Inverse emulsion polymer and preparation method and application thereof in preparation of water-based drilling fluid

A technology of inverse emulsion and polymer, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., to achieve the effects of convenient use, anti-calcium and enhancement and improvement of lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

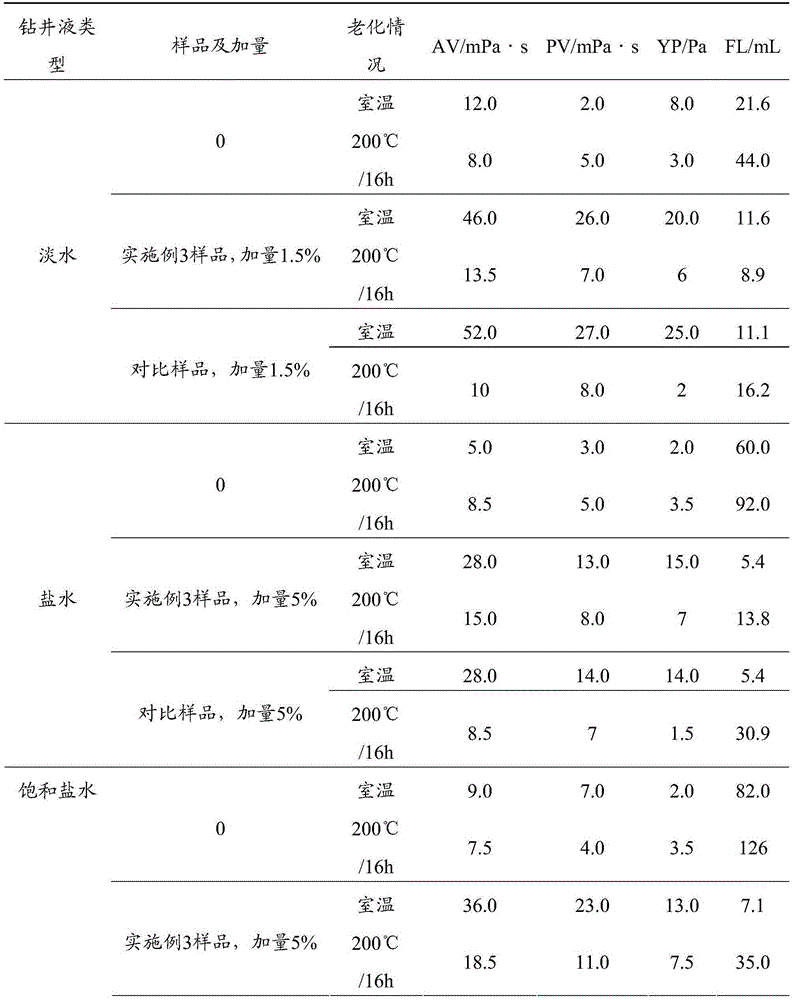

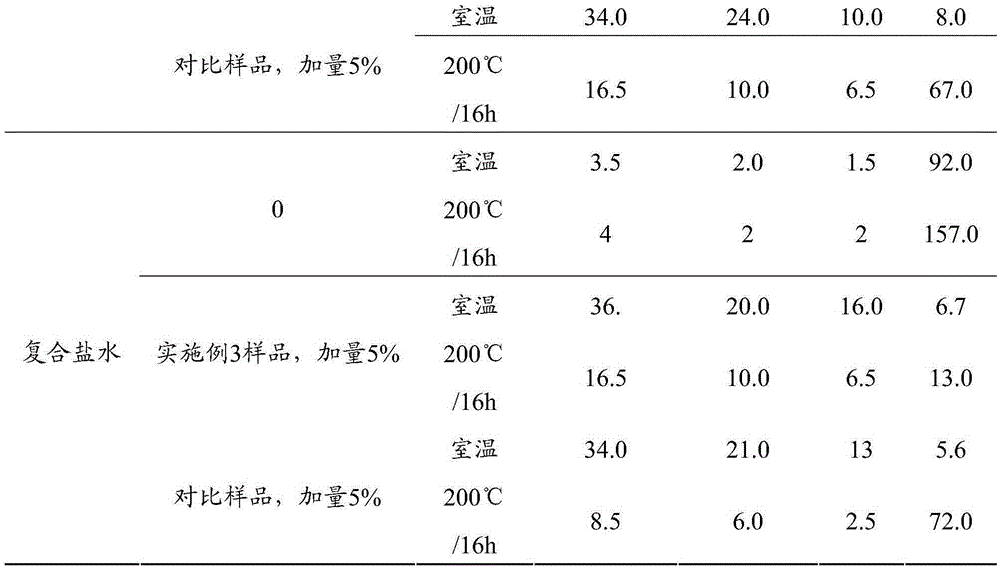

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing the above-mentioned temperature-resistant emulsion polymer, that is, the invention provides a method for preparing an inverse emulsion polymer, comprising the following steps:

[0036] 1) emulsifying the oil phase material and the water phase material to obtain a monomer emulsion;

[0037] The oil phase material includes white oil; the water phase material includes monomer A, monomer B, monomer C, the first emulsifier and water; the monomer A is selected from water-soluble propylene sulfonate; the Monomer B is selected from one or more of acryloyl morpholine, vinyl caprolactam and vinyl morpholine; the monomer C is selected from acrylate compounds containing polyoxyethylene and alkyl;

[0038] 2) The monomer emulsion obtained in step 1) is polymerized in the presence of an initiator to obtain an inverse emulsion polymer.

[0039] In the embodiment of the present invention, the oil-phase material and the water-p...

Embodiment 1

[0061] Add 55kg of water into the reaction kettle, start stirring, and add 100kg of monomer A (sodium 2-acryloyloxy-2-methylpropanesulfonate) aqueous solution with a mass fraction of 50% after dissolving, 15kg of monomer B (vinyl caprolactam ), 5kg monomer C (alkylphenol polyoxyethylene ether methacrylate, its EO value n=6~10) and 1.8kgTween-80, stir until completely dissolved, control the pH value of the system=7.5, and obtain the water phase .

[0062] Add 92.5kg of white oil and 13.2kg of Span-80 into the reaction kettle, and stir until completely dissolved to obtain an oil phase.

[0063] Put the oil phase and the water phase into the emulsification kettle, stir at a speed of 1000 rpm, and fully stir for 20 minutes to obtain a monomer emulsion.

[0064] Put the above-mentioned monomer emulsion into the reactor, turn on the mixer, heat up to 50° C., pass nitrogen for 15 minutes, add 0.6 kg of 10% potassium persulfate solution, 0.3 kg of 10% sodium metabisulfite solution, ...

Embodiment 2

[0066] Add 75kg of water into the reaction kettle, start stirring, and after dissolving, add 140kg of monomer A (sodium 2-acryloyloxybutylsulfonate) aqueous solution with a mass fraction of 50%, 45kg of monomer B (acryloylmorpholine), 15kg Monomer C (polyethylene glycol methyl ether acrylate, with an average molecular weight of 300-950), 3.5 kg of Tween-80, stirred until completely dissolved, and the pH of the system was controlled to be 9 to obtain an aqueous phase.

[0067] Add 110kg of white oil and 21.5kg of Span-80 into the reaction kettle, and stir until completely dissolved to obtain an oil phase.

[0068] Put the oil phase and the water phase into the emulsification tank, stir at a speed of 2000 rpm, and fully stir for 20 minutes to obtain a monomer emulsion.

[0069] Put the above-mentioned monomer emulsion into the reaction kettle, turn on the mixer, heat up to 50°C, pass nitrogen for 15 minutes, add 4kg of potassium persulfate solution with a mass fraction of 10%, 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com