Osmosis evaporation separation recombination white spirit

A technology of pervaporation and liquor, applied in the field of winemaking science and membrane science and engineering, can solve the problems of uncomfortable and dry taste of wine, the quality of new liquor has not yet been seen, and the processing time is long, so as to improve the irritation and spicy taste, Good market prospects and the effect of short processing cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

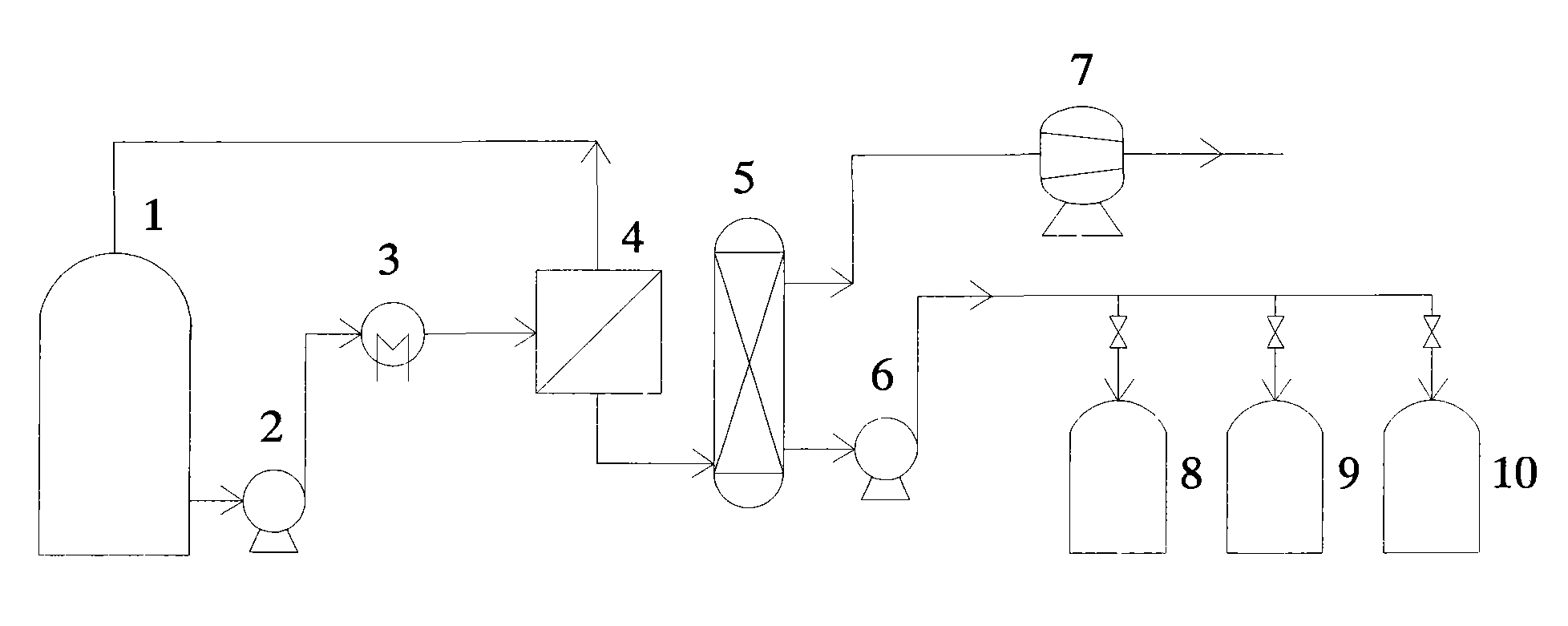

[0017] According to the flow chart of the attached figure, a silicone rubber composite membrane with an area of 0.024m 2 The membrane module is connected with other equipment to form a test device for pervaporation separation of recombined liquor. Take 8L of raw wine at 52 degrees, and maintain its temperature at 30°C for pervaporation, the circulating flow rate of feed liquid is 0.2m / s, the vacuum degree downstream of the membrane is 10mmHg, and the condensation temperature is -25°C. The raw liquor circulates upstream of the membrane for 10 hours, and the condensed liquor is collected every 2 hours. At the end of the operation, most of the flavor components in the original wine are completely separated through the membrane. The flavor components and their content changes in the condensed wine collected at each period are shown in Table 1.

[0018] Separation rate and recovery rate can characterize the removal ability of silicone rubber composite membrane to flavor compone...

Embodiment 2

[0028] Using the same device as in Example 1, take 8L of raw wine at 52 degrees, and maintain its temperature at 35°C for pervaporation, the circulating flow rate of the feed liquid is 0.2m / s, the vacuum degree downstream of the membrane is 10mmHg, and the condensation temperature is - 25°C. The raw liquor circulates upstream of the membrane for 10 hours, and the condensed liquor is collected every 2 hours. At the end of the operation, most of the flavor components in the original wine are completely separated through the membrane. The flavor components and their content changes in the condensed liquor collected at each period are shown in Table 3.

[0029] Table 3 Changes and data analysis of flavor substances in condensed liquor at 35°C Unit: mg / 100mL

[0030] Flavor Components

[0031] It can be seen from Table 3 that the composition of flavor substances in the condensed wine collected at each time period is different, and each component (except acetaldehyde and...

Embodiment 3

[0036] Using the same device as in Example 1 and Example 2, take 8L of raw wine with a temperature of 52 degrees, and maintain its temperature at 40°C for pervaporation. The temperature was -23°C. The raw liquor circulates upstream of the membrane for 10 hours, and the condensed liquor is collected every 2 hours. At the end of the operation, most of the flavor components in the original wine are completely separated through the membrane. The flavor components and their content changes in the condensed wine collected at each period are shown in Table 5.

[0037] Table 5 Changes and data analysis of flavor substances in condensed liquor at 40°C Unit: mg / 100mL

[0038] Flavor Components

[0039]It can be seen from Table 5 that the composition of flavor substances in the condensed wine collected at each time period is different, and each component (except acetaldehyde and ethyl lactate) is more concentrated than the original wine. The separation efficiency of the five...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com