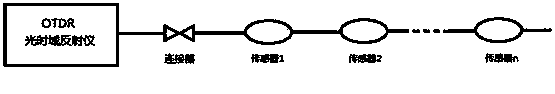

Ellipsoidal optical fiber pressure sensor and optical fiber fault pressure point detection method

A pressure sensor and ellipsoid technology, applied in the field of optical fiber sensing, can solve the problems of complex structure of optical fiber sensor and high cost of detecting pressure failure points, and achieve the effects of improving strain transfer rate, reducing cost and reducing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

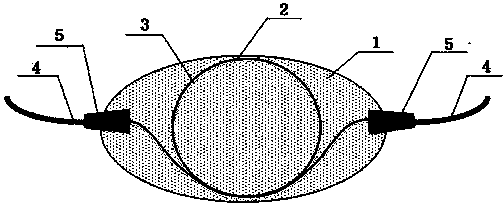

[0025] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

[0026] first combined with figure 1 The ellipsoid optical fiber pressure sensor described in the embodiment of the present invention will be described in detail.

[0027] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the ellipsoidal optical fiber pressure sensor, which is made of elastic sensitive material and consists of two semi-ellipsoids 1, and the two semi-ellipsoids 1 are pasted together by an adhesive, in which A circular disc fiber groove 3 with a predetermined radius is engraved on the adhesive surface of a semi-ellipsoid, and the sensing optical fiber disc is placed in the groove 3 and fixed in the groove 3 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com