Asymmetric star polyurethane thickener with cationic core and preparation method thereof

A polyurethane thickener, ionic core technology, applied in the direction of dyeing, coating, textile and papermaking, etc., can solve the problem that the thickener cannot be fully dissolved or dispersed, affects the quality and use effect of the product, and is difficult to control the product structure, etc. problems, to achieve the effect of rich structure, short cycle and strong association ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] One aspect of the present invention provides a method for preparing an asymmetric star-shaped polyurethane thickener with a cationic nucleus, the method comprising the following steps:

[0053] (1) Raw material preparation: the raw material contains a polymerized monomer, an organic solvent, a polymerization catalyst and an emulsifier; wherein, the polymerized monomer includes diisocyanate, polyether glycol monoalkyl ester and star chain extender;

[0054] The diisocyanate is isophorone diisocyanate;

[0055] The polyether glycol monoalkyl ester is one or two kinds of polyethylene glycol monoalkyl esters with a water content not higher than 2‰, and the chemical formula of the polyethylene glycol monoalkyl ester is HO(C 2 H 4 O) n OCC m H 2m+1 , n=90~150, m=12~20; when the polyether glycol monoalkyl ester is a mixture of two polyethylene glycol monoalkyl esters, the difference of n between the two is 20~30, and the difference of m is 3~ 5;

[0056] The star chain e...

Embodiment 1

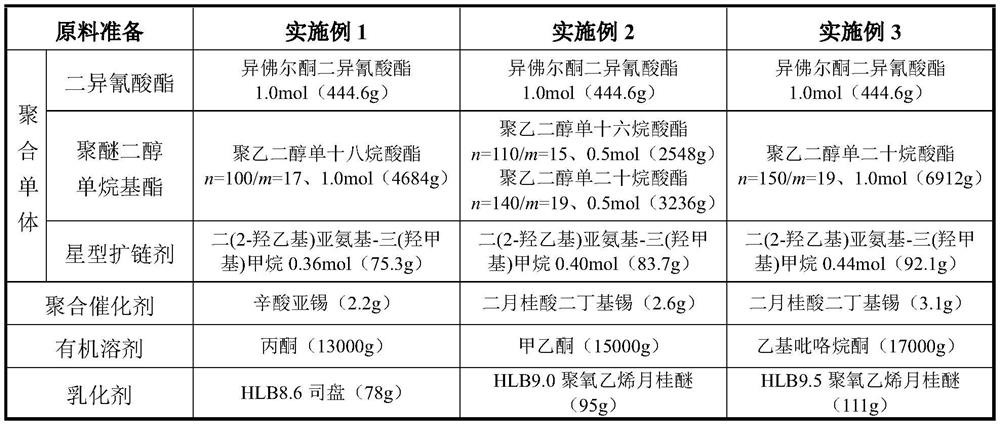

[0094] (1) raw material preparation, the concrete selection and consumption of described raw material are as shown in table 1;

[0095] (2) Active end capping: carry out active end capping reaction with diisocyanate, polyether diol monoalkyl ester, polymerization catalyst and part of organic solvent to obtain asymmetric star-shaped polyurethane thickener branched arms with cationic nucleus;

[0096] (2.1) drop the organic solvent of diisocyanate and total amount 40% into reactor, be warming up to 72.5 ℃;

[0097] (2.2) Within 42.5min, slowly put in polyether glycol monoalkyl ester, and control the temperature of the reaction system to be 72.5°C;

[0098] (2.3) After maintaining the temperature of the reaction system at 72.5°C and holding the reaction for 52.5min, the polymerization catalyst was put into the polymerization catalyst at a uniform speed within 12.5min;

[0099] (2.4) raising the temperature and controlling the temperature of the reaction system to be 82.5° C., an...

Embodiment 2

[0107] (1) raw material preparation, the concrete selection and consumption of described raw material are as shown in table 1;

[0108] (2) Active end capping: carry out active end capping reaction with diisocyanate, polyether diol monoalkyl ester, polymerization catalyst and part of organic solvent to obtain asymmetric star-shaped polyurethane thickener branched arms with cationic nucleus;

[0109] (2.1) drop the organic solvent of diisocyanate and total amount 47.5% into reactor, be warming up to 75 ℃;

[0110] (2.2) Within 42.5min, slowly put in polyether glycol monoalkyl ester, and control the temperature of the reaction system to be 75°C;

[0111] (2.3) after maintaining the temperature of the reaction system at 75°C and maintaining the reaction temperature for 52.5min, drop into the polymerization catalyst at a uniform speed within 12.5min;

[0112] (2.4) heating up and controlling the temperature of the reaction system to be 85° C., holding the reaction for 82.5 min, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com