Control method and device for heat-adsorption-free air drier

An adsorption dryer and control method technology, applied in the direction of electrical program control, separation methods, chemical instruments and methods, etc., can solve the problem that the adsorption regeneration time of the dryer controller cannot be adjusted, cannot reflect the quality index of the finished product gas of the dryer, and further Air temperature has no control function to achieve the effect of eliminating machine breakage accidents, ensuring reliability and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

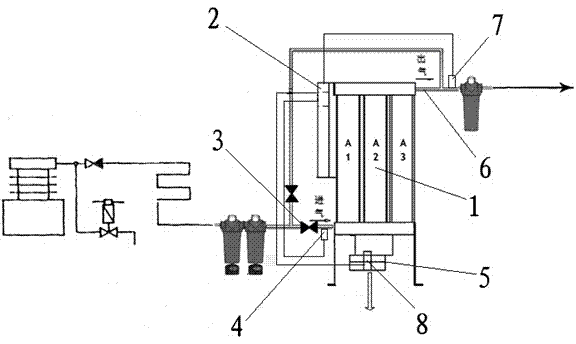

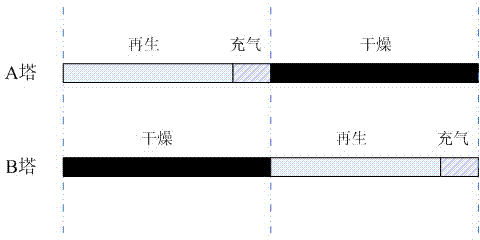

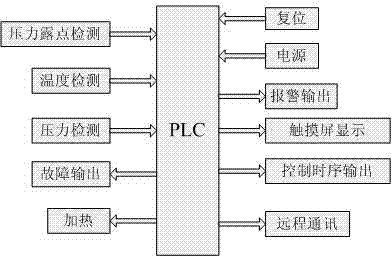

[0030] by attaching Figure 1-3 It can be seen that the present invention is a heatless adsorption drying control device for a heatless adsorption drying control method of a locomotive air compressor, including a PLC controller 2, a dew point temperature sensor and a pressure dew point sensor 7 are arranged at the air outlet 6 of the adsorption dryer, The dew point temperature at the air outlet and the pressure dew point at the air outlet are monitored by the dew point temperature sensor and the pressure dew point sensor 7; at the same time, a temperature sensor 4 is installed at the air inlet 3 to monitor the air inlet temperature sensor; Pressure sensors 8 are set at 5 places to collect abnormal pressure signals; all sensors are electrically connected to the PLC controller through wires, and the obtained data values are fed back to the PLC controller, and the PLC controller is based on the collected data information of each sensor Controls the operation of the heatless des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com