Solvent extraction method

An extraction and solvent technology, applied in the field of solvent extraction for separating magnesium, and can solve problems such as difficult separation of magnesium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, an embodiment of the present invention will be described.

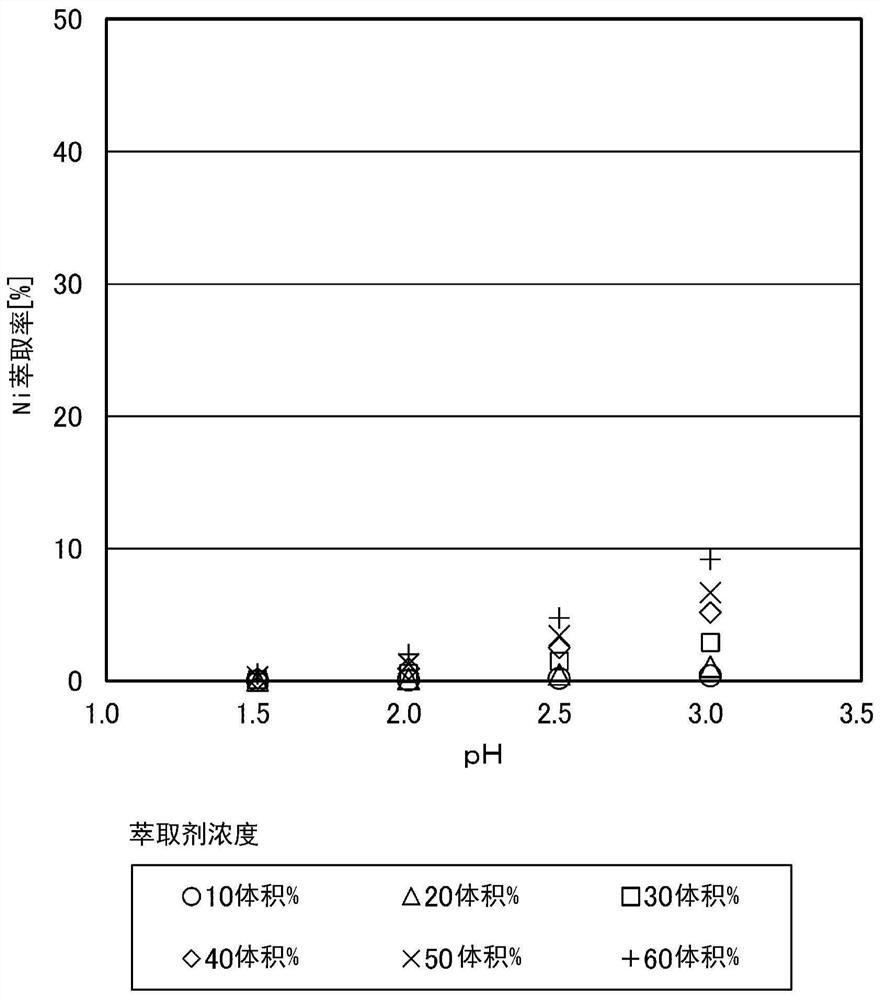

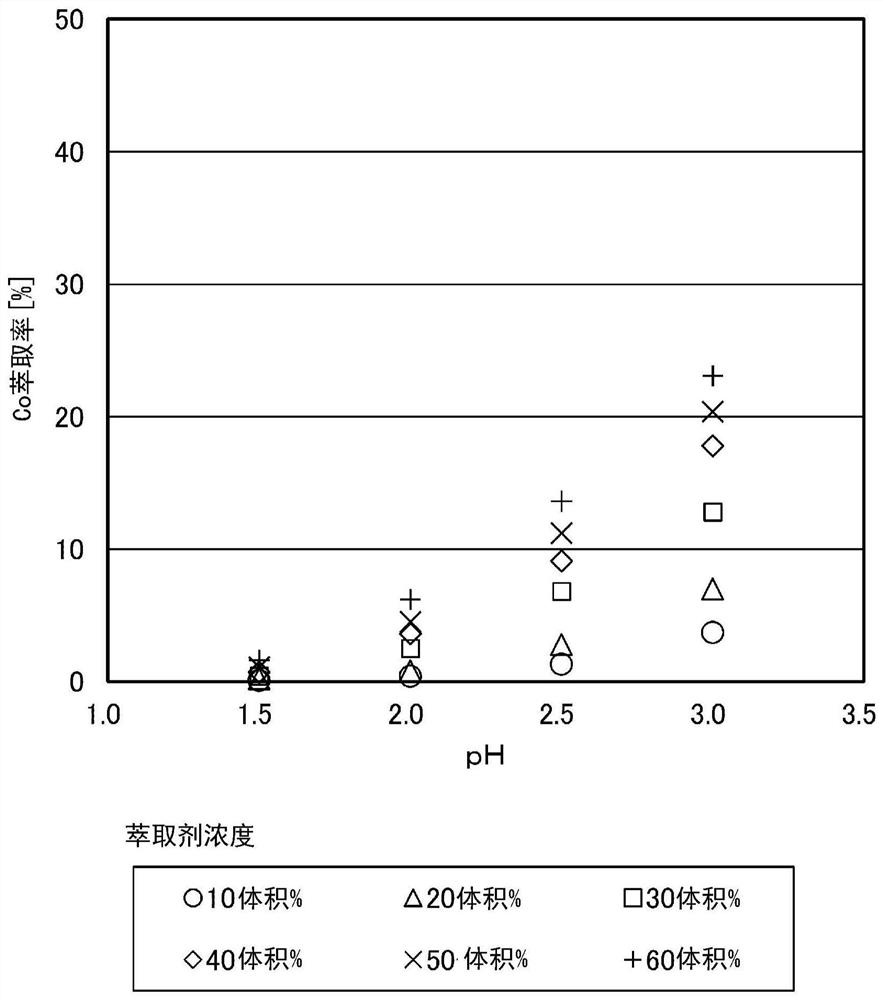

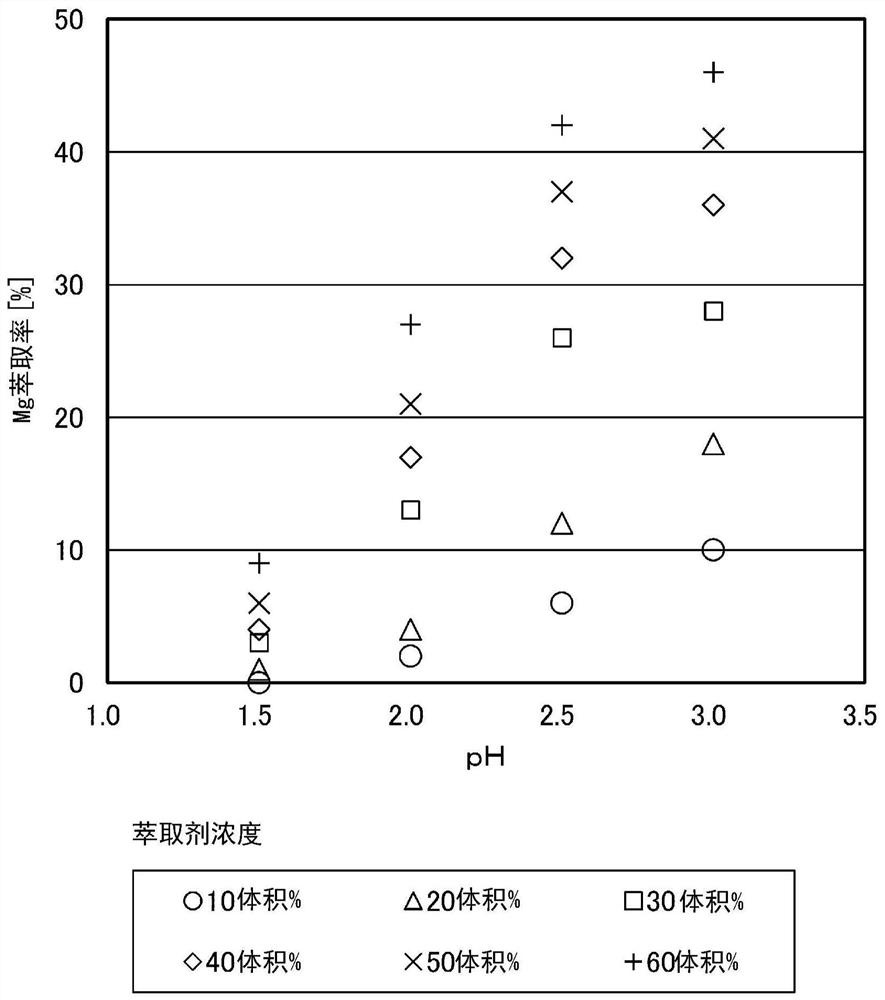

[0022] In the solvent extraction method of the present embodiment, magnesium is extracted into the organic solvent by contacting an acidic aqueous sulfuric acid solution containing nickel, cobalt, and magnesium with an organic solvent. Magnesium is selectively isolated by allowing nickel and cobalt to remain in the aqueous phase while extracting magnesium into the organic phase.

[0023] The apparatus used for solvent extraction is not particularly limited. As the solvent extraction device, a mixer-settler extractor can be exemplified.

[0024] As the organic solvent, a reagent obtained by diluting the extractant with a diluent is used. Alkylphosphonates are used as extractants. Examples of alkyl phosphonates include bis(2-ethylhexyl) hydrogen phosphate (D2EHPA, bis(2-ethylhexyl) hydrogen phosphate), 2-ethylhexyl (2-ethylhexyl) phosphonate (PC -88A, 2-ethylhexylhydrogen-2-ethylhexylphosphonate)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com