Drilling stress directional monitoring device and method

The technology of monitoring device and borehole stress gauge is applied in mining device, measurement, earthwork drilling and other directions, which can solve the problems of inability to control the direction of stress sensor, inability to accurately measure borehole stress, and easy formation of collapsed holes in boreholes, etc. Achieve the effect of simple structure, high reliability and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

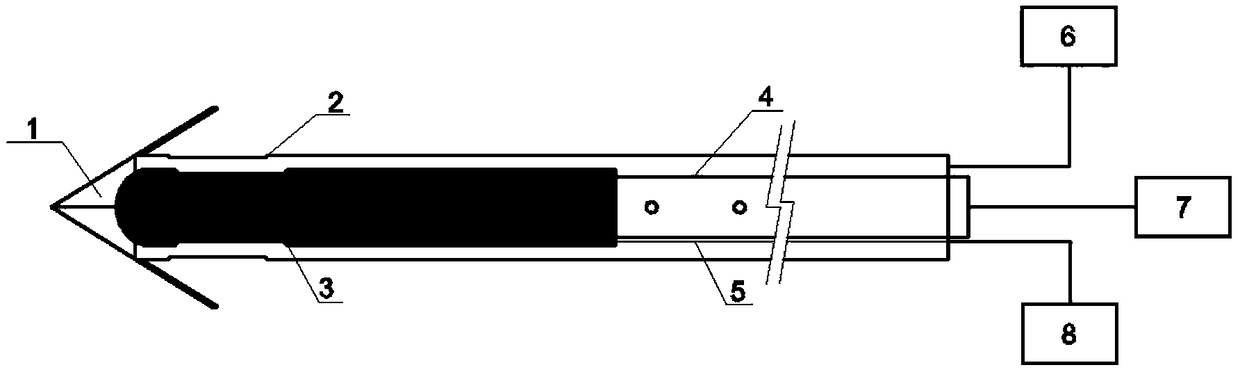

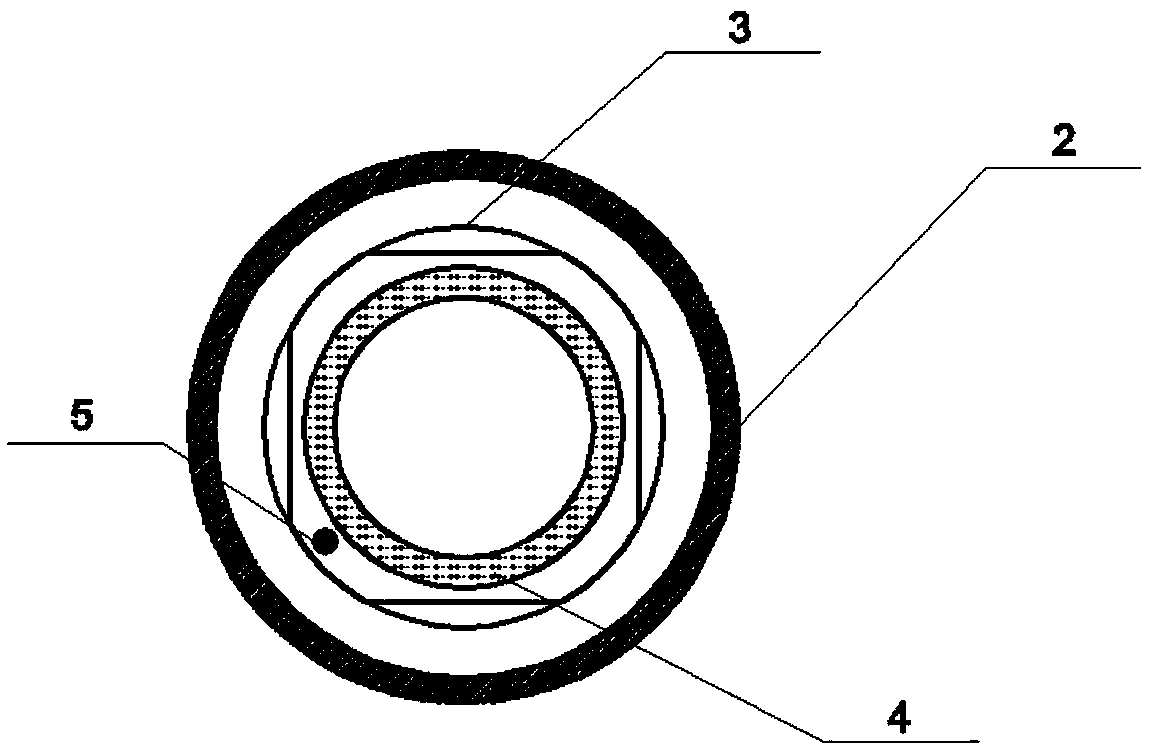

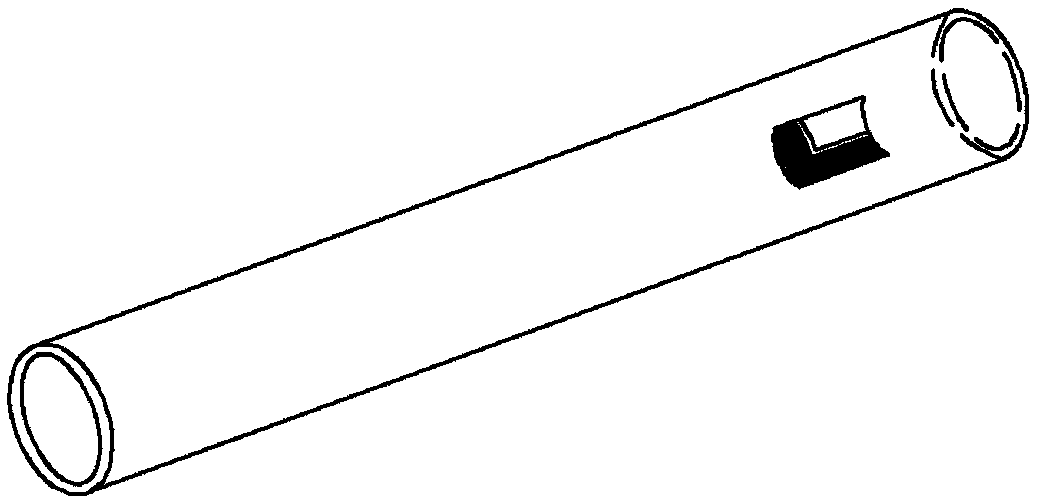

[0036] Embodiment 1: The test device includes 1. a detachable conical drill bit; 2. a blowing ash-cleaning sleeve; 3. a stress sensor; 4. a directional propulsion grouting pipe; 5. a wire; 6. a blower; 7. a grouting 8. Stress data acquisition instrument. The stress sensor 3 is connected to the stress data acquisition instrument 8 through the wire 5, and the direction control device is composed of the stress sensor 3, the air blowing and dust cleaning positioning sleeve 2, the directional propulsion grouting pipe 4, a spirit level, and a hole opening protractor.

[0037] The direction positioning device includes a blowing ash removal casing 2, a directionally advancing grouting pipe 4, a spirit level, and a hole protractor; Push the red marking line on the grouting pipe to correspond to the monitoring direction of the borehole stress gauge, and after connecting them into a straight line, advance the borehole stress gauge to the designated position along the air blowing and dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com