Method for preparing acetylated distarch phosphate modified starch

A technology of distarch phosphate and modified starch is applied in the field of preparation of acetylated distarch phosphate modified starch, and can solve the problems of easy aging, poor freeze-thaw stability, poor film-forming and transparency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

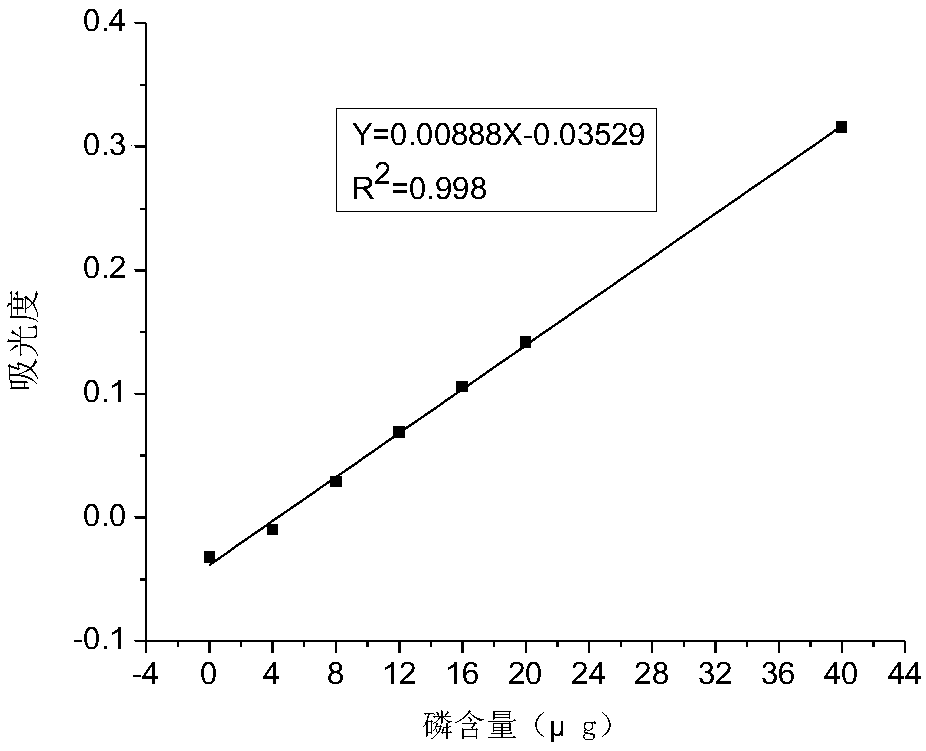

Image

Examples

preparation example Construction

[0030] The preparation method of acetylated distarch phosphate modified starch of the present invention comprises the following steps:

[0031] (1) get waxy cornstarch and add distilled water and mix, and the starch emulsion that makes mass concentration is 40wt%;

[0032] (2) adjust the pH value of the starch emulsion to a set pH value with 3wt% sodium hydroxide solution, and add a selected amount of sodium trimetaphosphate (in terms of the dry basis content of the starch) as a cross-linking agent. Carry out the crosslinking reaction at a specified temperature for a period of time;

[0033] (3) After the cross-linking reaction is finished, adjust the pH value of the reaction solution to 8.0-8.5 with 0.5mol / L hydrochloric acid solution, and then add a selected amount of acetic anhydride (in terms of the dry content of the starch) in the reaction solution as an ester The esterification agent is carried out at a specified temperature for a period of time, and 3% sodium hydroxid...

Embodiment 1-29

[0037] In above-mentioned embodiment 1-28, the addition amount of described crosslinking agent, the temperature of described crosslinking reaction setting, pH value, reaction time, and the addition amount of described esterification agent, the setting temperature of described esterification reaction The temperature and reaction time are shown in Table 1 below.

[0038] The reaction condition setting of table 1 embodiment 1-29

[0039]

[0040]

Embodiment 29

[0042] The preparation method of the acetylated distarch phosphate modified starch described in the present embodiment comprises the following steps:

[0043] (1) get waxy cornstarch and add distilled water and mix, and the starch emulsion that makes mass concentration is 30wt%;

[0044] (2) Regulate the pH value of the starch emulsion with 2wt% sodium hydroxide solution to be 10, and add sodium trimetaphosphate that accounts for 7wt% of the dry basis content of the starch as a crosslinking agent, and carry out crosslinking at 40°C Link reaction 2h;

[0045] (3) After the cross-linking reaction is finished, adjust the pH value of the reaction solution to 8.0-8.5 with 0.4mol / L hydrochloric acid solution, then add acetic anhydride accounting for 3wt% of the dry basis content of the starch as an esterifying agent in the reaction solution, The esterification reaction was carried out at 25°C for 1.5 hours, and 2% sodium hydroxide solution was added dropwise during the reaction to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com