Cutting insert and indexable rotary cutting tool

A cutting edge and blade technology, applied in the field of edge-replaceable turning tools, can solve the problems of increased storage costs, wrong installation of blades, etc., and achieve the effects of shortened replacement work time, smooth replacement, and easy mechanical operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

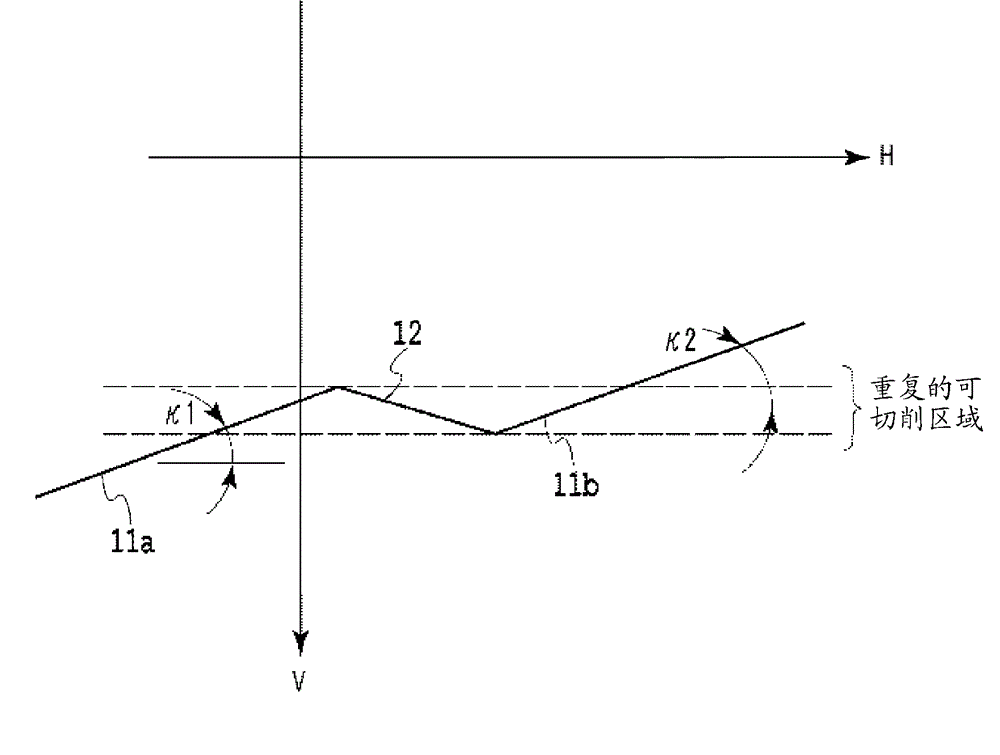

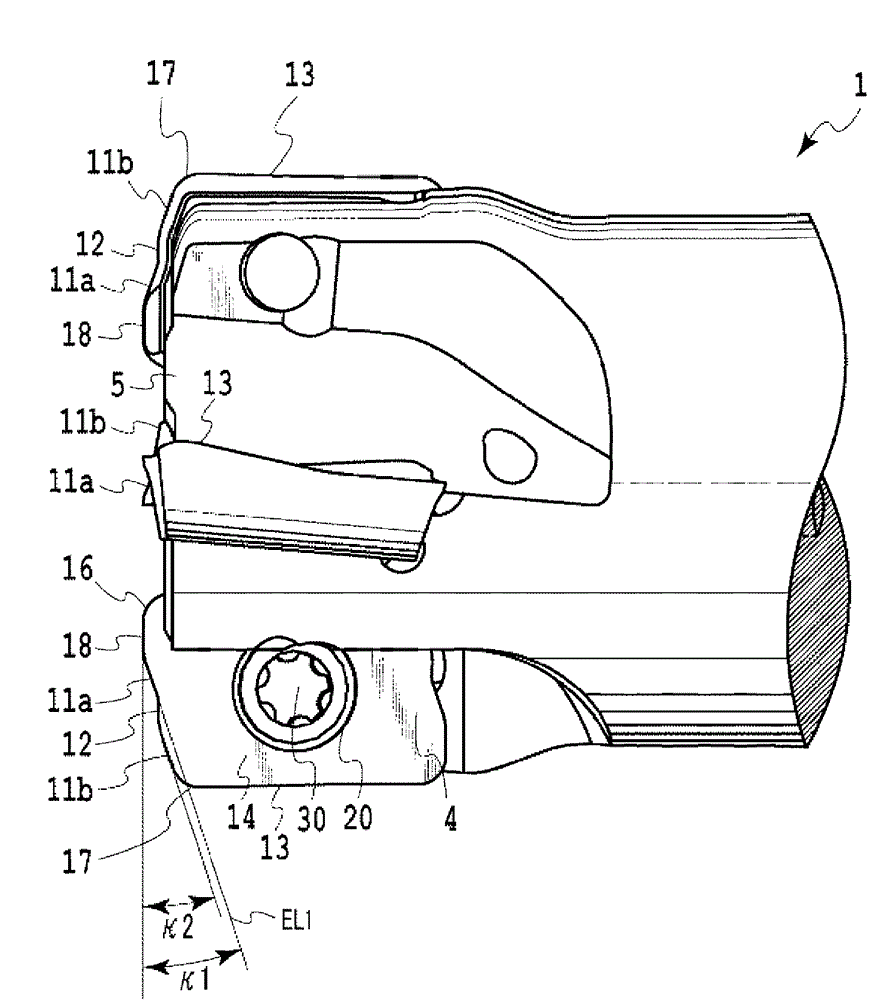

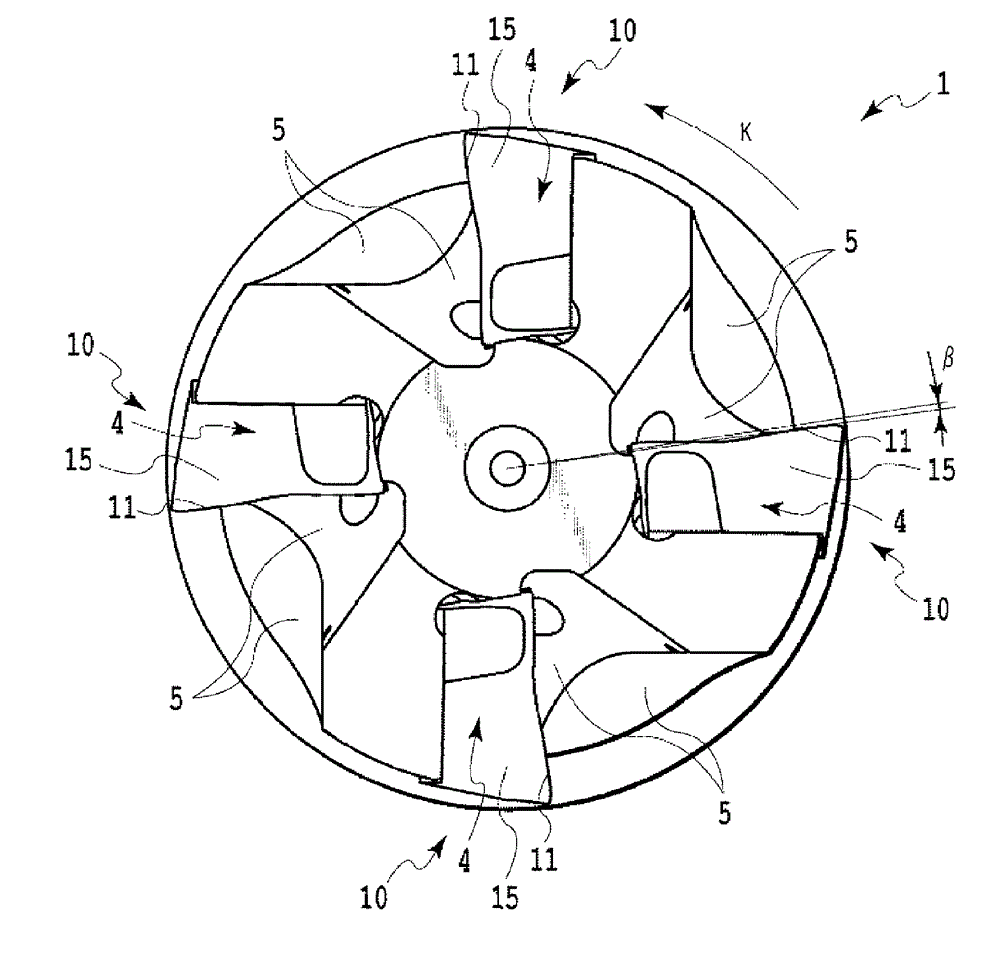

[0028] Hereinafter, an end mill according to an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a front view of the cutting insert used for this end mill. figure 2 as well as image 3 respectively figure 1 Right side view and top view of the cutting insert shown. Figure 4 yes figure 1 X-arrow view. Figure 5 yes figure 1 An enlarged view of the main cutting edge of the cutting insert. Image 6 is a front view of the end mill seen from the axial direction. Figure 7 as well as Figure 8 respectively Figure 5 The right side view and top view of the main part of the shown end mill.

[0029] The cutting insert 10 of this embodiment is as figure 1 As shown, it is in the shape of a substantially parallelogram plate, and among the opposing upper and lower surfaces, a rake surface 14 is formed on the upper surface, a seating surface 19 is formed on the lower surface, and a flank surface is formed on the side extending b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com