Method and device for guaranteeing normal operation of unit after abnormal pressure

A technology for normal operation and units, which is applied in mechanical equipment, heating and ventilation control systems, heating and ventilation safety systems, etc., and can solve problems such as failure to ensure the normal operation of units in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

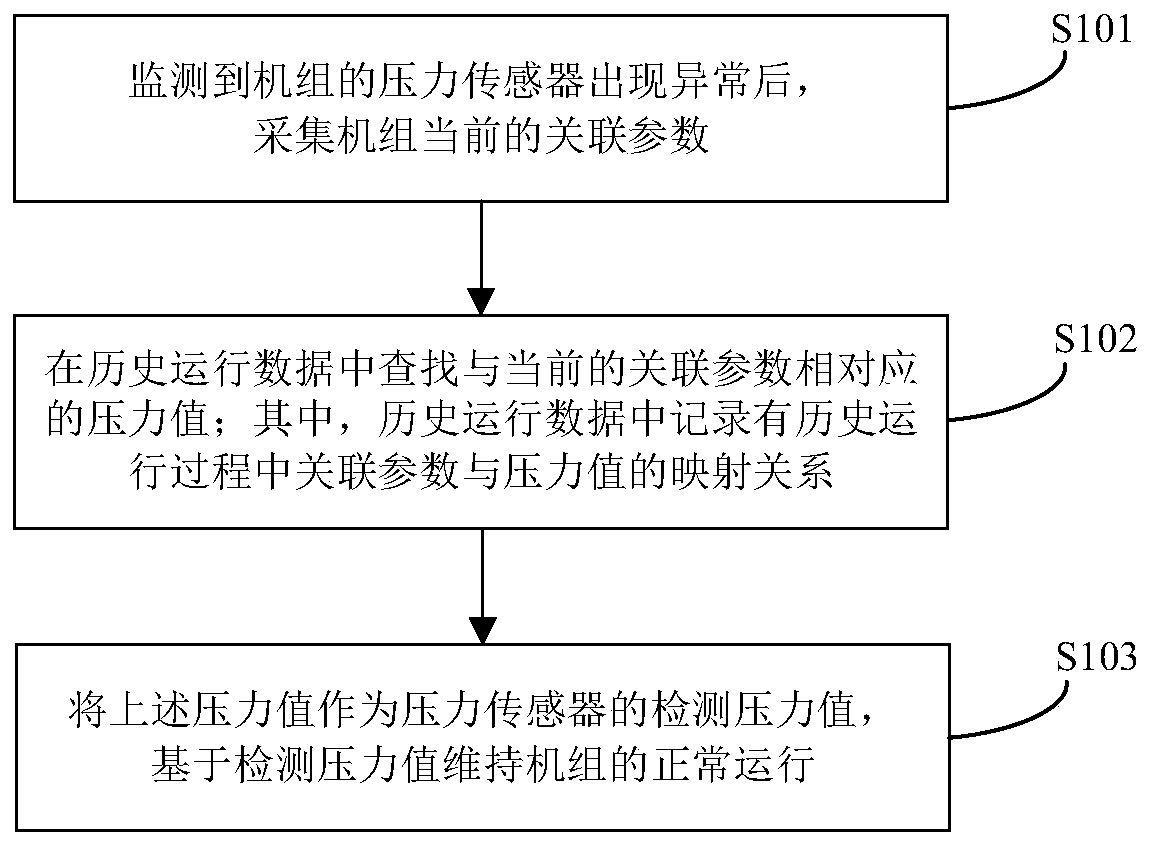

[0032] figure 1 is a flowchart of an emergency control method for abnormal pressure according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0033] Step S101, after monitoring that the pressure sensor of the unit is abnormal, collect the current associated parameters of the unit;

[0034] Step S102, look up the pressure value corresponding to the current associated parameter in the historical operating data; wherein, the historical operating data records the mapping relationship between the associated parameter and the pressure value during the historical operating process;

[0035] In step S103, the above-mentioned pressure value is used as the detected pressure value of the pressure sensor, and the normal operation of the unit is maintained based on the detected pressure value.

[0036] The embodiment of the present invention aims at the situation that the unit cannot operate normally when the pressure senso...

Embodiment 2

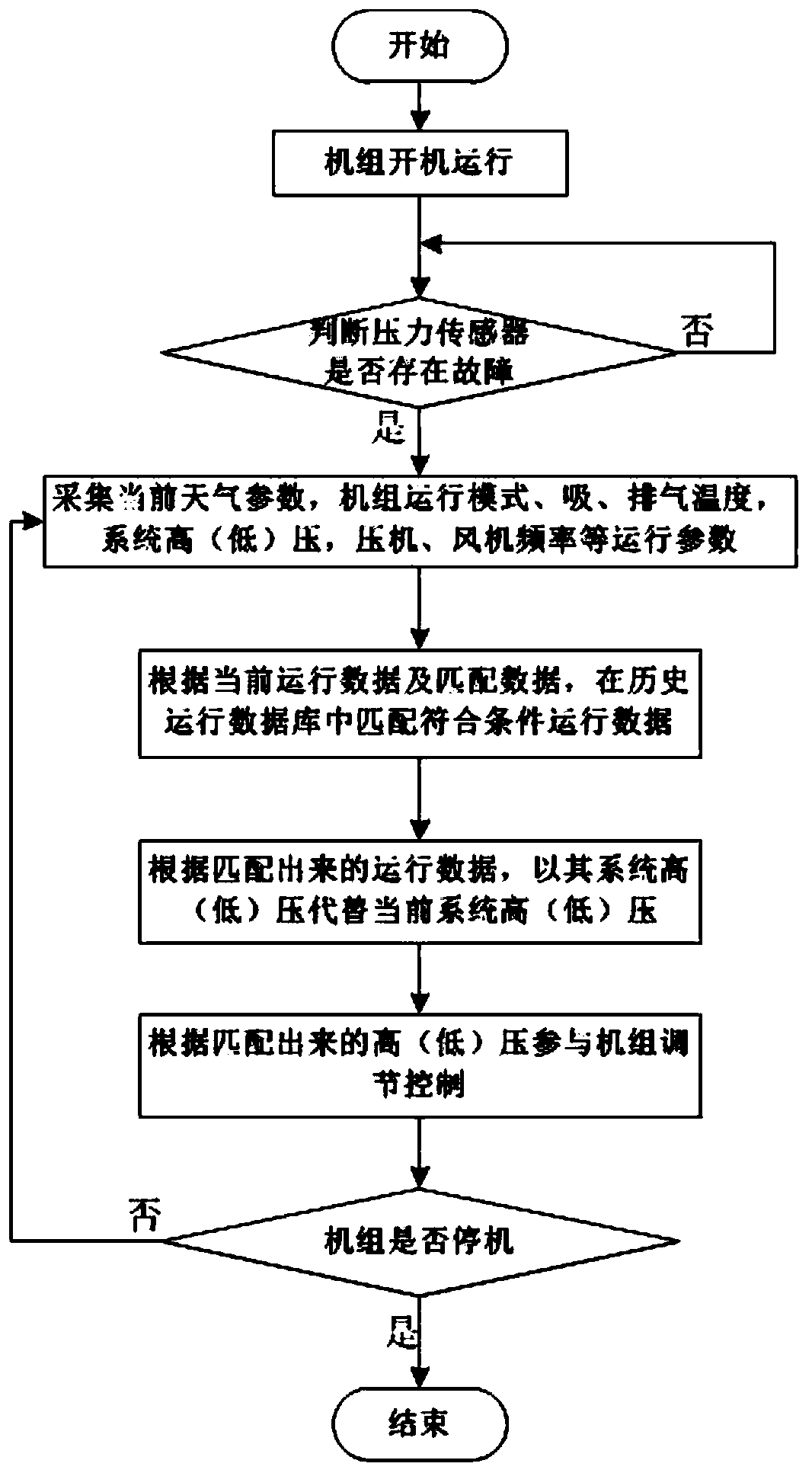

[0043] figure 2 is the emergency control flow chart of the unit according to the embodiment of the present invention, such as figure 2 As shown, the control flow is as follows:

[0044] After the unit is started and running, if it detects that the pressure sensor is abnormal, it will report the fault and notify the maintenance, and the unit will no longer collect the feedback signal of the pressure sensor. In order to maintain the sustainable and normal operation of the unit, parameters such as the weather information of the current location of the unit, the operating mode of the unit, the frequency of the compressor currently running, the frequency of the fan, the normal pressure of the system that can be detected, the suction temperature of the unit and the exhaust temperature of the unit are collected. According to the weather information collected above and the operating parameters of the unit, in the historical operation database of the unit, perform parameter matching...

Embodiment 3

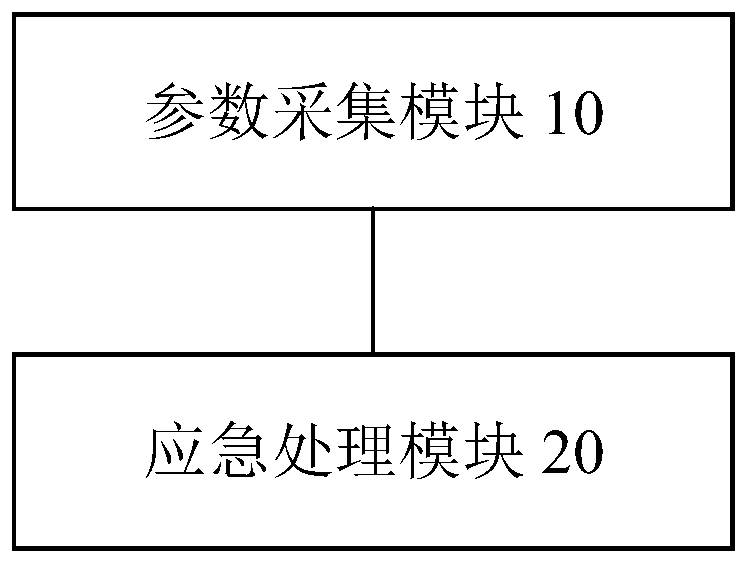

[0047] corresponds to figure 1 Introduced the emergency control method for abnormal pressure, this embodiment provides an emergency control device for abnormal pressure, such as image 3 The structural block diagram of the abnormal pressure emergency control device shown, the device includes:

[0048] The parameter acquisition module 10 is used to collect the current associated parameters of the unit after monitoring that the pressure sensor of the unit is abnormal;

[0049] The emergency treatment module 20 is connected to the parameter collection module 10, and is used to search the pressure value corresponding to the current associated parameter in the historical operation data; wherein, the historical operation data records the correlation parameter and the pressure value in the historical operation process Mapping relationship; the pressure value is used as the detected pressure value of the pressure sensor, and the normal operation of the unit is maintained based on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com