Production method of polymer for drilling fluid

A production method, polymer technology, applied in drilling compositions, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

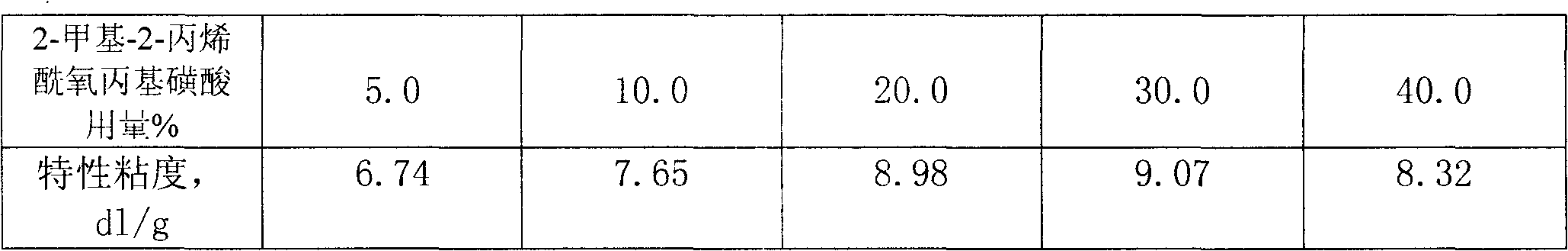

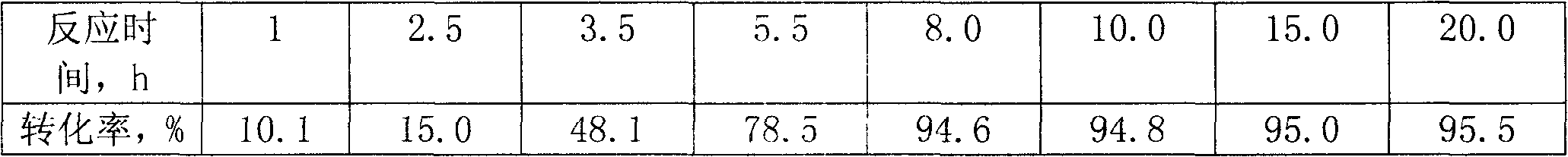

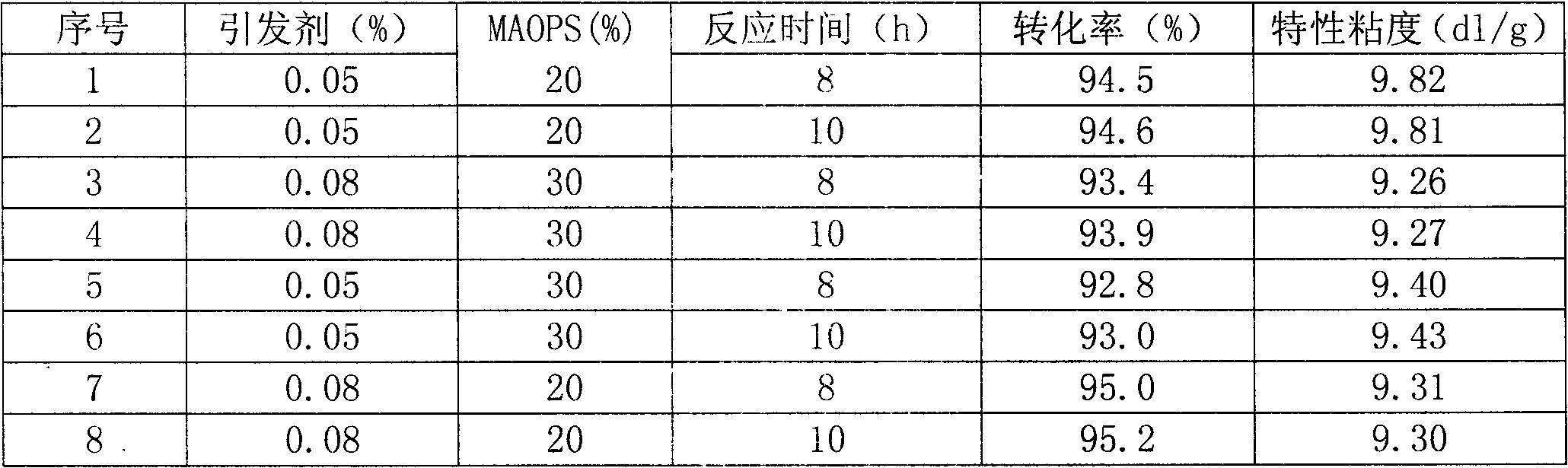

[0086] Embodiment 1, a kind of production method of drilling fluid polymer is synthesized by 2-methyl-2-acryloxypropyl sulfonic acid and acrylamide, acrylic acid copolymerization, and its specific production steps are as follows:

[0087] (1), an appropriate amount of 2-methyl-2-acryloyloxypropylsulfonic acid was dissolved in water to obtain solution A;

[0088] (2), adding an appropriate amount of water to equimolar sodium hydroxide, stirring and dissolving, then cooling to room temperature to obtain solution B;

[0089] (3) Slowly add solution A to solution B, then add an appropriate amount of acrylamide and acrylic acid, stir to dissolve, and obtain mixed solution C;

[0090] (4), under the condition of constant stirring and nitrogen flow, the temperature of the mixed liquid C is raised to 35° C., and then an initiator accounting for 0.05% of the total mass of acrylamide and acrylic acid is added, and nitrogen is passed for a certain period of time after stirring evenly;

...

Embodiment 2

[0096] Embodiment 2, the production method of this embodiment is the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the amount of 2-methyl-2-acryloyloxypropyl sulfonic acid is the total amount of acrylamide and acrylic acid. The molar percentage is 30%; the added amount of the initiator accounts for 0.08% of the total mass of acrylamide and acrylic acid; the total time of passing nitrogen is 80 minutes.

Embodiment 3

[0097] Embodiment 3, the production method of this embodiment is the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the amount of 2-methyl-2-acryloyloxypropyl sulfonic acid is the total amount of acrylamide and acrylic acid. The mole percentage is 25%; the added amount of the initiator accounts for 0.06% of the total mass of acrylamide and acrylic acid; the total time of passing nitrogen is 65 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com