PMMA coating slurry, PMMA composite coating diaphragm and preparation method thereof

A composite coating and diaphragm technology, applied in the direction of structural parts, electrical components, battery pack parts, etc., can solve problems such as insufficient adhesion, PVDF coating adhesion difficult to meet customer requirements, etc., to reduce interface resistance , Conducive to large-scale production, simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

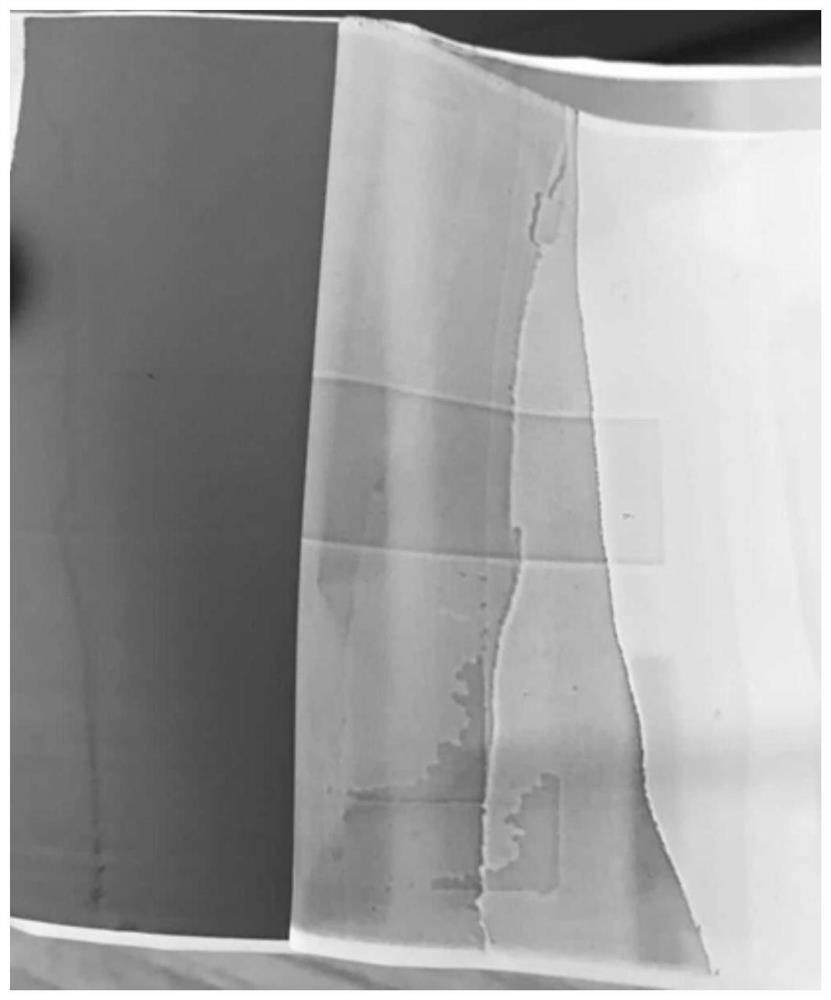

[0029] Some embodiments of the present invention propose a method for preparing the above-mentioned PMMA composite coating diaphragm, comprising: coating the PMMA coating slurry on the surface of the base coating diaphragm to form a water-based coating, and then at a temperature of 30-60 ° C dry under conditions. Wherein, the coating method includes spray coating.

[0030] The base coat separator is obtained by forming water-based boehmite slurry on a polyolefin base film. In some embodiments of the present invention, the PMMA composite coating is obtained by coating one side or both sides of the PMMA coating on the substrate coating diaphragm, and the PMMA coating is compounded with the boehmite coating, and the PMMA composite coating is arranged on The PMMA composite coating separator was thus prepared on the polyolefin base film.

[0031] The above water-based boehmite slurry is prepared in the following manner: add 5-15 parts of boehmite and 0.05-0.2 parts of dispersant ...

Embodiment 1

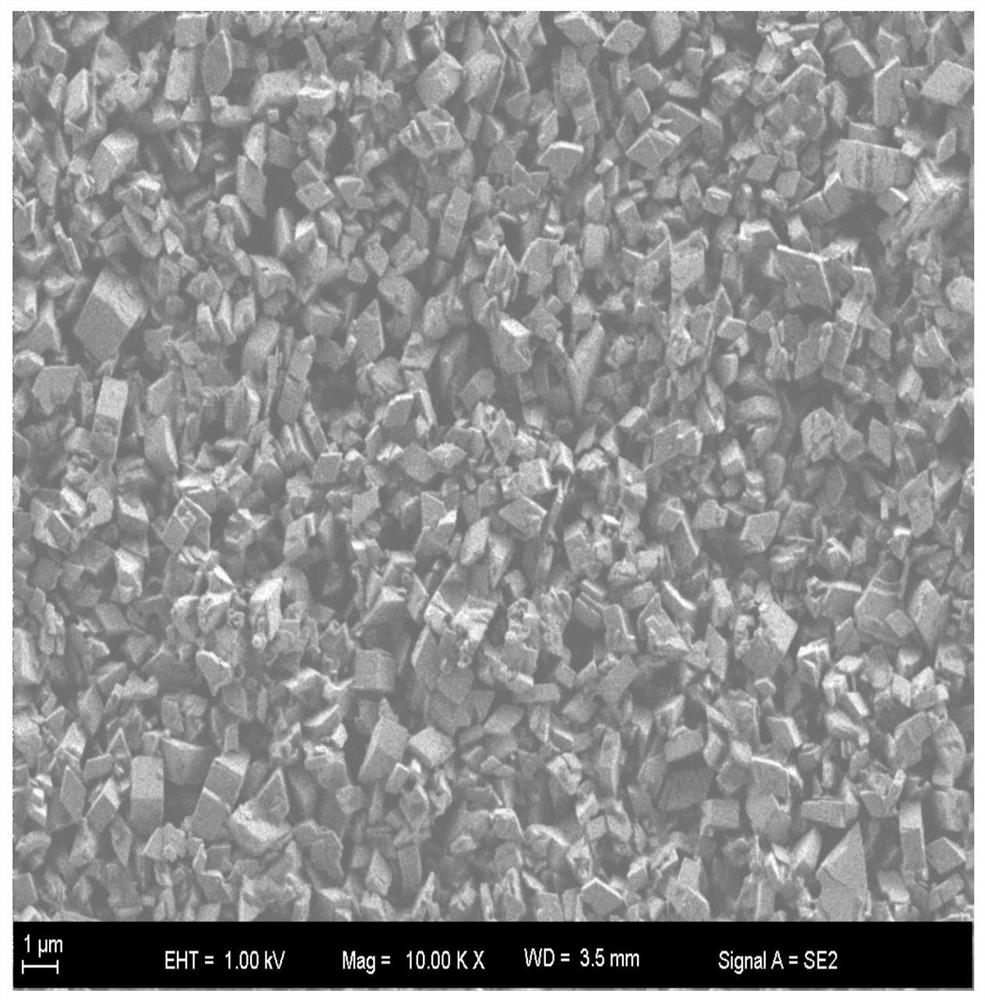

[0040]Add 10kg of boehmite powder and 100g of vinyl bisstearamide to 8kg of deionized water, mix and stir for 1 hour to disperse evenly, then add 2kg of polyvinyl alcohol and 1.0kg of polyether-modified polydimethylsiloxane emulsion, Stir 0.8kg of polyacrylate evenly to obtain water-based boehmite slurry; apply the above-mentioned water-based boehmite slurry to one side of the polyolefin base film by micro-gravure roll coating to form 2-3um boehmite The coating is then baked and dried in an oven at 30° C. for 5 minutes to obtain a base coating separator.

[0041] Add 2.5 kg of PMMA, 1.5 kg of polyvinyl alcohol and 0.05 g of sodium lauryl sulfate to 10 kg of deionized water, mix and stir for 1 h to obtain a PMMA spray coating slurry. A certain amount of PMMA slurry is sprayed on one side of the boehmite-coated diaphragm by a spraying process to form a 2-3um PMMA coating, and the PMMA composite-coated diaphragm is obtained through an oven at 60° C. for 1 min.

Embodiment 2

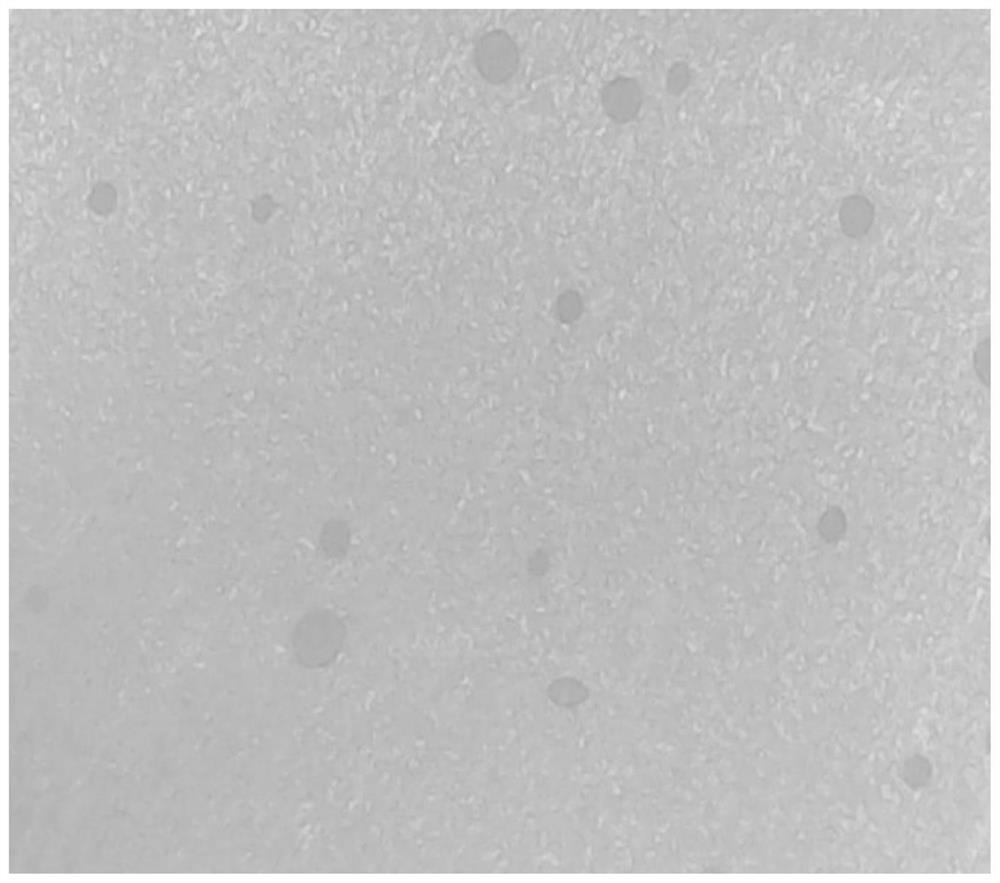

[0043] Add 5kg boehmite powder and 50g stearamide to 5kg deionized water, mix and stir for 0.8h to disperse evenly, then add 1kg polyethylene glycol, 0.5kg polyether modified polydimethylsiloxane emulsion, 0.5kg Stir the polyacrylate evenly to obtain the water-based boehmite slurry; apply the above-mentioned water-based boehmite slurry on both sides of the polyolefin base film by micro-gravure roll coating to form a 1-2um boehmite coating , and then passed through an oven at 40° C., and baked and dried for 4 minutes to obtain a base-coated separator.

[0044] Add 1.0 kg of PMMA, 1.0 kg of polyethylene glycol and 0.01 g of sodium dodecylbenzenesulfonate to 5 kg of deionized water, mix and stir for 1 h to obtain a PMMA spray coating slurry. A certain amount of PMMA slurry is sprayed on both sides of the boehmite-coated diaphragm by a spraying process to form a 1-2um PMMA coating, and the PMMA composite-coated diaphragm is obtained after an oven at 50°C for 2 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com