Integrated lightweight filter-material water treatment filter tank

A light-weight filter material and water treatment technology, applied in the direction of adsorption water/sewage treatment, loose filter material filter, filtration separation, etc., can solve the problems of high operating cost, affecting the quality of effluent water, and large investment costs, etc., to achieve Reduce equipment investment and use costs, facilitate promotion and use, and reduce floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

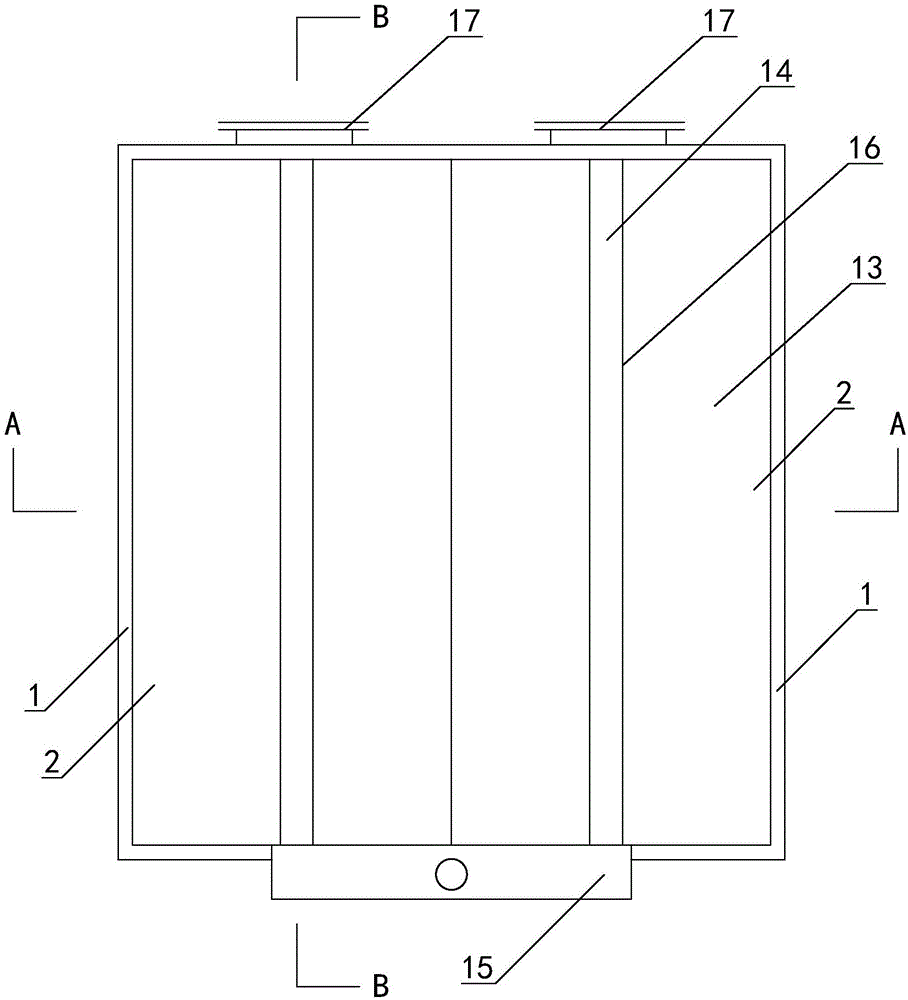

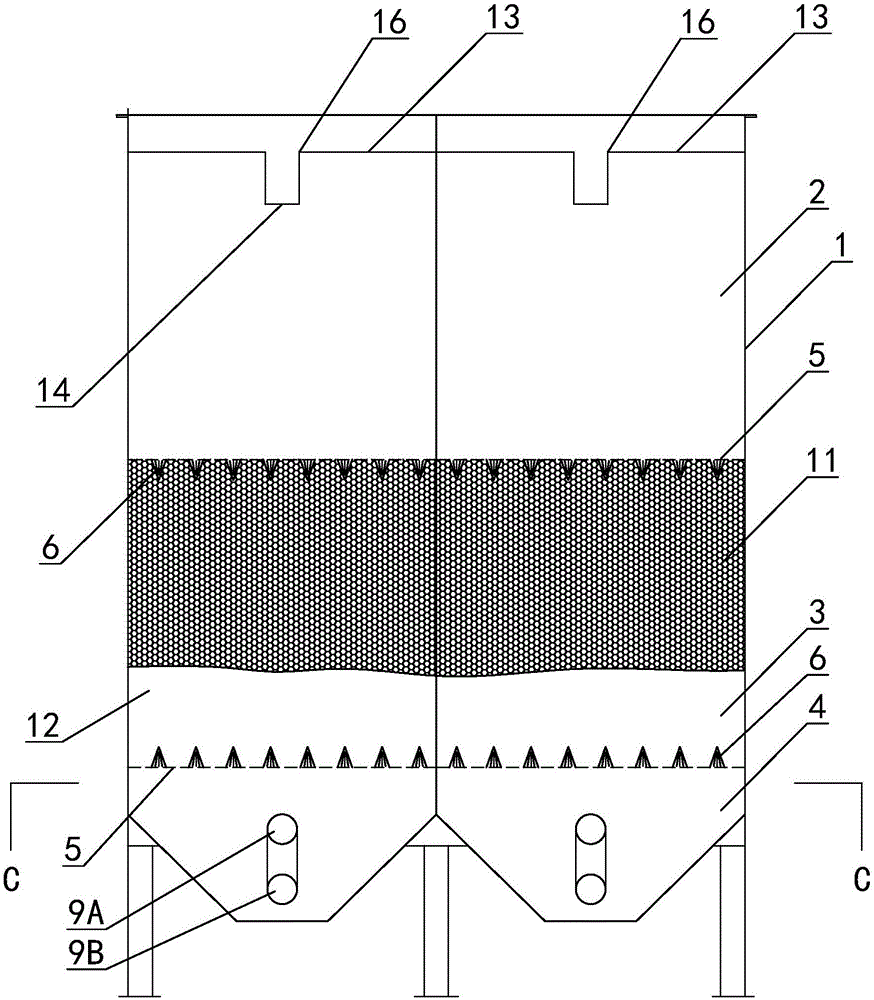

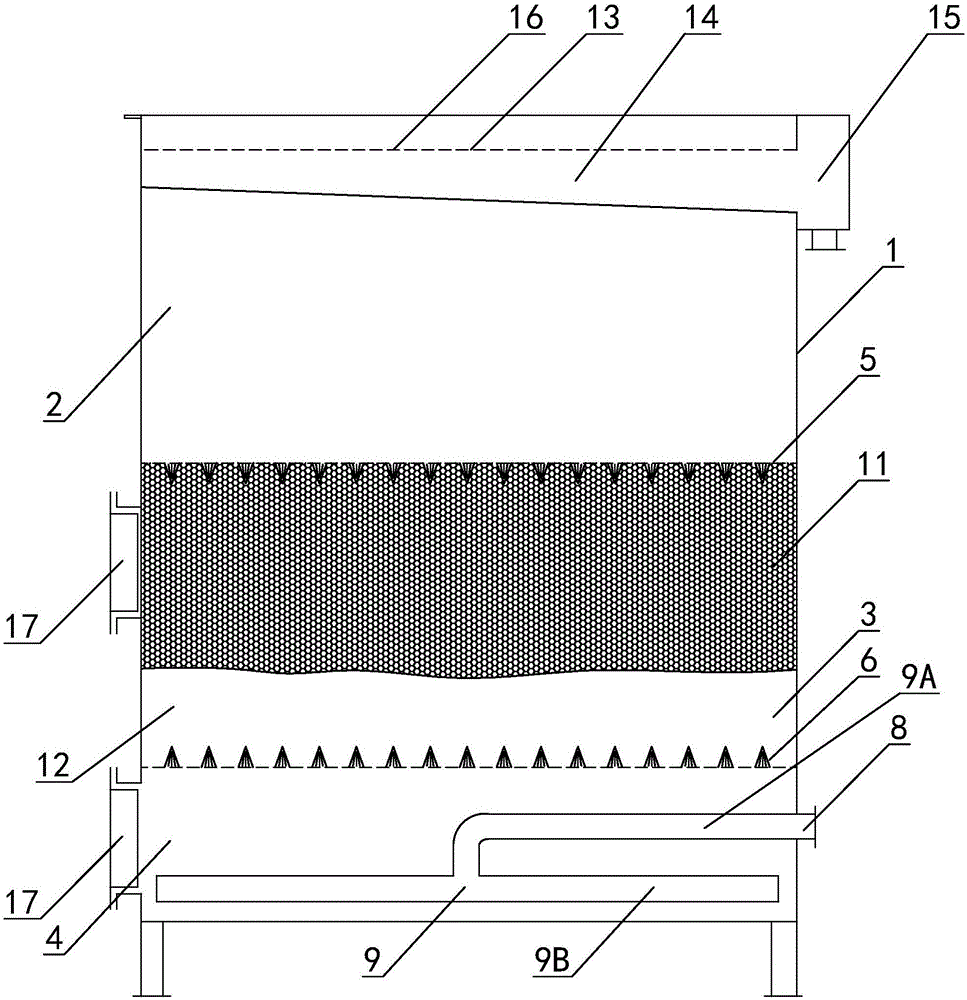

[0066] Example: see attached Figure 1~6 As shown, the integrated lightweight filter material water treatment filter includes two water treatment units arranged side by side. Each of the water treatment units includes a pool body 1, and the pool body 1 is connected from top to bottom by a clear water area 2 that communicates with each other. , Filtration area 3 and water intake area 4 constitute.

[0067] Wherein, between the clean water area 2 and the filter area 3, between the filter area 3 and the water inlet area 4, all are separated by a filter plate 5, and the filter plate 5 is formed by a plate body and is evenly distributed on the It consists of a plurality of filter heads 6 (commonly known as water caps) on the plate body; the filter head 6 includes a filter cap 61 and a water inlet 62 arranged in communication, and the filter cap 61 is arranged on the filter plate 5 and is located in the filter area 3 One side of the water inlet 62 is located on the filter plate 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com