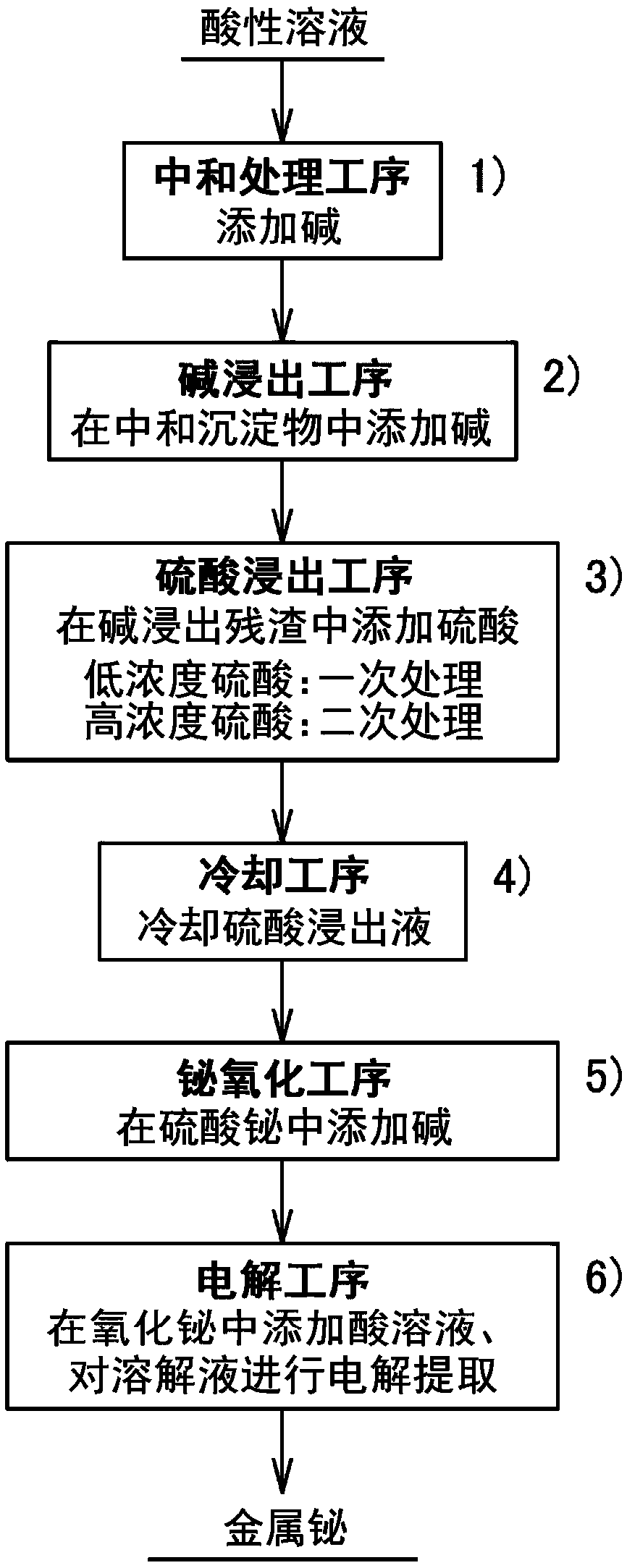

Bismuth purification method

A purification method and electrolytic purification technology, which is applied in the field of bismuth purification, can solve the problems of increased investment costs such as investment and energy used, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

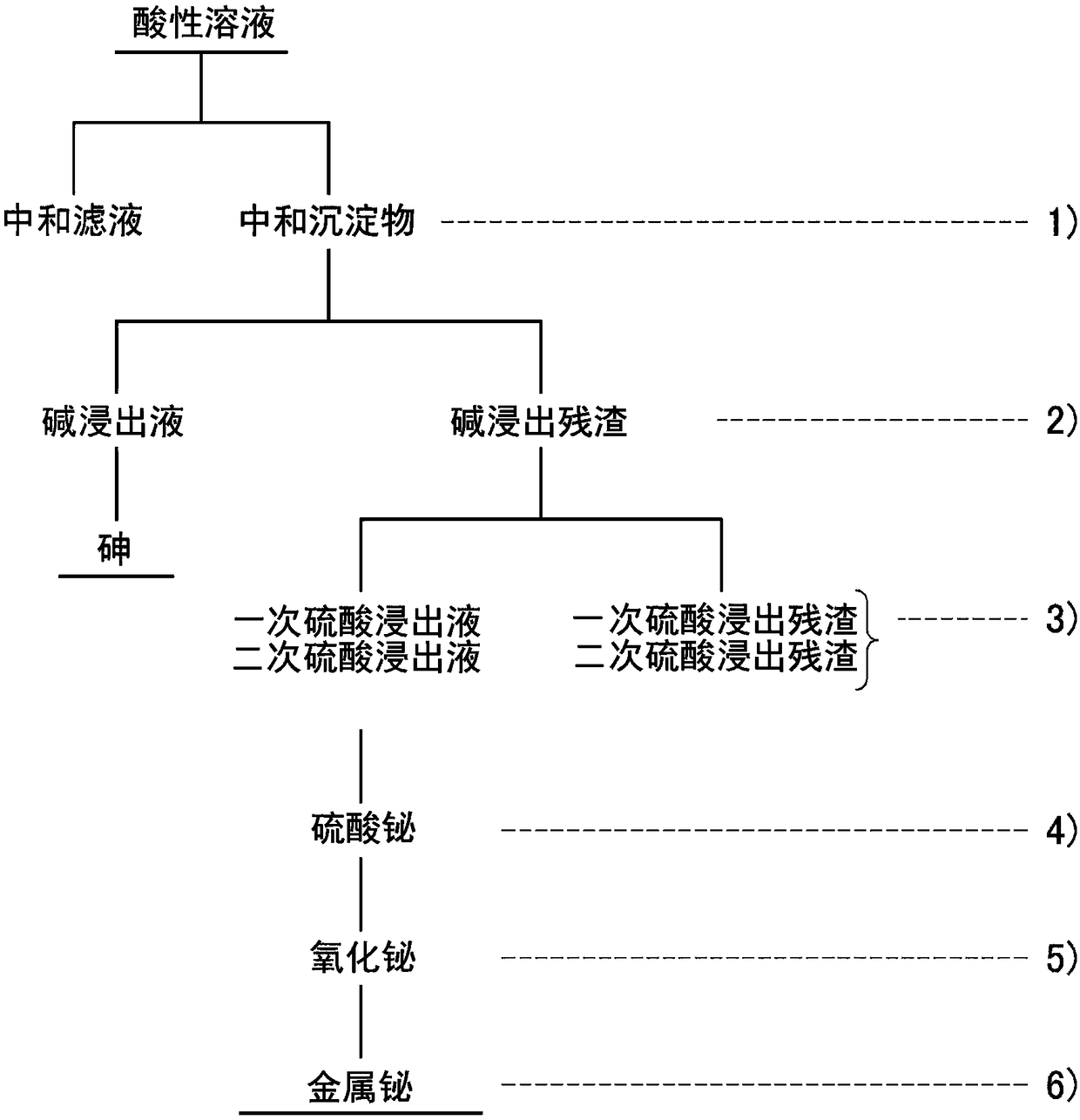

Method used

Image

Examples

Embodiment 1

[0111] The copper concentrate is put into the furnace, melted at high temperature to separate impurities, and the anode obtained by casting blister copper in this way is immersed in the electrolytic tank filled with sulfuric acid acid solution, and placed in front of the cathode made of copper or stainless steel Electricity is applied between them, and the known copper electrolytic purification method that electrolytically deposits electrolytic copper on the surface of the cathode is used to obtain copper electrolytic slime containing precious metals such as gold and silver. , an acidic solution containing noble metals leached from copper electrolytic slime was prepared.

[0112] Then, sodium hydroxide was added to this acidic solution under normal temperature conditions, and the slurry whose pH was adjusted to 2.6 was obtained. Thereafter, the slurry was solid-liquid-separated into a neutralization precipitate and a neutralization filtrate using a 5C filter paper using a Nuts...

Embodiment 2

[0114] In the same manner as in Example 1 above, the acidic solution obtained after the noble metal was leached from the copper electrolytic slime containing the noble metal was used, and the pH was adjusted to 2.6 by adding a sodium hydroxide solution, and the neutralized precipitate and the neutralized precipitate were obtained in the same manner as in Example 1. and filtrate (neutralization treatment process).

[0115] Then, sodium hydroxide with a concentration of 2 mol / L was added to the neutralized precipitate for leaching to obtain an alkali leaching residue (alkali leaching step). Further, low-concentration sulfuric acid was added to the obtained alkali leaching residue to adjust the slurry concentration to 100 g / L, and stirred for 1 hour to obtain a sulfuric acid leaching solution (sulfuric acid leaching step). The pH of the slurry after adding sulfuric acid was adjusted to 0.8.

[0116] The leaching rate of copper leaching to sulfuric acid leach solution is 53%. On...

Embodiment 3

[0125] Using the same acidic solution as in the above-mentioned Examples 1 and 2, sodium hydroxide was added to the acidic solution under normal temperature conditions to obtain a slurry whose pH was adjusted to 2.6, and thereafter, using the same method as in Examples 1 and 2 Solid-liquid separation into neutralization precipitate and neutralization filtrate (neutralization treatment process). The bismuth grade contained in this neutralized precipitate was 19 weight%, and the chloride ion grade was 11 weight%.

[0126] Then, a sodium hydroxide solution with a concentration of 2 mol / L was added to the neutralized precipitate to make the slurry concentration 100 g / L, and the slurry was stirred for 1 hour while maintaining the temperature of the slurry at 60° C. (alkali leaching process) . Then, solid-liquid separation is performed on the slurry after stirring, the obtained alkali leaching residue is washed with water, and the washed alkali leaching residue obtained by solid-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com