Glucoheptonate restraining agent for drilling fluid and method for preparing same

A gluconate, drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of the deterioration of drilling fluid rheology and wall-building properties, increase the cost of drilling fluid, and the inhibition effect of drilling fluid is not enhanced. and other problems to achieve the effect of inhibiting hydration and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] ① Mix 200ml of water with 200g of potato starch (mass ratio 1:1), add 5ml of formic acid, react at 120°C and 0.5MPa for 2 hours, and hydrolyze the starch;

[0025] ② Add 1 g of potassium permanganate to the hydrolyzate and oxidize it at 90°C for 1 h;

[0026] ③ Adjust the pH value of the oxidation product to about 9 with KOH to obtain the gluconate inhibitor for drilling.

[0027] The following is a comparative experiment indoors on the inhibitory effects of a single inorganic salt and the present invention.

[0028] In the solution of the present invention and the KCl solution with a concentration of 15%, add 6 to 10 mesh Xinjiang Xiazijie Bantu granules, roll in heat for 16 hours at 120°C, after cooling, rinse with a 40 mesh screen, and put Put into an oven and weigh after drying at 100°C. Calculate the rolling recovery rate, as shown in Table 1:

[0029] Table 1 solution of the present invention, KCl solution rolling recovery rate

[0030] Solution name ...

Embodiment 2

[0032] ① Mix 200ml of water with 100g of potato starch (mass ratio 1:0.5), add 5ml of nitric acid, react at 120°C and 0.5MPa for 2 hours, and hydrolyze the starch;

[0033] ② Add 1 g of potassium permanganate to the hydrolyzate, and oxidize it at 90°C for 1 hour;

[0034] ③ Adjust the pH value of the oxidation product to about 9 with KOH to obtain the product.

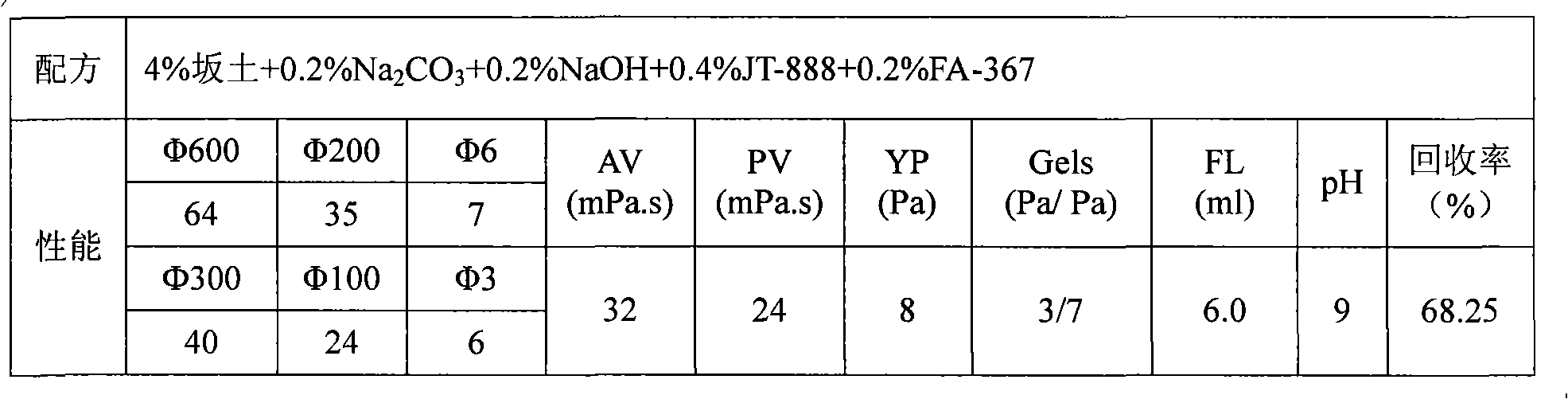

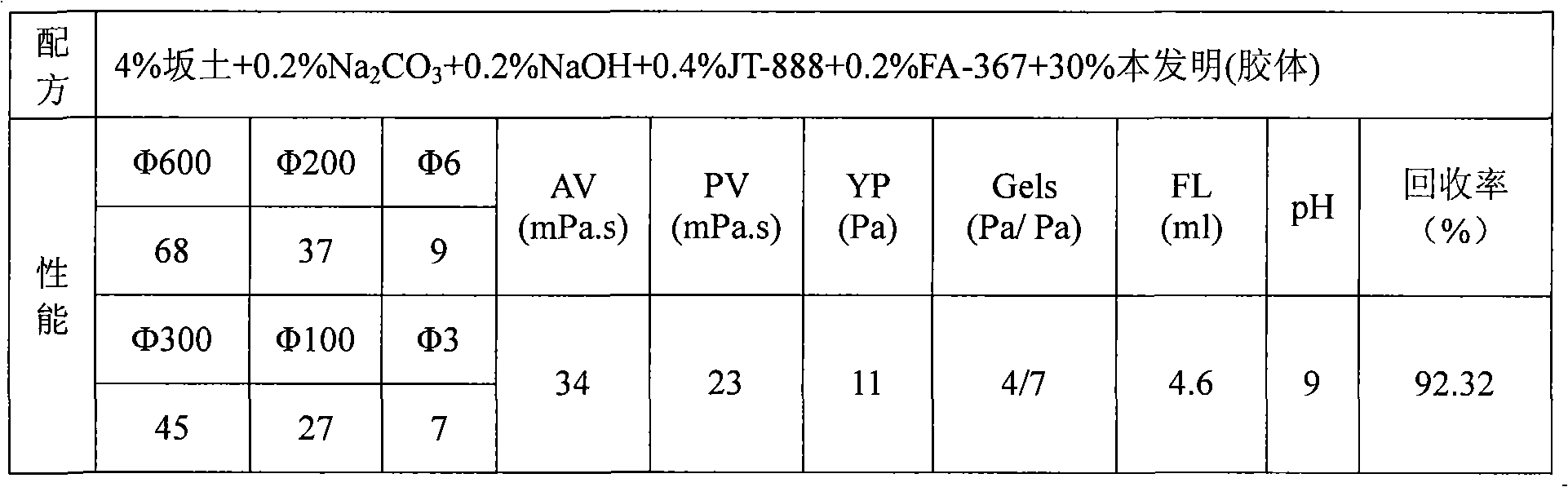

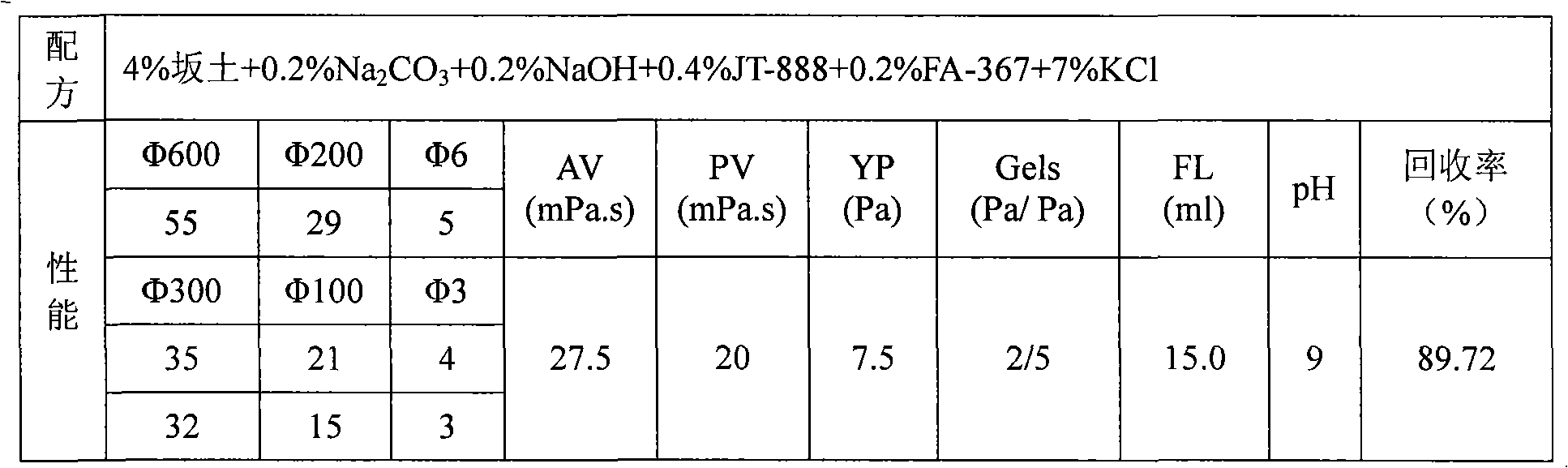

[0035] The following is the performance test of the present invention in drilling fluid.

[0036] The present invention is added to banclay base mud, the rheological property is tested, and its influence on drilling fluid is determined qualitatively. The table below is a comparative experiment to qualitatively evaluate the rheology and inhibition of the present invention relative to KCl. It can be seen from the experimental data that the rheology and inhibition ability of the drilling fluid of the present invention are better than those of KCl. It can be seen from experiments that the present invention can fully mee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com