Artificial well wall sand control based on CMAS technologyand water control construction process thereof

A technology of artificial well wall and construction technology, which is applied in the direction of wellbore/well parts, earthwork drilling, sealing/package, etc. It can solve the problems of insufficient strength of artificial well wall, troublesome cleaning of mixing device, and easy generation of dust, etc. Achieve the effect of simple construction, low cost and avoiding dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following is further described in detail through specific implementation methods:

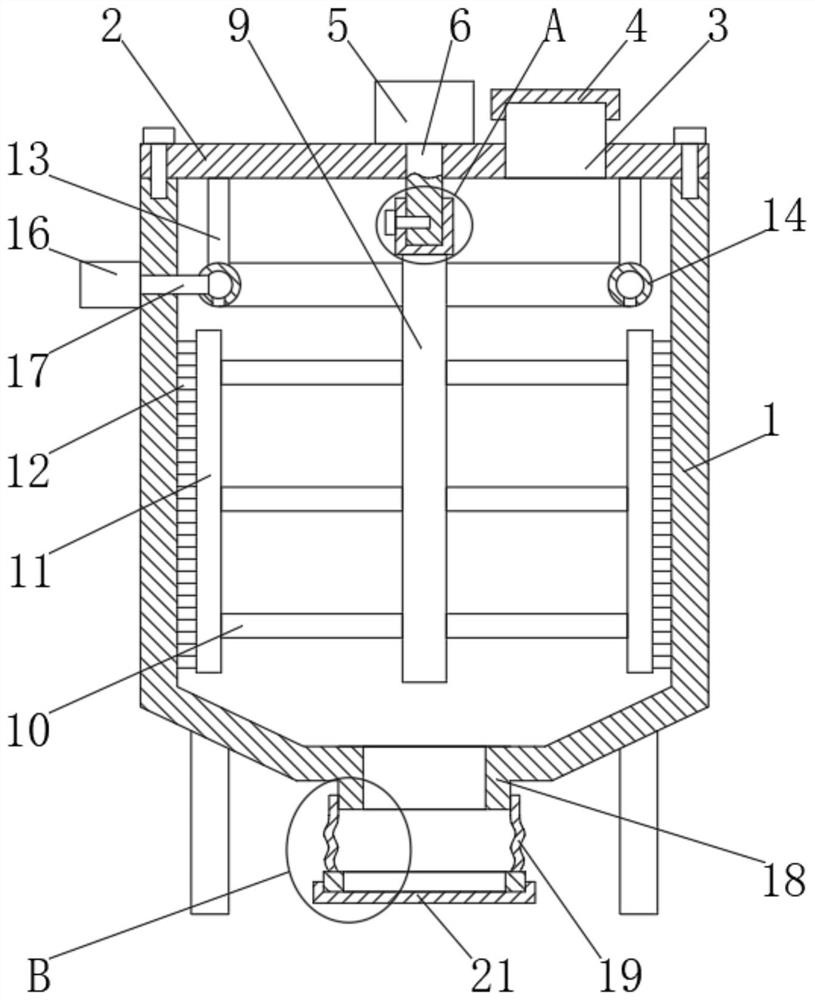

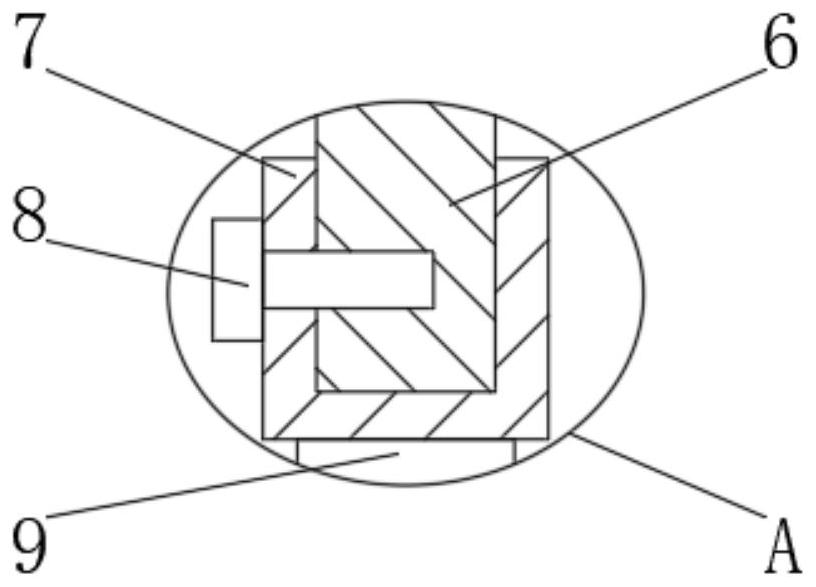

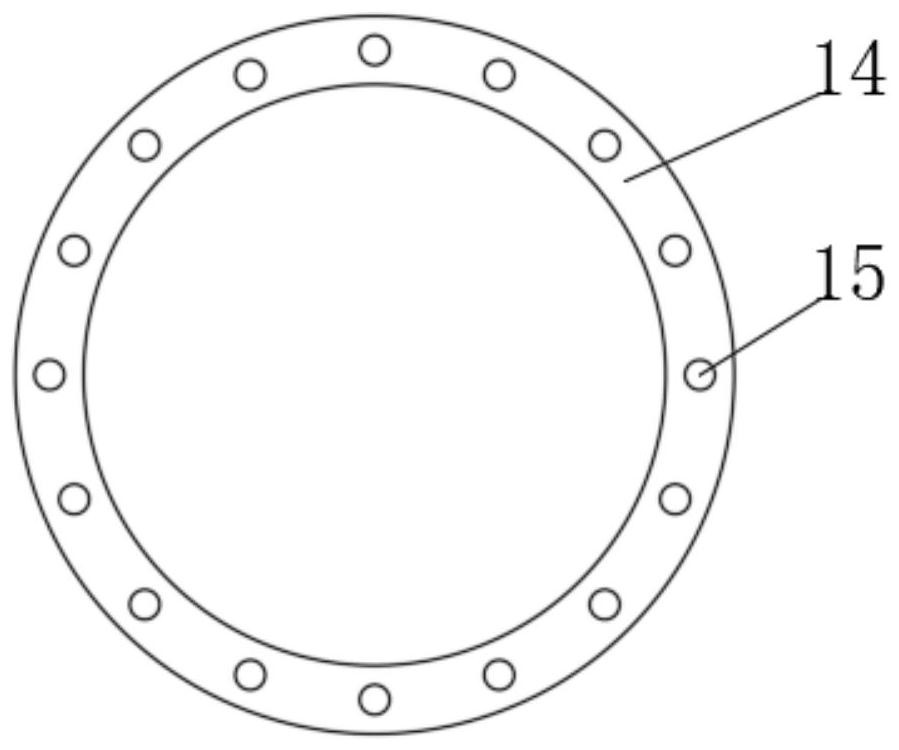

[0052] The reference signs in the drawings of the description include: box body 1, box cover 2, feed port 3, sealing cover 4, motor 5, rotating shaft 6, connecting sleeve 7, limit pin 8, main shaft 9, stirring rod 10, installation Rod 11, brush 12, connecting rod 13, annular pipe 14, air outlet 15, air pump 16, air intake pipe 17, discharge port 18, bellows 19, support ring 20, end cap 21.

[0053] This embodiment provides artificial borehole wall sand control based on CMAS technology, which is prepared from raw materials including the following parts by weight: 10-20 parts of calcium oxide, 20-30 parts of magnesium oxide, 8-10 parts of aluminum oxide, silicon dioxide 30-40 parts, copper peroxide 5-7 parts, borax powder 6-8 parts, slag 4-6 parts, fly ash 8-10 parts.

[0054] The artificial well wall sand control and water control construction technology based on CMAS technology incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com