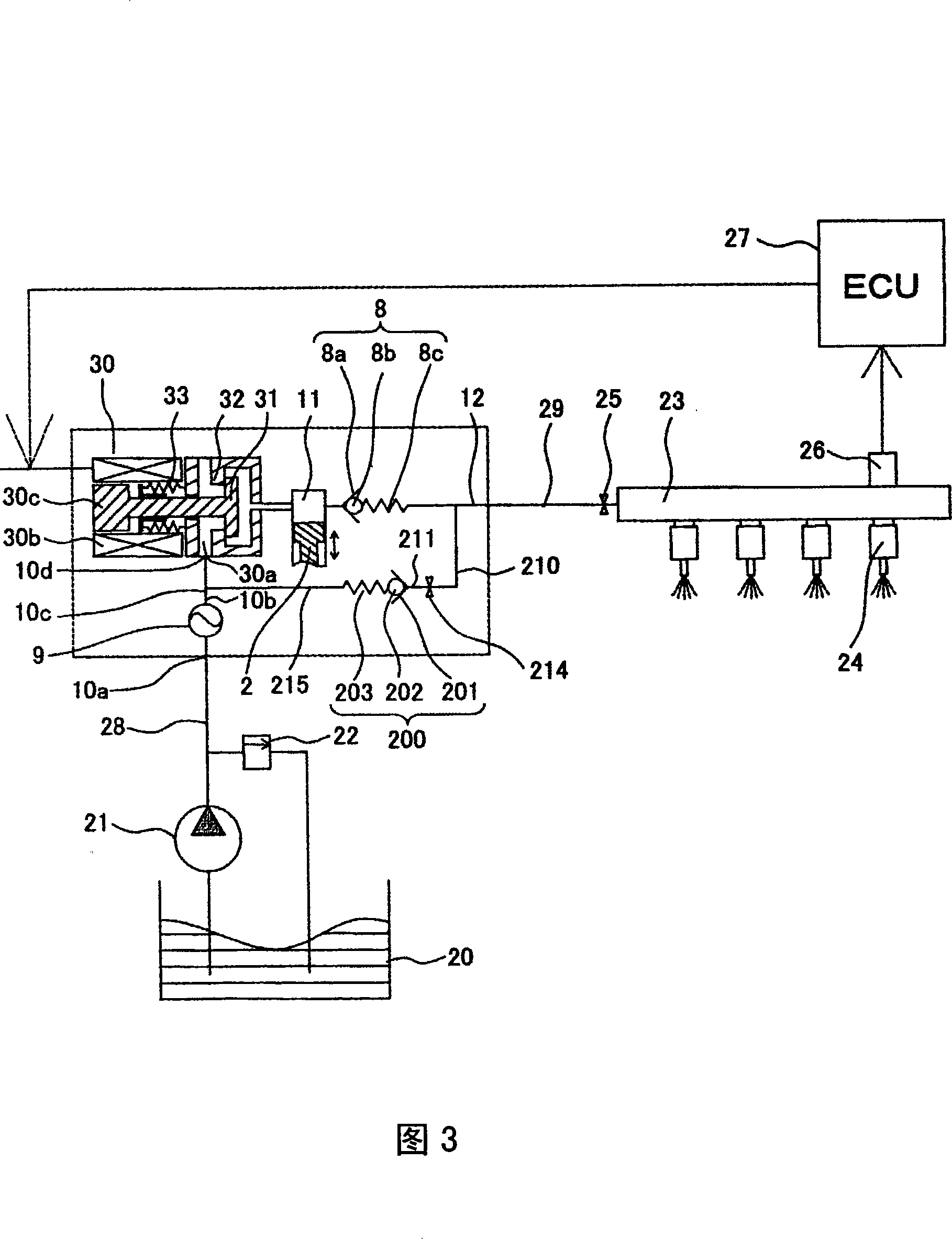

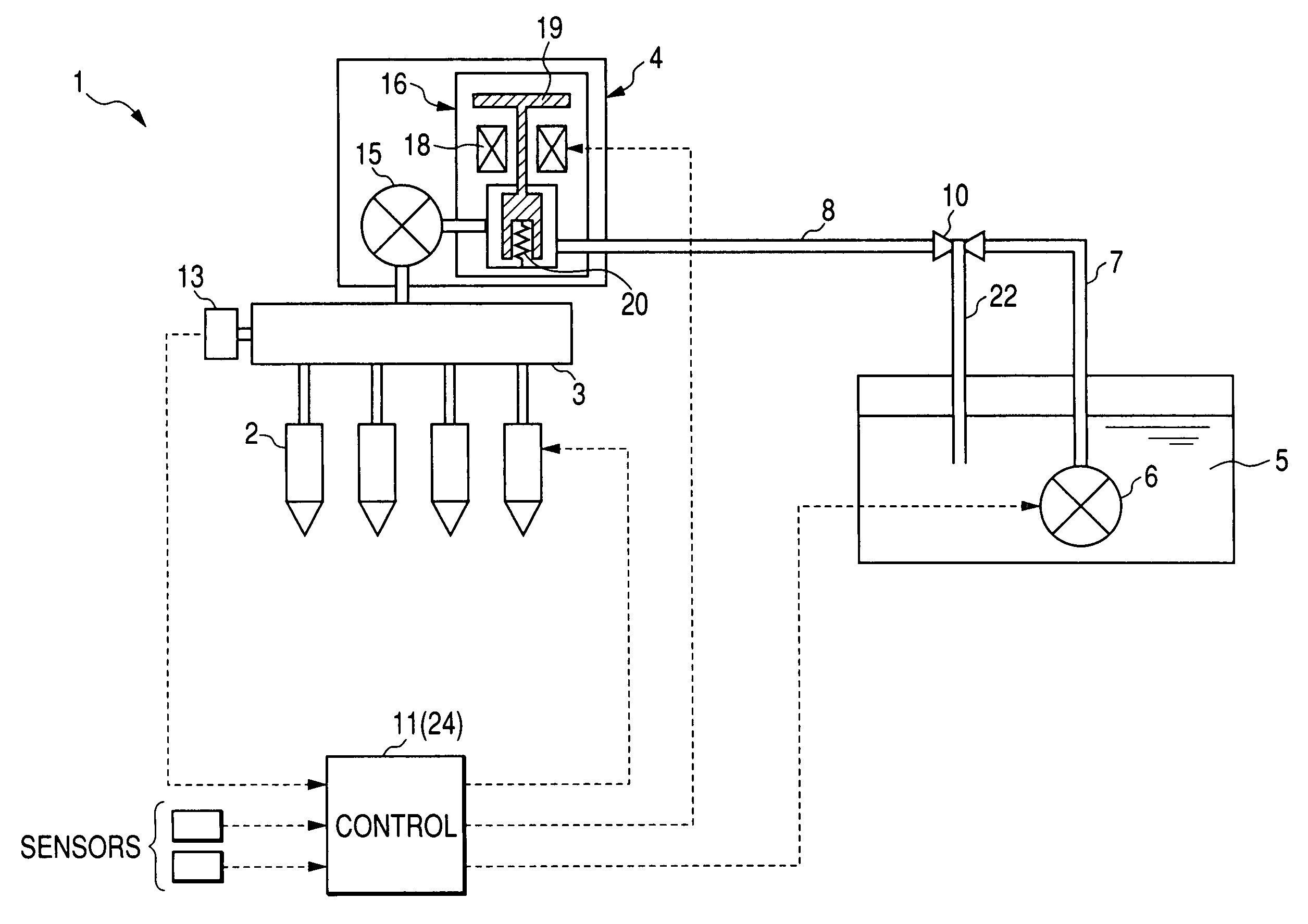

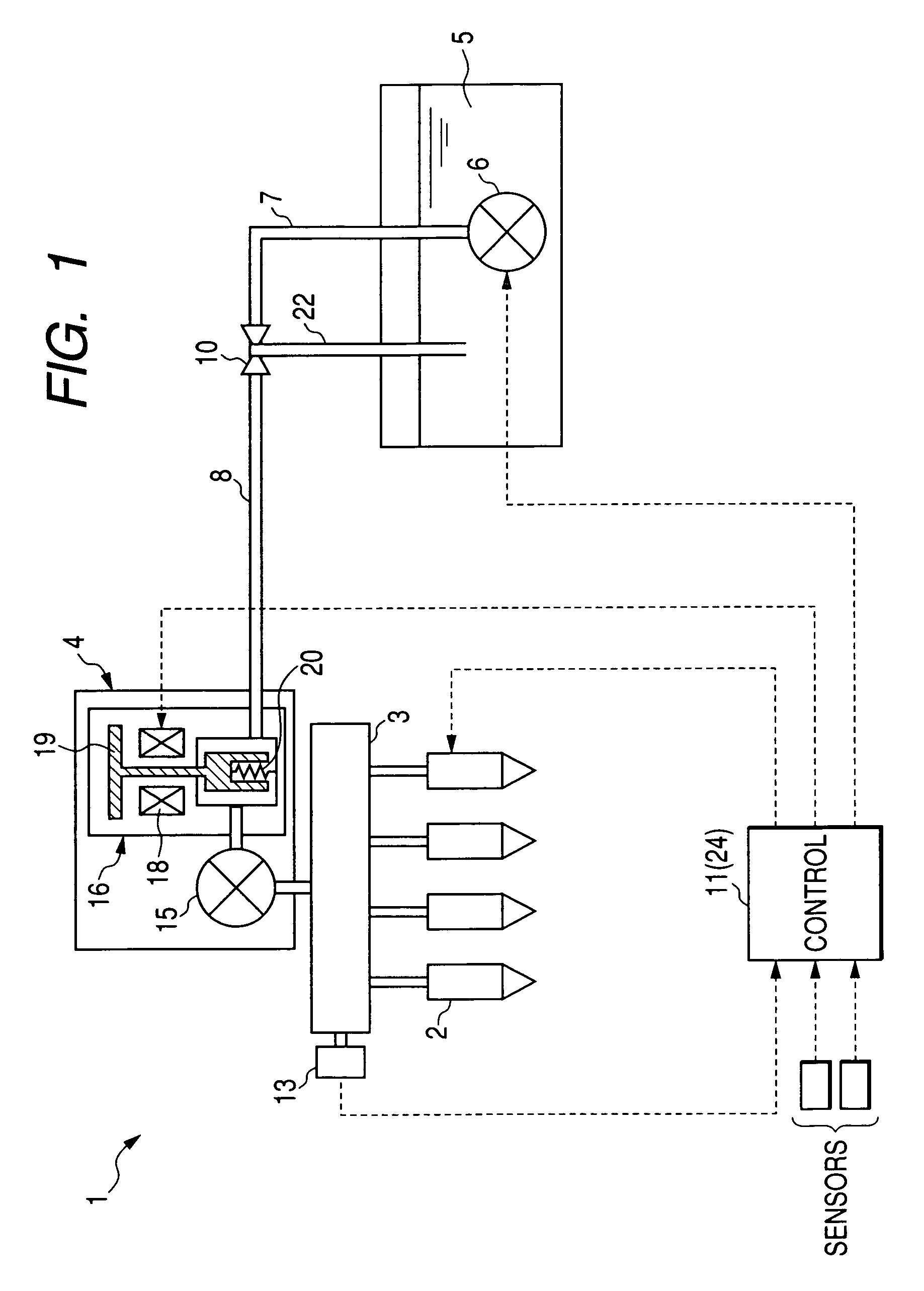

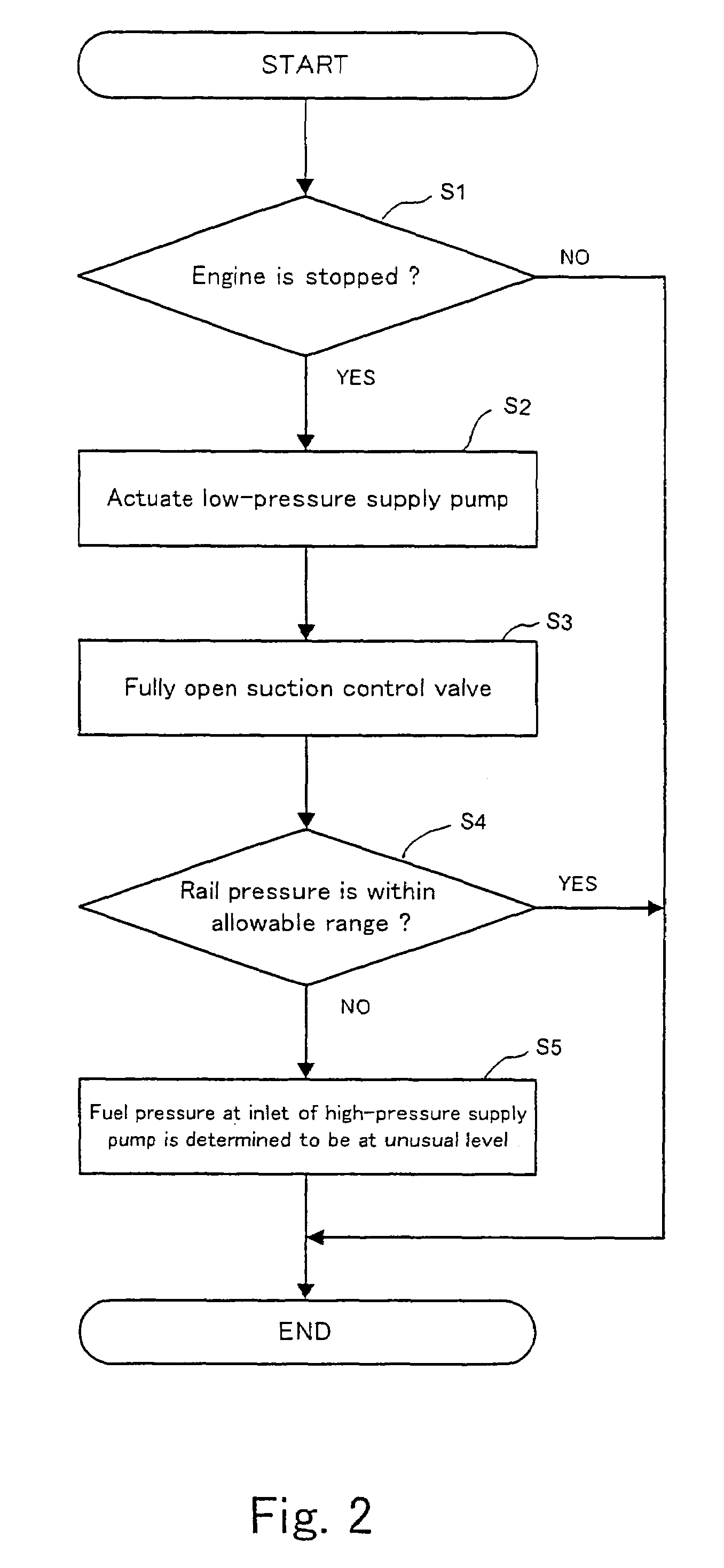

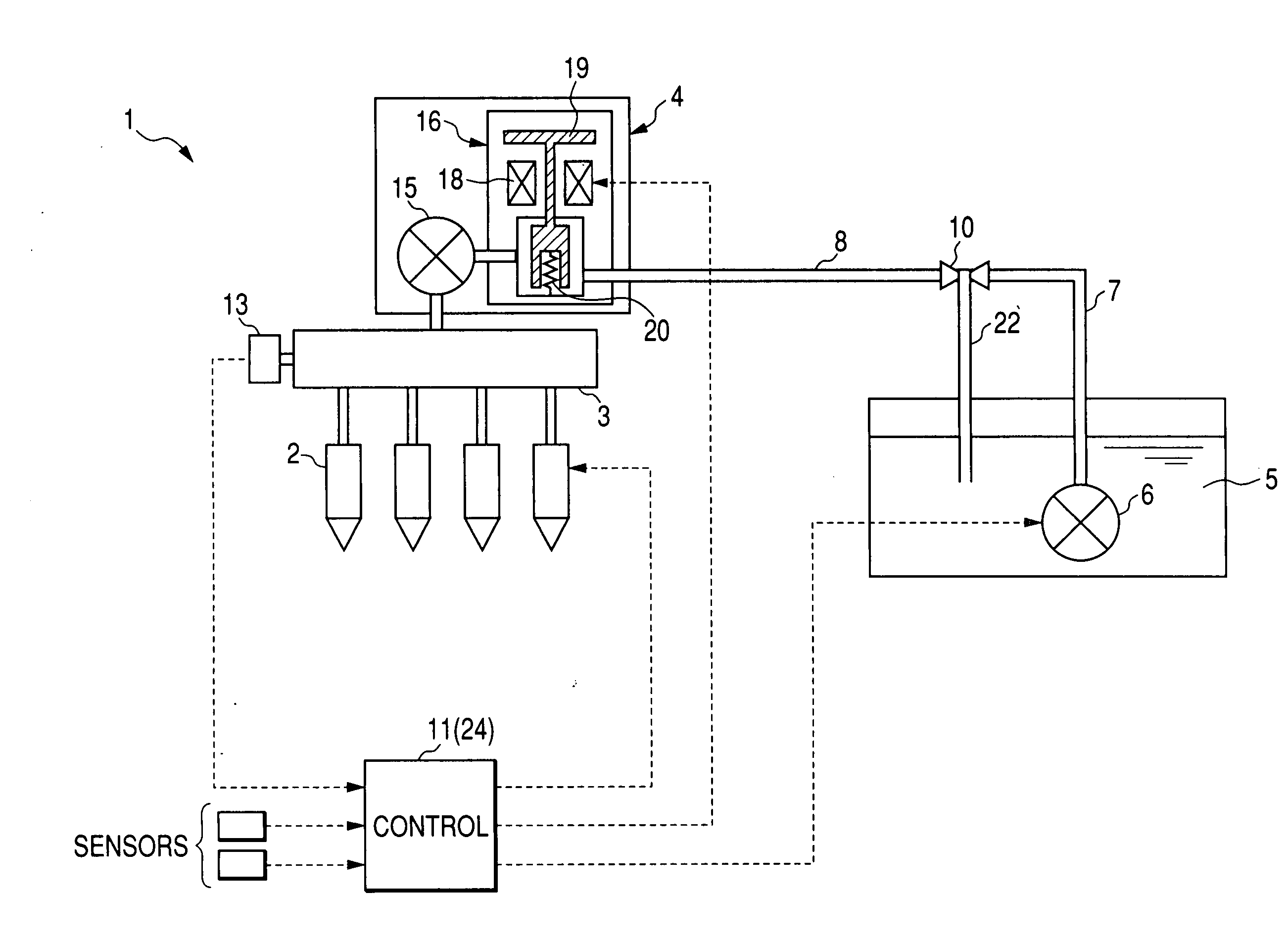

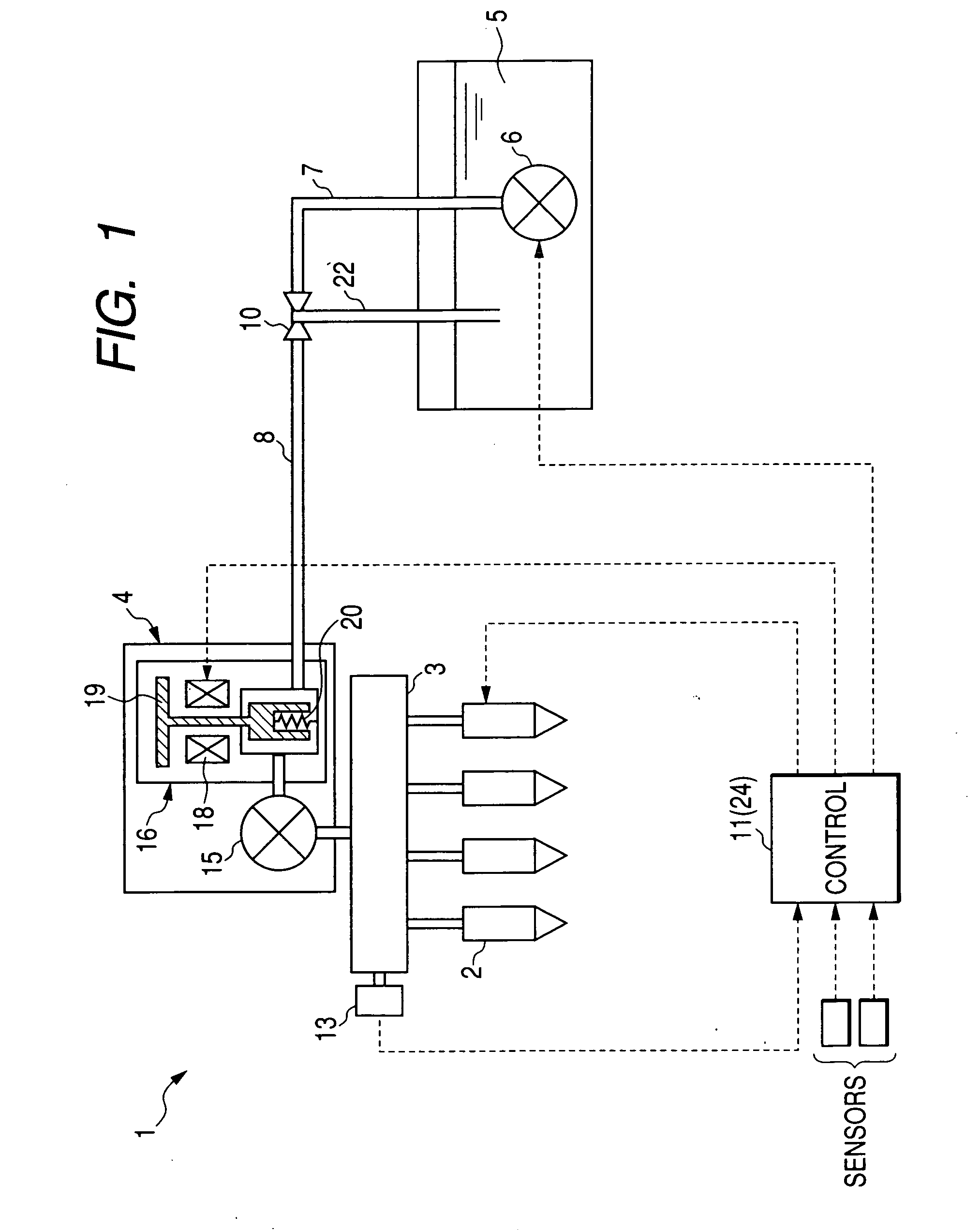

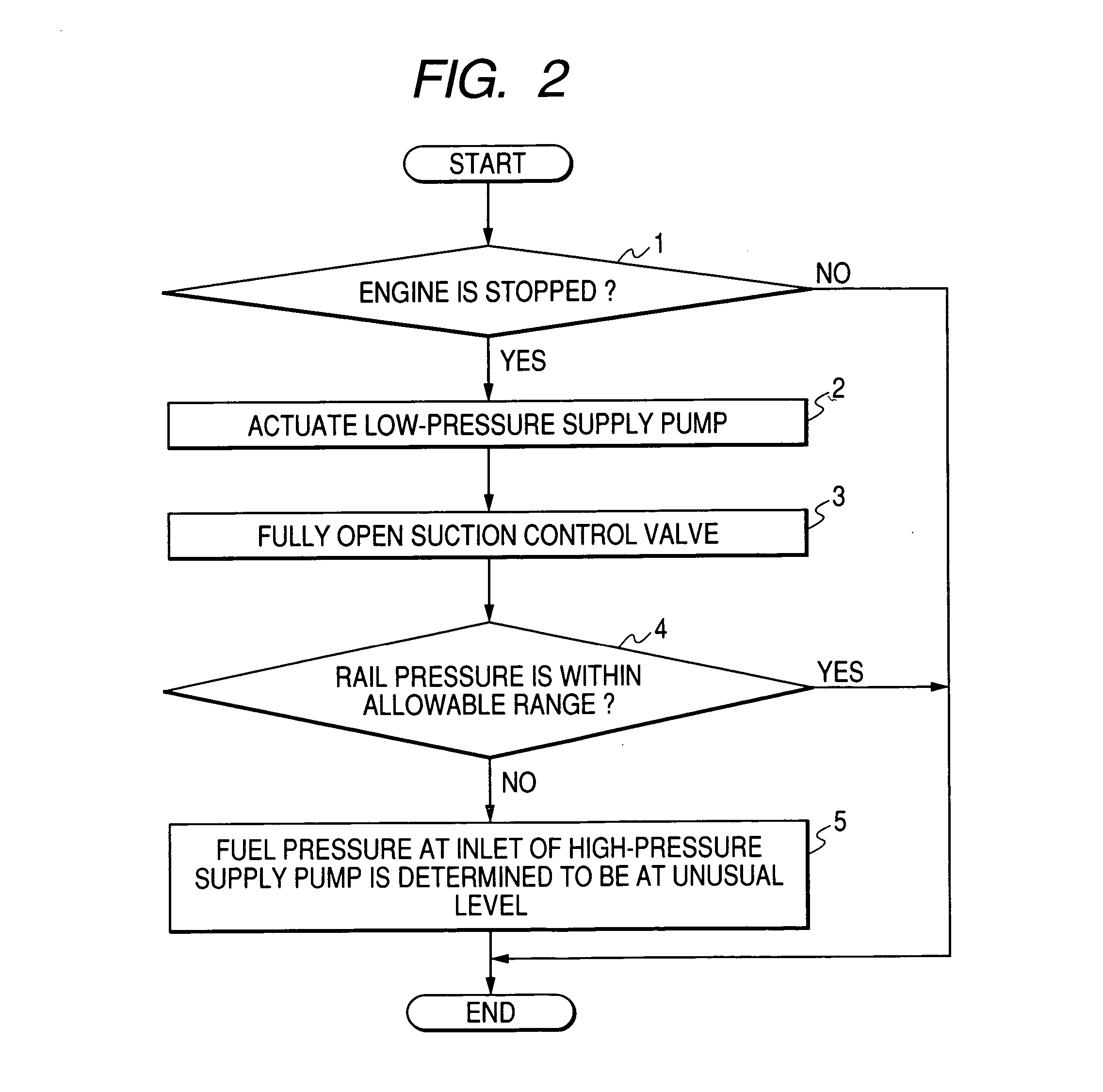

Fuel injection system monitoring abnormal pressure in inlet of fuel pump

A fuel injection system is equipped with a high-pressure supply pump driven by an output of an internal combustion engine to supply fuel to an accumulator, a low-pressure supply pump driven by a power source other than the engine to suck the fuel from a fuel tank and supply the sucked fuel to the high-pressure supply pump, and a pressure regulator working to regulate the pressure of the fuel supplied from the low-pressure supply pump to the high-pressure supply pump. The system also includes an abnormal pressure detector working to monitor a preselected parameter that bears a correlation to the energy held by the fuel at an inlet of the high-pressure supply pump to detect whether a pressure of the fuel at the inlet of the high-pressure supply pump is in an abnormal level or not without monitoring it directly.

Owner:DENSO CORP

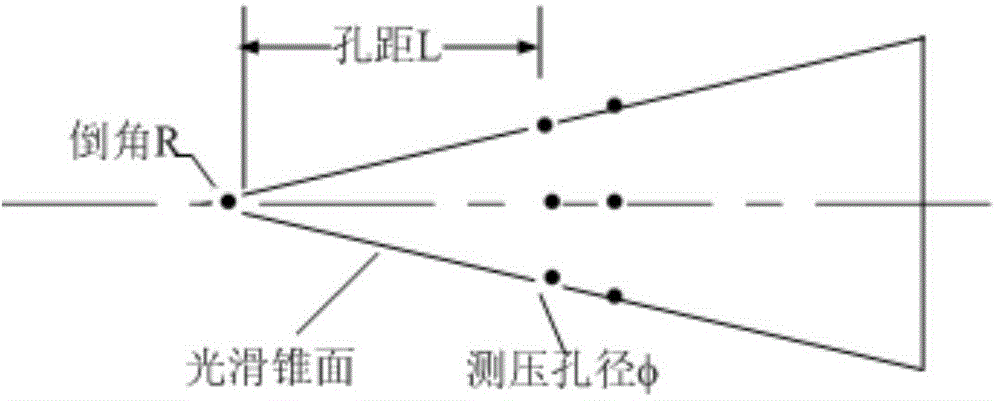

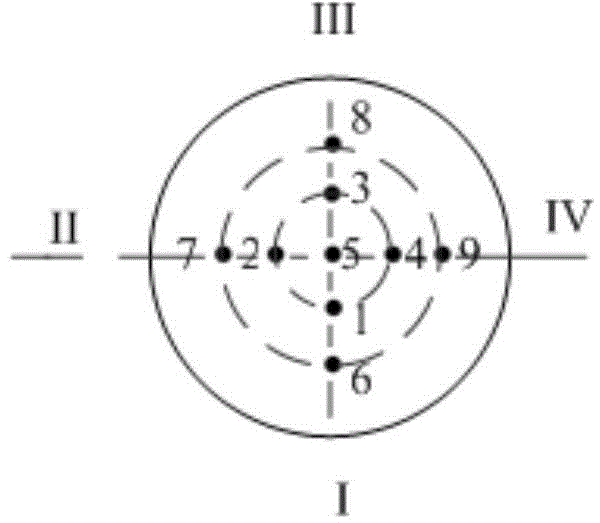

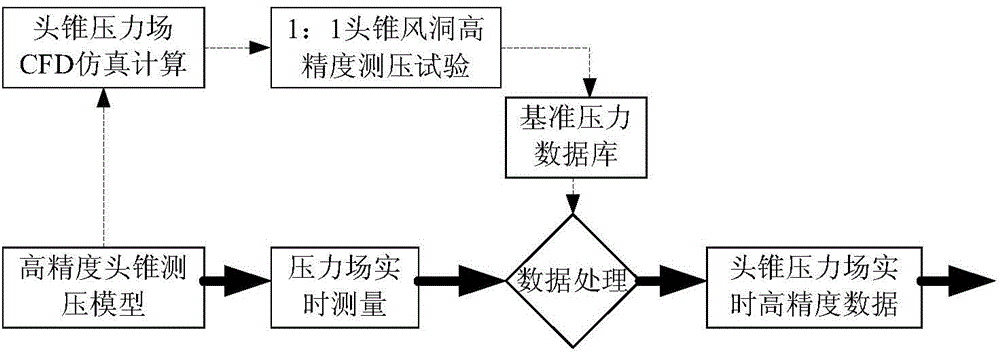

Real-time high-precision acquiring method for conical surface pneumatic pressure field

ActiveCN105628325AHigh precisionSolve the problem of high-precision measurement of pneumatic pressure fieldAerodynamic testingFlight heightData acquisition

The invention relates to the technical field of pneumatic pressure field high-precision measurement, and particularly discloses a real-time high-precision acquiring method for a conical surface pneumatic pressure field. The real-time high-precision acquiring method comprises the steps of 1, establishing a high-precision nose cone section surface and a pressure measuring hole structure model and a pressure measuring model; 2, acquiring surface pressure field data of aircrafts with different heights, different Mach numbers, different angles-of-attack and different sideslip angle states; 3, acquiring high-precision pressure data of a 1:1 nose cone section surface and the pressure measuring hole through air blowing in wind tunnel testing; 4, performing conversion on the surface pressure field data of the aircraft and the high-precision pressure measuring data in air blowing in wind tunnel testing for obtaining a different-state high-precision reference pressure database; and 5, performing difference comparison on a real-time measured pressure and a reference pressure database, eliminating abnormal pressures, thereby supplying reliable high-precision pressure distribution data for solving atmospheric parameters. The method settles a problem of high-precision measurement for the pneumatic pressure field. In a range in which flight height is 0-20km, the Mach number is 2-4Ma, and the angle-of-attack is -12-+12 DEG, high data acquisition precision of the pressure field is realized, and pressure deviation is smaller than + / -300 Pa.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

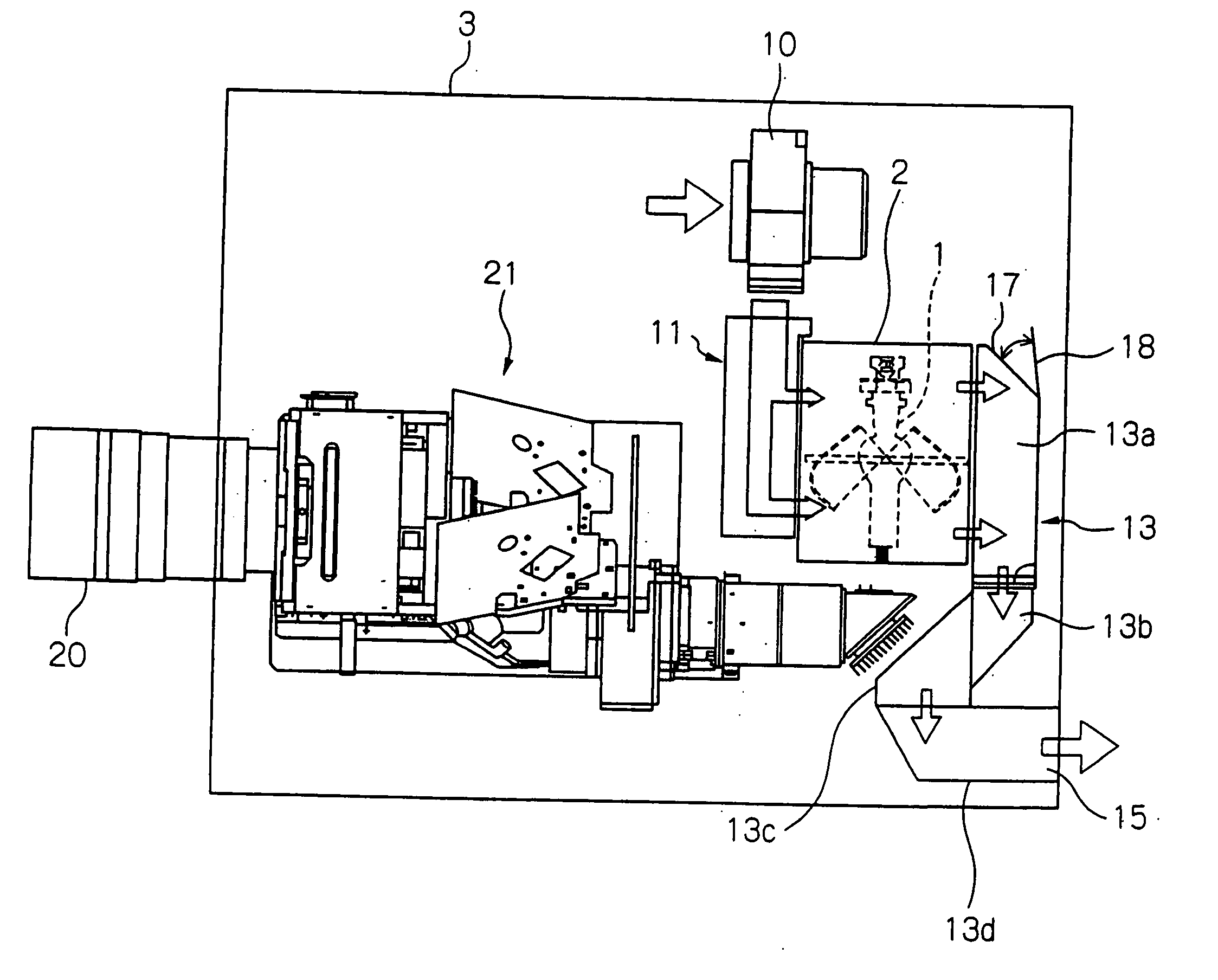

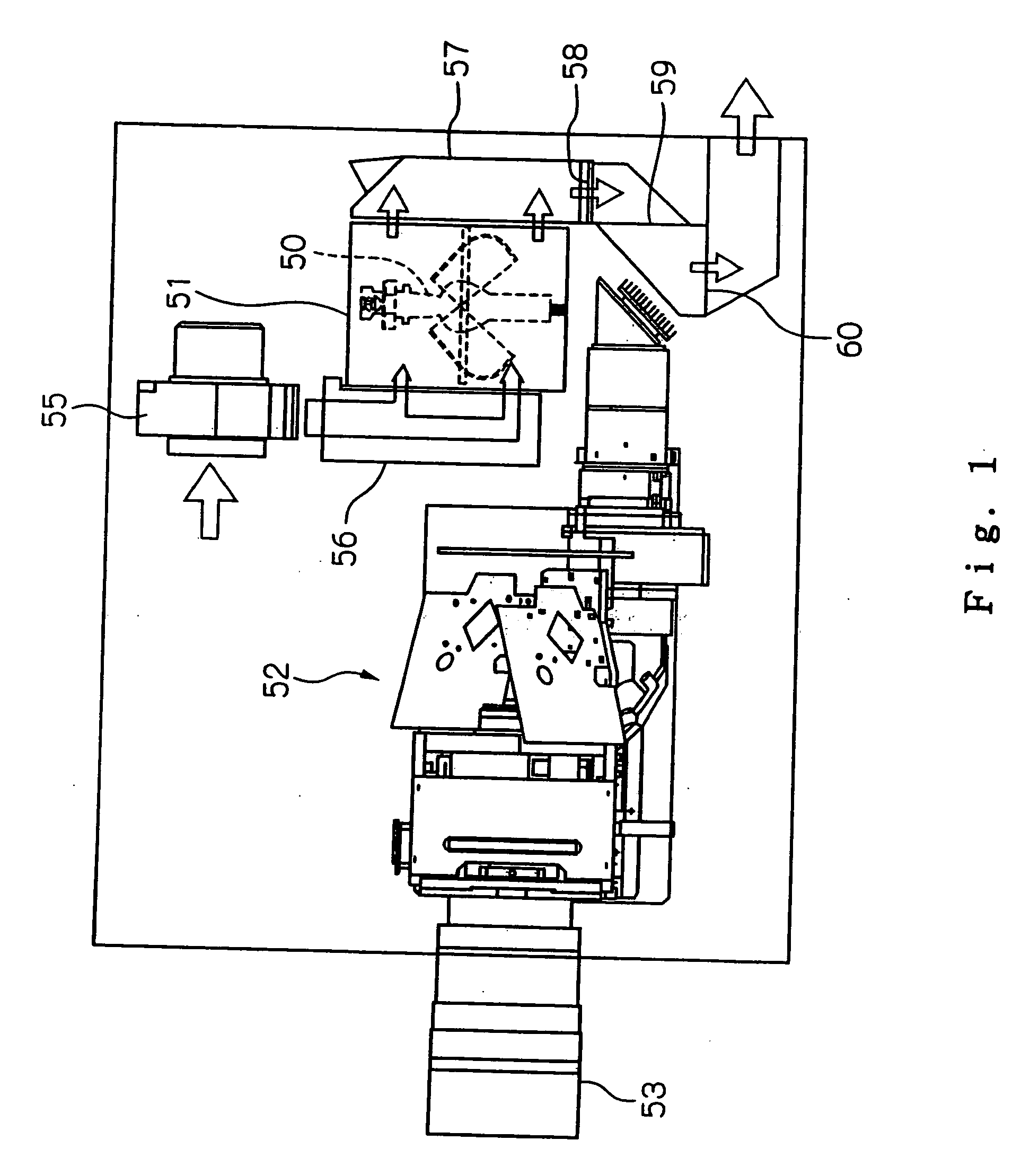

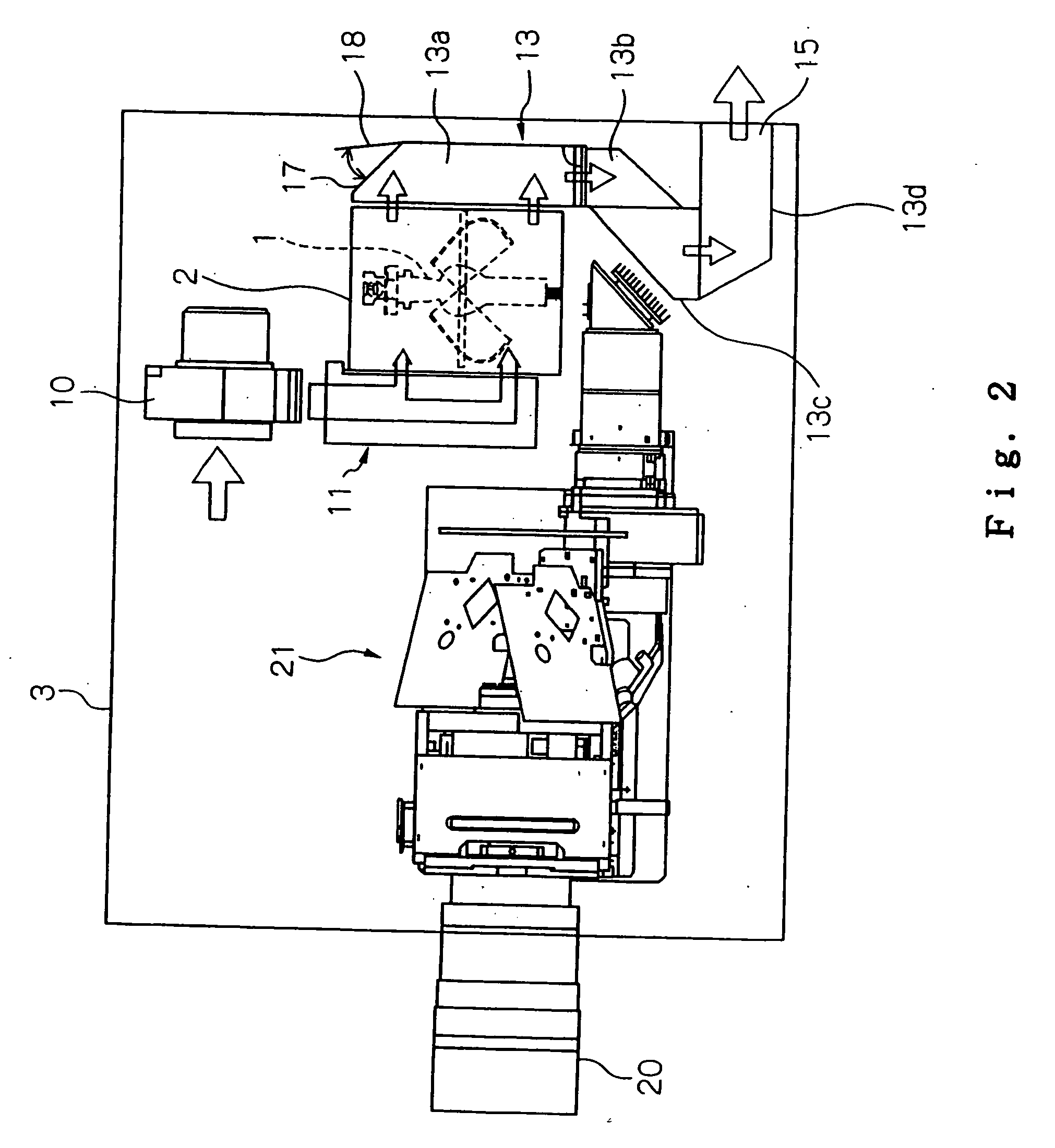

Light source device and projection display apparatus

InactiveUS20060109656A1Reduce heat dissipationIncrease in sizeLighting heating/cooling arrangementsProjectorsOptoelectronicsImage signal

A projection display apparatus generates image light by modulating, with an image signal, light emitted from a light source disposed in a lamp house, and projects the generated image light onto a screen. The projection display apparatus has an air inlet duct for introducing air, to cool the light source, into the lamp house and an air outlet duct for expelling the air discharged from the lamp house out of the projection display apparatus. The air outlet duct has an opening defined in a side wall thereof, and a lid pivotally mounted thereon for selectively opening and closing the opening. The lid is not opened under normal pressure in the air outlet duct when the light source operates normally, and is opened when an abnormal pressure buildup higher than the normal pressure is applied to the lid, thereby releasing the pressure buildup.

Owner:NEC DISPLAY SOLUTIONS LTD

Endoluminal device and system and method for detecting a change in pressure differential across an endoluminal device

An endoluminal device for deployment in a body lumen includes a radially expandable stent, a graft attached to the stent, and a plurality of indicator members affixed to the graft and adapted to form a normal pattern in response to a normal pressure differential and an abnormal pattern in response to an abnormal pressure differential across the graft. By forming different patterns at different pressure differentials, the indicator members enable the detection of a change in pressure which could be evidence of a leak. A system for detecting a change in pressure differential includes the endoluminal device and an imaging system for displaying the indicator members. A method for detecting a change in pressure includes the steps of identifying the normal pattern, implanting the device, imaging the indicator members, and comparing the imaged pattern with the normal pattern to determine whether the normal pressure or an abnormal pressure differential exists.

Owner:LIFESHIELD SCI

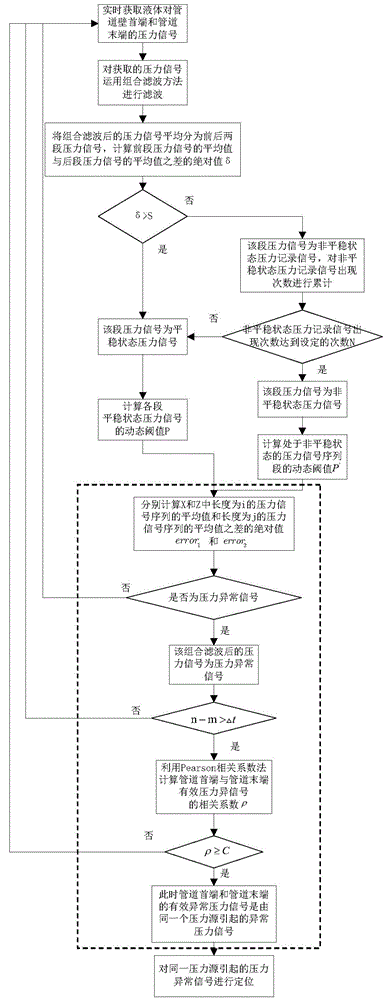

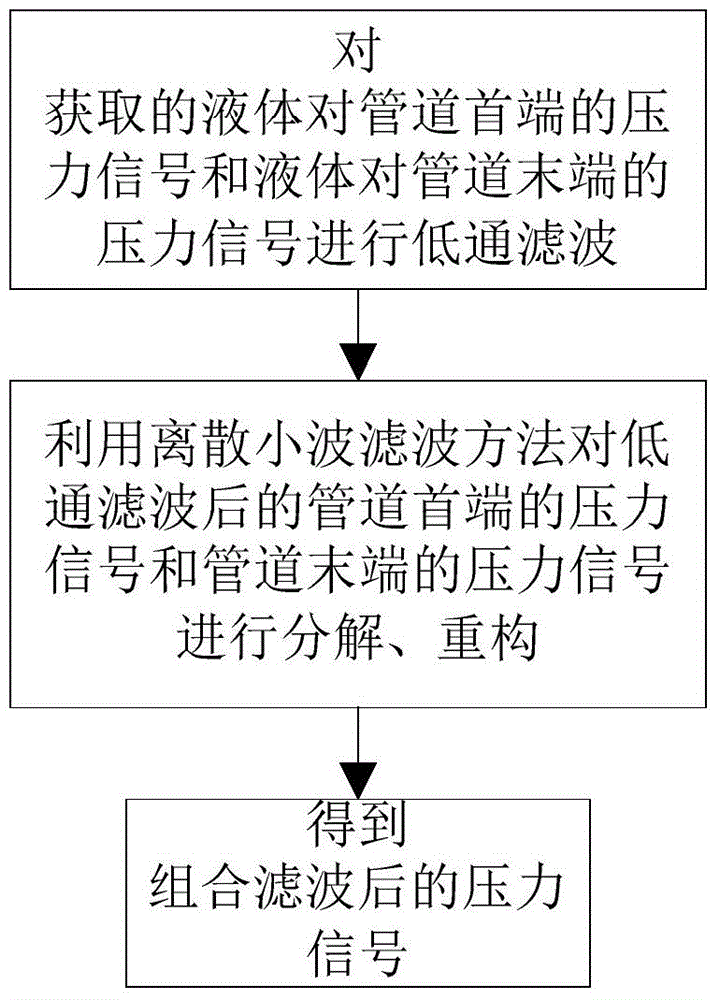

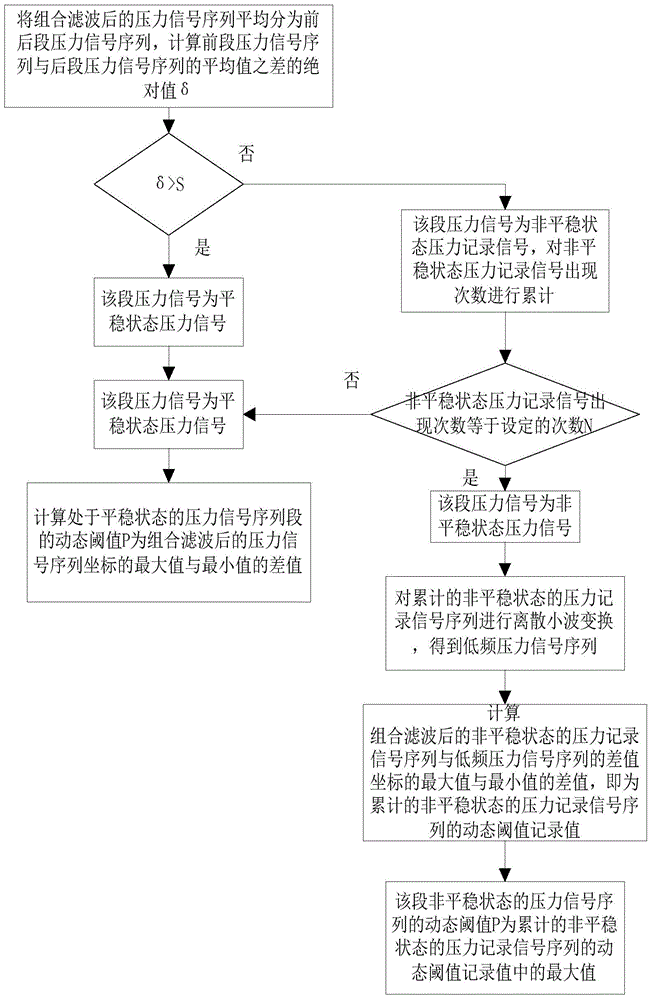

Pipe pressure anomaly diagnostic method based on combined filtering and dynamic thresholds

ActiveCN104089186AHigh sensitivityReduce false positive ratePipeline systemsDecompositionEngineering

The invention relates to a pipe pressure anomaly diagnostic method based on combined filtering and dynamic thresholds. The pipe pressure anomaly diagnostic method includes the steps of obtaining pressure signals of liquid to the head end and the tail end of a pipe in real time, carrying out decomposition reconstruction through low-pass filtering and discrete wavelet filtering, obtaining pressure signals generated after combined filtering, carrying out segment treatment on the pressure signals, calculating the dynamic thresholds of the segmented pressure signals obtained after combined filtering, judging whether the pressure signals of the pipe are abnormal or not in real time through the dynamic thresholds, judging whether the pressure anomaly signals at the head end and the tail end of the pipe are pressure anomaly signals caused by a same source or not with the Pearson related coefficient method, carrying out continuous wavelet transformation on the pressure anomaly signals with the same source to obtain moments corresponding to the maximum value points of wavelet coefficients, and carrying out anomaly point positioning through the difference of the moments corresponding to the maximum value points. By means of the pipe pressure anomaly diagnostic method, the pipe anomaly diagnostic sensitivity is improved, the misjudgment rate is reduced, and pressure anomaly points are accurately detected and positioned in the shortest time.

Owner:NORTHEASTERN UNIV

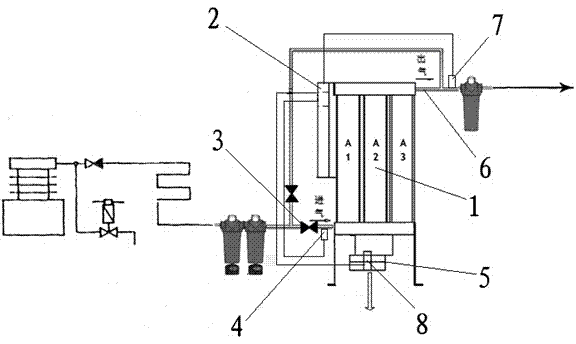

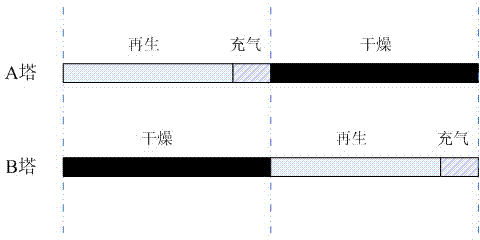

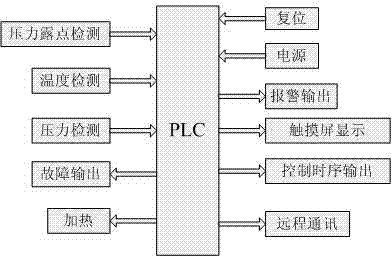

Control method and device for heat-adsorption-free air drier

ActiveCN104122834AGuaranteed reliabilityEffective shockproofGas treatmentDispersed particle separationProgrammable logic controllerData information

Disclosed is a control method and device for a heat-adsorption-free air drier. A programmable logic controller (PLC) is used as a control center, a dew point temperature and pressure dew point transducer is arranged at an air outlet end, the dew point temperature of the air outlet end and a pressure dew point of an air outlet are monitored through the dew point temperature and pressure dew point transducer, meanwhile, a temperature transducer is arranged at the position of an air inlet, the temperature transducer of the air inlet is monitored, a pressure transducer is mounted at the position of an air control combined valve silencer to collect abnormal pressure signals, data values obtained by all transducers are fed back to the PLC, and the PLC controls the operation of the heat-adsorption-free drier according to collected data information of all transducers.

Owner:ZHUZHOU YIXING TECH CO LTD

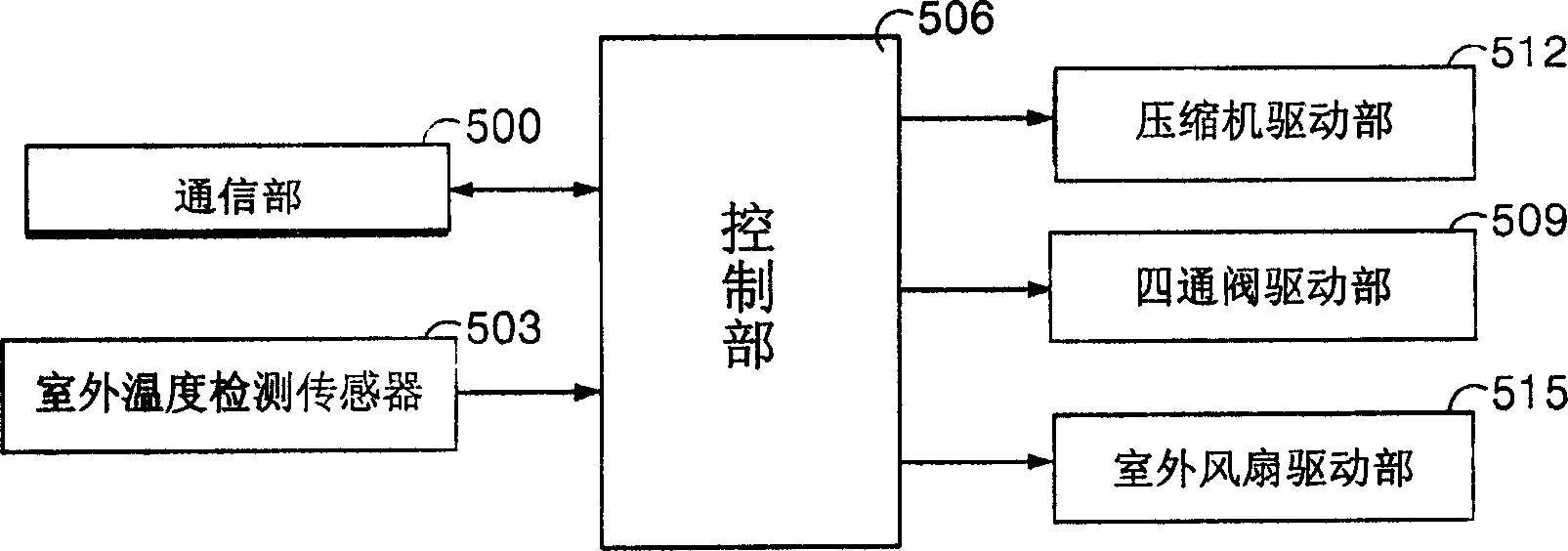

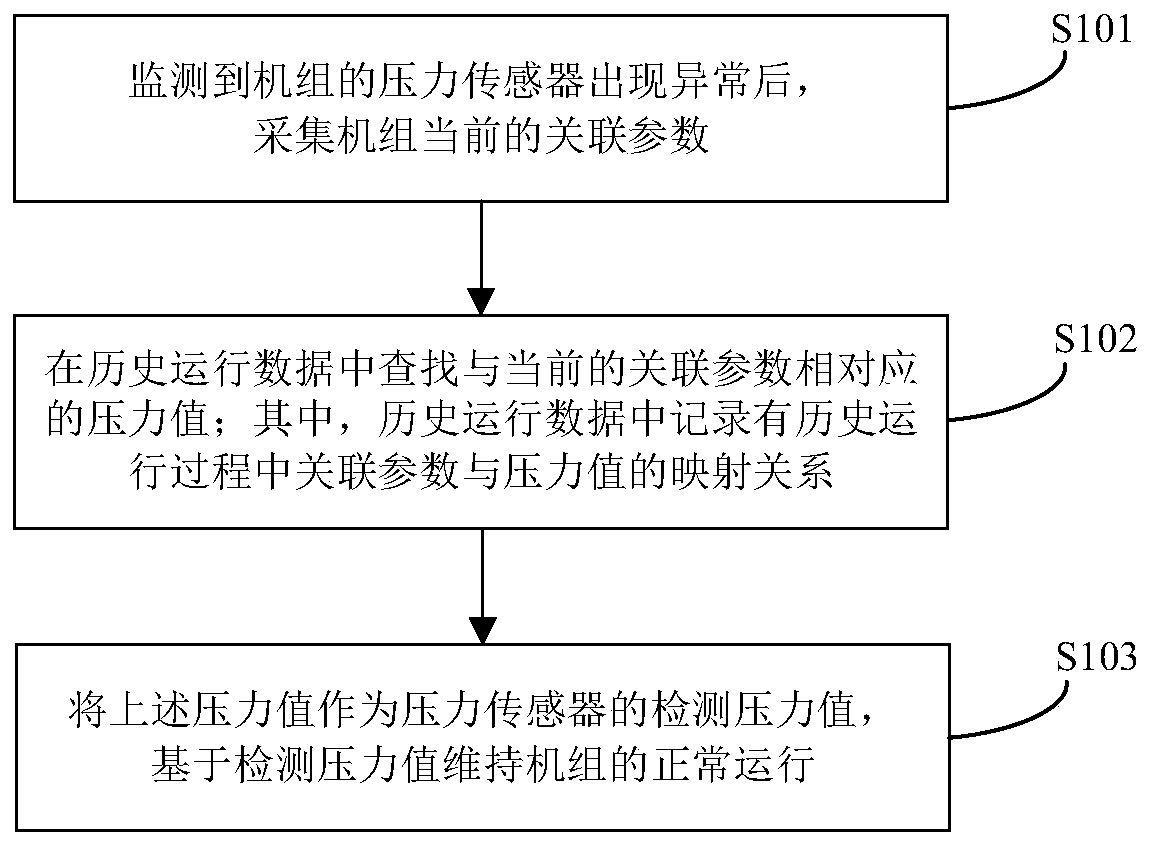

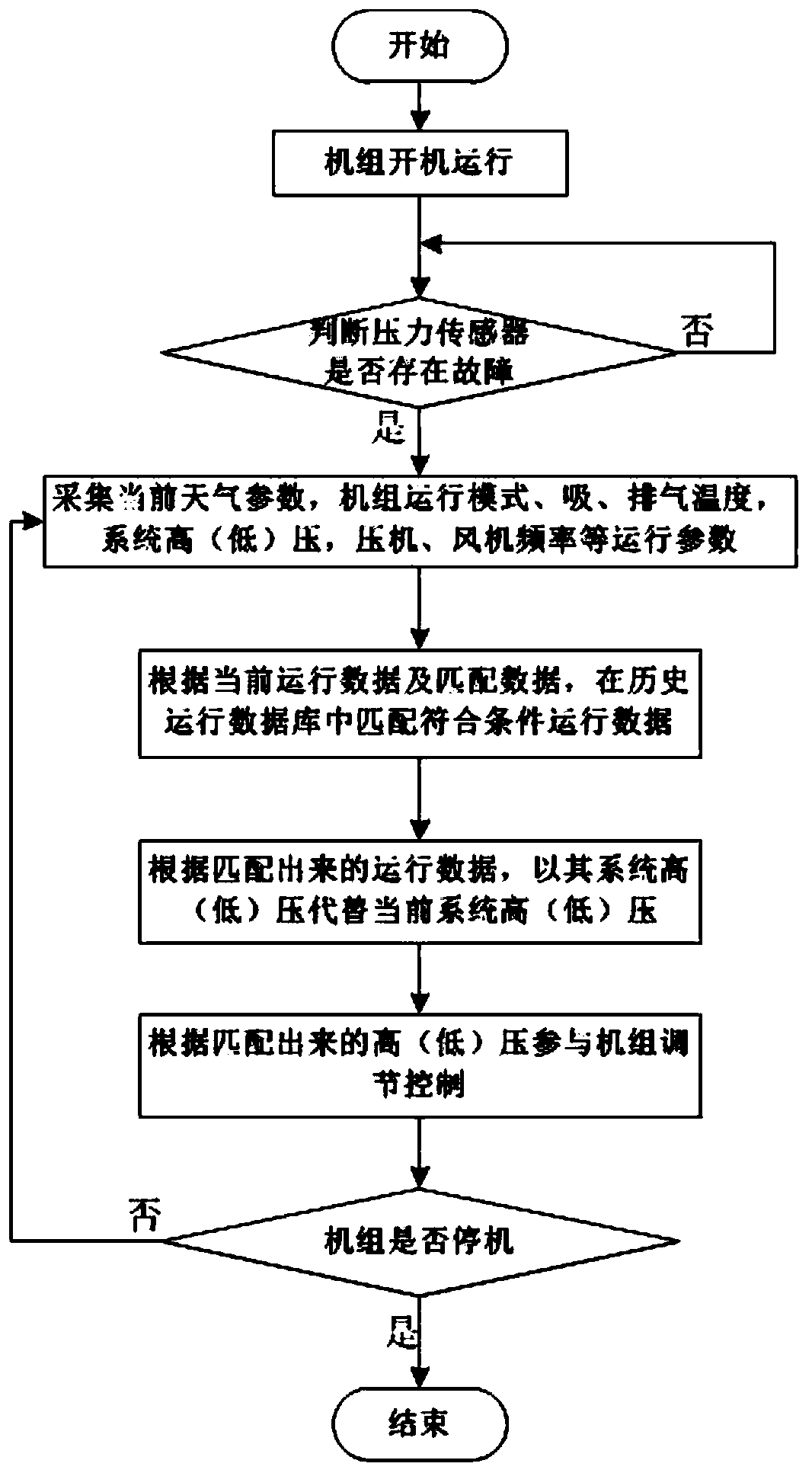

Method and device for guaranteeing normal operation of unit after abnormal pressure

InactiveCN110107993AGuaranteed uptimeMechanical apparatusSpace heating and ventilation safety systemsEmergency treatmentEngineering

The invention discloses a method and device for guaranteeing normal operation of a unit after abnormal pressure. The method comprises the steps: after monitoring that a pressure sensor of the unit isabnormal, collecting current associated parameters of the unit; searching historical operation data for a pressure value corresponding to the current associated parameters, wherein a mapping relationbetween an associated parameter and a pressure value is recorded in historical operation data; taking the pressure value as a detection pressure value of the pressure sensor, and maintaining normal operation of the unit based on the detection pressure value. The device provides an emergency treatment scheme for the situation that the unit cannot normally operate when the pressure sensor is abnormal. According to the emergency treatment scheme, the pressure value in the historical operation data is taken as the detection pressure value of the pressure sensor, so that the subsequent normal operation of the unit can be guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

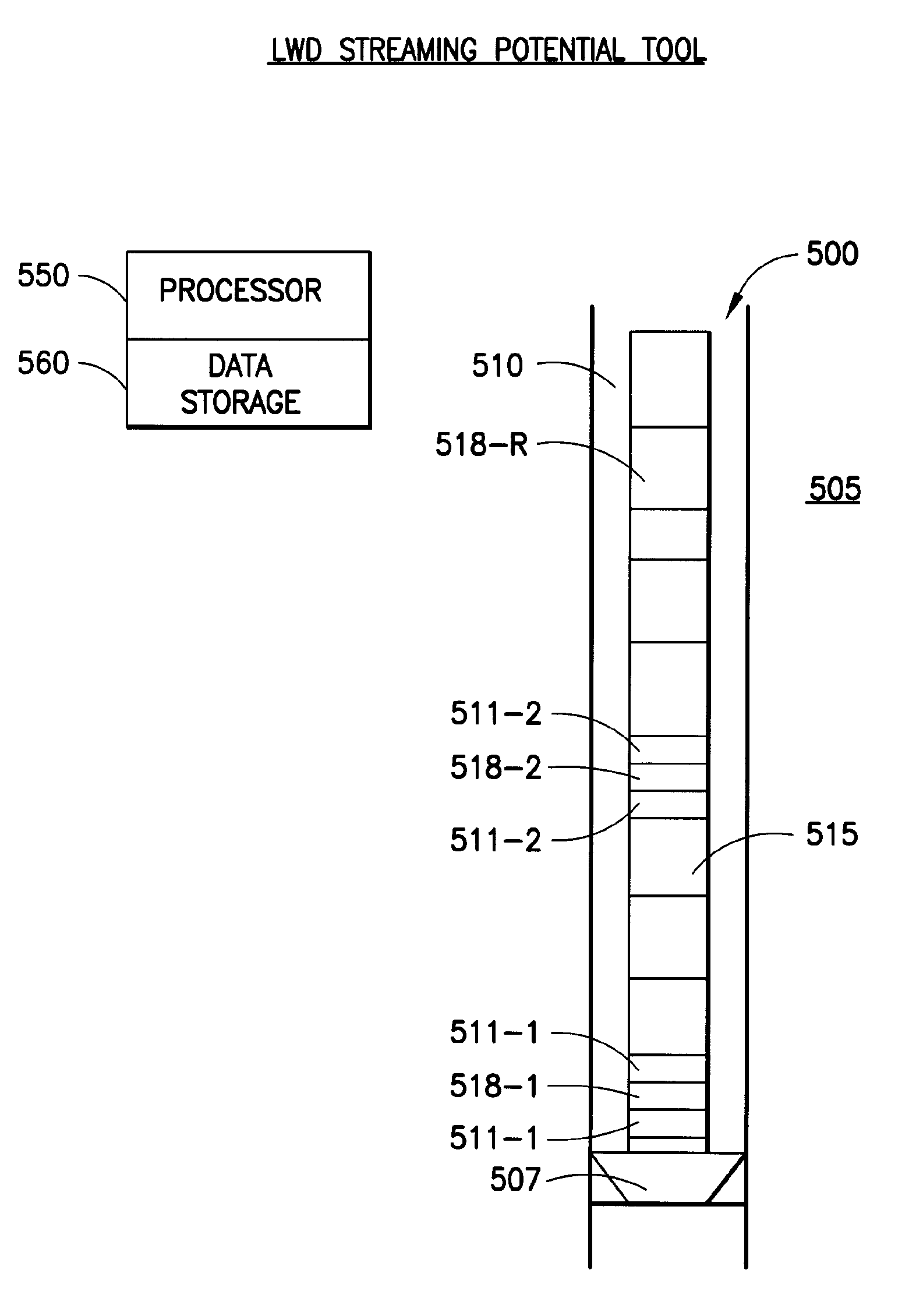

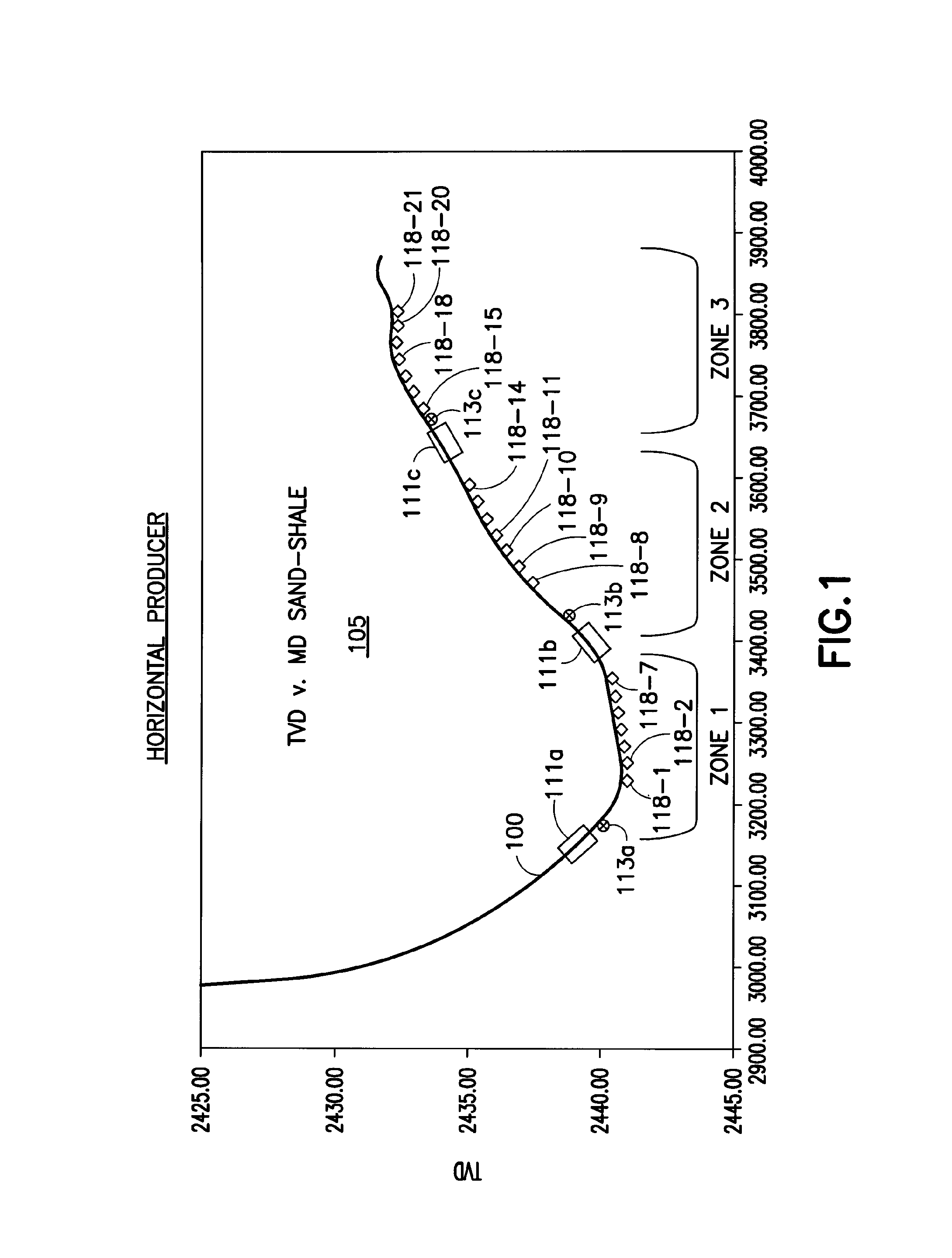

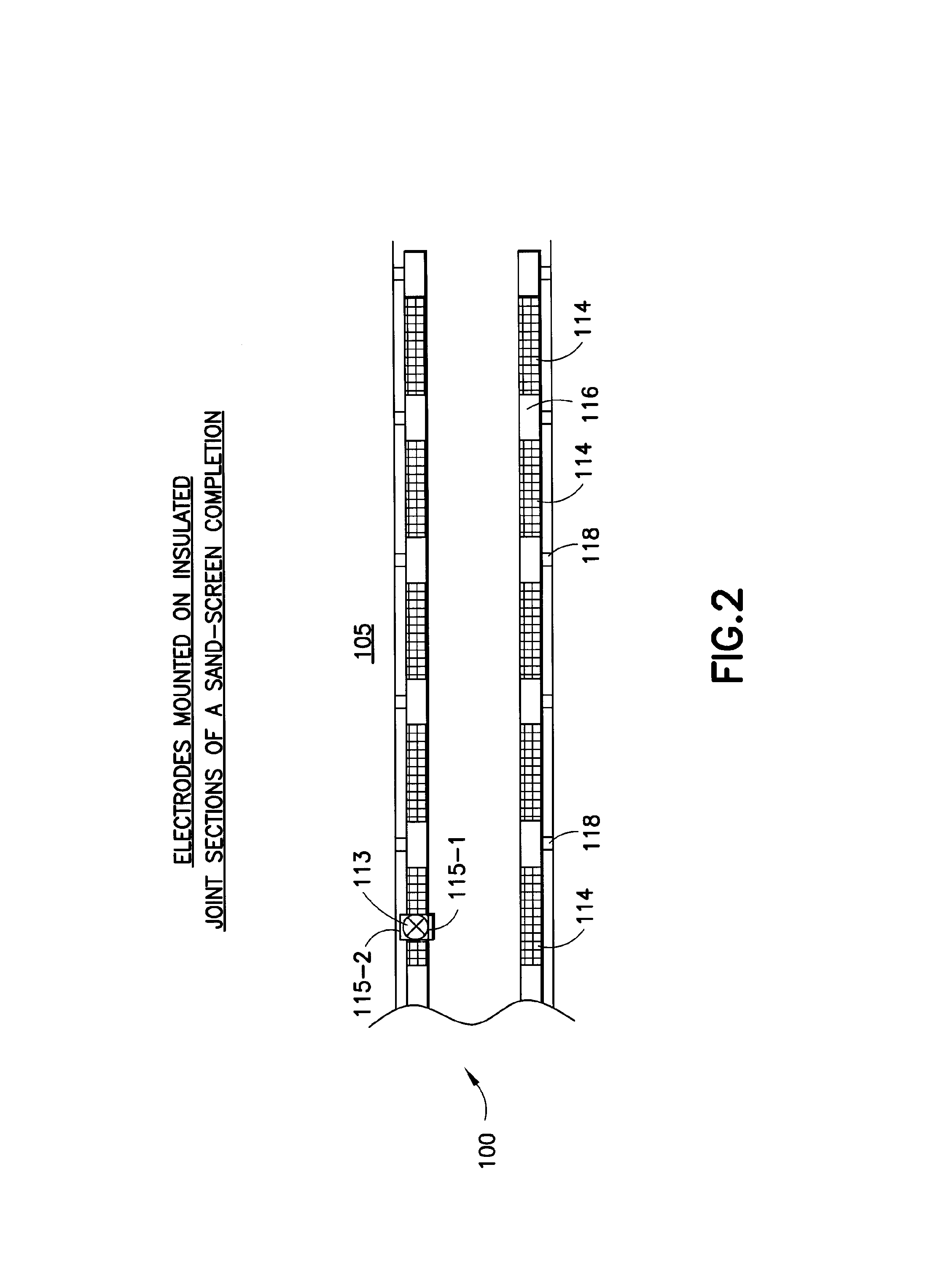

Apparatus for measuring streaming potentials and determining earth formation characteristics

Earth formations are characterized by using an array of electrodes which can measure streaming potentials in the formation, and by interpreting the data obtained by the electrodes. The electrodes are placed on a wireline tool, a LWD tool, or in a fixed manner about a completed wellbore. The measured streaming potentials are generated by drilling with an overbearing pressure, slitting the mudcake in a borehole, acid injection, or any of various other manners which causes fluid movement. The data obtained is interpreted to locate fractures, measure formation permeability, estimate formation pressure, monitor drilling fluid loss, detect abnormal pressure, etc. Particularly, a streaming potential voltage transient having a double peak profile signifies the presence of a formation fracture.

Owner:SCHLUMBERGER TECH CORP

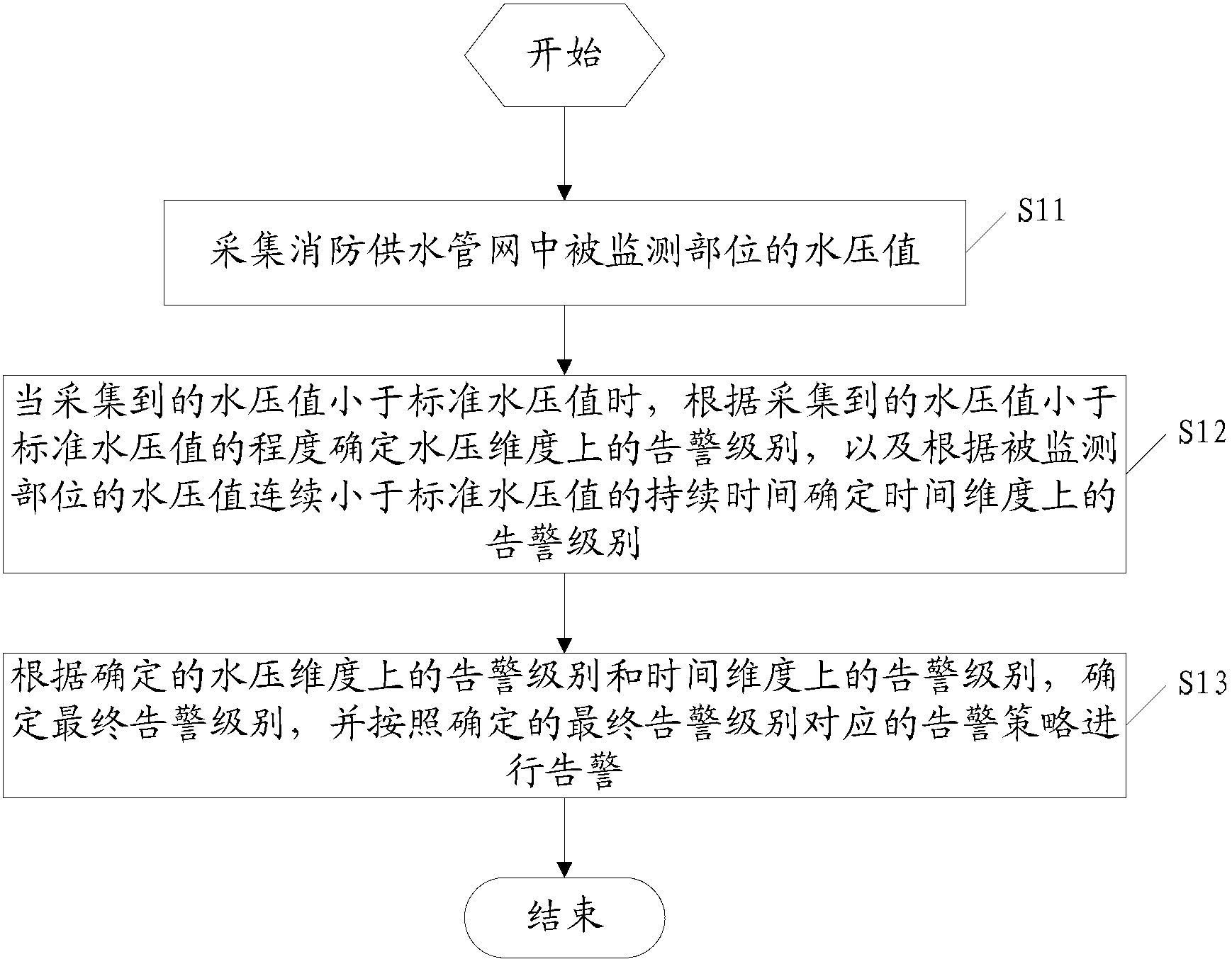

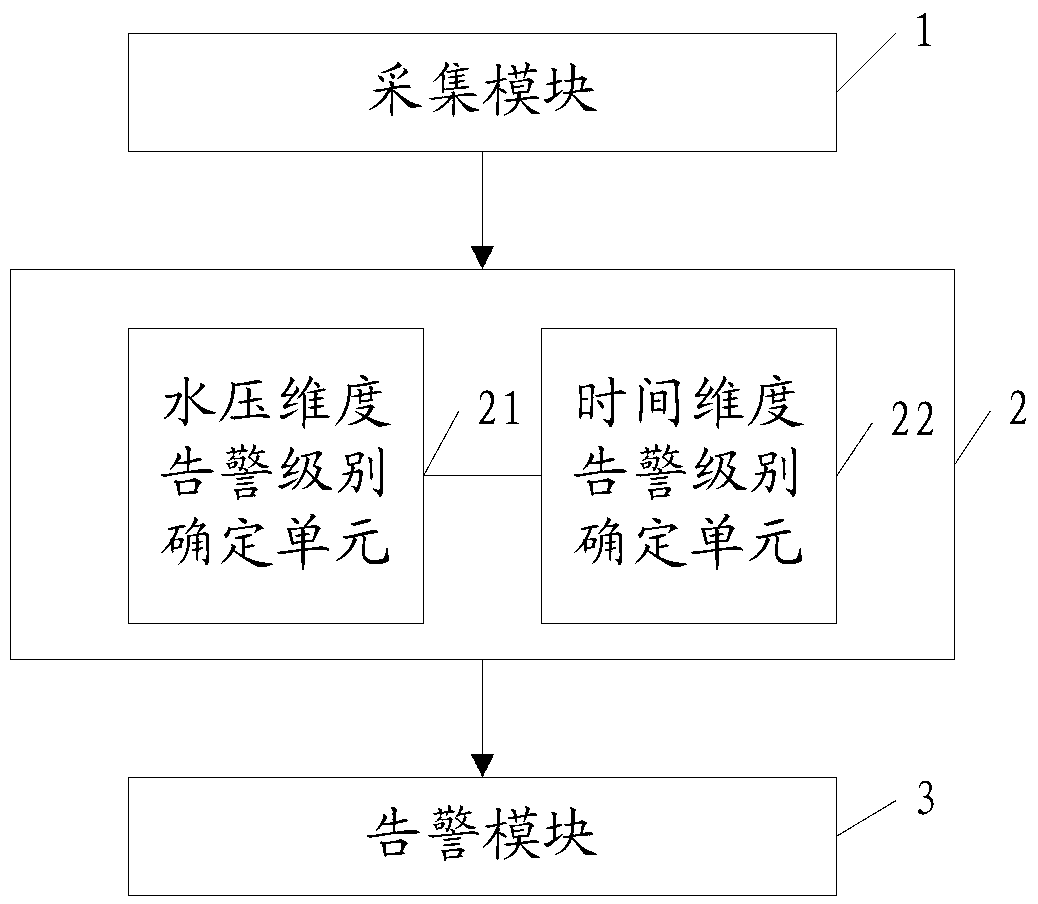

Method and system for warning abnormal water pressure of fire-fighting water supply pipe network

Owner:CHONGQING HEHANG TECH

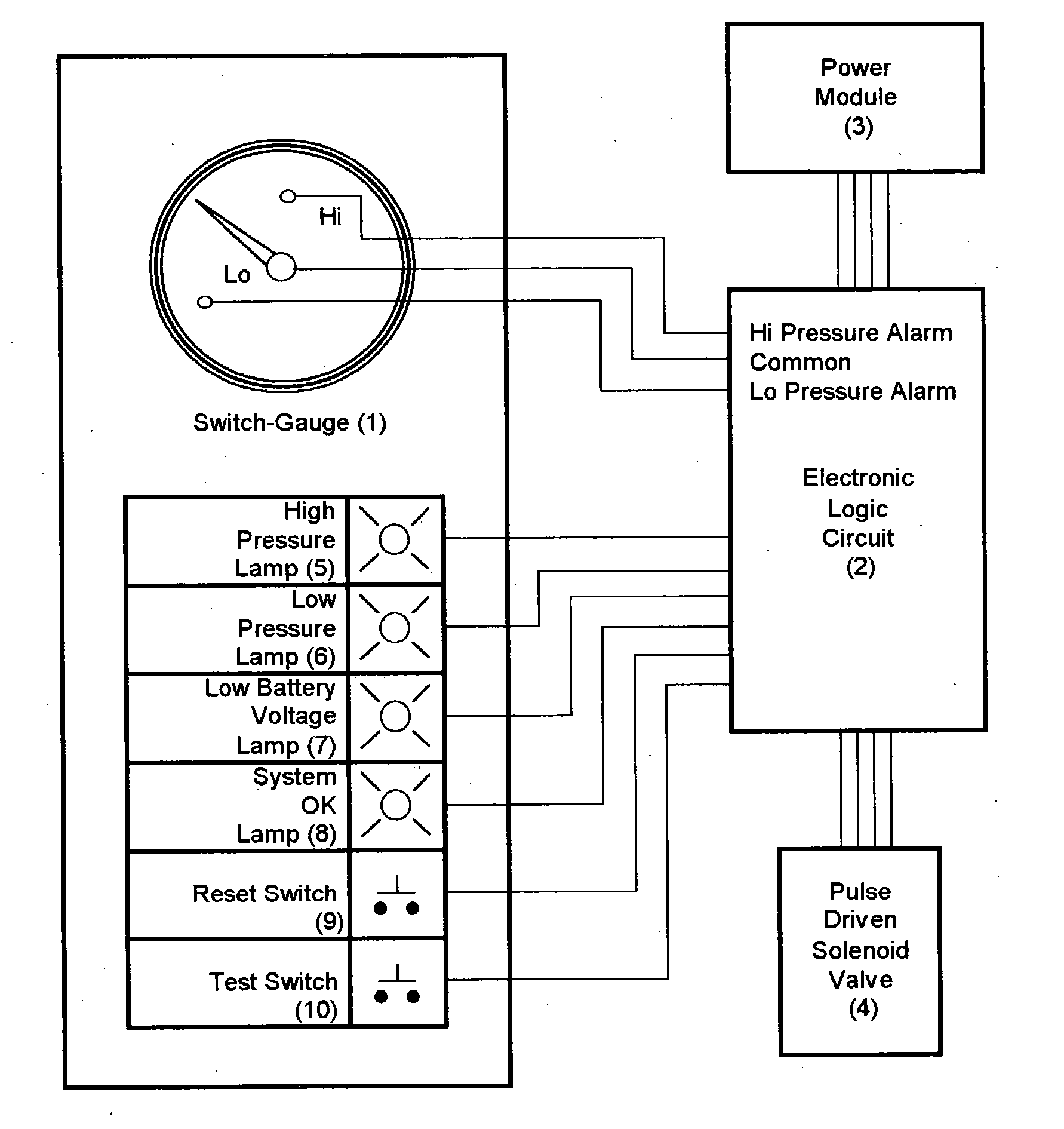

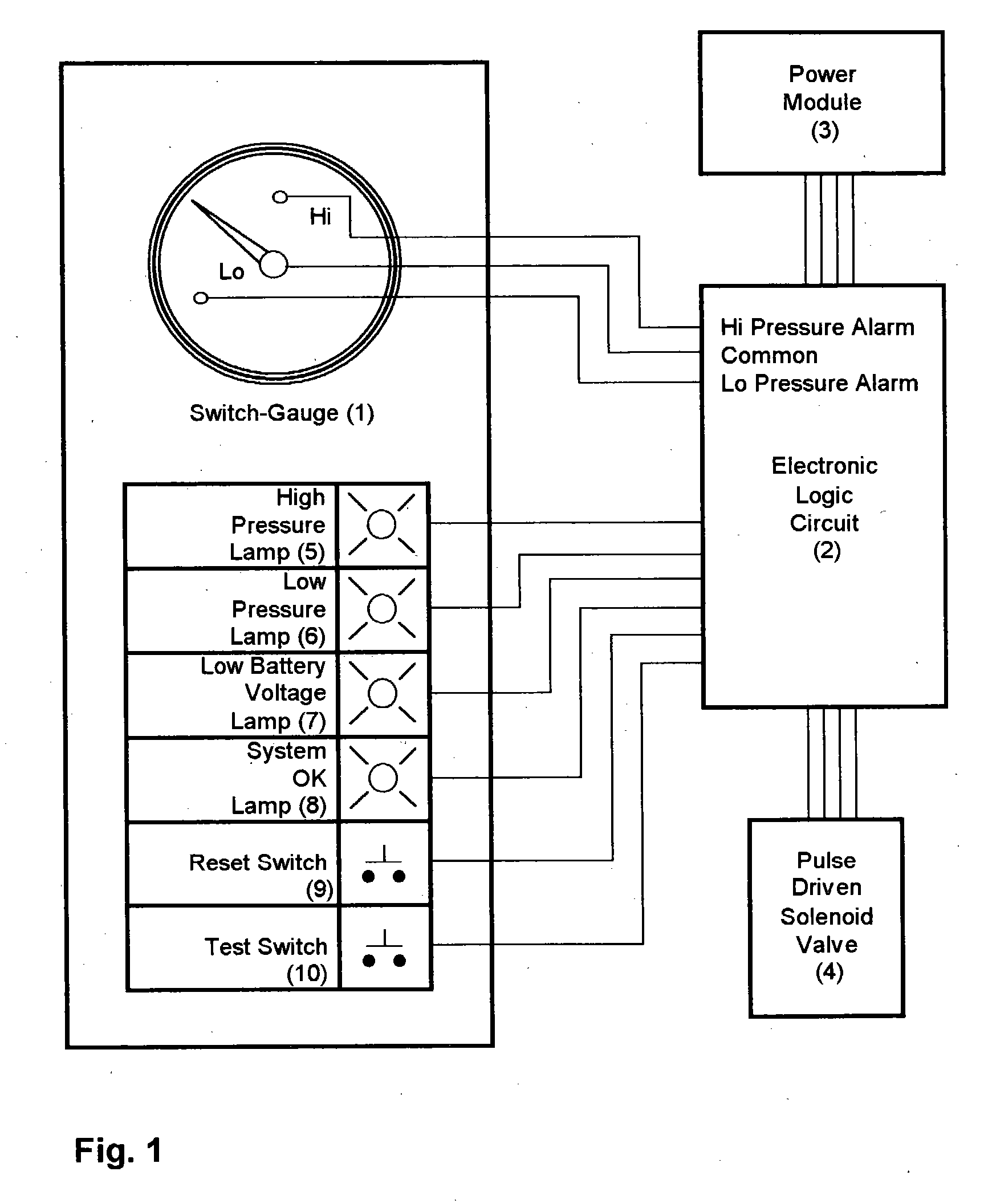

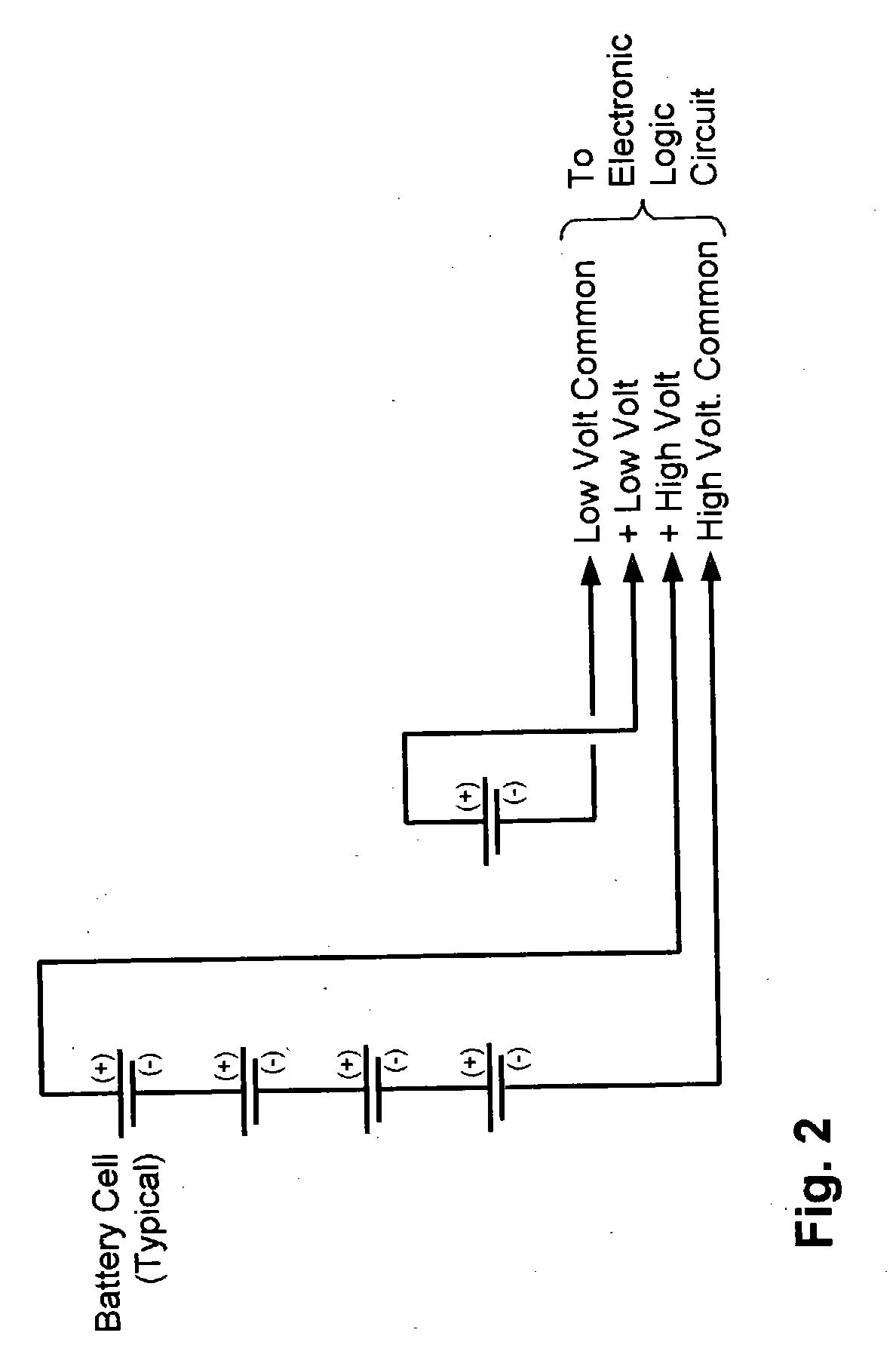

Self-contained electronic pressure monitoring and shutdown device

InactiveUS20050021189A1Minimal maintenanceReading directlyFluid-pressure actuator safetyEqualizing valvesCapacitanceSolenoid valve

The invention is a self-contained process shutdown device that detects abnormal pressures and initiates shutdown by removing the pneumatic or hydraulic pressure needed for a given process or flow to continue. The process' pressure is detected by means of a switch-gauge (a pressure gauge with high and low alarm electrical contacts) which has a pressure sensing port connected to the monitored pressure. The contacts from the switch-gauge are connected to an electronic logic circuit that sends one or more shutdown pulses to trip a pulse driven solenoid and initiate the shutdown. This device provides indicator lamps to show statuses and alarms as well as switch or pushbuttons to activate the “Reset” and “Test” functions. The electrical power is supplied by a power module that is constituted of battery cells connected in such way that it provides a dual voltage output to feed the electronic logic separate from the pulse driven solenoid driver circuit. Alternatively, the power module may be constituted of a circuit made of a photovoltaic module, voltage regulator circuits and three main capacitors with enough capacitance to keep the electronic logic circuit and the solenoid valve driver circuit operating throughout the night or longer.

Owner:TIMM MIGUEL A

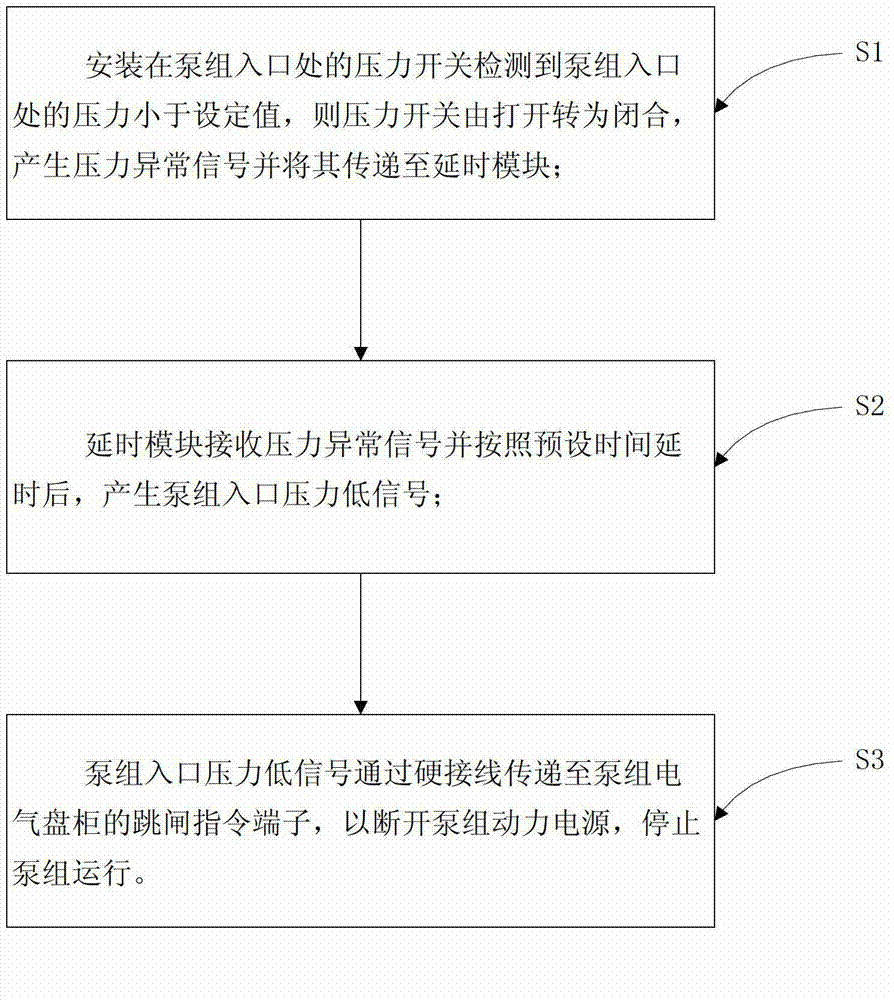

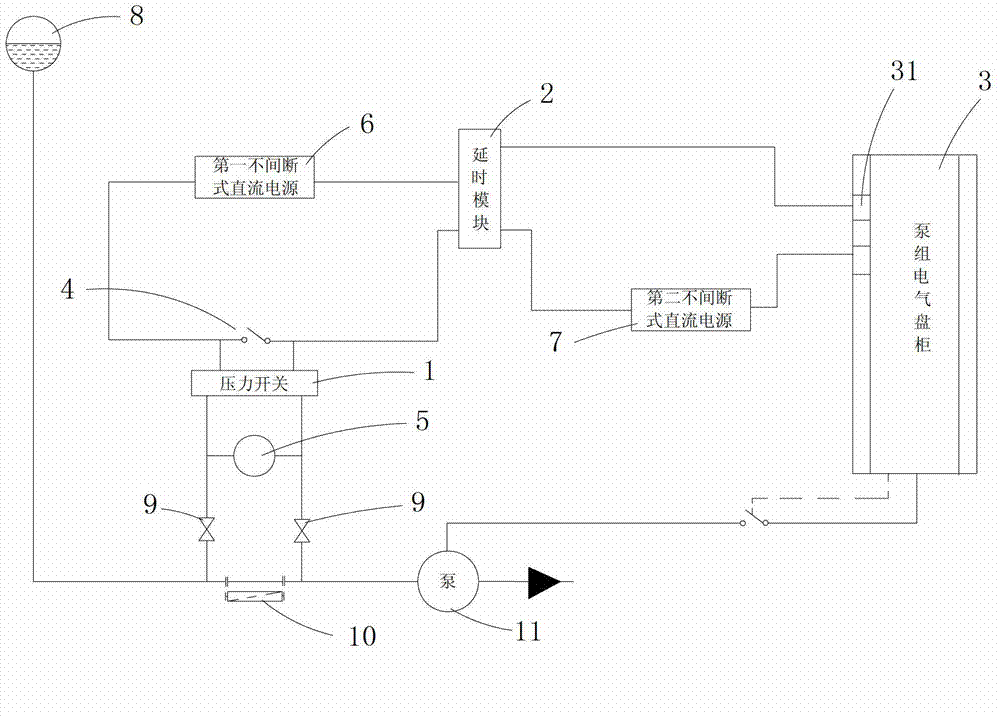

Pressure control method and device for pump unit of nuclear power station

ActiveCN102966578AGuaranteed safe operationAvoid uncontrollable risksPump controlNon-positive displacement fluid enginesNuclear powerDistributed control system

The invention discloses a pressure control method and a device for a pump unit of a nuclear power station. The pressure control method comprises the steps that S1, a pressure switch is turned from on to off after pressure at an inlet of the pump unit detected by the pressure switch mounted at the inlet of the pump unit is smaller than a set value, an abnormal pressure signal is generated and transmitted to a delaying module; S2, the delaying module receives the abnormal pressure signal and generates a low pump unit inlet pressure signal after being delayed according to the pre-set time; and S3, the low pump unit inlet pressure signal is transmitted to a trip instruction terminal of an electric plate cabinet of the pump unit through a hard wire to cut off a power supply of the pump unit and allow the pump unit to stop operation. The pressure control device for the pump unit comprises the pressure switch (1) and the delaying module (2). The pressure control method and the device have the benefits that the immediate stop of the operation of the pump unit in an abnormal condition (for example, the low pressure at the inlet of the pump unit) can be ensured under the situation that a DCS (Distributed Control System) and LSA (Test Loops) are unavailable, the safety of equipment is ensured, and the construction time and cost are saved.

Owner:中广核工程有限公司 +1

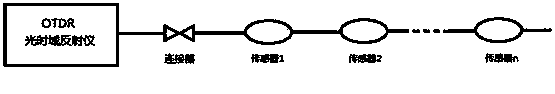

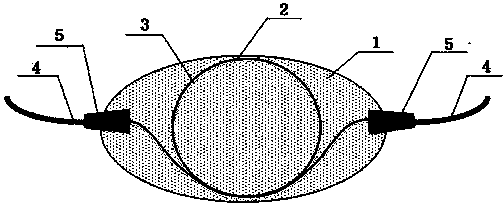

Ellipsoidal optical fiber pressure sensor and optical fiber fault pressure point detection method

InactiveCN103983385AIncreased strain transfer rateSensing quickly and accuratelyForce measurement by measuring optical property variationTime domainTime-domain reflectometer

The invention discloses an ellipsoidal optical fiber pressure sensor and an optical fiber fault pressure point detection method. The ellipsoidal optical fiber pressure sensor is composed of two semi-ellipsoids, a circular fiber coiling groove with the radius being in a predetermined length is engraved on the adhesive surface of one of the semi-ellipsoids, and sensing optical fibers are coiled in the groove and fixed into the groove through an adhesive. The optical fiber fault pressure point detection method includes the steps that a plurality of ellipsoidal optical fiber pressure sensors are connected onto the same sensing optical fiber in series; when pressure fault detection is conducted on the sensing optical fiber, an optical time domain reflectometer is connected with the sensing optical fiber through a connector, and the ODTR detects and determines a pressure fault point. When some ellipsoidal optical fiber pressure sensor on the optical fiber bears outside pressure to generate obvious bending losses, abnormal pressure points on an optical fiber circuit can be positioned through displaying of the optical time domain reflectometer, fault judgment and positioning can be conducted on project conveniently, and a basis is provided for timely first-aid repair and maintenance.

Owner:王东方

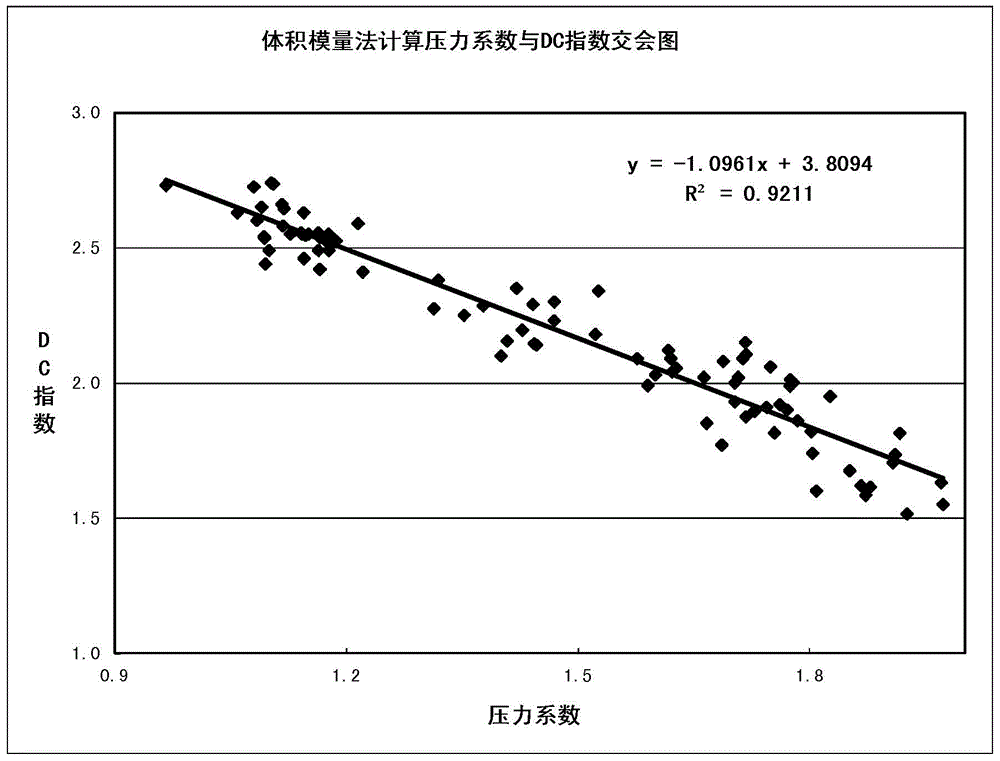

Method for calculating abnormal formation pressure

InactiveCN104698494AHigh precisionEliminate the effects ofSeismic signal processingBulk modulusEffective stress

The invention relates to a method for calculating abnormal formation pressure. The method includes: acquiring bulk modulus by compressional and shear velocity and rock physical features; calculating by the bulk modulus and the strain borne by a rock framework to obtain effective stress; determining formation sections with abnormal pressure. The method has the advantages that formation pressure prediction precision is increased, a high-precision model between formation speed and the effective stress is built by eliminating the influence of gas contained in formation on the formation speed, and the bulk modulus method is developed to predict the formation pressure.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com