Orientating monitoring device and method for drilling stress

A monitoring device and stress technology, which is applied in the field of drilling stress directional monitoring devices, can solve the problems of inability to control the direction of the stress sensor, the inability to accurately measure the drilling stress, and the tortuous drilling path, etc., and achieve simple structure, high reliability, The effect of saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

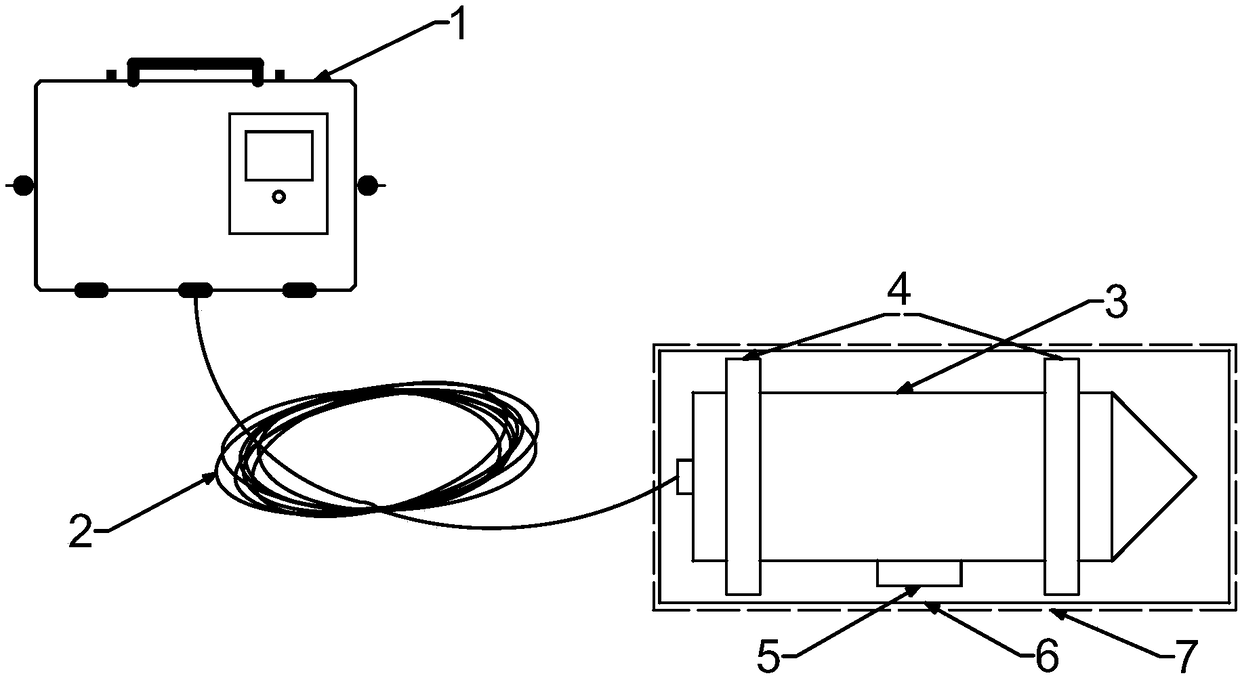

[0028] Embodiment 1: the testing device comprises a stress data acquisition instrument 1, a lead 2, a stress sensor 3, a direction control device and a protective case; the stress sensor 3 is connected to the stress data acquisition instrument 1 by a lead 2, and the direction control device is installed on the stress sensor 3, the protective shell is installed outside the direction control device.

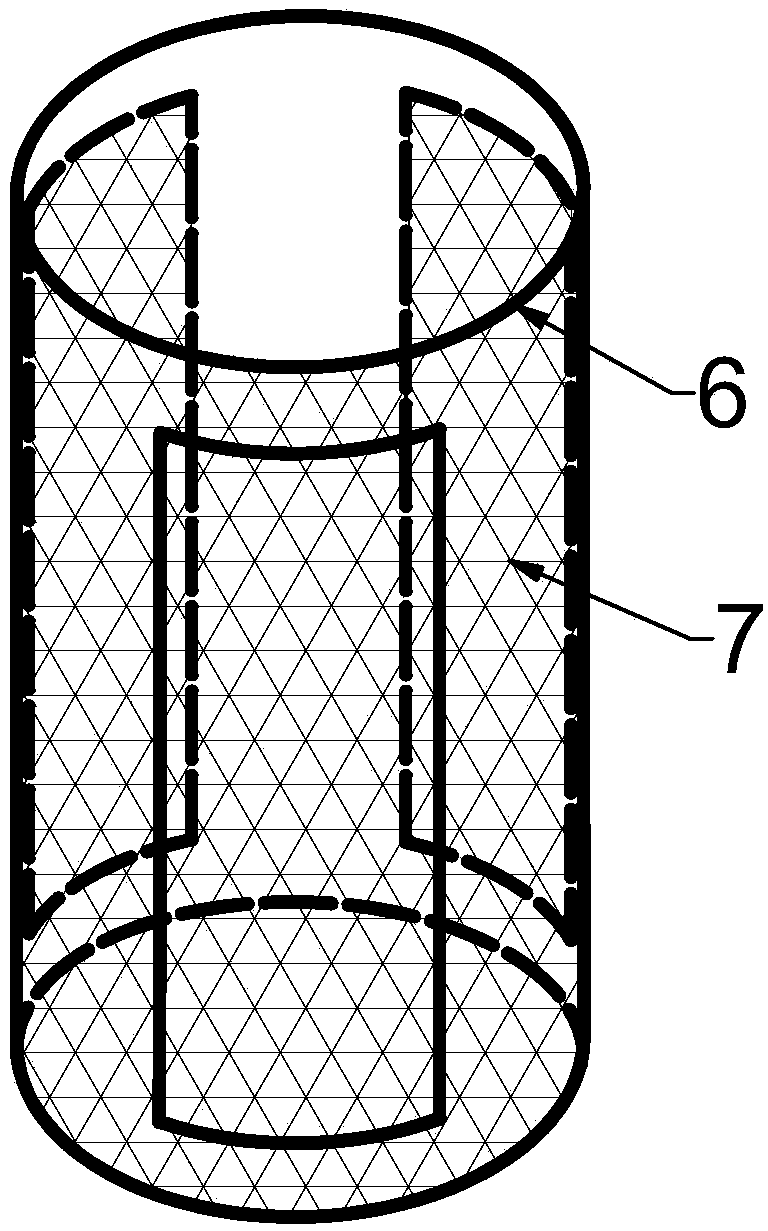

[0029] The direction control device includes two bearings 4 and a counterweight 5; the two bearings 4 are fixed at both ends of the stress sensor 3 to keep the stress sensing area on the stress sensor 3 in the process of advancing the equipment into the borehole The middle direction remains unchanged, the inner diameter of bearing 4 should be slightly larger than the outer diameter of stress sensor 3, and the steel ball in bearing 4 should be protected. Actual effect: the counterweight 5 is an iron block with a suitable size, and by fixing the counterweight 5 on one side of the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com