Suspended formwork lining method for cover arch outside tunnel portal with weak surrounding rocks

A technology for weak surrounding rock and tunnels, which is applied in the field of hanging formwork lining of internal self-supporting systems, can solve the problems of difficulty in ensuring safe tunnel entry and the collapse of open troughs, and meet the requirements of preventing tunnel openings from instability and construction time. Tight, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

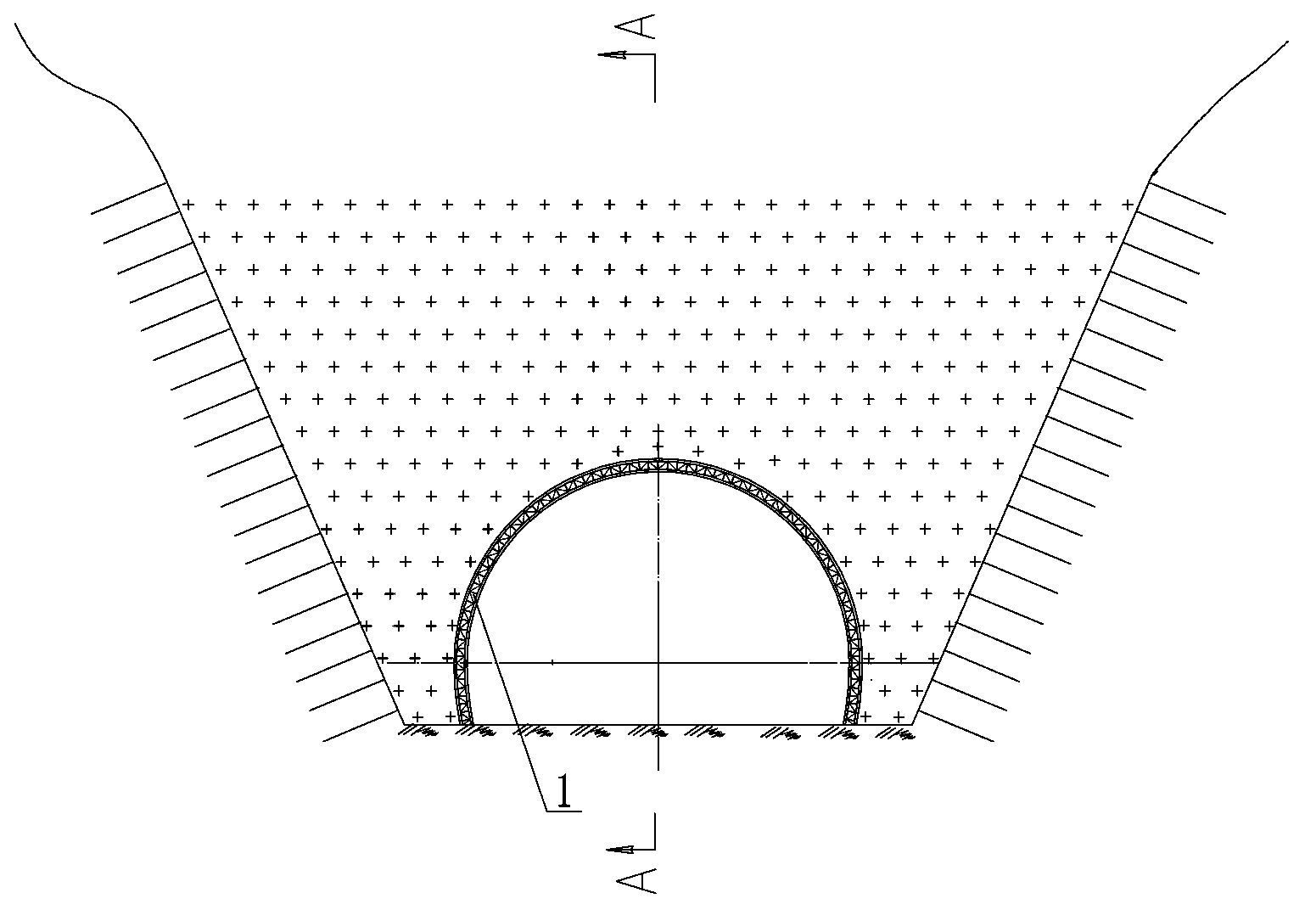

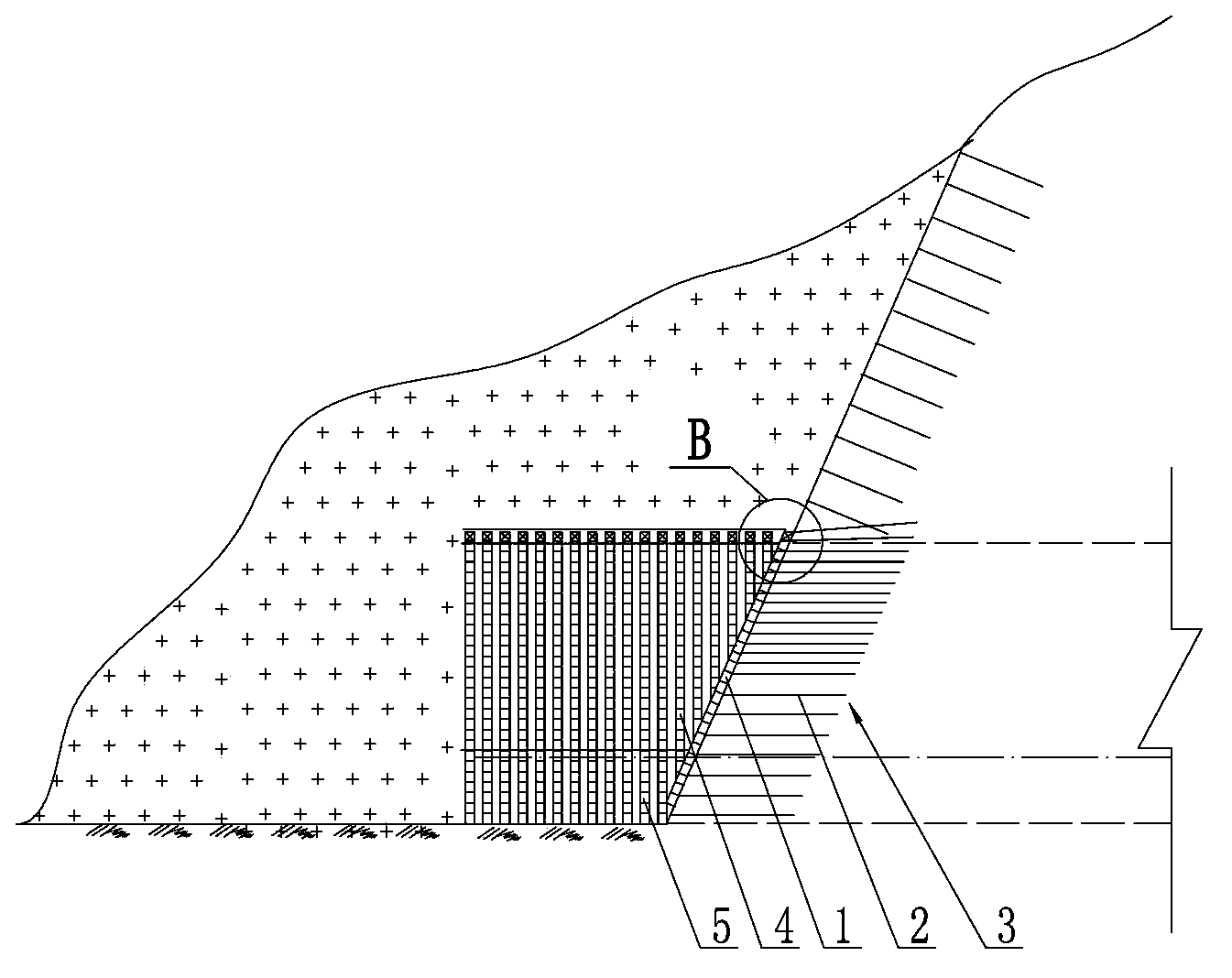

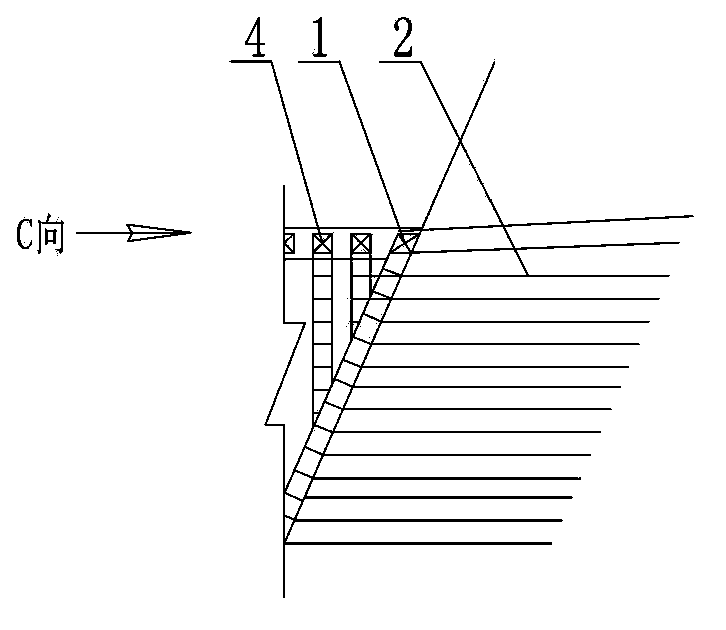

[0023] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the lining method of arch suspension form for tunnel opening in weak surrounding rock includes the following steps:

[0024] 1) Install a first set of arch grid steel frame 1 that is suitable for the shape of the tunnel opening at the junction of light and shade at the tunnel entrance. The inner section of the first set of arch grid steel frame 1 is slightly larger than that of the tunnel Cross-section outline, the first set of arch grid steel frame 1 is preferably welded by 22mm rebar, and the cross-sectional size of the first set of arch grid steel frame 1 is preferably 250×250mm 2 ;

[0025] 2) Close to the outer edge of the first set of arch grid steel frame 1 and drive in several hole lock anchor rods 2 along the tunnel direction to form an advanced small tube shed 3. The hole lock an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com