Real-time high-precision acquiring method for conical surface pneumatic pressure field

An acquisition method and high-precision technology, which is applied in aerodynamic tests, measuring devices, instruments, etc., can solve the problems of difficult high-precision measurement of aerodynamic pressure field, and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

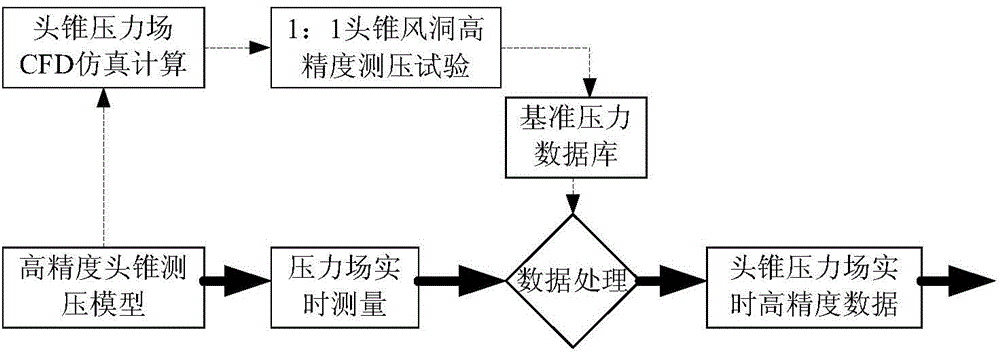

[0031] like Figure 1~3 As shown, a real-time high-precision acquisition method of the aerodynamic pressure field of a conical surface, the method specifically includes the following steps:

[0032] Step 1. Establish high-precision nose cone surface and pressure measurement hole structure model and pressure measurement model;

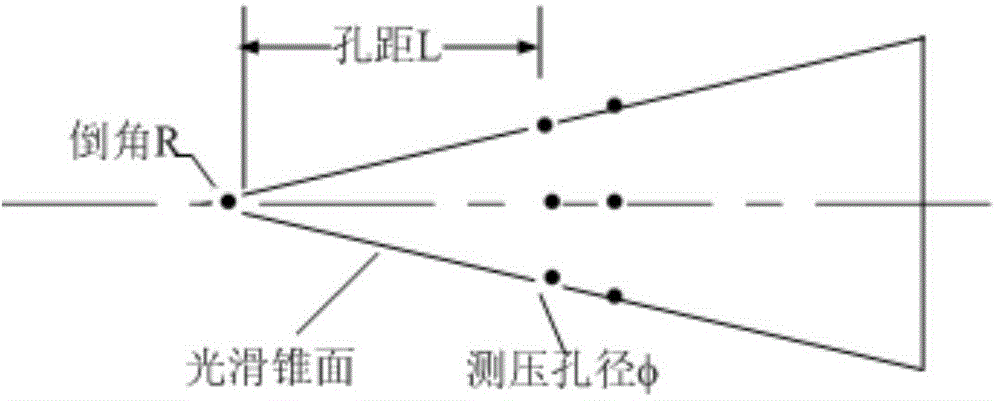

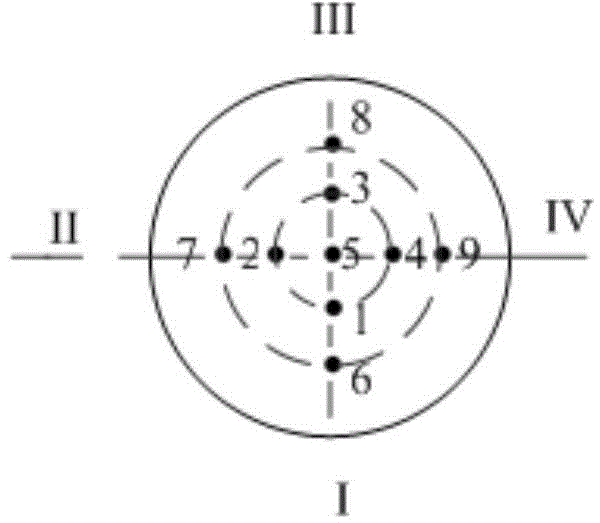

[0033] established as figure 1 , figure 2 The high-precision nose cone profile and pressure measurement hole structure model and pressure measurement model shown specifically include:

[0034] The pressure measuring holes are located on the cone tip and the quadrant of the cone surface, among which, the 8 pressure measuring holes on the cone surface are distributed strictly symmetrically with respect to the axis, and the circumferential position deviation is less than 10';

[0035] The distance L between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com