Dust and waste gas cleaning and dedusting system

A technology of dust removal system and waste gas, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve the problems of reducing the cleaning efficiency of waste gas, unable to replace the dust removal system of dust and waste gas, affecting normal cleaning and dust removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

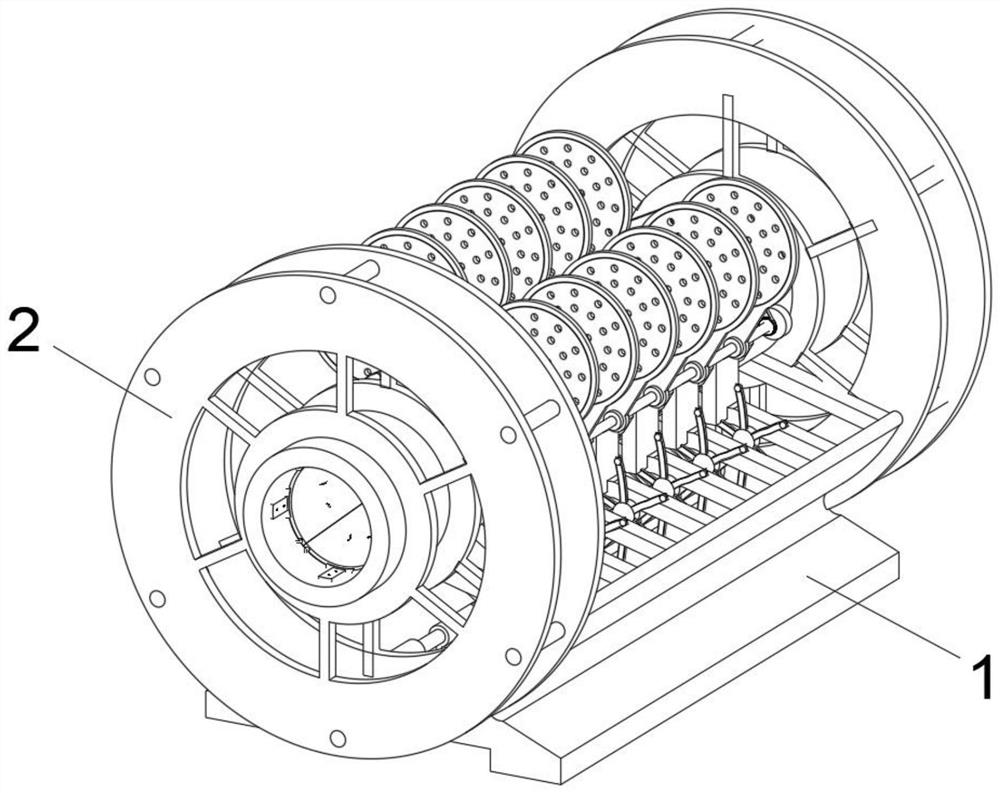

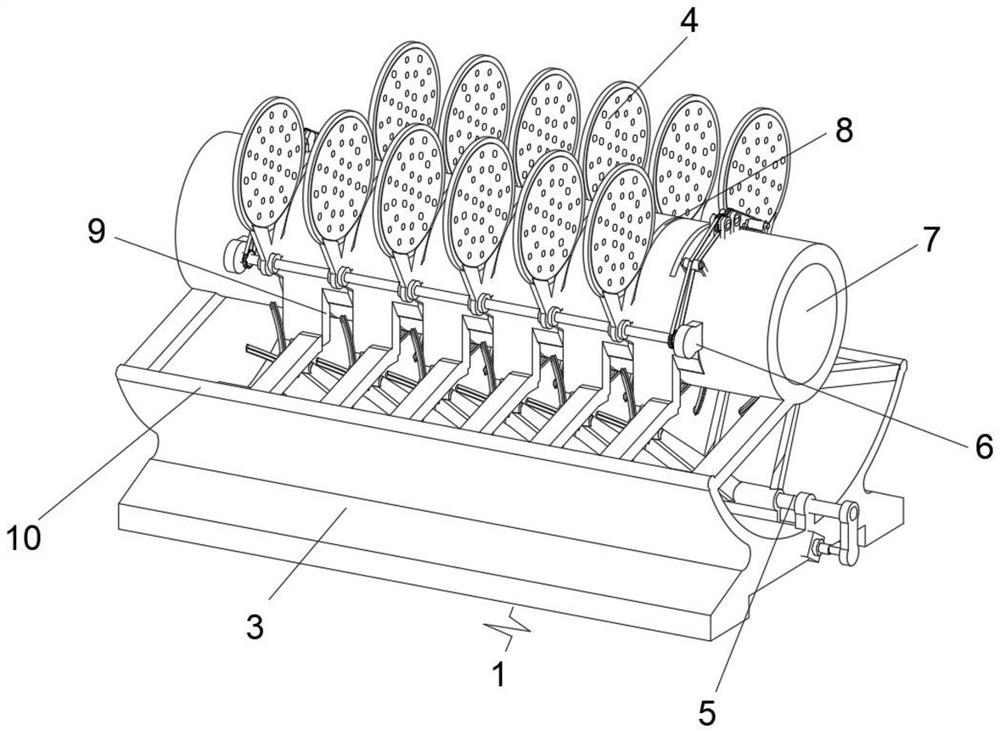

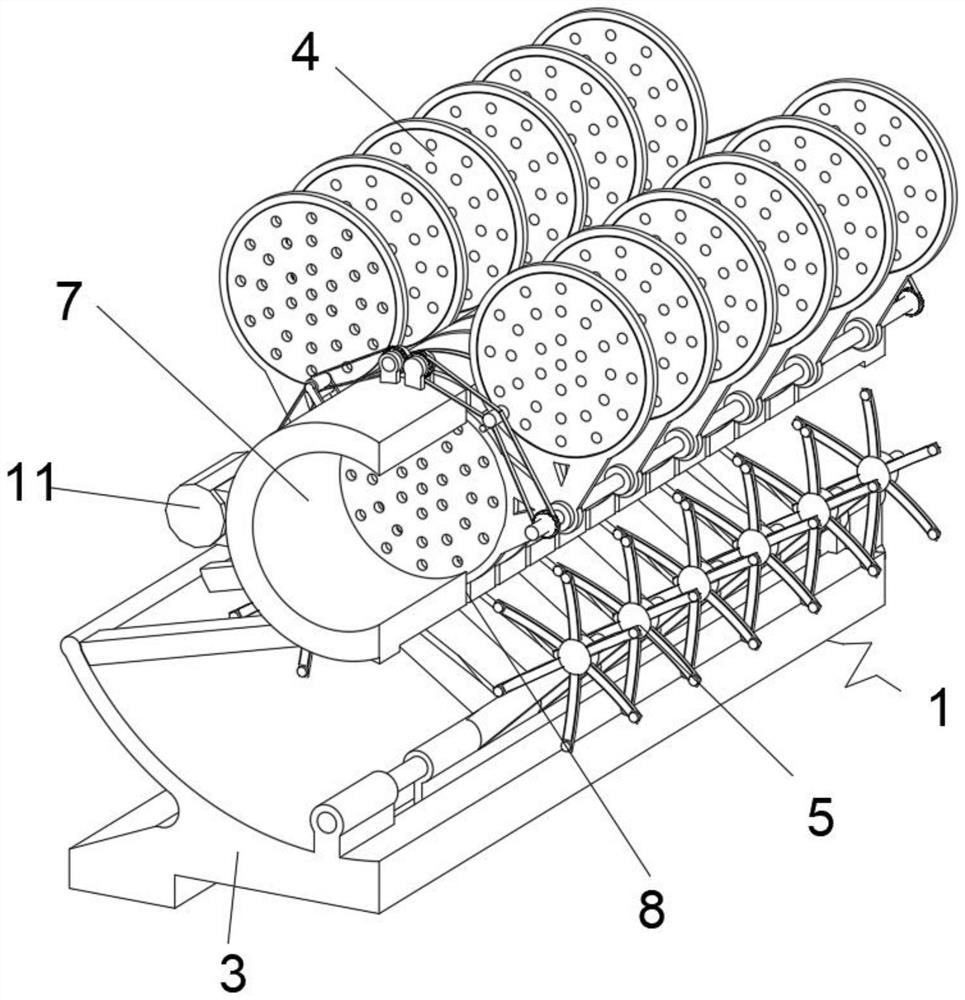

[0030] see Figure 1-7 , an embodiment provided by the present invention: a dust and waste gas cleaning and dedusting system, including a waste gas conveying device 1 and a waste gas flow control device 2, the waste gas flow control device 2 is fixedly installed on both ends of the waste gas conveying device 1, and the waste gas conveying device 1 The inside includes support seat 3, dust removal device 4, control device 5, bearing seat 6, exhaust gas pipe 7, socket slot 8, groove 9, arc plate 10 and drive motor 11, arc plate 10 is welded symmetrically on the support seat 3, the control device 5 is slidably installed on the center of the upper surface of the support base 3, the exhaust gas pipeline 7 is welded on the top surface center of the support base 3, and the bearing housing 6 is symmetrically welded on the outer surface of the two ends of the exhaust gas pipeline 7, plugged in Grooves 8 are evenly opened on the outer surface of the exhaust gas pipeline 7, the dust remov...

Embodiment 2

[0039] On the basis of Example 1, such as Figure 8 As shown, the inside of the support base 3 also includes a drainage groove 33 and a collecting plate 34. The drainage groove 33 is provided on both sides of the center of the upper surface of the support base 3.

[0040] During the implementation of this embodiment, the control device 5 will slide laterally to push and drop the used waste gas pipe 7 to the inside of the support seat 3, and the dust on the surface will fall when the filter plate 21 falls, so that the collecting plate 34 Collect the falling dust to prevent the dust from scattering and polluting the environment.

[0041] Working principle: When dedusting the exhaust gas, it is necessary to pass the exhaust gas into the interior of the exhaust gas pipeline 7, so that the exhaust gas passes through the filter plate 21 inside the exhaust gas pipeline 7, and the particles inside the exhaust gas are filtered to clean the exhaust gas. After filtering the exhaust gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com