Patents

Literature

190results about How to "Promote emission standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex microbial inoculum for treating sewage and application method thereof

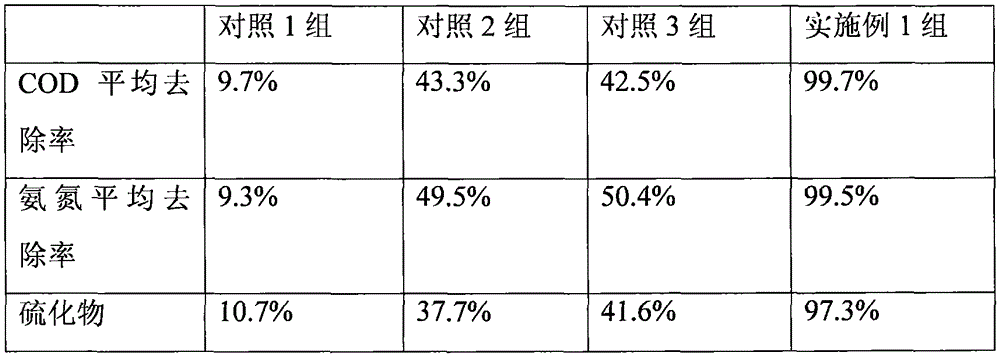

InactiveCN104694447APromote degradationGood removal effectFungiBacteriaHigh concentrationActivated sludge

The invention relates to an improved biological microbial inoculum for treating industrial sewage and a preparation method and application thereof. The microbial inoculum is thrown in a sewage treating system, has a good degrading effect on macromolecular, degradation-resistant, toxic and harmful substances such as arsenic, ammonia nitrogen and phosphorus and has a unique treatment effect on high-concentration organic sewage and high-ammonia-nitrogen sewage which are difficult for a traditional activated sludge method to treat.

Owner:朱凌玮

Biological agent for processing glutamic acid fermentation waste water

ActiveCN104230004ASolve pollutionPromote growthMultistage water/sewage treatmentWaste water treatment from food industryMycoproteinGlutamic acid

The invention relates to biological agent for processing glutamic acid fermentation waste water. Mycoprotein is separated from glutamic acid fermentation liquid through a high-speed disc separator, bacteria removing liquid is gathered, the mycoprotein is precipitated, compound seed liquid is added to the mycoprotein for preparing probiotics, the waste water generated by extracting glutamic acid from the bacteria removing liquid is drained into a sewage processing system, compound microorganism bacterium agent is added to the waste water to perform advanced treatment, and the waste water is discharged after reaching the standard. The biological agent for processing glutamic acid fermentation waste water is economical and environmental friendly and has broad application prospect.

Owner:内蒙古阜丰生物科技有限公司

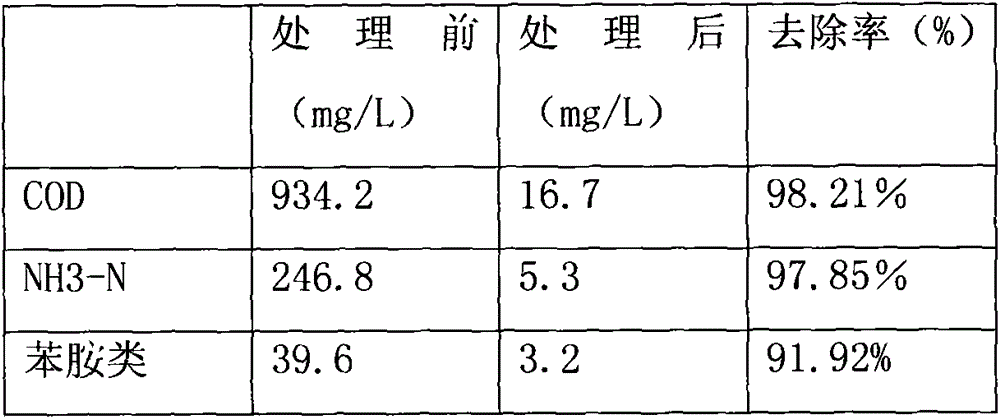

Resourceful treatment method for organic waste

ActiveCN107363076AReduces chemical oxygen demand (COD)Promote emission standardsSolid waste disposalCarbon chainWaste treatment

The invention relates to the technical field of treatment and resourceful utilization of organic waste and aims at providing a resourceful treatment method for organic waste. The resourceful treatment method can improve the economic benefits of fermentation products. According to the adopted technical scheme, the method includes the steps of lactic acid fermentation, carbon chain lengthening and medium-chain fatty acid extracting, wherein according to carbon chain lengthening, microorganisms for synthesizing medium-chain fatty acid are added for anaerobic fermentation; and the organic waste is biodegradable organic waste. The brand new organic waste treatment method is provided, in other words, the technology for synthesizing medium-chain fatty acid as the main product through coupling of organic matter hydrolysis lactic acid generating and carbon chain lengthening is provided. The principle of the technology is obviously different from a previous anaerobic biochemical treatment technology, harmlessness and stability of organic waste are achieved, meanwhile, medium-chain fatty acid which is easy to extract and has high economic benefits can be generated, organic matter such as ethyl alcohol does not need to be additionally added, the technological cost is greatly reduced, and the economic benefits of the technology are obviously reduced.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Environment-friendly process for treating glutamic acid fermentation wastewater

ActiveCN104261631ASolve pollutionPromote growthWater contaminantsAnimal feeding stuffBiotechnologyMycoprotein

The invention relates to an environment-friendly process for treating glutamic acid fermentation wastewater. Glutamic acid fermentation broth is subjected to mycoprotein separation by a high-speed disc separator, a degerming liquid is collected, mycoprotein is precipitated, a composite seed solution is added to the mycoprotein for fermentation to prepare a probiotic preparation, wastewater generated by extracting glutamic acid by the degerming liquid enters a sewage treatment system, a compound microbial agent is added for deep treatment, and then the wastewater is drained up to the standard. The environment-friendly process for treating glutamic acid fermentation wastewater is economical and environment-friendly, and has broad application prospect.

Owner:内蒙古阜丰生物科技有限公司

Microbial preparation for restoring fertilizer plant sewage and application thereof

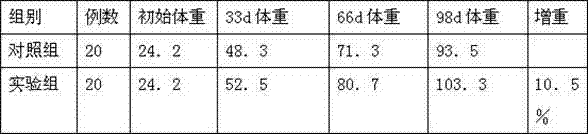

InactiveCN104528955APromote degradationIncrease contact areaBiological water/sewage treatmentSorbentFertilizer plant

The invention belongs to the technical field of microbes, and discloses a microbial preparation for restoring fertilizer plant sewage. The microbial preparation for restoring fertilizer plant sewage is prepared by the following steps: 1) preparing an adsorbent; 2) preparing a microbial carbon source; 3) preparing a microbial carrier; and 4) preparing the microbial preparation. The microbial preparation can effectively remove ammonia nitrogen, SS (suspended sediment) and phenols in the fertilizer plant sewage, has favorable removal effect, and achieves the discharge standard.

Owner:杭州润泽科学器材有限公司

Biological agent for treating ammonia-nitrogen-containing wastewater and preparation method thereof

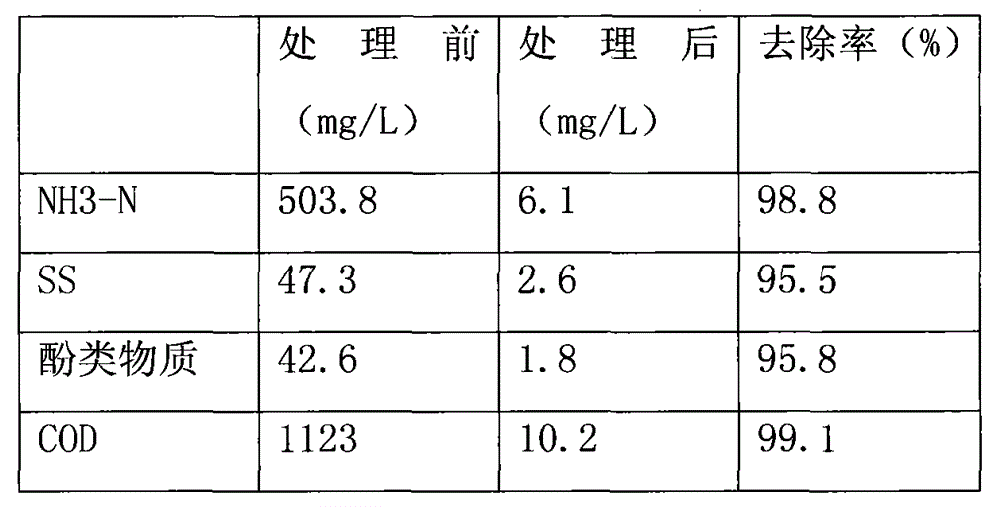

InactiveCN104630101APromote degradationIncrease contact areaBacteriaWater contaminantsPseudomonas fluorescensAniline

The invention belongs to the field of microorganisms and discloses a biological agent for treating ammonia-nitrogen-containing wastewater. The biological agent comprises rhodococcus ruber, micrococcus luteus, enterococcus faecalis, acinetobacter baumannii, arthrobacter crystallopoietes, thiobacillus denitrificans and pseudomonas fluorescens. The biological agent comprises multiple strains, has the advantages of reasonable compatibility and strong synergic effect and can be used for effectively removing ammonia nitrogen, sulfide, aniline substances and industrial COD in wastewater.

Owner:江苏睿智建筑工程有限公司

Environmental protection technology for processing threonine fermentation wastewater by using biological agent

ActiveCN104276732APromote degradationHigh activityWater/sewage treatment by centrifugal separationWater/sewage treatment bu osmosis/dialysisMycoproteinWater treatment system

The invention relates to an environmental protection technology for processing a threonine fermentation wastewater by using a biological agent. The process comprises the following steps: separating mycoprotein from threonine fermented liquid by virtue of a high-speed disc separator, recovering mycoprotein sediments, and collecting supernate; filtering the supernate by virtue of a film; recovering mycoprotein by virtue of the film, collecting filtrate, merging the mycoprotein, and adjusting the solid content to prepare a probiotic agent in a fermentation manner; concentrating, carrying out isopotential sedimentation on a production wastewater generated in the threonine extraction step; carrying out natural sedimentation and solid-liquid separation, discharging the supernate into a sewage treatment system; and adjusting the pH and adding a composite microbial agent to carry out advanced treatment, so as to discharge with standards. The process disclosed by the invention is low in wastewater discharge, economical and environmentally friendly, and has a wide application prospect.

Owner:SHANDONG CHENZHANG BIOTECHNOLOGY CO LTD

New treatment method of threonine mother liquid

ActiveCN103723894AWell mixedReduce usageOrganic compound preparationMultistage water/sewage treatmentBacterial agentChemistry

The invention relates to a new treatment method of threonine mother liquid. The method comprises a step of adding an alcohol substance into a threonine mother liquid solution obtained in an extraction process of threonine mother liquid so as to reduce the solubility and separate out threonine, and a compound microbial bacterial agent is added into other impurities to reach the emission standard. The method provided by the invention has the advantages of low production cost, high threonine extraction yield and little wastewater discharge, is economical and environment-friendly and has a broad application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

Treatment method of ammonia-nitrogen-containing industrial wastewater

ActiveCN104628225APromote degradationImprove biological treatment efficiencyWater contaminantsAnimal feeding stuffEnvironmental resistanceBiological oxidation

The invention belongs to the field of wastewater treatment environmental protection, and discloses a treatment method of ammonia-nitrogen-containing industrial wastewater, which comprises the following steps: 1) preparing a composite microbial inoculant; 2) precipitating to remove impurities; 3) regulating the pH value; 4) preparing a carbon source; 5) carrying out biological oxidation; and 6) preparing a feed protein. The method can effectively treat the ammonia nitrogen wastewater at low cost, and is suitable for industrialized popularization and use.

Owner:张玉兰

Method for treating artificial wetland breeding wastewater by integration of straw, biochar and organism

InactiveCN105967328ASolve the problem of environmental pollutionPromote emission standardsTreatment with anaerobic digestion processesSustainable biological treatmentBiologyMyriophyllum verticillatum

The invention discloses a method for treating artificial wetland breeding wastewater by integration of straw, biochar and organism. According to the method, breeding wastewater passes an anaerobic fermentation tank, three substrate tanks and four wetland tanks in sequence; a substrate channel is arranged between the anaerobic fermentation tank and the first substrate tank, between two adjacent substrate tanks, as well as between the third substrate tank and the first wetland tank; straw is laid in the substrate channels and the substrate tanks; wild plants are added onto the straw; a water blocking drop water dam is arranged at the water outlet of each substrate tank; the wetland tanks are surrounded by ridges; two adjacent wetland tanks are separated through one ridge; overflow openings of which the cross sections are in the shape of an inverted trapezoid are formed in the upper end surfaces of two ridges of each wetland tank; myriophyllum verticillatum is added into each wetland tank; a biochar layer is arranged in front of the overflow opening, near discharged water, of the last wetland tank. According to the method for treating artificial wetland breeding wastewater by integration of straw, biochar and organism, the water quality of the end discharged water is greatly superior to the water pollutant discharge standard of the national breeding industry.

Owner:SHAOXING UNIVERSITY

Preparation for treating sewage produced by production of xanthan gum

ActiveCN104313004APromote degradationHigh activityMicroorganism based processesNature of treatment waterCooling towerMicrobial agent

Owner:内蒙古阜丰生物科技有限公司

Method for preparing biochemical preparations for treating threonine fermentation wastewater

ActiveCN106082532ALarge specific surface areaHigh tensile strengthTreatment using aerobic processesMultistage water/sewage treatmentBiotechnologyThreonine

The invention relates to a method for preparing biochemical preparations for treating threonine fermentation wastewater. The method includes preparing physical adsorbents and complex microbial inoculants. The complex microbial inoculants comprise, by volume, 6-7 parts of yeast, 5-6 parts of arthrobacter, 5-6 parts of pseudomonas, 4-5 parts of rhodococcus, 4-5 parts of bacillus amyloliquefaciens, 4-5 parts of clostridium and 3-4 parts of scenedesmus obliquus. The method has the advantages that the biochemical preparations contain diversified microorganisms with excellent degradation capacity for refractory pollutants, various strains are reasonably compatible with one another, accordingly, excellent degradation effects can be realized, and the method has a broad application prospect.

Owner:内蒙古阜丰生物科技有限公司

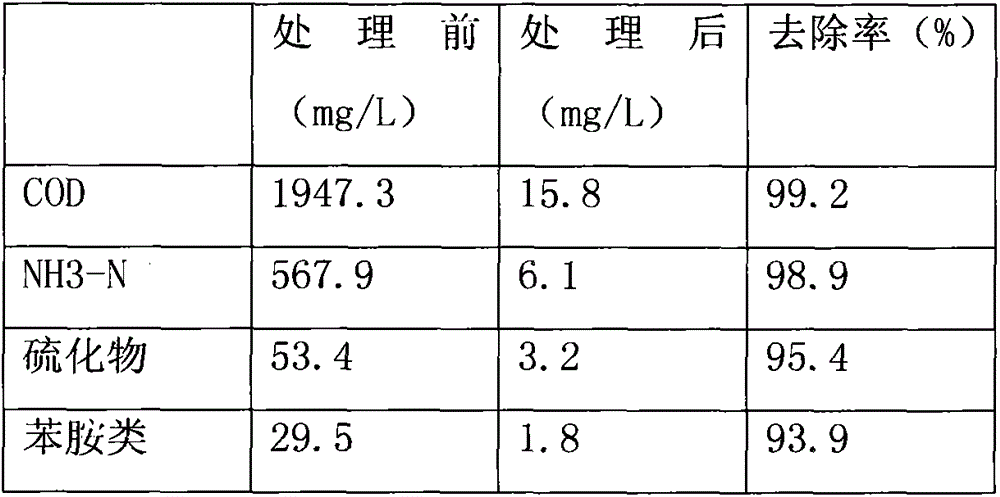

Biological agent for glutamate wastewater treatment

InactiveCN105039228APromote degradationHigh activityFungiBacteriaAspergillus nigerBacteroides species

The invention relates to a biological agent for glutamate wastewater treatment. The biological agent is formed by mixing aerobic denitrifier, bacillus, aspergillus niger, rhodococci, alcaligenes faecalis, streptomyces lateritius, Candida albicans and an adsorbent carrier. The biological agent contains various microorganisms with the good degradation ability to non-biodegradable pollutants, all the bacteria are reasonably matched, the good degradation effect is achieved, and the wide application prospect is achieved.

Owner:内蒙古阜丰生物科技有限公司

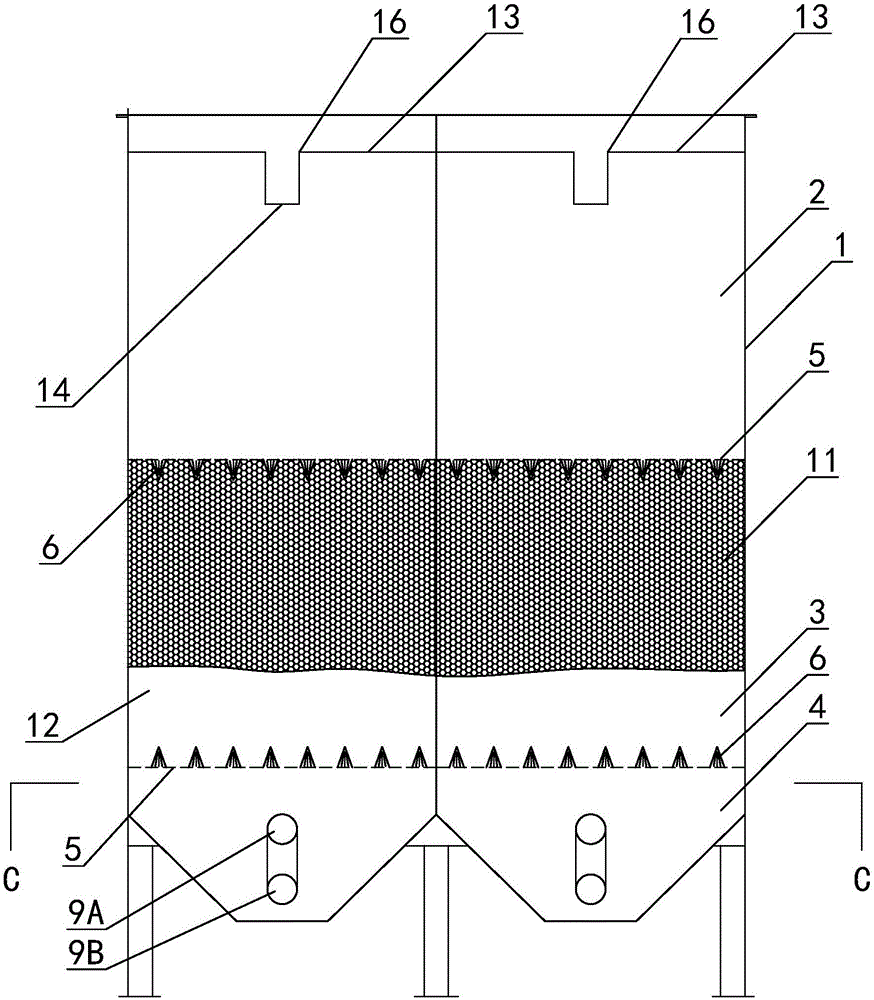

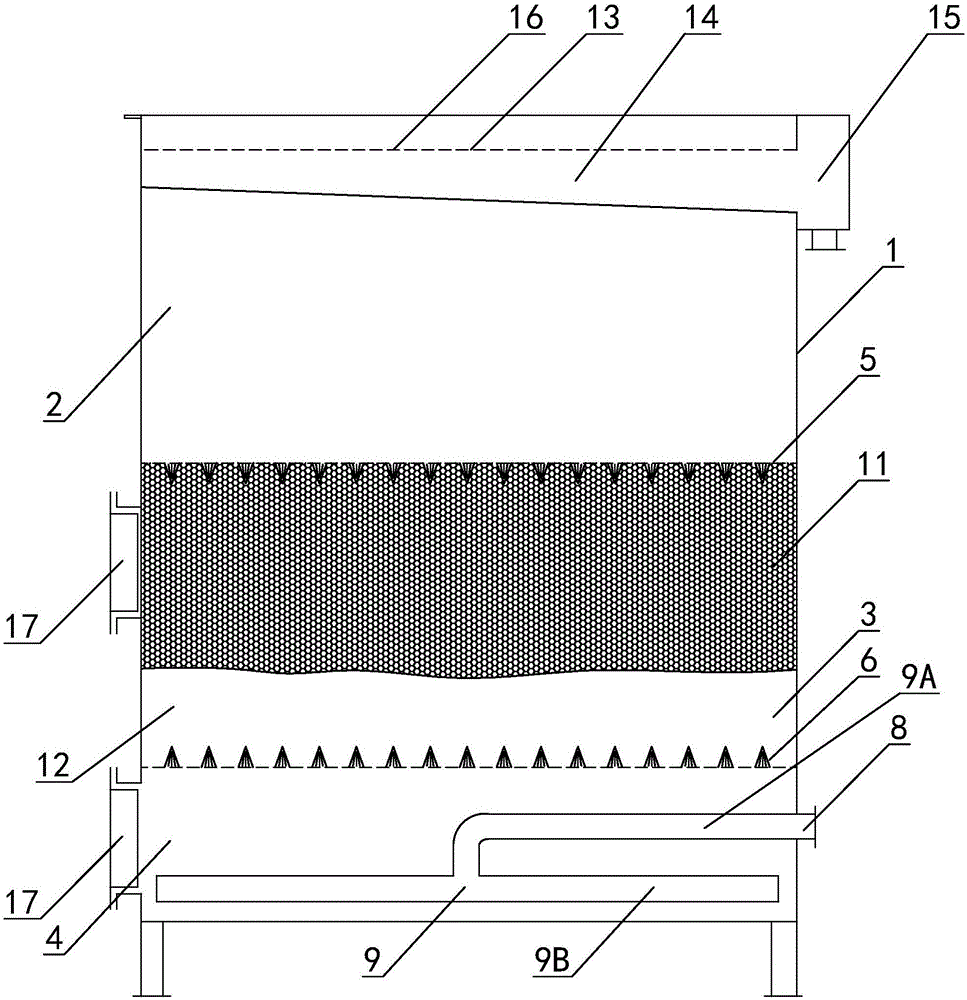

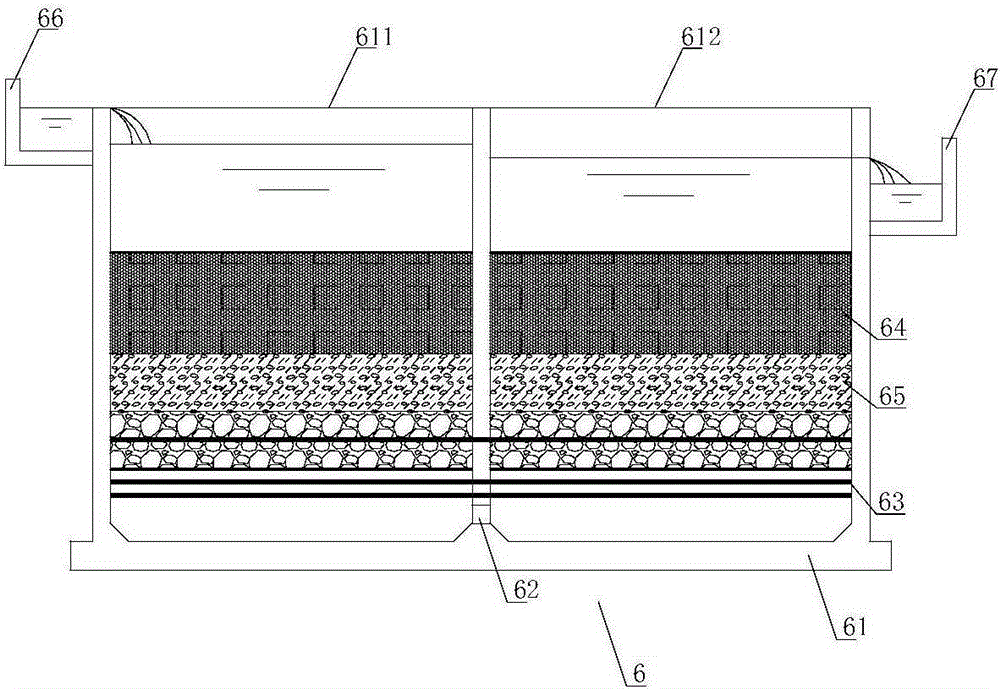

Integrated lightweight filter-material water treatment filter tank

InactiveCN106466532AFilter evenlyEvenly distributedLoose filtering material filtersGravity filtersWater flowSewage

An integrated lightweight filter-material water treatment filter tank is characterized by comprising at least a water treatment unit. The water treatment unit comprises a tank. The tank is composed of a clear water area, a filtering area and a water inlet area which are communicated with each other through water-flow from the top to the bottom. Adjacent two areas of the above three areas are isolated through a filter board respectively. The filter board is provided with several water channels used for water flowing. The water inlet area has a water inlet used for receiving sewage to be filtrated. The filtering area holds several lightweight elastic filter material particles which have lower density than water. Particle size of the lightweight elastic filter material particles is greater than width of the water channels. After water-flowing, each lightweight elastic filter material particle forms a filter layer, and there is a gap between the filter layer and the lower filter board. The top of the clear water area is an overflow surface of clear water. The filter tank has advantages of good filtering effect, low backwashing requirement, high reliability, low cost, low operation cost, less land occupation and convenience in operation management.

Owner:谢绍舜

Treatment method for dephosphorizing and denitrifying sewage

ActiveCN105859060AReduce dosageShorten the timeWater treatment parameter controlWater contaminantsBacillus cereusPseudomonas

The invention relates to a treatment method for dephosphorizing and denitrifying sewage. The method is characterized by carrying out treatment by combining a physical method and a biological agent, wherein the biological agent comprises the following raw materials in parts by weight: 5-7 parts of paracoccus denitrificans, 5-7 parts of saccharomyces cerevisiae, 4-5 parts of rhodococcus, 4-5 parts of bacillus amyloliquefaciens, 3-4 parts of clostridium papyrosolvens, 3-4 parts of penicillium ochrochloron, 2-3 parts of pseudomonas and 1-2 parts of bacillus cereus. The biological agent contains various microorganisms with excellent capacity of degrading refractory pollutants, is reasonable in compatibility of the strains, has good degrading effects and has a broad application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

Producing technology for microcrystalline cellulose with waste acid cotton linter

InactiveCN101067287AReduce harmReduce dosagePulp liquor regenerationPulp de-wateringFiberChemical reaction

The process of producing microcrystalline cellulose with waste acid lint includes the steps of: soaking, eliminating residue, bleaching, washing, eliminating residue for the second time, concentrating and dewatering, drying, and sieving. The bleaching procedure is one three section one, and uses one of chlorine dioxide, ozone and hydrogen peroxide as the bleaching agent and alkali as the neutralizing agent. The bleaching procedure has low water consumption, less waste drainage, selective elimination of pigment and impurity in fiber and less damage to fiber, and the bleached product has low viscosity, high whiteness, high cellulose content, raised chemical reaction activity, high product quality and wide application range.

Owner:王光建 +1

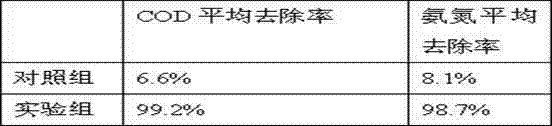

Environmental protection process for treating xanthan gum fermentation wastewater

ActiveCN106882909AStrong adhesionReduce outputTreatment involving filtrationTreatment with anaerobic digestion processesLiquid wasteSludge

The invention relates to an environmental protection process for treating xanthan gum fermentation wastewater. The environmental protection process comprises the following steps: xanthan gum industrial wastewater flows through a plurality of grids and is discharged into a sedimentation tank, the grid gaps of a plurality of the grids are gradually reduced, then an adsorbent is added to wastewater according to the adding amount which is 0.5kg per ton of wastewater to perform settlement treatment, and then anaerobic biochemical treatment-bioremediation through hydrolytic acidification. The bioremediation preparation disclosed by the application of the invention can improve the water treatment capacity and the treatment water quality to reduce the operation cost and promote the standardized discharge, and can further reduce the sludge production, is beneficial to the removal of pollutants such as COD and ammonia nitrogen in waste liquid, and has good application prospects.

Owner:内蒙古阜丰生物科技有限公司

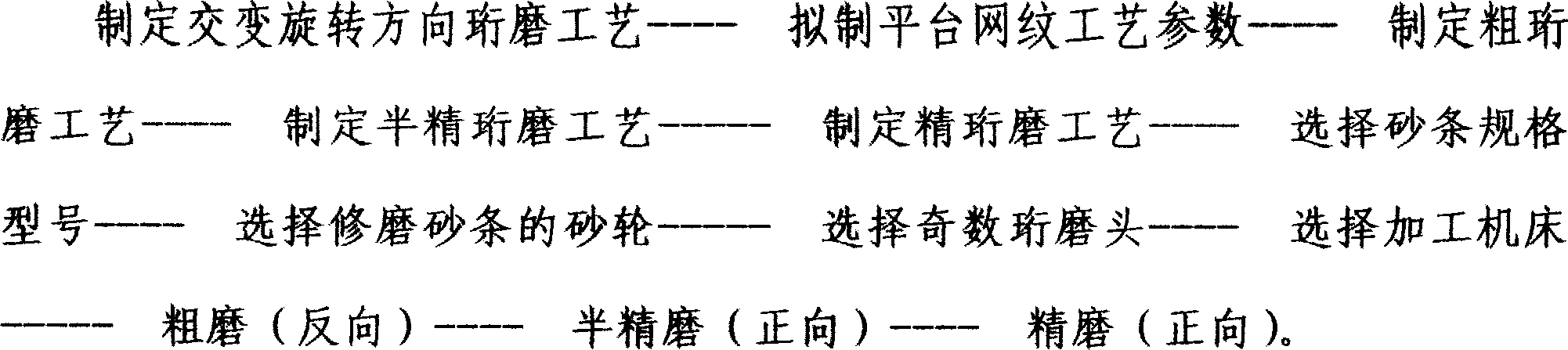

Alternating rotating direction honing cylinder jacket platform webbing technique

InactiveCN101058165AEnhanced frictional oil storageImprove the lubrication effectHoning machinesInternational standardGraphite

The invention relates to an alternating direction of rotation honing cylinder jacket platform cob webbing technique that is used to facilitate the oil storage and lubrication feature of the engine friction, extend durability, reduce engine oil consumption, improve engine tail gas emission quality, for the benefit of environment protection and human health. Through alternating direction rotation honing cylinder jacket platform cob webbing, it can expose the graphite sufficiently, timely release lubrication oil to the friction system. This technique has acquired international standard parameter, allowing the inner wall of the cylinder jacket acquiring small platform and deep slot, increase bearing area of the small platform, with the deep slot storing oil better, improving sealing capacity, reducing oil consumption, allowing the engine tail gas emission reaching Euro III standard for the benefit of environment protection and health of mankind.

Owner:韦斌

Environment-friendly technology for cleanly producing sodium glutamate

The invention relates to an environment-friendly technology for cleanly producing sodium glutamate. The environment-friendly technology comprises the following steps of: simultaneously adding liquid ammonia and sodium carbonate into sodium glutamate fermentation liquor for reaction, and thereby obtaining coarse fermentation liquor; filtering by micromembrane, and collecting degerming liquid and mycoprotein; adopting the mycoprotein to prepare probiotics, pumping the degerming liquid into a bleaching tank to perform decoloration process, and concentrating and crystallizing to obtain sodium glutamate coarse crystal; then refining and processing waste water; the technology is economical and environment-friendly, and has wide application prospects.

Owner:内蒙古阜丰生物科技有限公司

Microbial preparation for processing industrial fermentation wastewater

InactiveCN105274024APromote degradationGood removal effectFungiBacteriaStreptomycesIndustrial fermentation

The invention relates to a microbial preparation for processing industrial fermentation wastewater. The microbial preparation is prepared by mixing nitrosobacterium, Trichoderma longibrachiatum Rifai, aerobic denitrifying bacterium, acinetobacter baumannii, aspergillus niger, alcaligenes faecalis, Streptomyces lateritius, Candida albicans, Paenibacillus polymyxa and an adsorbent carrier. The microbial preparation contains multiple microbes having excellent ability of degrading non-biodegradable pollutants. Through reasonable compatibility between various strains, the microbial preparation has a good degradating effect and has a wide application prospect.

Owner:张胜平

Treatment method for high salt content and high COD alkaline residue neutralization water

ActiveCN102452696ANo impactPromote emission standardsWater contaminantsNature of treatment waterSalt contentDesalination

The present invention relates to a treatment method for high salt content and high COD alkaline residue neutralization water. According to the method, an extraction treatment is performed at a temperature of -5-5 DEG C, wherein an extraction agent is a petroleum fraction and / or an organic amine; the extracted material is subjected to settlement separation to obtain the oil phase, the water phase and the solid substance. With the method of the present invention, the high COD removal efficiency can be obtained by using the simple extraction method, the high desalination effect can be obtained, the biodegradability of the treated effluent is improved, and the impact on the wastewater treatment plant is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

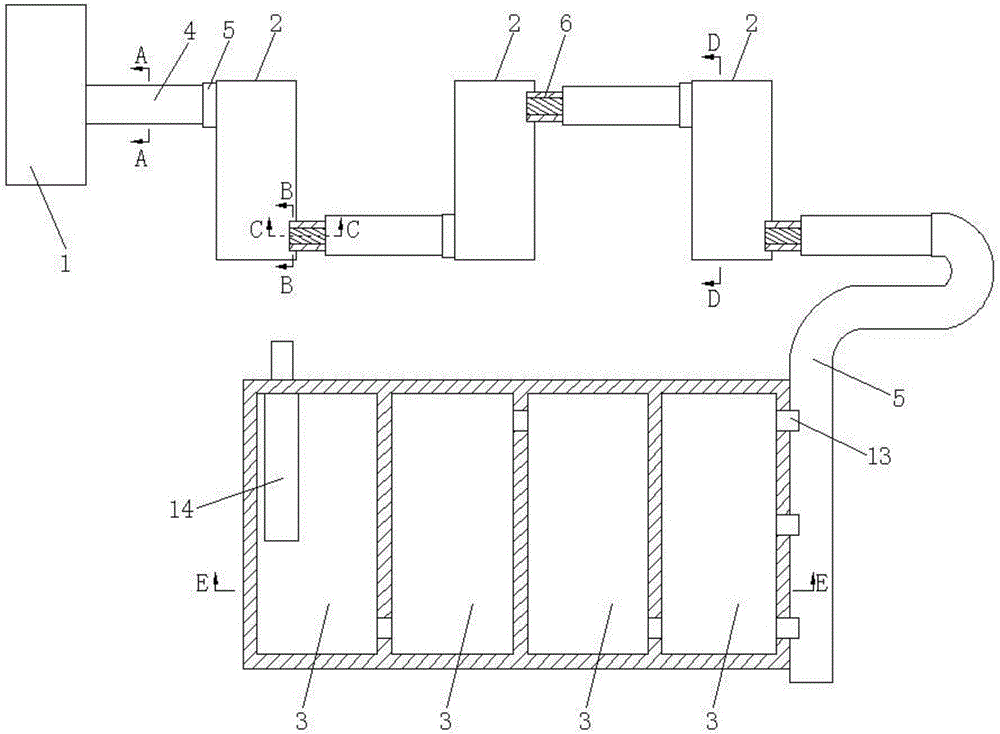

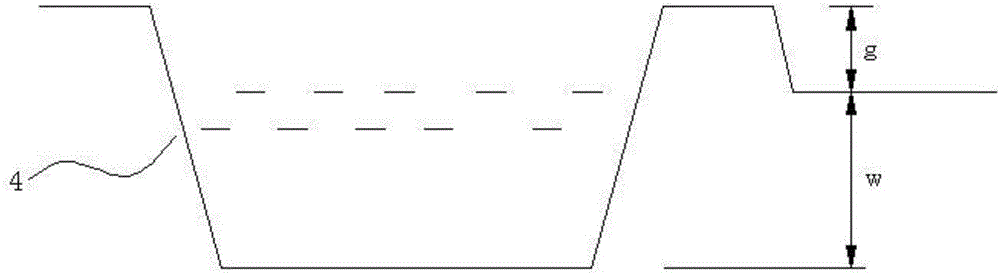

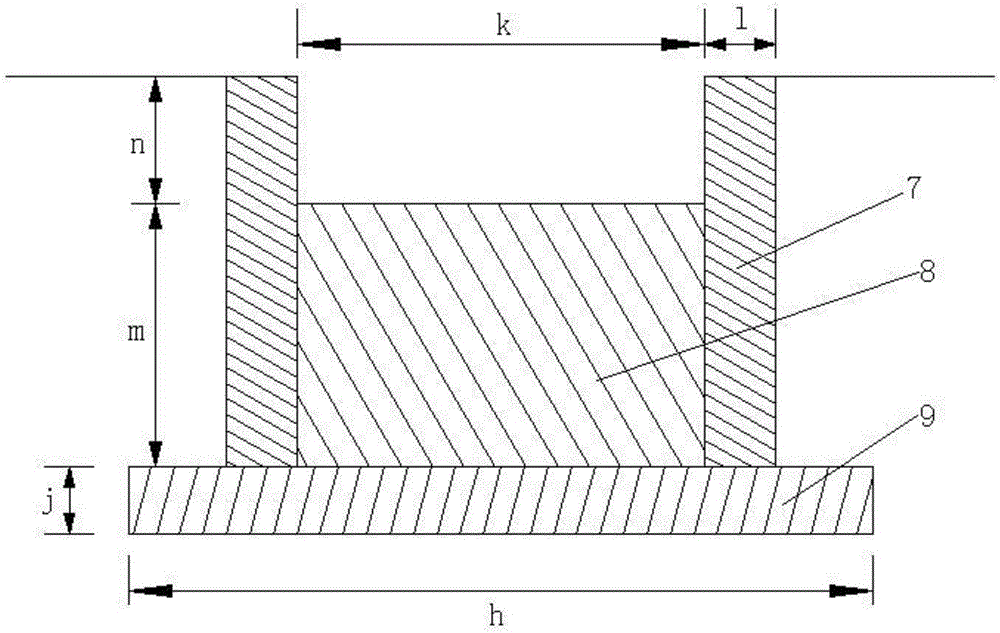

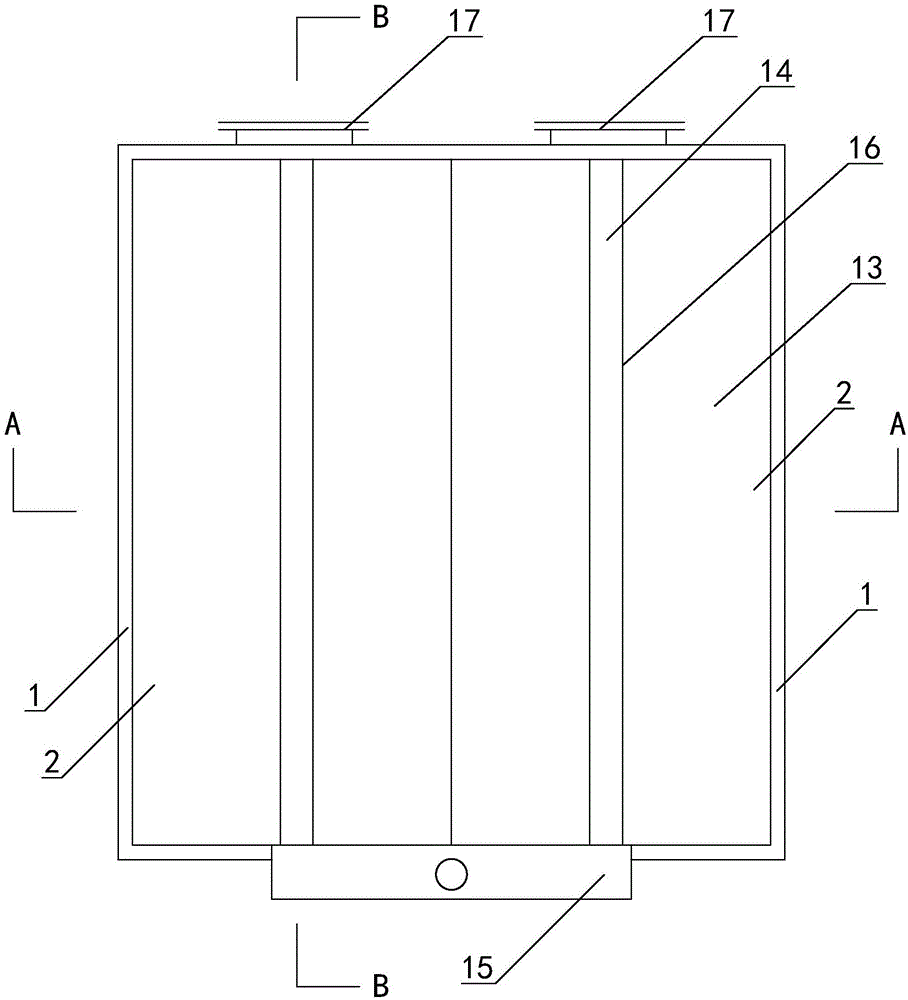

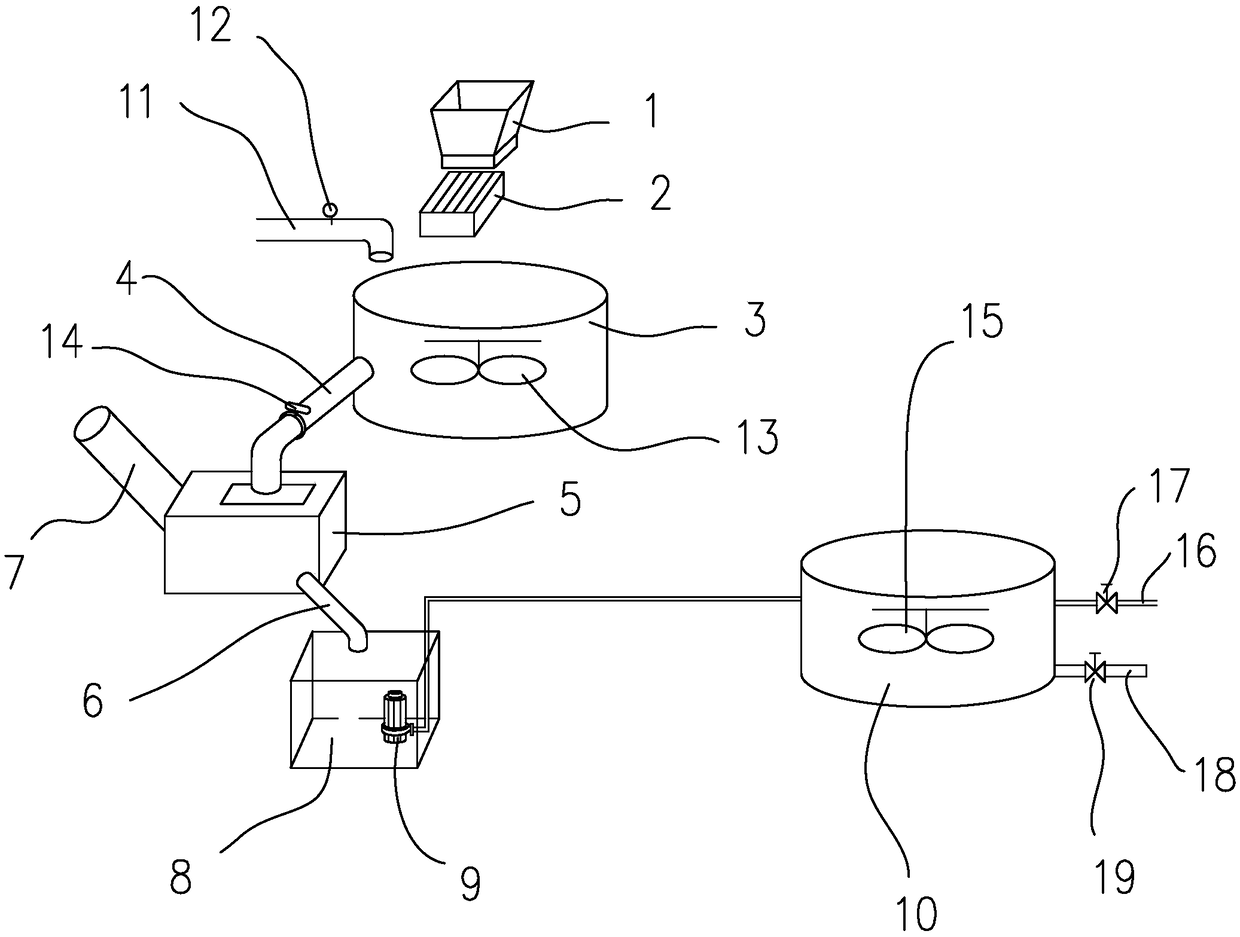

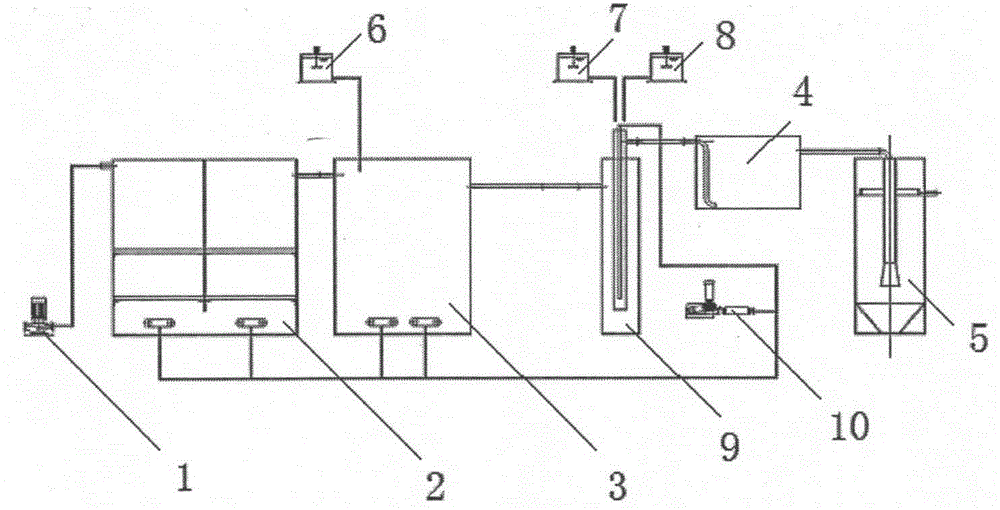

Device and method for extracting carbon source of sewage treatment plant from kitchen waste

PendingCN109277394AHigh COD concentrationIncrease concentrationSolid waste disposalWater/sewage treatment by flocculation/precipitationOil and greaseGrating

The invention relates to a device and a method for extracting a carbon source of a sewage treatment plant from kitchen waste. The device comprises a double-shaft shear type crusher (1), a crushing grating (2), a soaking and stirring barrel (3), a gravity pipe (4) and a screw press (5). The method comprises the following steps that firstly, the kitchen waste is crushed and soaked in hot water, andsqueezing and filtering are carried out on the soaked solid-liquid mixture to obtain the kitchen waste filtrate; and then ferric chloride and lime are added into the kitchen waste filtrate in sequence, coagulation reaction is carried out under stirring, and combined treatment is carried out on the upper-layer kitchen waste filtrate and the urban sewage after precipitation. According to the deviceand method, organic carbon source in the kitchen waste is released by hot water soaking, a part of grease is removed through coagulation, and C / N and C / P of the kitchen waste filtrate are improved; and the kitchen waste filtrate can be used as the carbon source needed by nitrogen and phosphorus removal reaction of the sewage treatment plant, contribution is made to upgrading and transformation ofthe sewage treatment plant, meanwhile, foul smell generation is reduced, and the purpose of recycling the kitchen waste is achieved.

Owner:XIAMEN WATER GRP +1

SWSR-8 pressurization sulfur recovery process

ActiveCN105947992AEmission reductionReduce sizeEnergy inputSulfur preparation/purificationSulfurFlue gas

The invention belongs to the field of sulfur recovery, and particularly relates to an SWSR-8 pressurization sulfur recovery process. The process comprises the steps that acid gas enters a sulfur making furnace, H2S is subjected to a high-temperature Claus reaction and converted into sulfur, and sulfur enters a two-stage converter to conduct two stage catalytic conversion for recovering sulfur; sulfur making tail gas enters a hydrogenation reactor, under the action of a hydrogenation catalyst, SO2 and COS are reduced to H2S through hydrogenation hydrolysis, reduced H2S gas is absorbed with an MDEA solution, and after purified tail gas recovers heat through incineration, flue gas is exhausted to the atmosphere through a chimney, wherein the pressure of acid gas entering the sulfur making furnace ranges from 90 kPa(g) to 120 kPa(g), and the pressure of the sulfur making furnace ranges from 90m kPa(g) to 120 kPa(g). The pressure of cooling and heat exchange equipment such as a sulfur making waste heat furnace, a first stage sulfur condenser, a second stage sulfur condenser, a third stage sulfur condenser, a steam generator and a tail gas waste heat boiler is higher than that in the prior art, the total heat transfer coefficient is increased, the occupied area is decreased, catalytic and absorption reactions can be conducted conveniently, the sulfur recovery rate is increased, and SO2 discharge is reduced.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

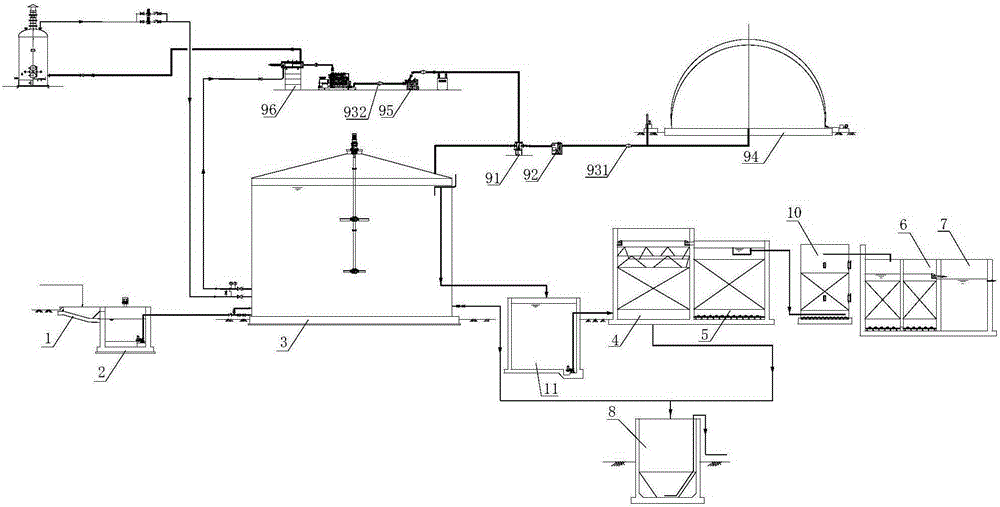

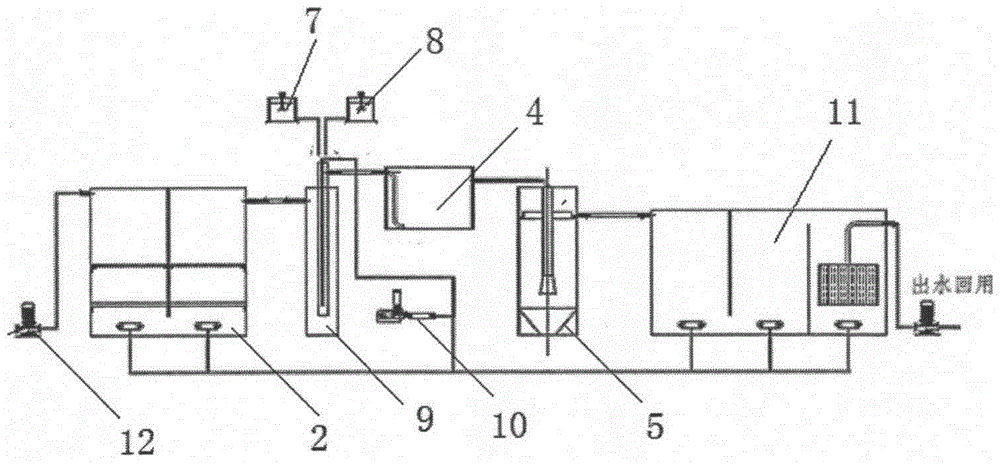

System and method for treating wastewater by applying activated sludge

InactiveCN105174621AImprove purification intensitySimple processWaste based fuelTreatment with anaerobic digestion processesBiogasAnaerobic digestion

The invention relates to the technical field of sewage treatment and discloses a system for treating wastewater by applying activated sludge. The system comprises a feed hopper (1), a homogenizing tank (2), a biogas tank (3), an up-flow anaerobic sludge bed (4), an activated sludge reaction tank (5), a microelectrolysis reactor (10), a baffled biological aerated filter (BBAF) (6) and an ozone disinfection tank (7), which are connected in sequence, wherein the biogas tank is connected with a sludge thickening tank (8). The invention also discloses a method for treating wastewater by applying activated sludge. The method comprises anaerobic digestion treatment, treatment by adopting an activated sludge method, microelectrolysis reaction, biochemical treatment with the BBAF and ozone disinfection. The system and the method have the beneficial effects that the process is simple; the concentration gradient in the reaction process is large, so that sludge bulking is not easy to happen; the system has strong load impact resistance and good treatment effects; and the simultaneous denitrification and dephosphorization effects of the BBAF are obvious by adjusting the cycle of operation and controlling the working procedure time length.

Owner:HANGZHOU DINGLONG ENVIRONMENTAL PROTECTION SCI & TECH

Salix mongolica sulfate pulp bleaching process

The invention relates to a salix mongolica sulfate pulp bleaching process belonging to the technical field of a paper pulp bleaching process. The process comprises the following steps: boiling and washing pulp, and carrying out AU series xylanase pretreatment at 48-50 DEG C under the condition that the pH value is 6.5-7; washing, and carrying out chlorine dioxide bleaching; washing, and carrying out cellulase treatment at 50-55 DEG C under the condition that the pH value is 5.5-6.5; and washing, carrying out hydrogen peroxide bleaching, and washing to obtain high-whiteness high-strength salix mongolica bleaching sulfate pulp. Under the short-time bleaching process conditions, the invention improves the bleaching property of the paper pulp, increases the bleaching yield and strength property of the paper pulp, reduces the consumption of bleaching chemical agent, lessens the environmental pollution, improves the utility value of the fast growing shrub salix mongolica sulfate pulp, and widens the application range of the salix mongolica sulfate pulp, thereby solving the resource and environment problems hampering the development of the paper making industry in China.

Owner:QILU UNIV OF TECH

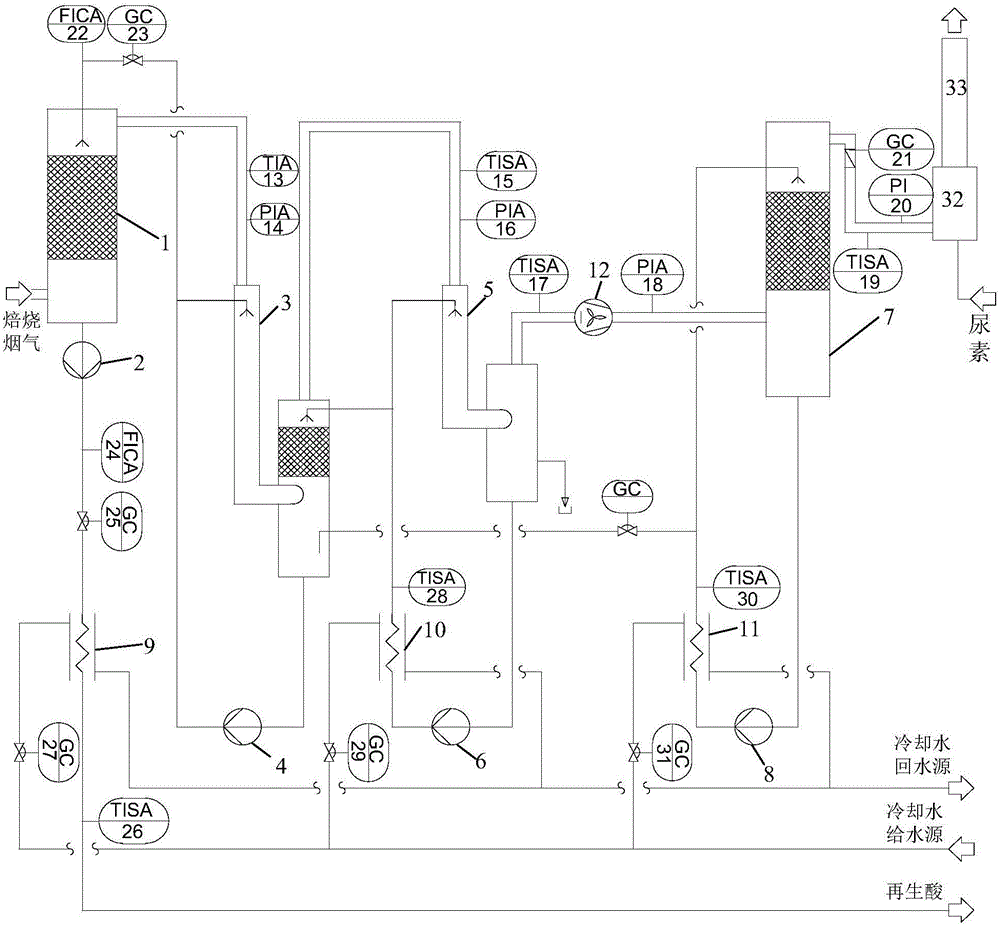

Stainless steel liquid waste regeneration system based on spray roasting method and control method thereof

ActiveCN105776385AHigh recovery rateImprove recycling effectGas treatmentUsing liquid separation agentLiquid wasteCooling tower

The invention discloses a stainless steel liquid waste regeneration system based on the spray roasting method.The system comprises an adsorption tower, a jet cleaning tower, a spray cooling tower, an oxidizing tower and a denitration device which are connected in sequence, wherein a spray liquid outlet of the jet cleaning tower is communicated with a first spray liquid inlet of the jet cleaning tower and a spray liquid inlet of the adsorption tower through pipelines, a spray liquid outlet of the spray cooling tower is communicated with a spray liquid inlet of the spray cooling tower and a second spray liquid inlet of the jet cleaning tower through pipelines, a spray liquid outlet of the oxidizing tower is communicated with a spray liquid inlet of the oxidizing tower and a chamber of the jet cleaning tower through pipelines, a jet cleaning pump is installed on a pipeline at the position of the spray liquid outlet of the jet cleaning tower, a spray cooling pump and a spray cooling circulating liquid cooler are installed on a pipeline at the position of the spray liquid outlet of the spray cooling tower, and an oxidizing tower pump and an oxidizing tower circulating liquid cooler are installed on a pipeline at the position of the spray liquid outlet of the oxidizing tower.By the adoption of the system, HNO3 recovery rate is increased.

Owner:WISDRI ENG & RES INC LTD

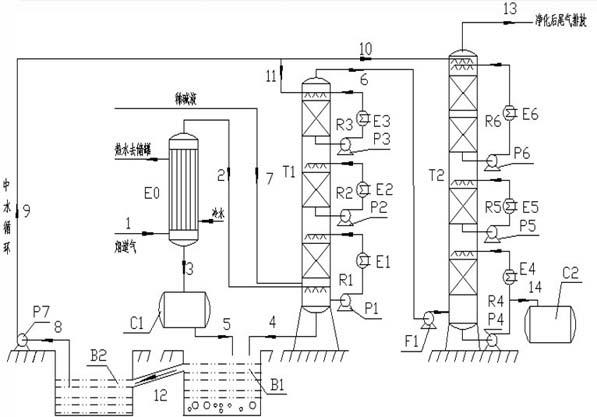

High-efficiency low-cost purification process of flue gas

InactiveCN102600708AReduce the amount requiredFull recoveryDispersed particle separationLiquid wasteHazardous substance

The invention provides a high-efficiency low-cost purification process of flue gas. The process comprises a heat exchange system, a comprehensive cleaning system, a denitration system and a waste liquid treatment system, wherein the comprehensive cleaning system is a comprehensive cleaning tower T1 consisting of 2 to 5 circular cleaning loops, the cleaning solution in the first circular cleaning loop is diluted alkaline solution, and the cleaning solutions in subsequent circular cleaning loops is water, the cleaning solution after cleaning is recycled after neutralization and biochemical treatment, and the sludge generated after treatment is cleaned and detoxified regularly; and the denitration system is a denitrition tower T2 consisting of 2 to 4 circular absorption loops, the circular absorption solution is water, and the absorption solution after NOX is absorbed is diluted nitric acid which can be directly sold or used. The contents of various toxic and harmful substances in the flue gas emitted from the top of the denitration tower T2 can be respectively controlled to be that SOx is less than or equal to 5mg / m<3>, NOx is less than or equal to 50mg / m<3>, HCl is less than or equal to 5mg / m<3>, HF is less than or equal to 1mg / <3>, HBr is less than or equal to 1mg / m<3>, solid particles are less than or equal to 3mg / m<3>, and dioxin (DOX) is less than of equal to 0.001TEQng / m<3>, which are far superior to the emission standard of related flue gas of America, European Union and China.

Owner:NANJING UNIV

Printing and dyeing wastewater grading treatment method

InactiveCN104386798AReduce pollution loadPromote emission standardsWater contaminantsMultistage water/sewage treatmentRare earthWater quality

The invention provides a printing and dyeing wastewater grading treatment method which is characterized by comprising the following steps: independently treating concentrated wastewater of which the COD value is 8000-50000mg / L and the pH value is 13-14 in printing and dyeing wastewater without regulating the pH value, and directly performing rare-earth catalyzed oxidation for 0.5-8 hours under the aeration condition, wherein a rare-earth catalyzed oxidizing agent is added into a rare-earth catalyzed oxidation pool; standing, naturally settling and separating so as to obtain effluent, or adding 0.015-0.030 percent of XSD accelerant, carrying out an aeration reaction for 0.5-2 hours, adding a coagulant for carrying out a coagulation reaction, and separating to obtain the effluent, wherein the COD value is less than or equal to 200mg / L, and the requirement on the discharged centralized sewage treatment plant in the textile dyeing industrial water pollutant discharge standard of GB4287-2013 is met. The fresh wastewater is subjected to rare-earth catalyzed oxidation treatment and is separated for recycling, the textile dyeing industrial recycled water quality standard of FZ / T01107-2011 is met, the reuse rate is 85 percent, and the amount of discharged wastewater and the total amount of discharged pollutants in the printing and dyeing mill are greatly reduced.

Owner:DONGHUA UNIV +1

Treating preparation suitable for high-concentration nondegradable wastewater

InactiveCN105198161APromote degradationHigh activityMultistage water/sewage treatmentWaste water treatment from food industryHigh concentrationPaenibacillus polymyxa

The invention relates to a treating preparation suitable for high-concentration nondegradable wastewater, which is prepared by mixing aerobic denitrifying bacterium, Paenibacillus polymyxa, Aspergillus niger, Rhodococcus, Bacillus foecalis alkaligenes, Streptomyces lateritius, Candida albicans, nitrococcus and an adsorbent carrier. The preparation contains multiple microbes having favorable degradation capacity for nondegradable pollutants; and due to the reasonable proportioning of the strains, the preparation has favorable degradation effect and has wide application prospects.

Owner:尤新军

Biological preparation for treating sodium glutamate fermentation sewage

ActiveCN105906169AReduce dosageShorten the timeTreatment using aerobic processesWater contaminantsBiotechnologyMonosodium glutamate

The invention relates to a biological preparation for treating sodium glutamate fermentation sewage. The biological preparation comprises a physical preparation and a complex microbial agent, wherein the complex microbial agent comprises the following components in parts by weight: 4-5 parts of Azotobacter chroococcum, 4-5 parts of phanerochaete chrysosporium, 5-6 parts of Bacillus amyloliquefaciens, 4-6 parts of Clostridium papyrosolvens, 3-4 parts of penicillium ochrochlorron, 3-4 parts of Pseudomonas aeruginosa and 2-3 parts of bacillus cereus. The biological preparation contains multiple microorganisms having excellent degradation capacity to non-biodegradable pollutants, and by virtue of reasonable compatibility of the strains, the good degradation effect is achieved, and the application prospect of the biological preparation is wide.

Owner:内蒙古阜丰生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com