Technology and system for removing dust and sulfur by using coal ash

A technology of desulfurization process and desulfurization system, which is applied in the application field of desulfurization of sulfur dioxide in flue gas of small and medium-sized industrial pulverized coal boilers, can solve the problem of no good solution for treatment and comprehensive recycling, and achieve comprehensive recycling full and technological process concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

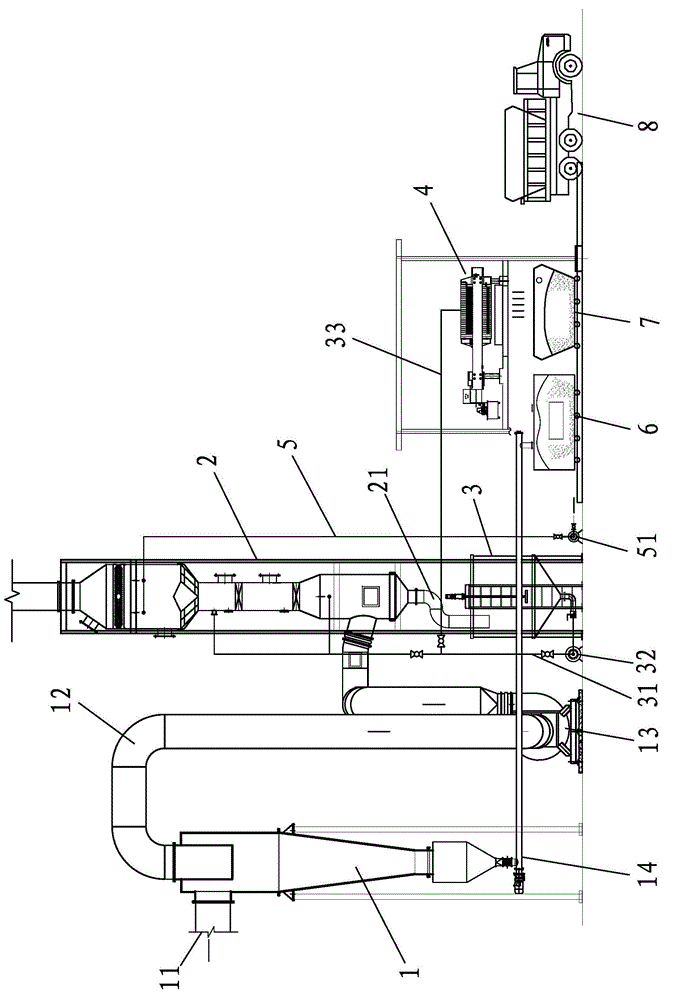

[0032] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] A process for dust removal and desulfurization using fly ash mainly includes the following steps:

[0034] 1) Introduce the flue gas with fly ash after combustion into the cyclone dust collector. The fly ash is mainly composed of glass microspheres, spongy porous particles and calcium oxide powder;

[0035] 2) The glass microbead crystals contained in the flue gas and the adsorbed SO by the cyclone dust collector 2 The sponge-like porous particles are separated from the flue gas, and the fly ash contained in the flue gas sent out of the cyclone dust collector is mainly calcium oxide powder and some light spongy particles;

[0036] 3) The flue gas sent from the cyclone dust collector is sent to the desulfurization tower. In the desulfurization tower, the calcium oxide powder and some light spongy particles have physical and chemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com