Patents

Literature

61results about How to "Suppression defect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drill

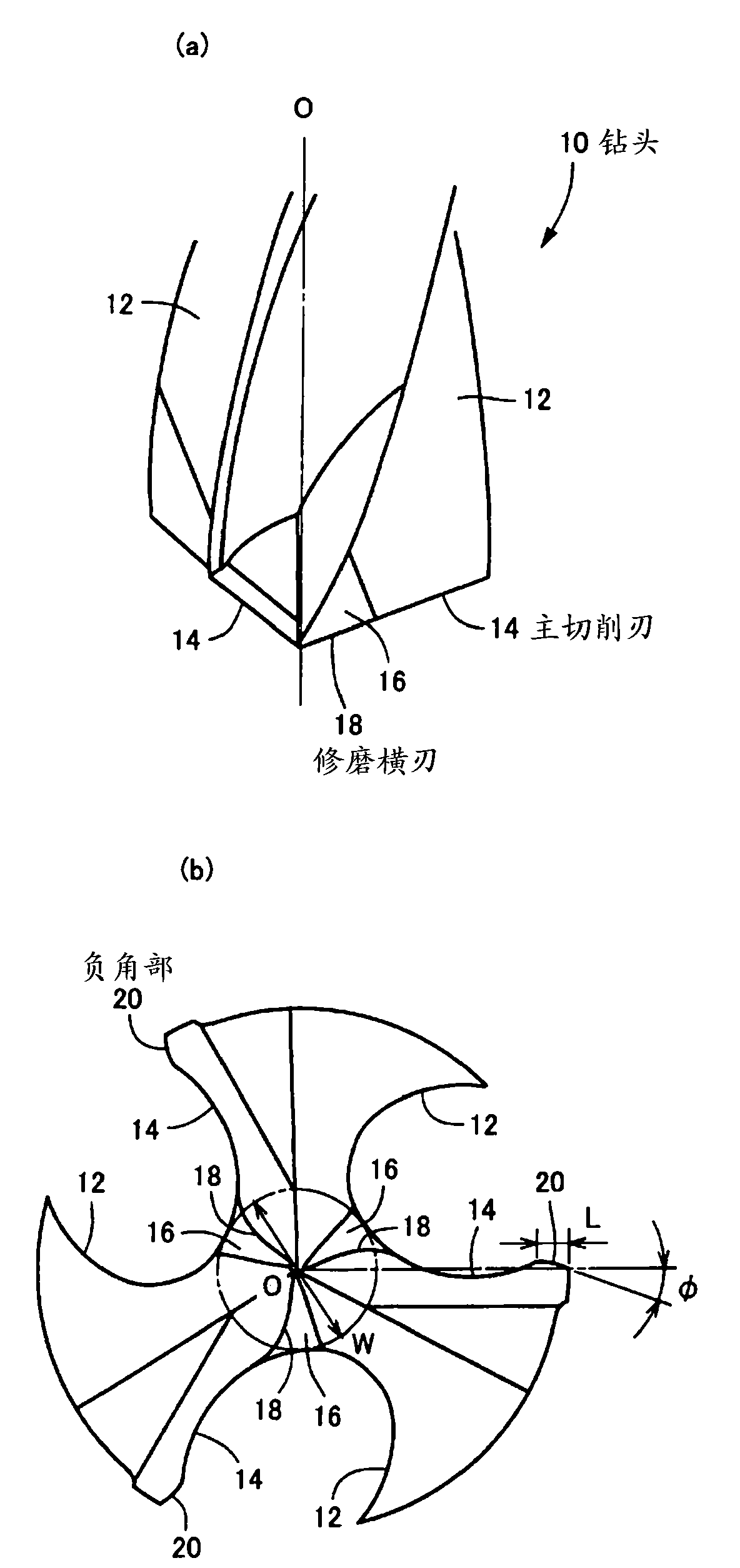

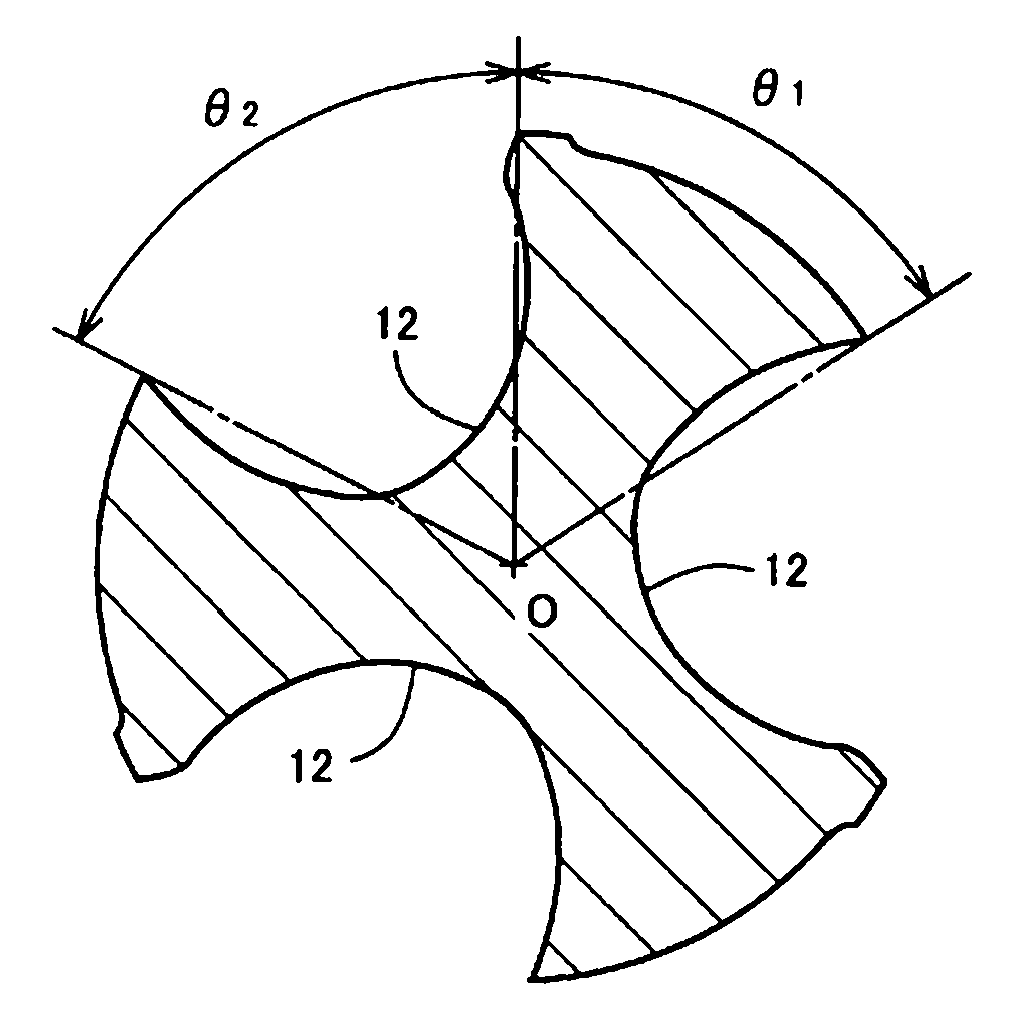

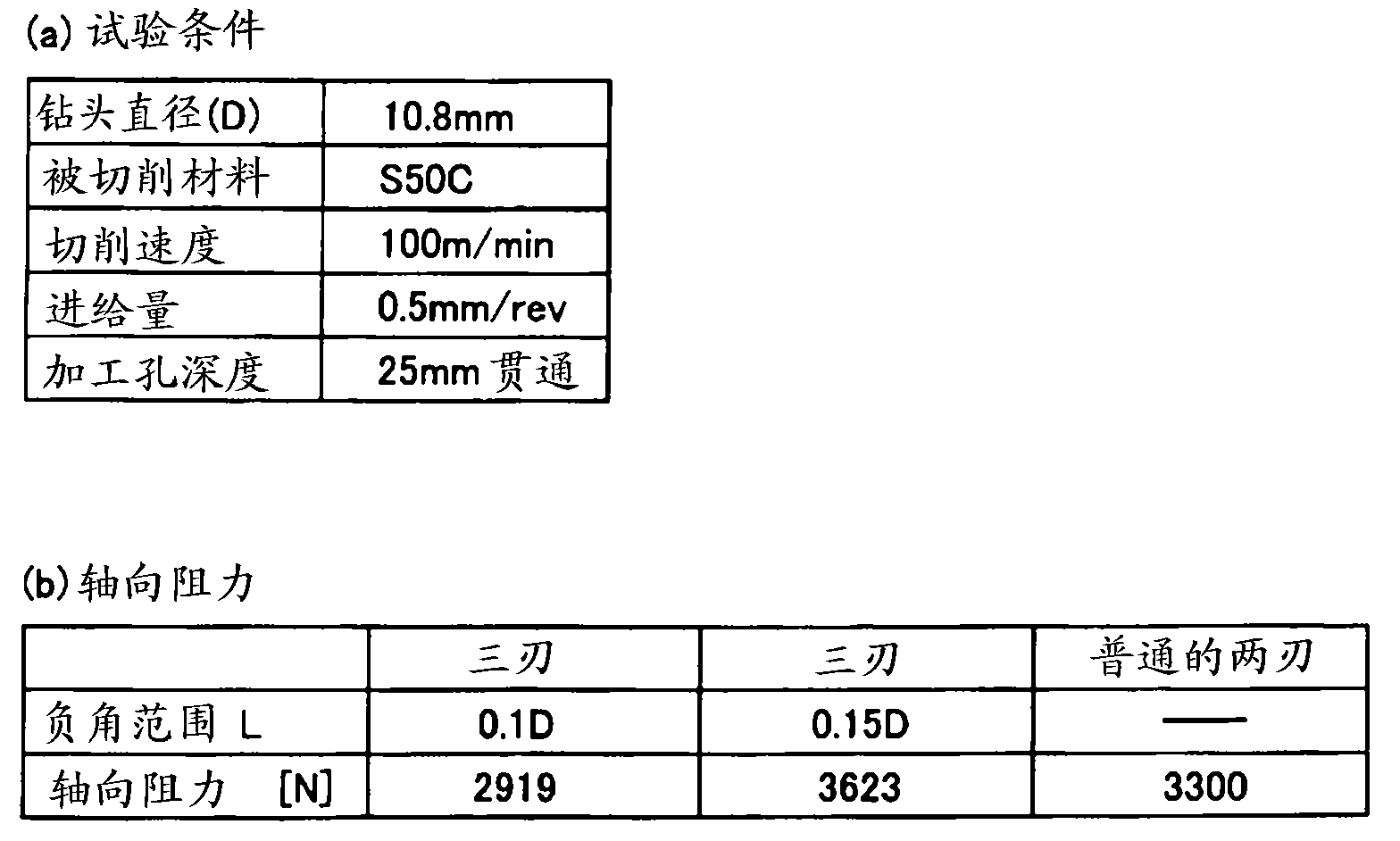

InactiveCN102170989AEasy to curlImprove discharge effectTransportation and packagingWorkpiecesEdge strengthEngineering

Owner:OSG

Cubic boron nitride sintering body cutting tool and manufacturing method of the same

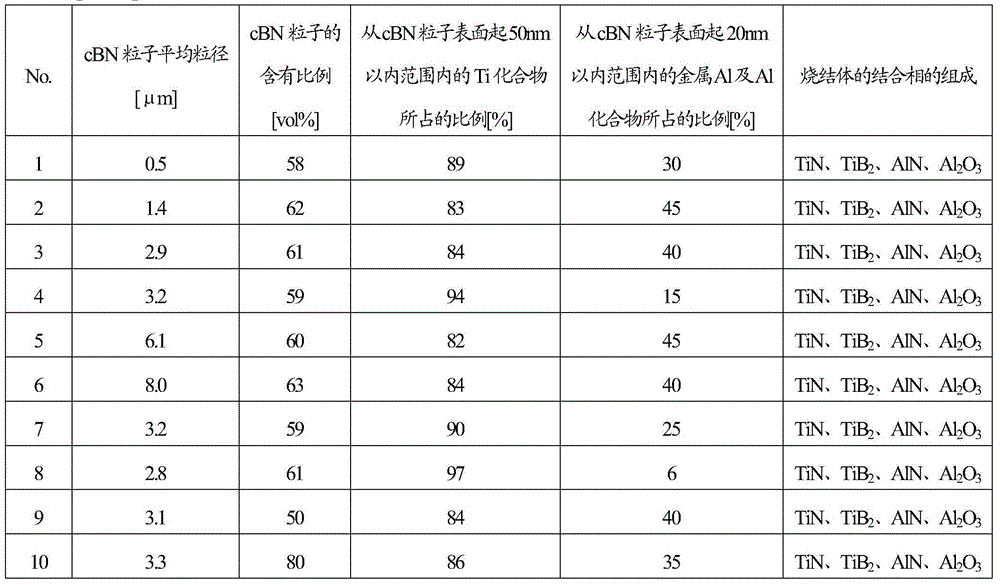

The invention provides a cubic boron nitride sintering body cutting tool that exhibits excellent defect resistance, and a manufacturing method of the same. The cutting tool is a cBN tool that still exhibits excellent defect resistance and breaking resistance even if continuously cutting and machining high-hardness steel, and that has an excellent cutting property even if being used for a long time. A sintering body comprising cubic boron nitride particles and a bonding phase serves as a tool base body of the cubic boron nitride sintering body cutting tool. Nitride, boride and oxide containing Ti and a solid solution of the nitride, boride and oxide, in an area within 50nm from the surfaces of the cubic boron nitride particles, account for more than 80vol% of the total volume of the area. In this way, the aim of the invention is achieved.

Owner:MITSUBISHI MATERIALS CORP

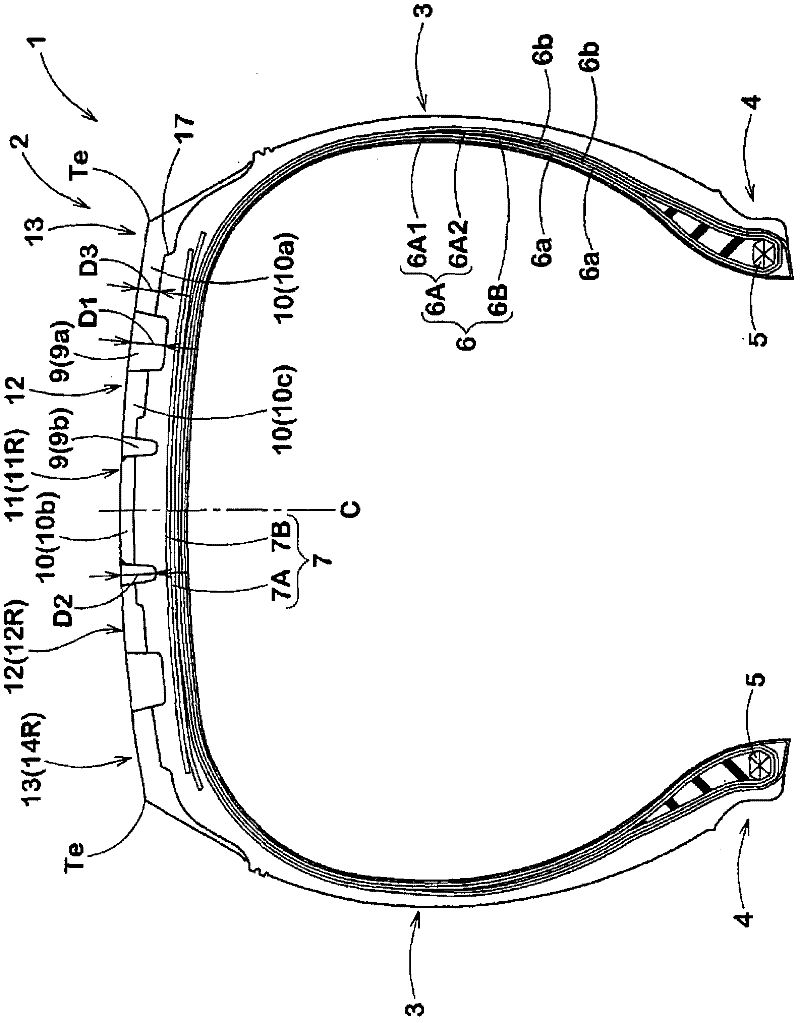

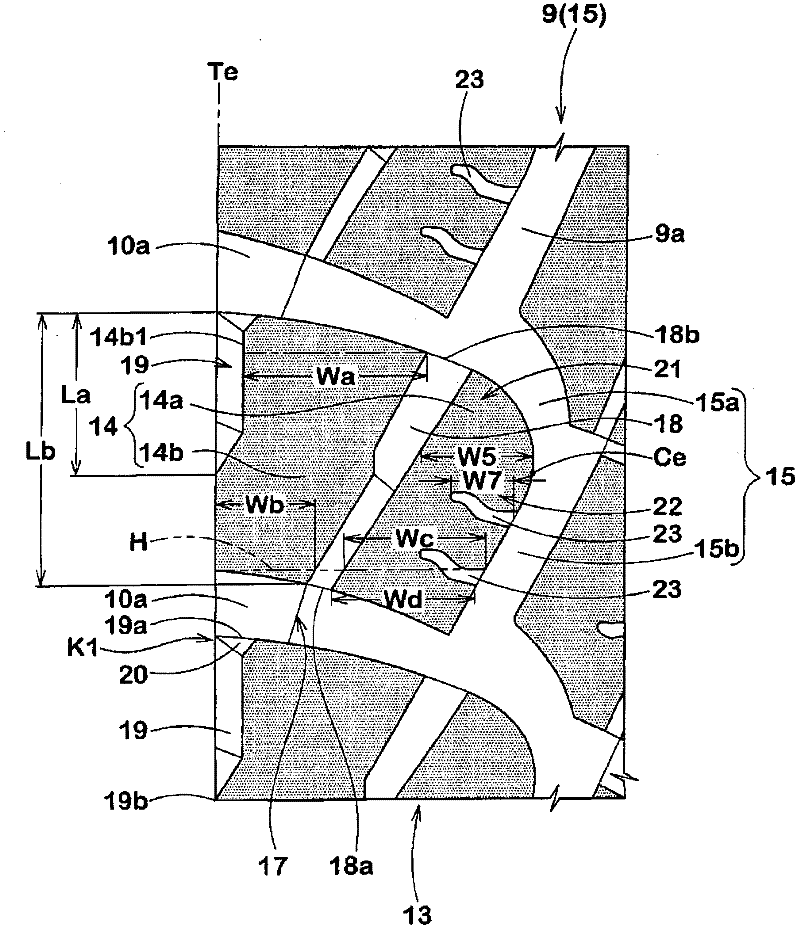

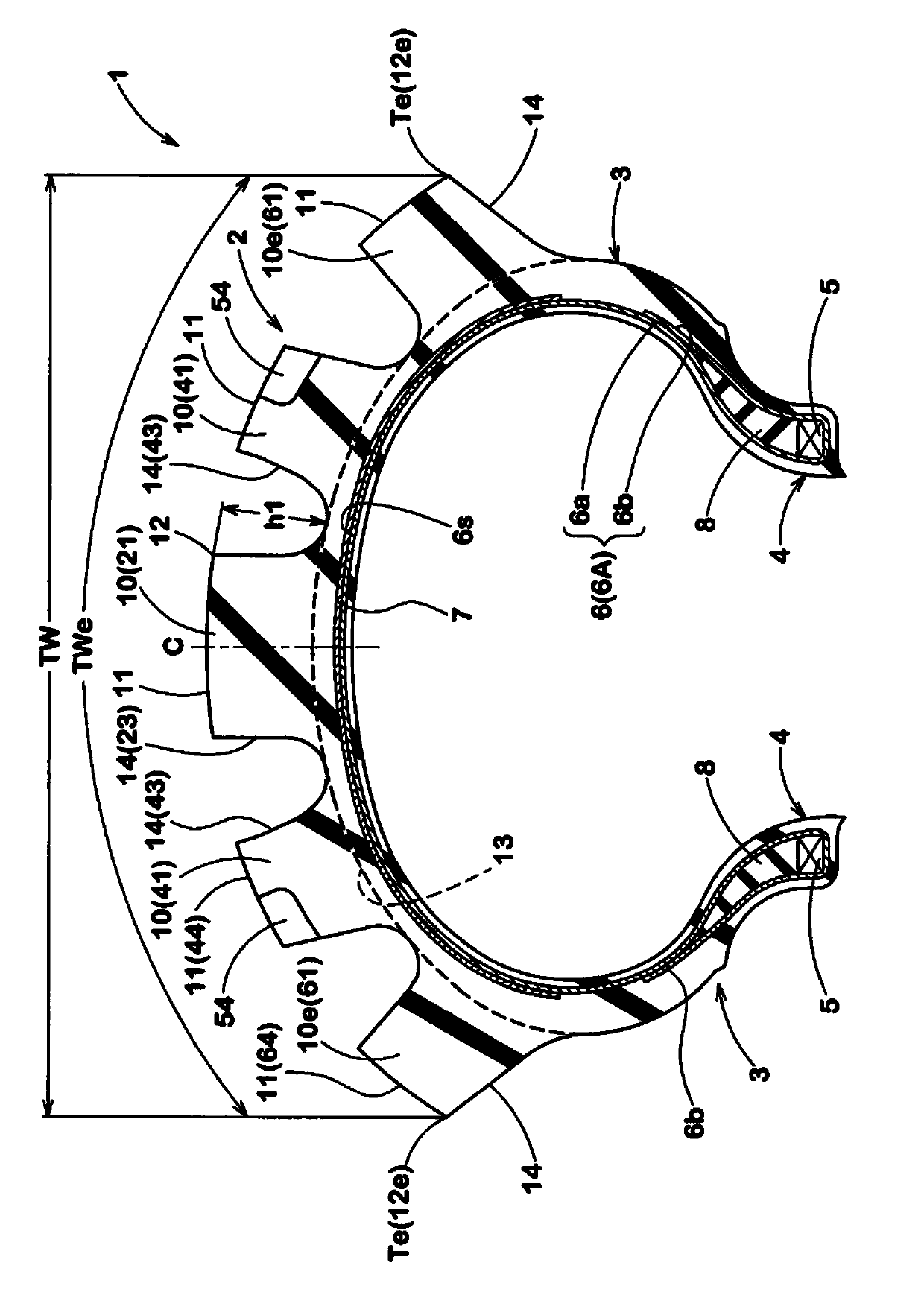

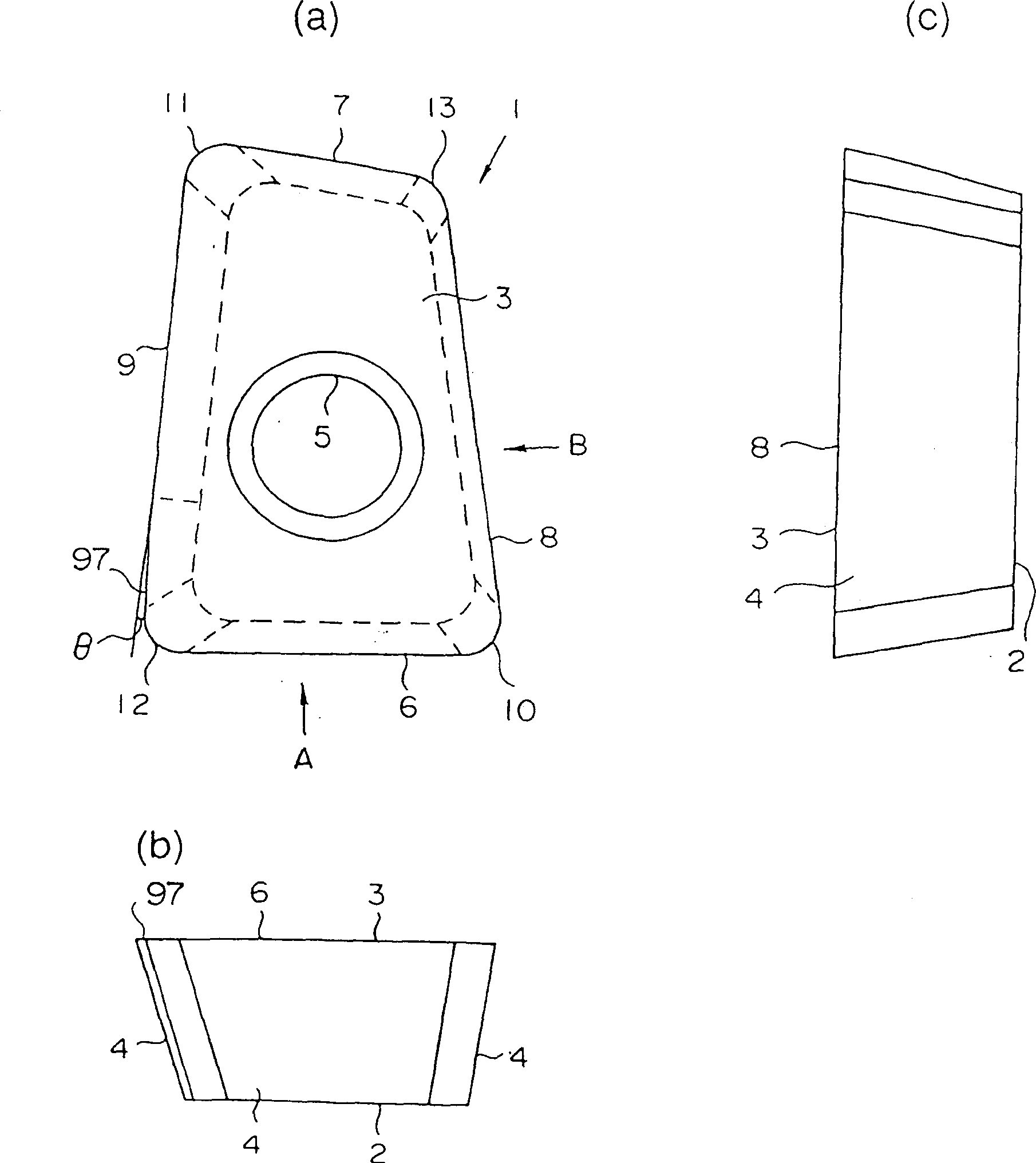

Pneumatic tire

InactiveCN102416829AImprove rigidityImprove drainage capacityTyre tread bands/patternsEngineeringTread

A pneumatic tire (1) comprises a tread portion provided along each tread edge with shoulder blocks (14) defined by a circumferentially extending shoulder main groove (9a) and shoulder lateral grooves (10a) extending from the shoulder main groove to the tread edge. The shoulder main groove (9a) is made up of groove segments (15) curved convexly toward the tire equator. The shoulder lateral grooves (10a) extend at 45 to 90 degrees with respect to the tire circumferential direction, and are coupled with the first inclined parts (15a) of the groove segments (15). The shoulder blocks (18) are each subdivided by a shoulder sub groove extending at an angle of from 15 to 45 degrees with respect to the tire circumferential direction. The shoulder sub groove has an axially outer end (18a) connected with the shoulder lateral groove (10a) and an axially inner end (18b) coupled with the second inclined part (15b).

Owner:SUMITOMO RUBBER IND LTD

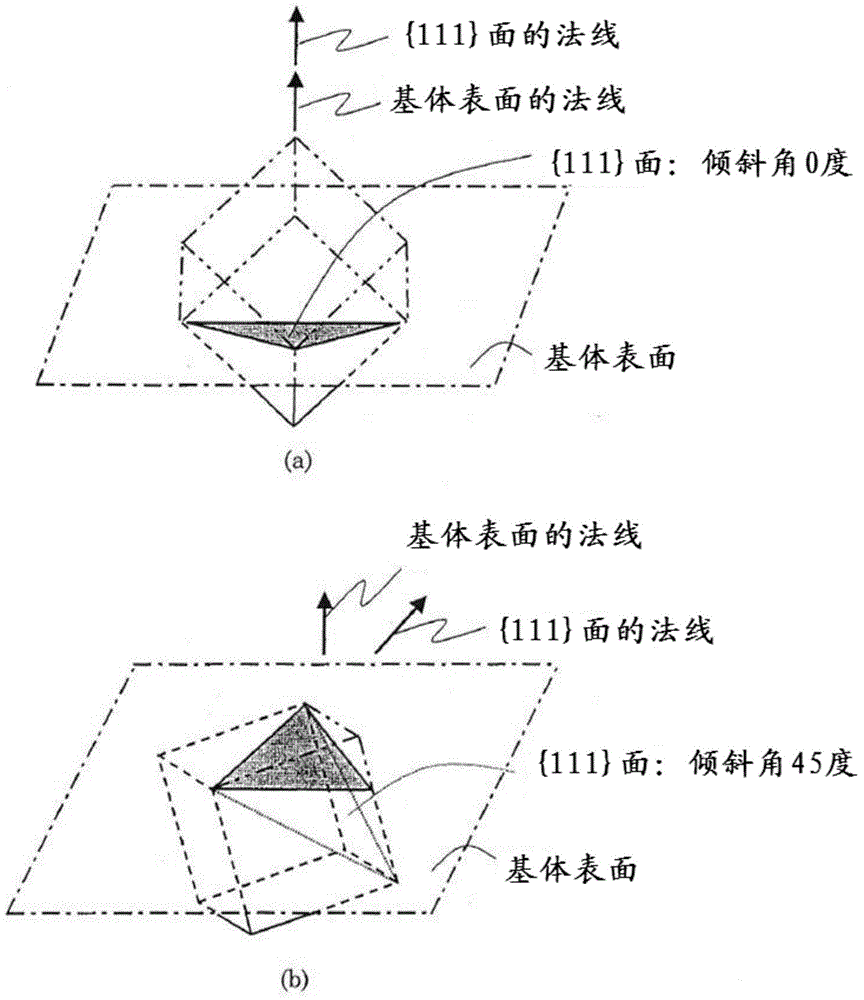

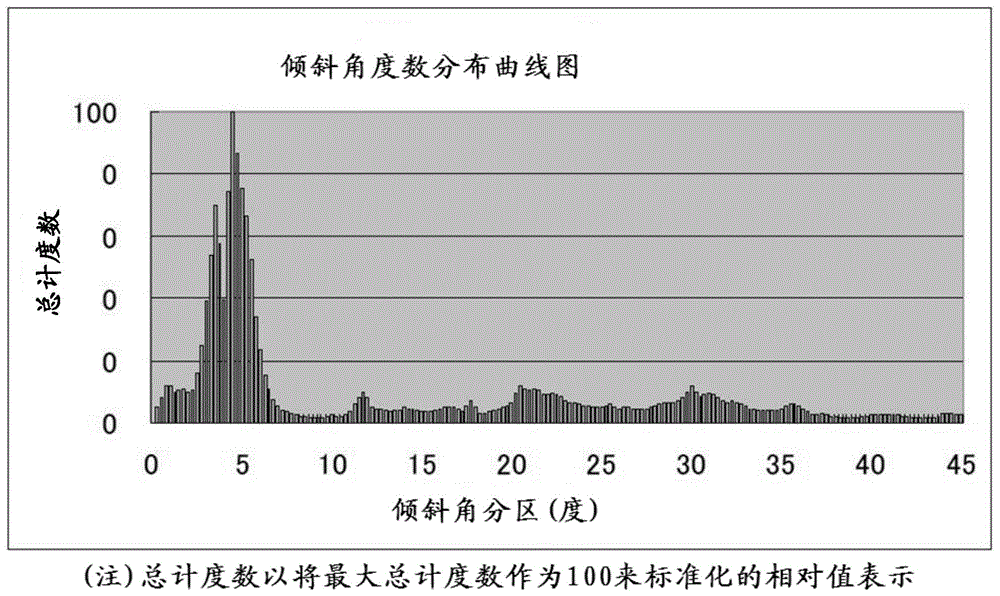

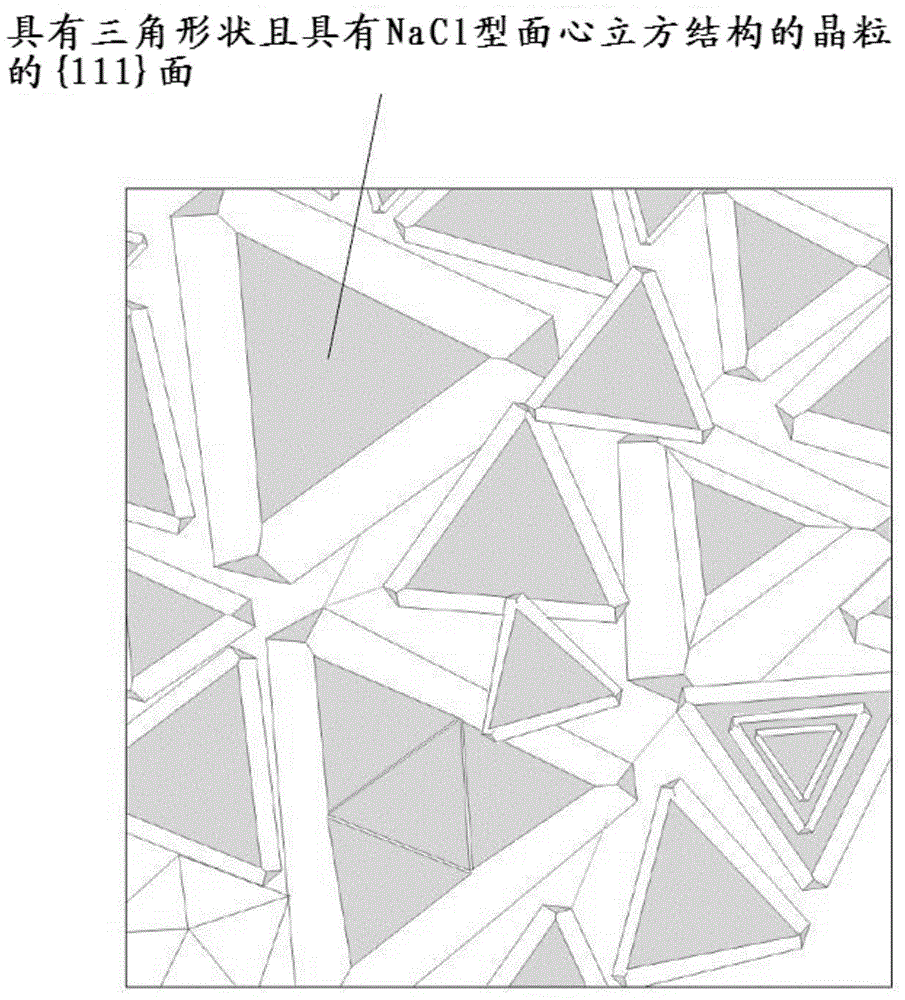

A surface coating cutting tool

ActiveCN104816141ASuppresses chippingSuppression defectChemical vapor deposition coatingEvaporationScanning electron microscope

The invention provides a surface coating cutting tool. An average proportion X[avg] of A1 and an average proportion Y[avg] of C of a (Ti[1-X]A1[X])(C[Y]N[1-Y]) layer, of which film formation is realized through chemical evaporation with A1(CH3) as reaction gases on the surface of a substrate, wherein (Xavg and Yavg are both atomic ratios), satisfy 0.60<= X[avg]<=0.95 and 0<= Y[avg]<=0.005. Crystalline grains having cubic crystalline structures exist in crystalline grains forming complex nitrides or a layer of the complex nitrides. In measurement of distribution of degrees of inclination angles of an inclination angle between a normal of surfaces of crystalline grains (111) and the surface of the substrate, a degree ratio in a scope of 0-12 degrees is more than 45% of all the degrees. When a scanning electron microscope is used to observe organizations from the surface sides of the complex nitrides or the layer of the complex nitrides, the crystalline grains having the c cubic crystalline structures have triangular shapes in surfaces perpendicular to a layer thickness direction. A facet formed by an equivalent crystalline plane expressed by (111) of the crystalline grains accounts for an area proportion of more than 35% in the surface perpendicular to the layer thickness direction.

Owner:MITSUBISHI MATERIALS CORP

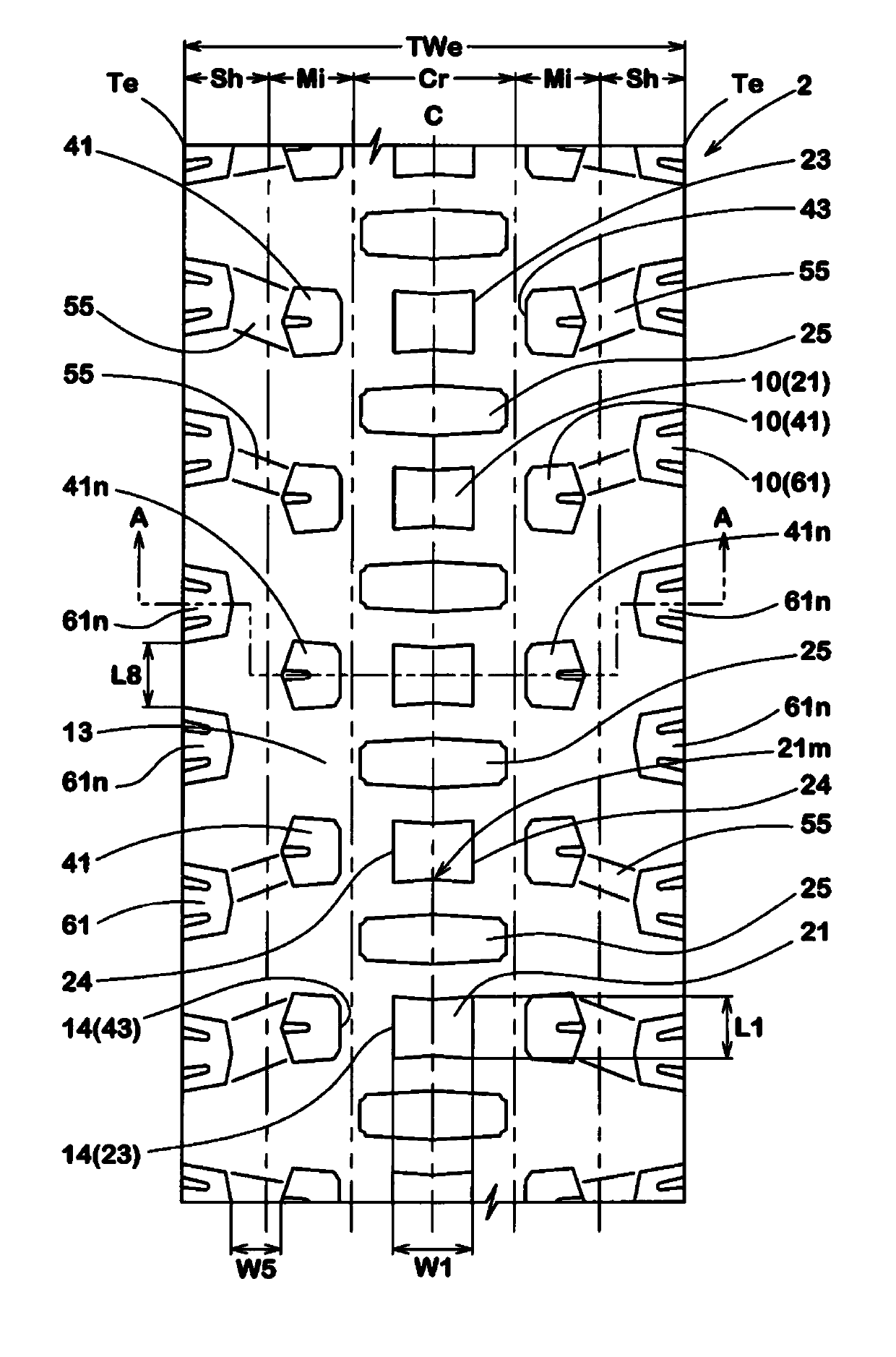

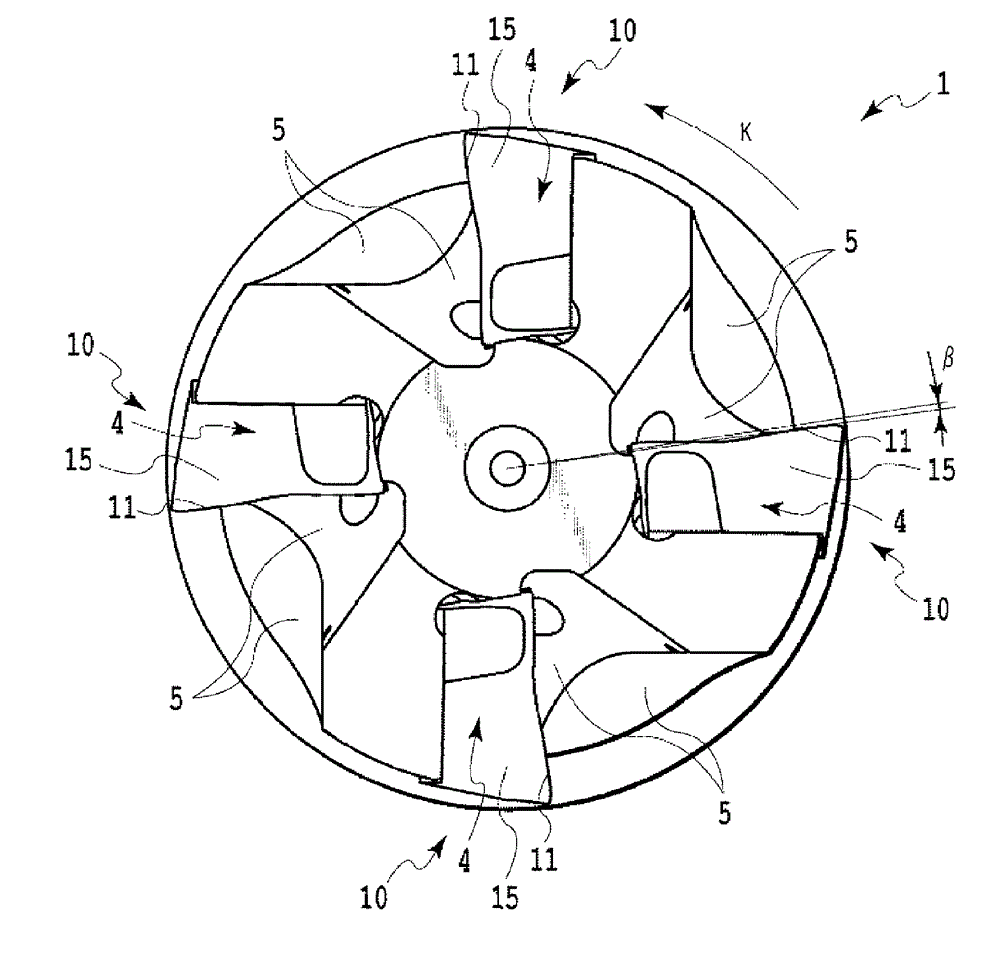

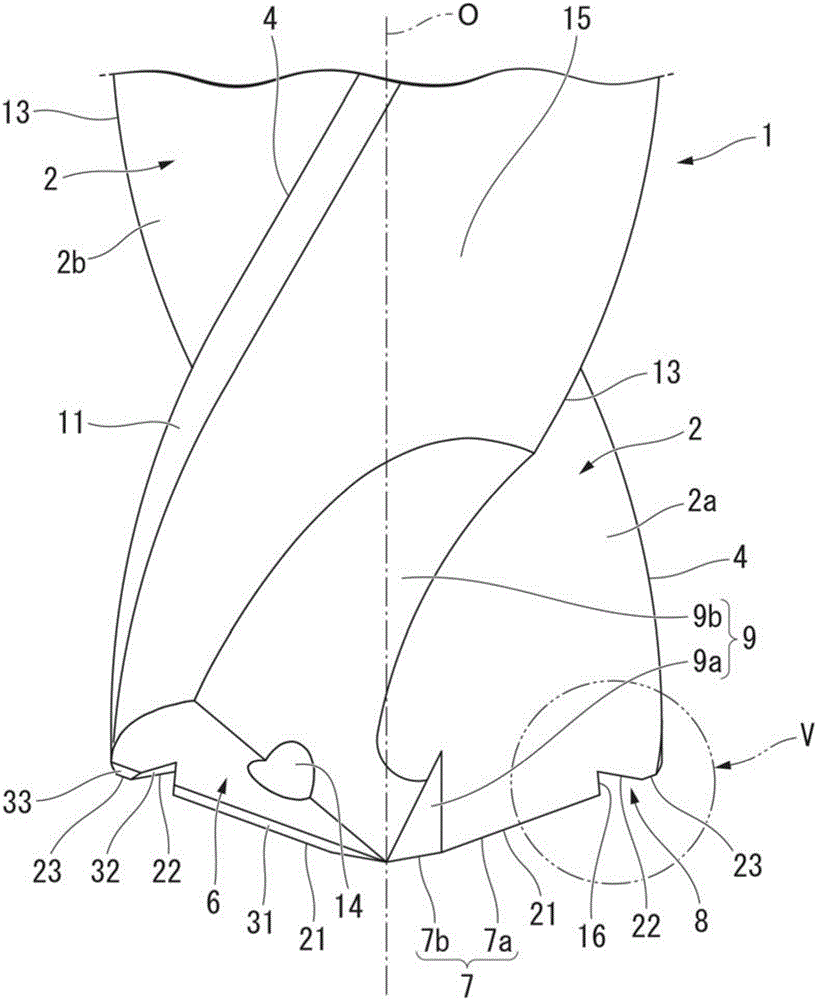

Motorcycle tire for running on rough terrain

ActiveCN103963571AImprove driving performanceInhibition of attachmentOff-road vehicle tyresMotorcycle tyresTerrainRoad surface

Owner:SUMITOMO RUBBER IND LTD

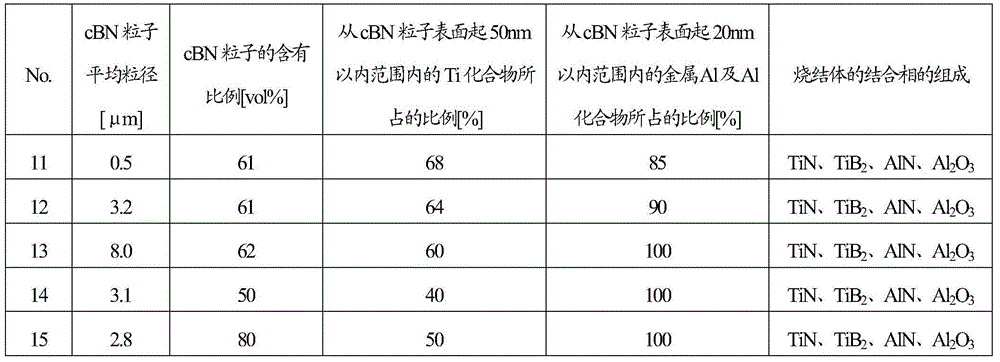

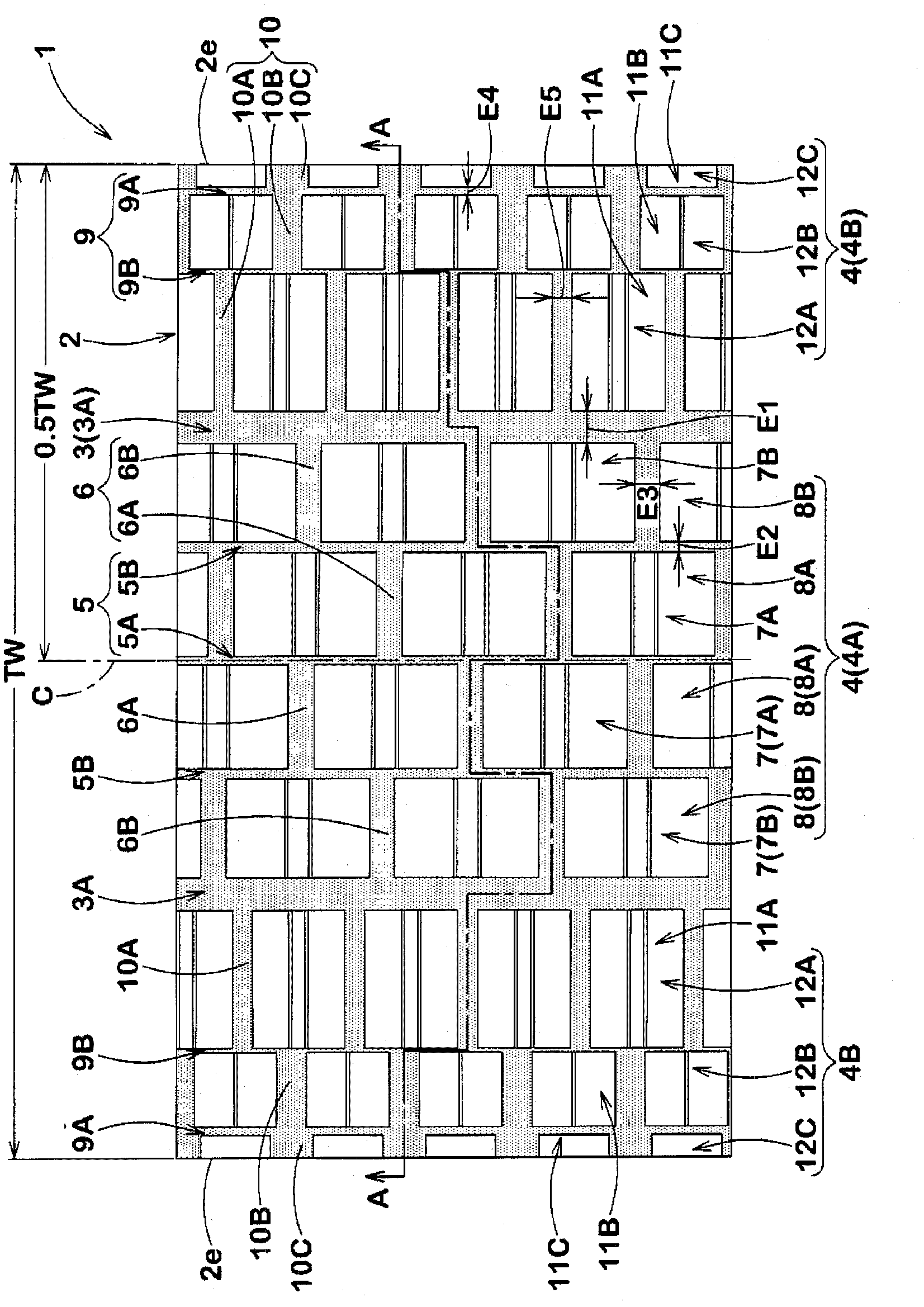

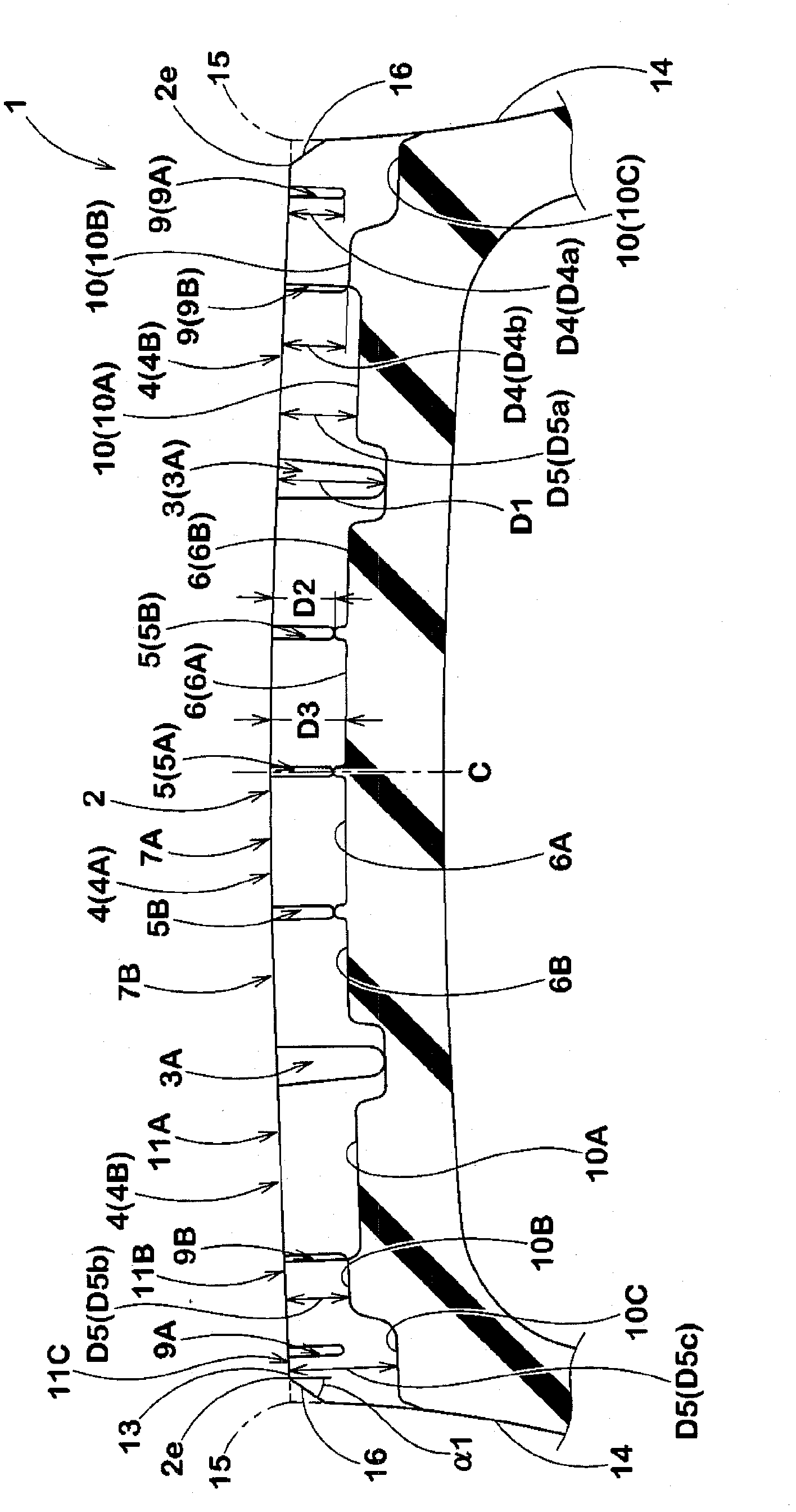

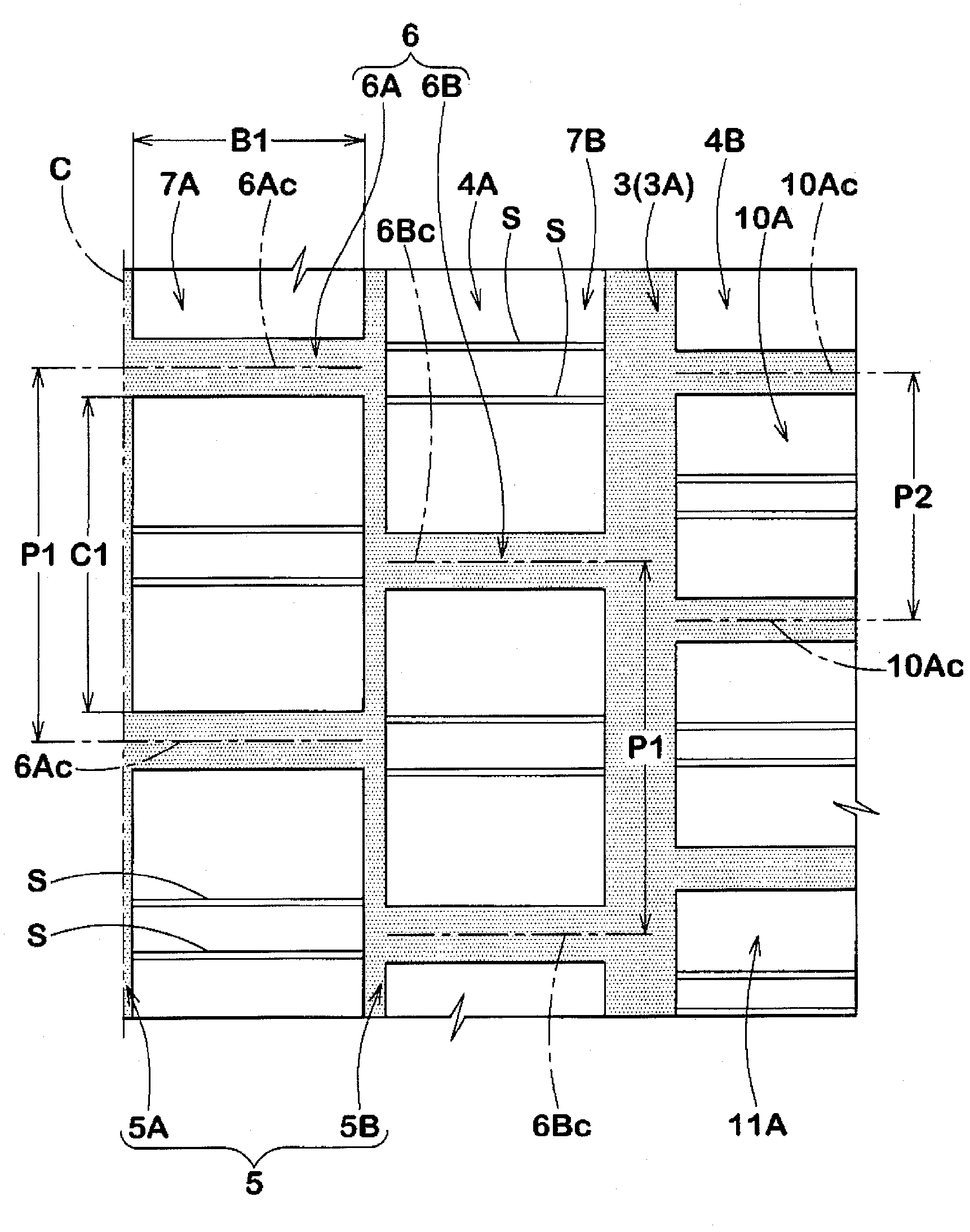

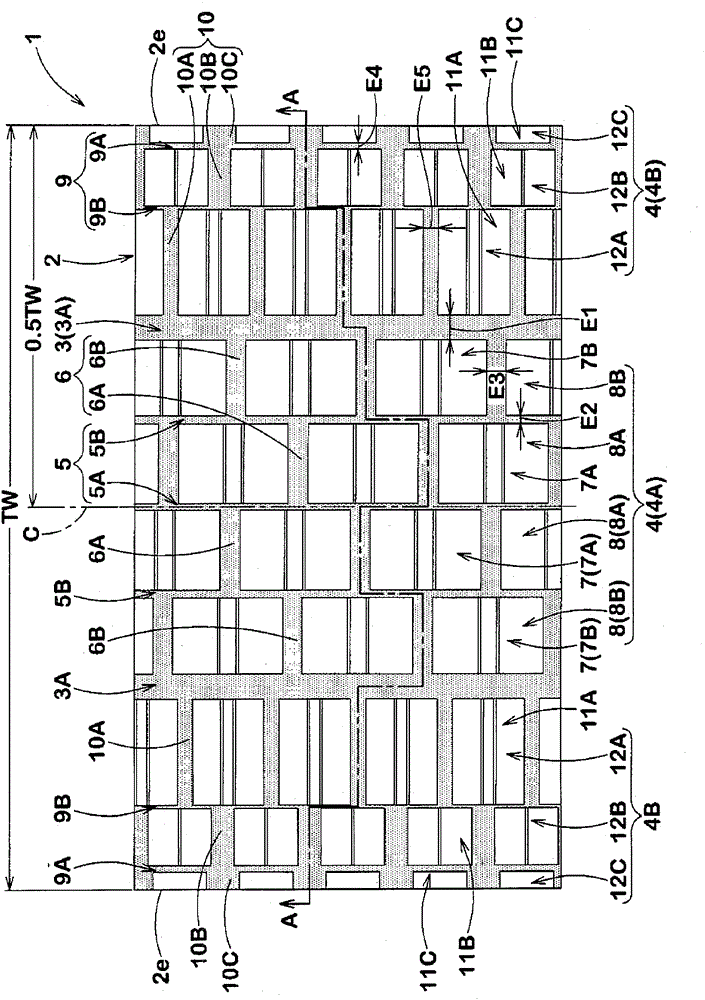

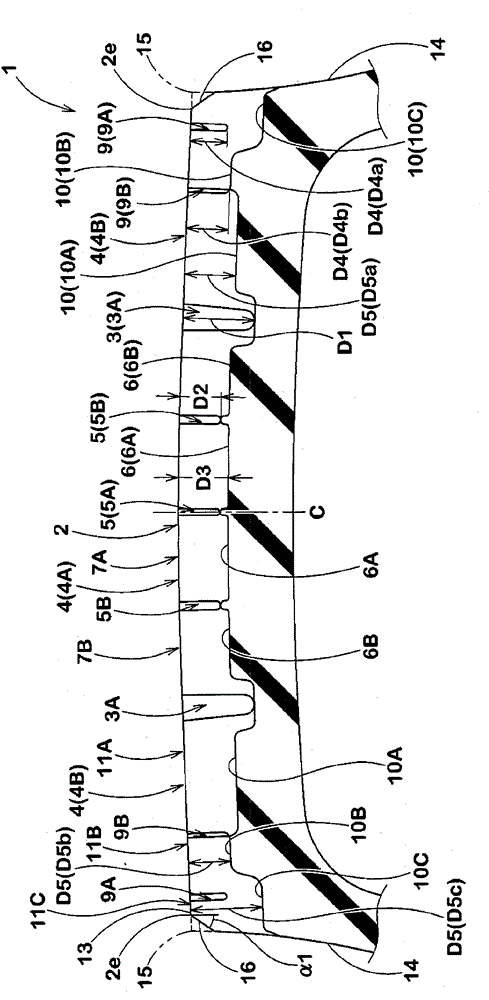

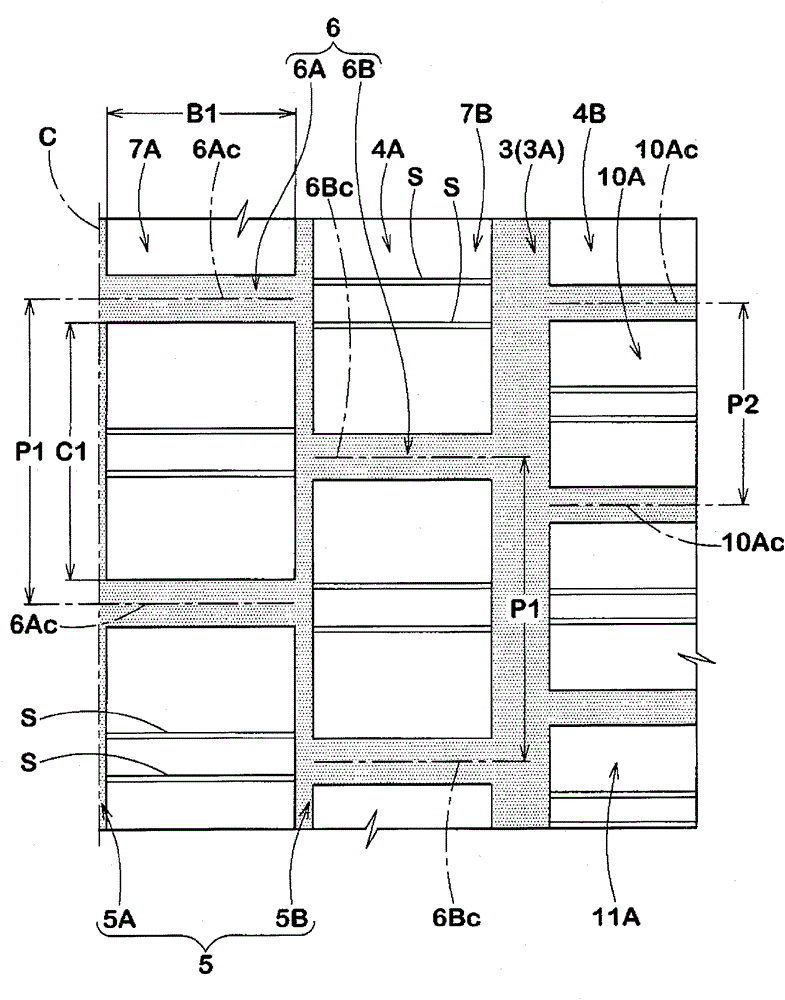

High-capacity inflatable tire

ActiveCN102616090AReduce rigidityImprove anti-yaw performanceHeavy duty tyresHeavy duty vehicleTransverse grooveAgricultural engineering

The invention provides a high-capacity inflatable tire, which is capable of preventing rubber loss and damage and improving the nibbling performance. A tread part (2) of the high-capacity inflatable tire (1) has a main groove (3) and a land portion (4). The main groove (3) comprises a tire-shoulder main groove (3A). The land portion (4) comprises a central land portion (4A) and a tire-shoulder land portion (4B). The central land portion (4A) is spacedly provided with central pattern blocks (7). A tire-shoulder auxiliary groove (9) and a tire-shoulder transverse groove (10) are formed on the tire-shoulder land portion (4B). The tire-shoulder auxiliary groove (9) comprises an outer tire-shoulder auxiliary groove (9A) and an inner tire-shoulder auxiliary groove (9B). The tire-shoulder transverse groove (10) comprises an inner portion (10A), a central portion (10B) and an outer portion (10C). The tire-shoulder land portion (4B) is spacedly provided with an inner tire-shoulder pattern block row (11A), a central tire-shoulder pattern block row (11B) and an outer tire-shoulder pattern block row (11C). The spacing distance (P2) between the inner portion (10A), the central portion (10B) and the outer portion (10C) is smaller than the spacing distance (P1) of a central transverse groove (6).

Owner:SUMITOMO RUBBER IND LTD

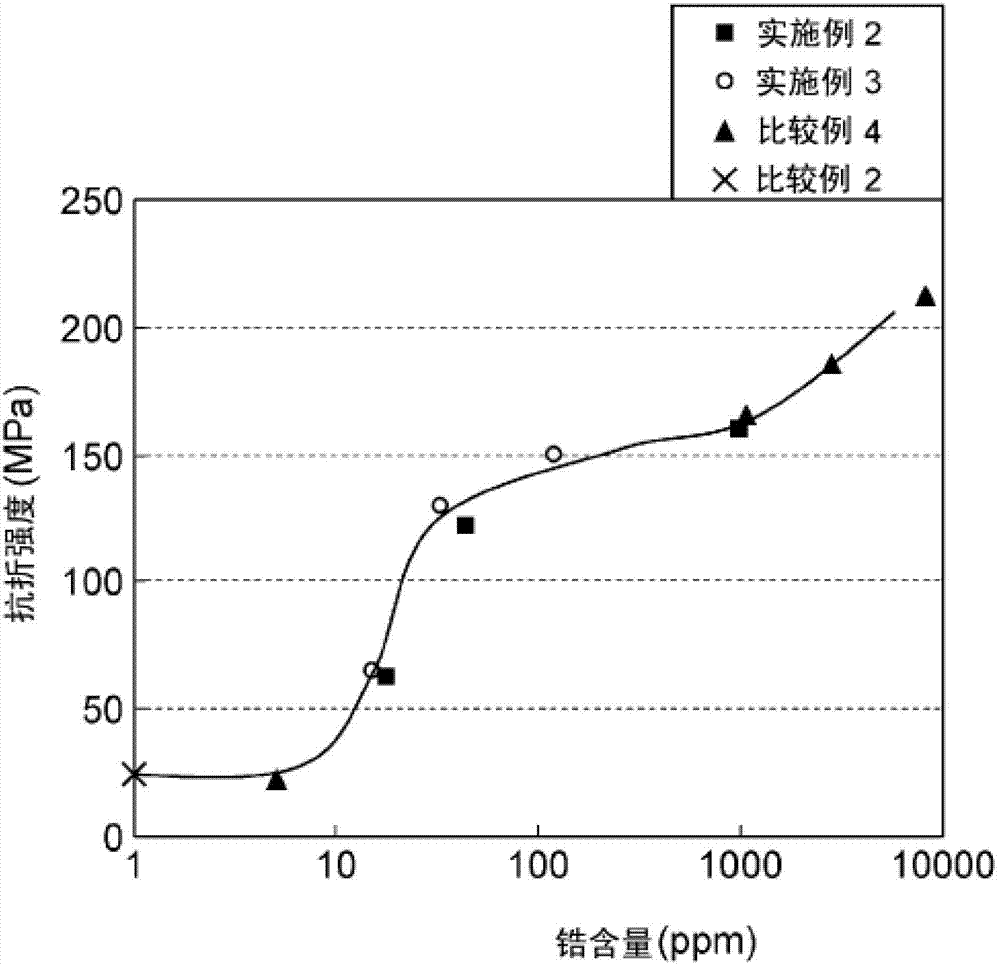

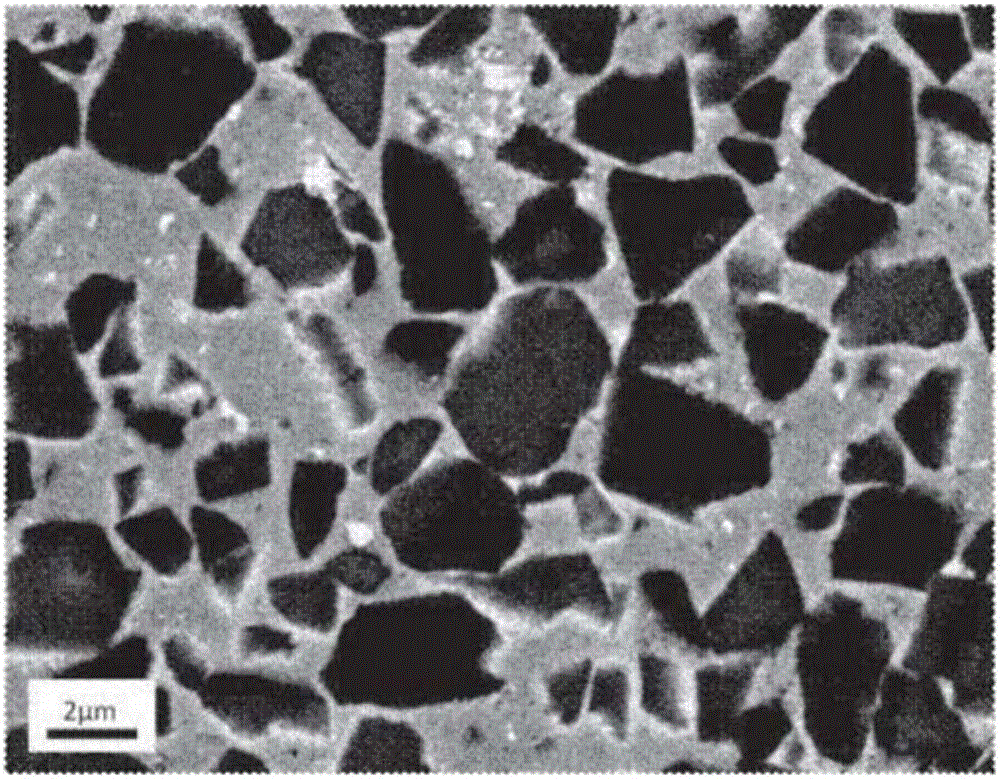

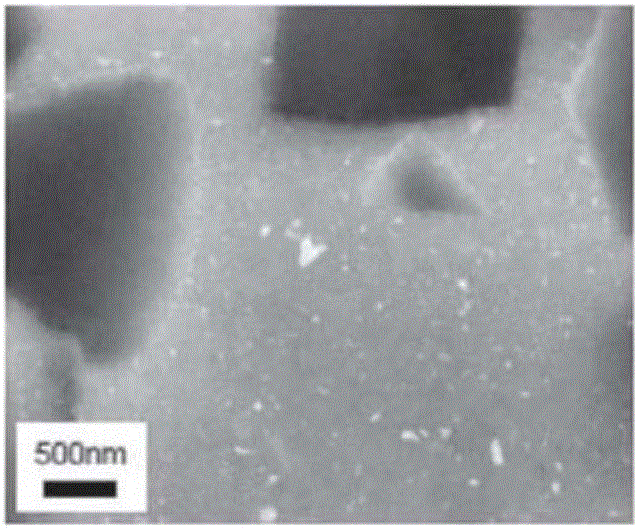

Zinc oxide sintered compact, sputtering target, and zinc oxide thin film

ActiveCN103249693AHigh strengthHigh resistivityVacuum evaporation coatingSemiconductor/solid-state device manufacturingZinc oxide thin filmsZirconium

Owner:TOSOH CORP

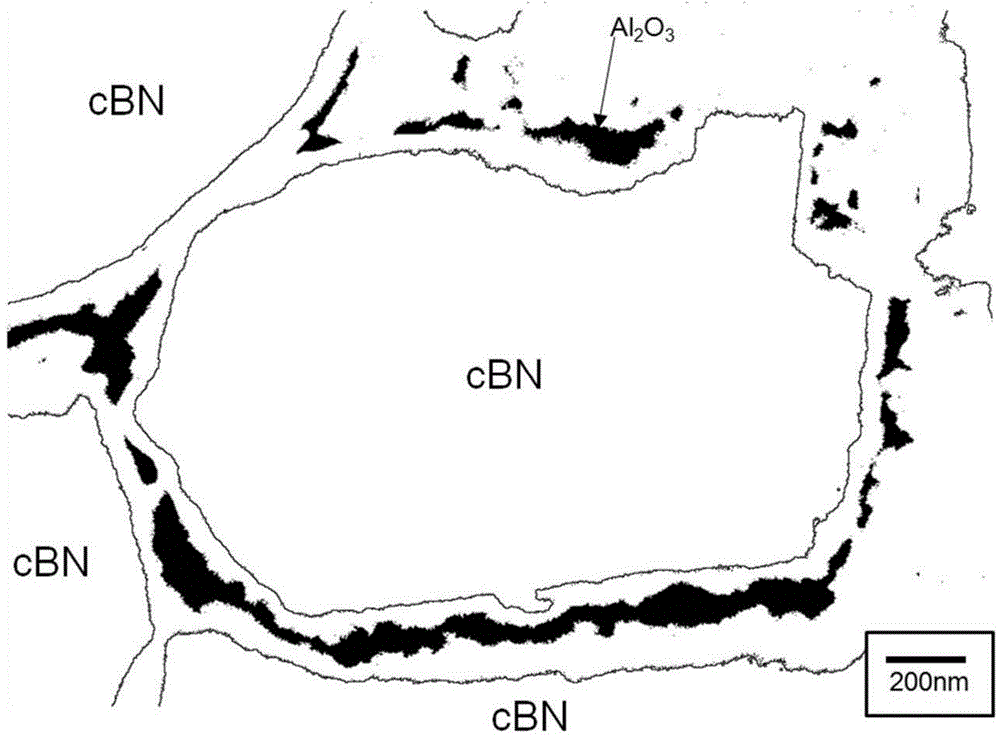

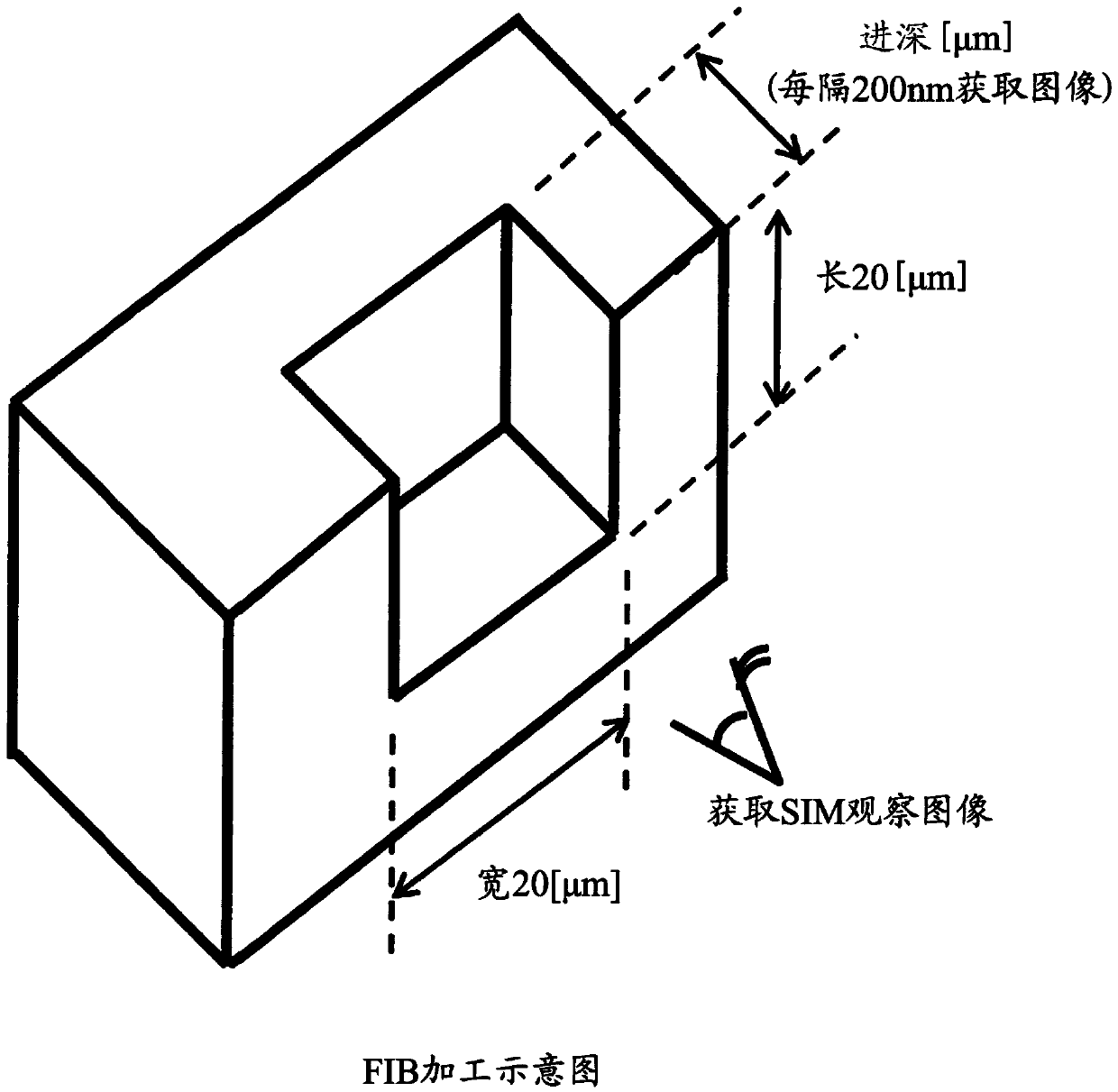

Cubic boron nitride sintered body cutting tool

ActiveCN106132604ALow wear resistanceHigh strengthTurning toolsChemical vapor deposition coatingBoron nitrideImpurity

In a cBN sintered body cutting tool having a sintered body including cBN grains and a binder phase as the tool base body therefor, the sintered body contains at least 40 capacity% but less than 60 capacity% cBN grains, a minimum of 2% by mass of Al, and a maximum within a range that fulfils the relationship Y= -0.1X+10, when Y is the Al content ratio (capacity %) and X is the cBN content ratio (% by mass). The binder phase contains at least a Ti-based compound, Al2O3, and unavoidable impurities. Al2O3 that has a diameter of 10-100 nm, among said Al2O3, is dispersed and generated within the binder phase and at least 30 Al2O3 being generated within a 1 [mu]m * 1[mu]m cross-sectional area of the binder phase.

Owner:MITSUBISHI MATERIALS CORP

End mill

InactiveCN101076421AInhibit wearSuppression defectMilling cuttersAdverse effect compensationMetabolic stabilityMilling cutter

The present invention provides methods and kits for determining the metabolic stability of compounds (e.g., stability to oxidative metabolism). In particular embodiments, the invention provides a method of determining the susceptibility of a compound to metabolism by an enzyme. In one representative embodiment, the enzyme is a cytochrome P450 enzyme. The invention is well-adapted for use in high throughput drug screening programs.

Owner:OSG

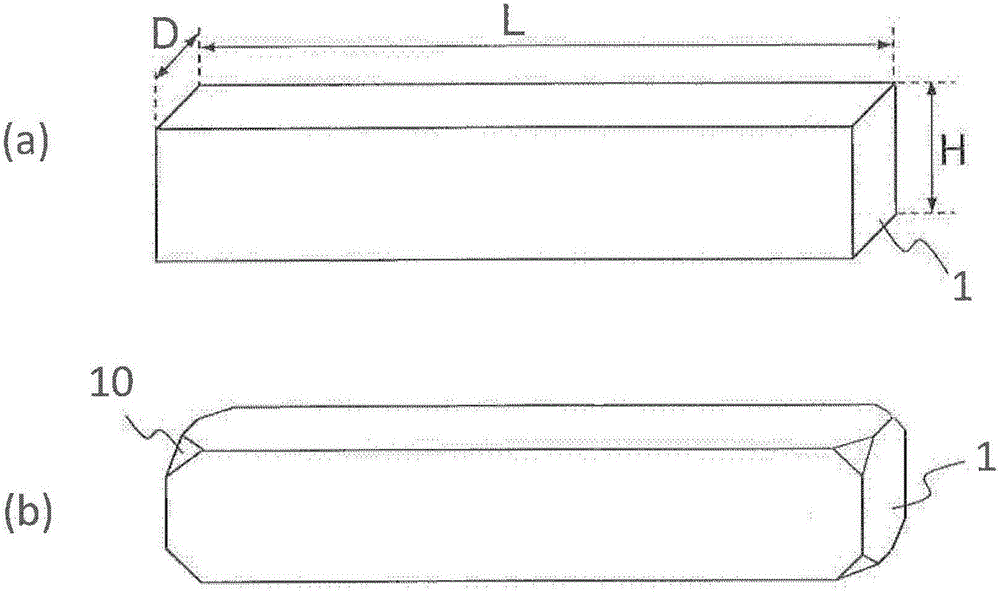

Manufacturing method of R-T-B sintered magnet

ActiveCN106024364AInhibition of ruptureSuppression defectInductances/transformers/magnets manufactureRare-earth elementMetallurgy

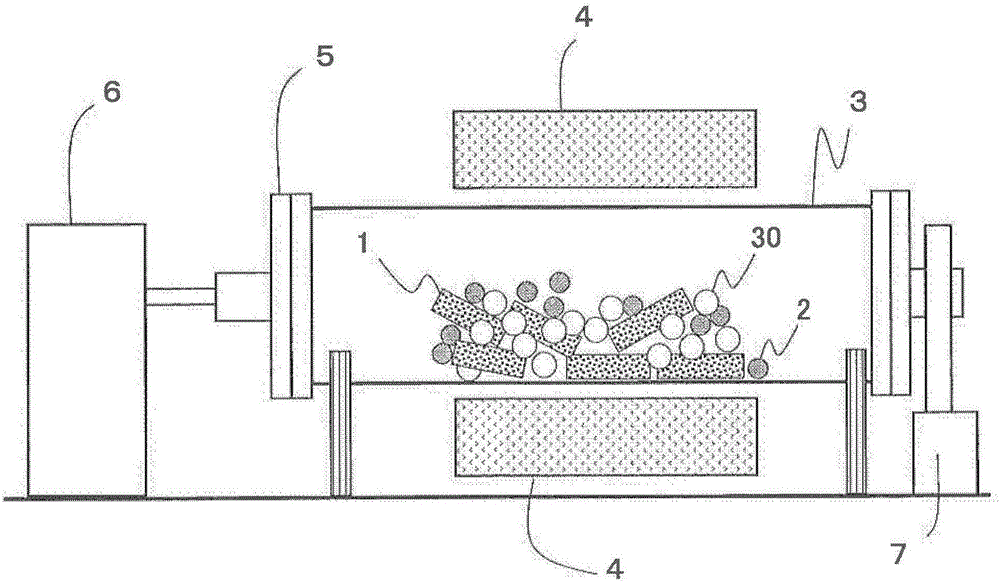

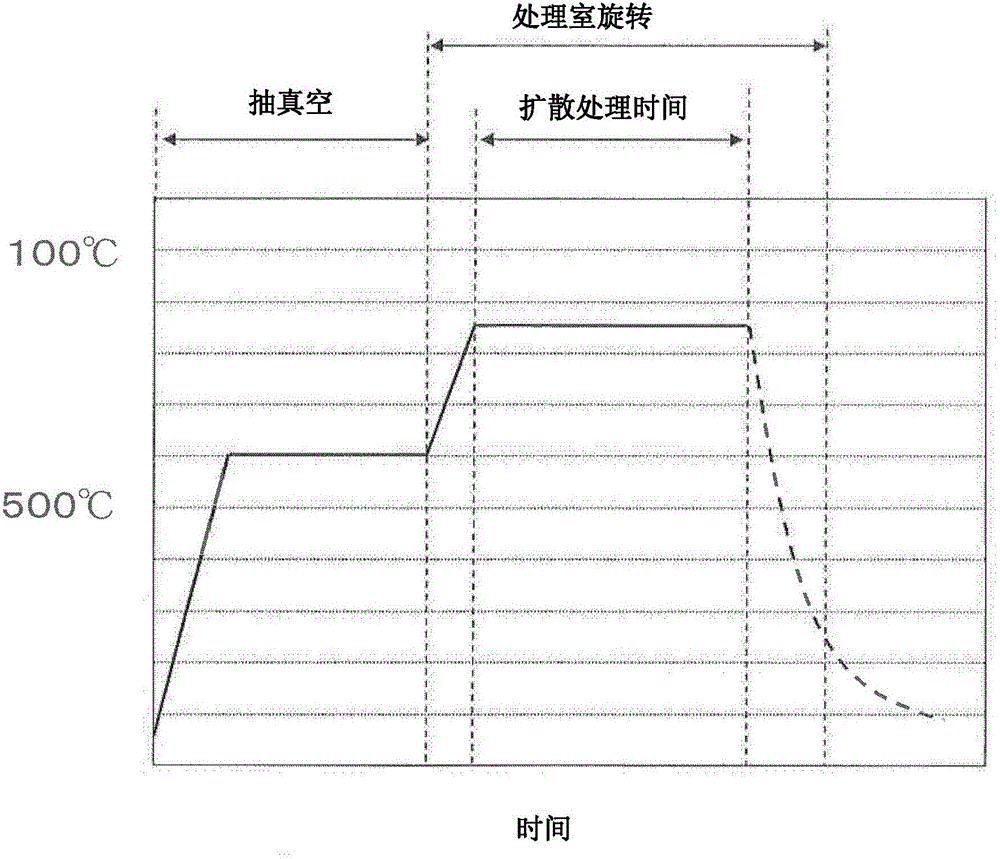

The invention provides a manufacturing method of an R-T-B sintered magnet. By adopting the method, a heavy rare earth element RH diffuses inwards from the surface of R-T-B sintered magnet raw materials without lowering the residula magnetic flux density, and the fracturing and damages of the R-T-B sintered magnet are inhibited. The manufacturing method comprises an R-T-B sintered magnet raw material preparing step, an RH diffusion source preparing step, a step for loading the R-T-B sintered magnet raw materials, RH diffusion sources and stirring auxiliary parts in a processing chamber; and an RH diffusion step for moving the R-T-B sintered magnet raw materials, the RH diffusion sources and stirring auxiliary parts and simultaneously heating the R-T-B sintered magnet raw materials and the RH diffusion sources. The size of each R-T-B sintered magnet raw material is larger than 1000mm3, and the maximum size is two times of the minimum size among the sizes in three orthotropic directions. Each RH diffusion source is smaller than 3 mm. The stirring auxiliary parts include a plurality of first ball bodies and a plurality of second ball bodies.

Owner:HITACHI METALS LTD

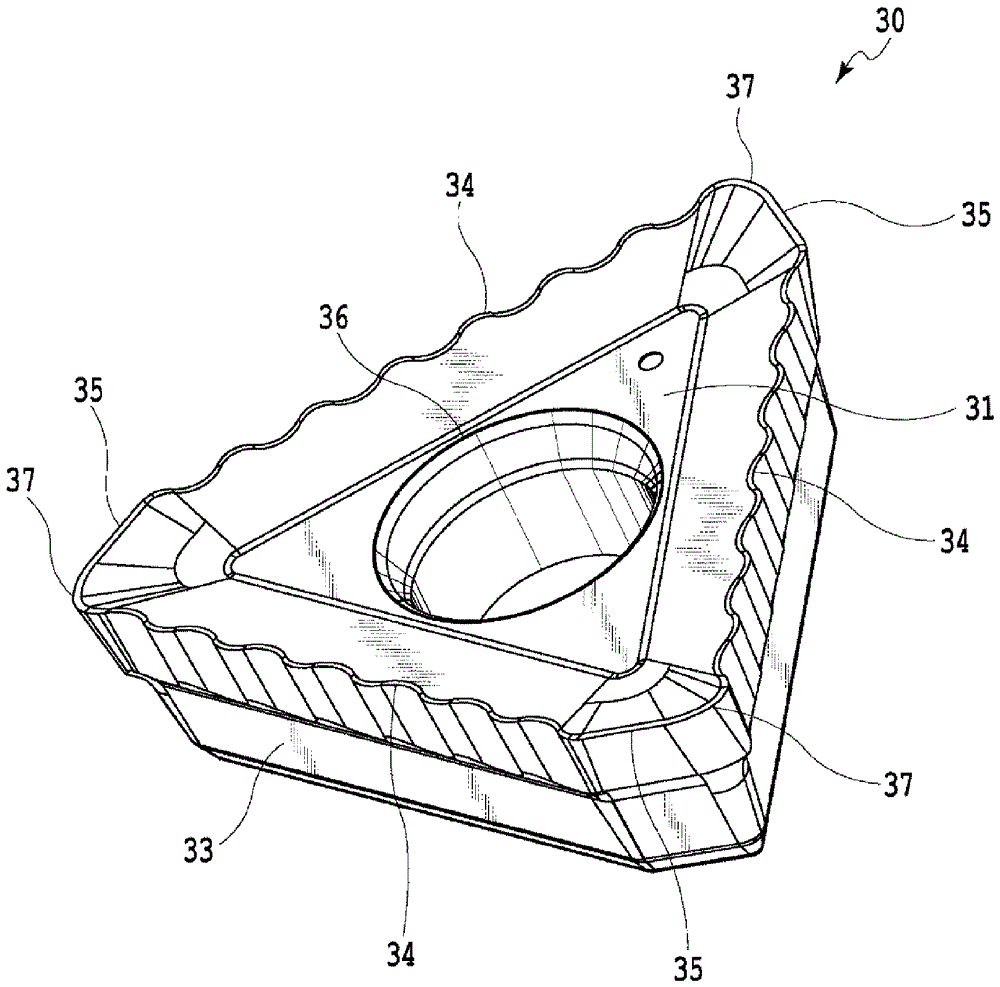

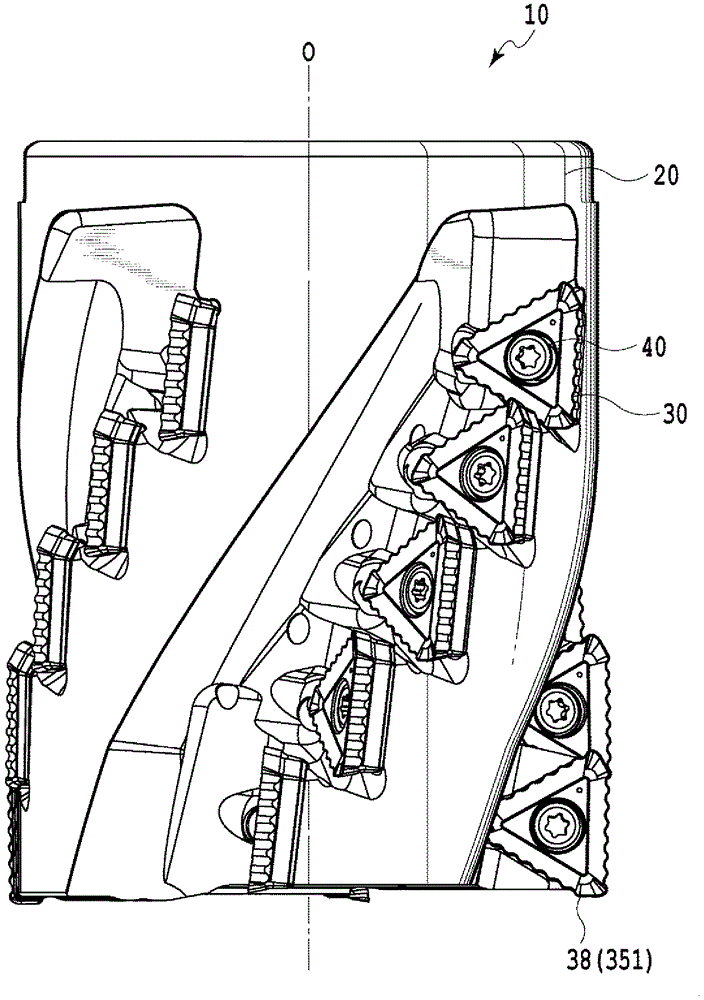

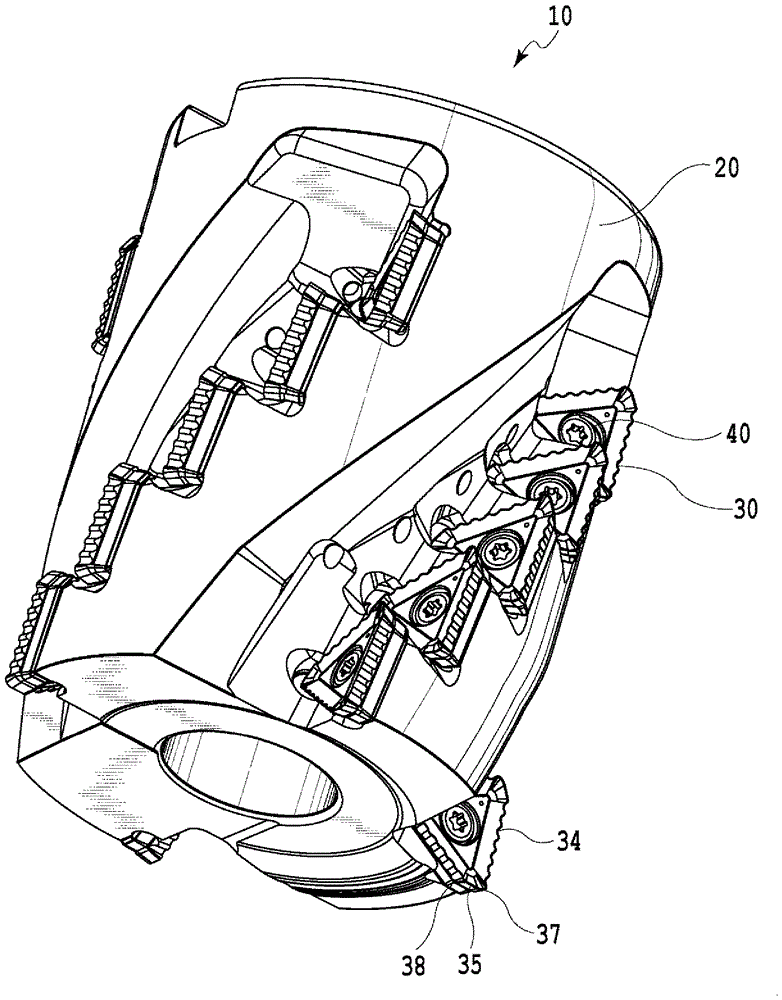

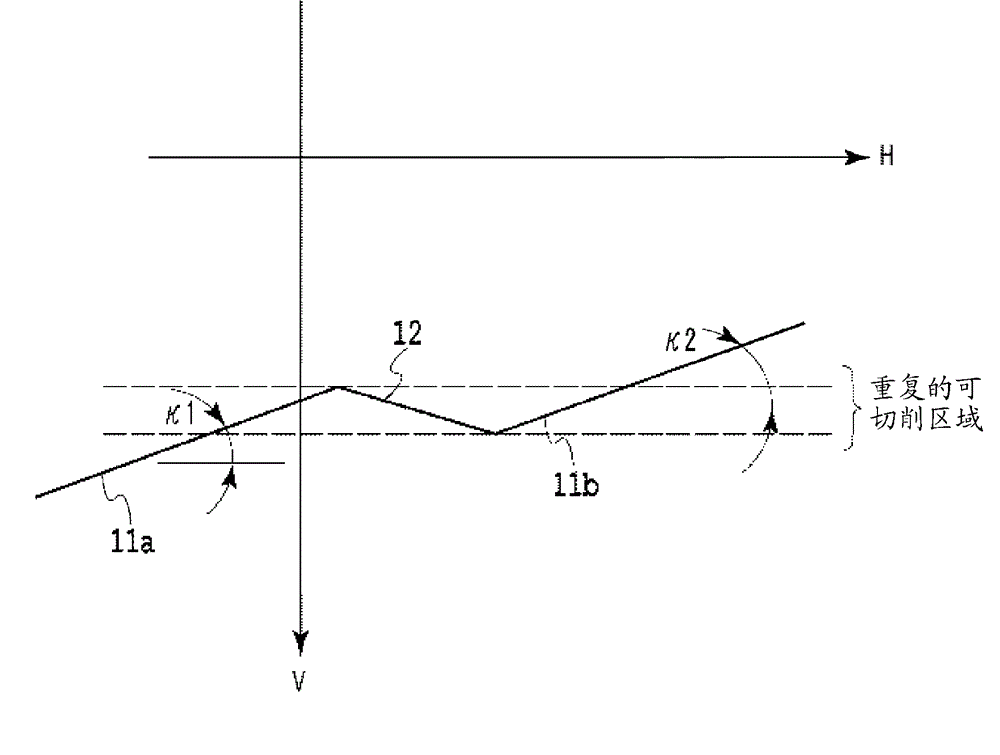

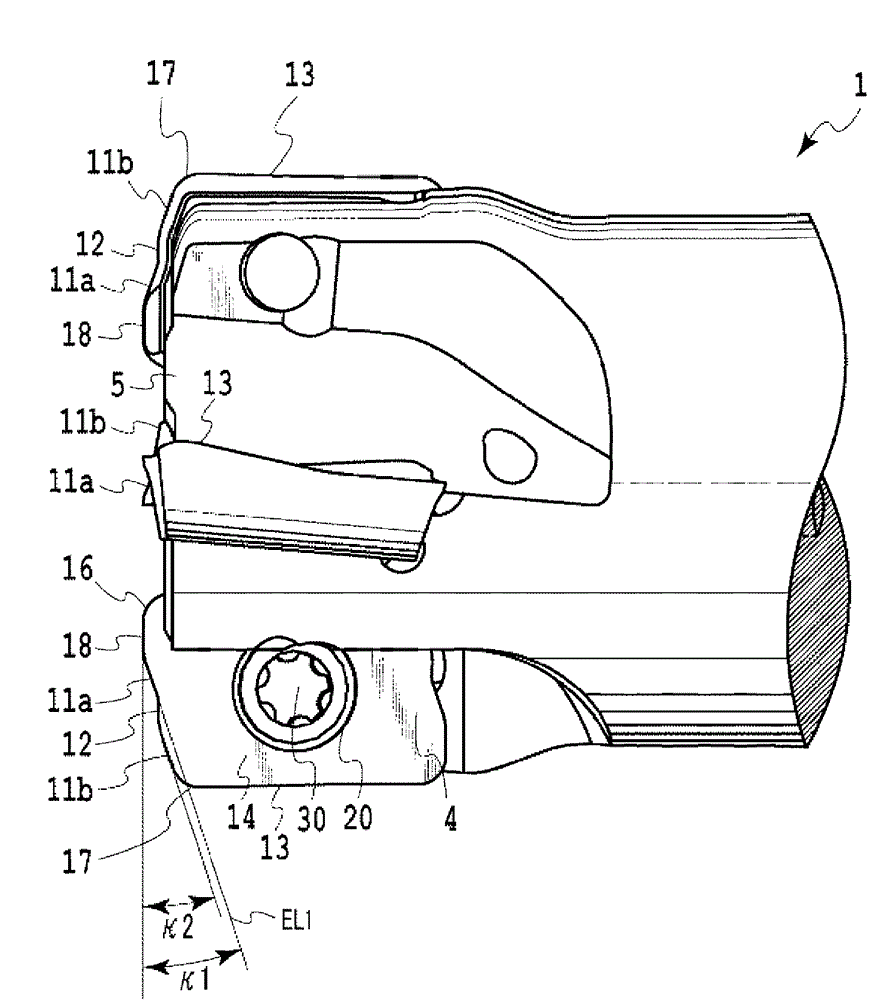

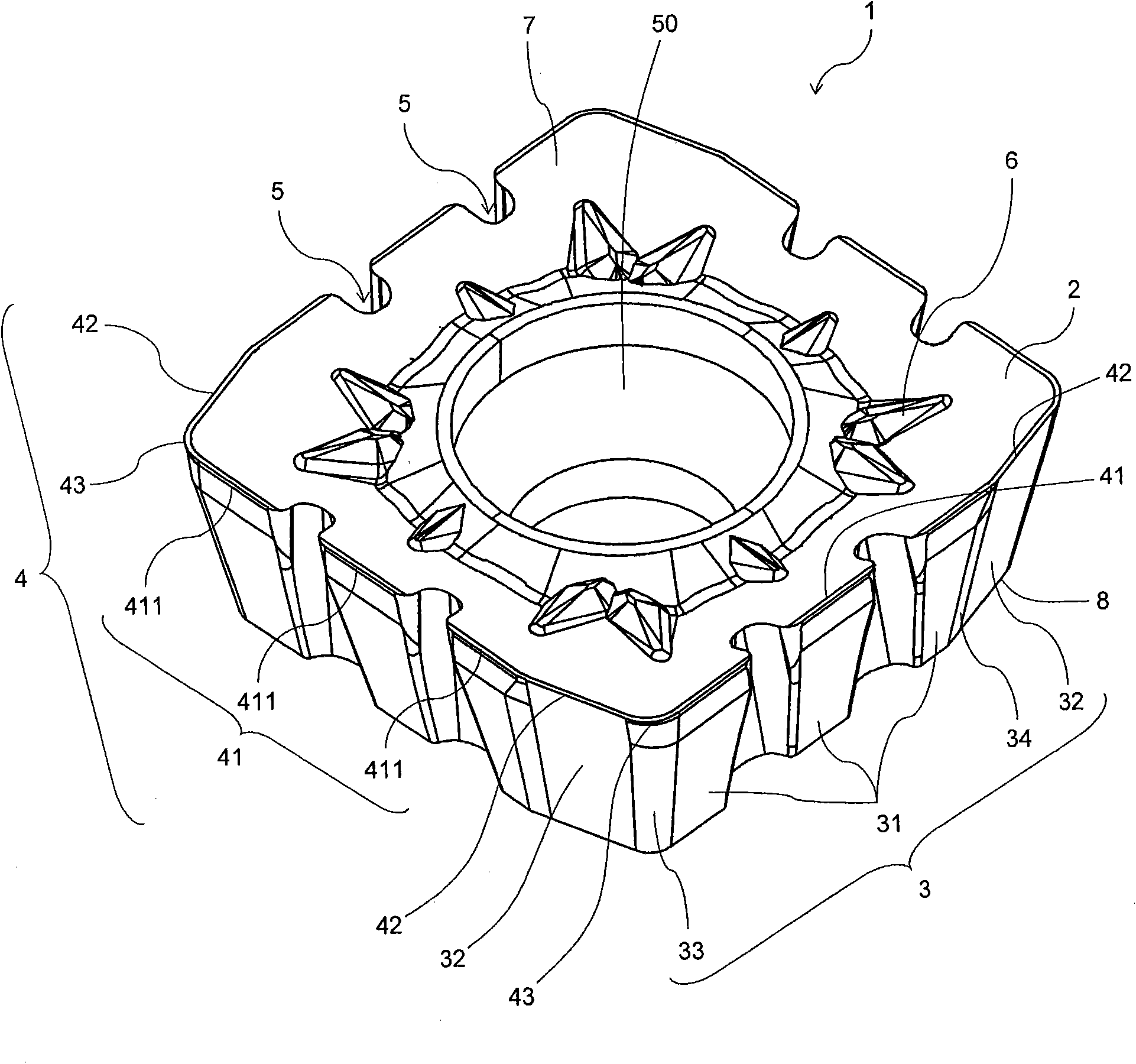

Replaceable edge-type rotating cutting tool

ActiveCN105813785ASuppression defectReduce cutting loadMilling cuttersMilling cutting insertsEdge typeWave form

Multiple grooves (27) are formed and in each of said grooves, multiple insert seats (28) are formed and cutting inserts (30) are detachably disposed. The cutting inserts (30) have main cutting edges (34), corner cutting edges, and auxiliary cutting edges (35), and the main cutting edges (34) are formed with a wave form when viewed from the direction of the cutting face. The cutting inserts (30) are disposed so that in the rotation tracks formed by the main cutting edges (34) of the respective cutting inserts (30) when the roughing cutter (10) is rotated around the rotation center axis (O), the wave phases of the rotation tracks formed by adjacent cutting inserts (30) in a single groove (27) in the direction along the rotation center axis (O) coincide, and at least some of the cutting inserts (30) are disposed so that the rotation tracks formed by some of the cutting edge portions overlap each other in the rotation center axis (O) direction. As a result, even when said cutting edge portions are used as a main cutting edge portion and as an inner blade, cutting load is reduced and damage is limited.

Owner:TUNGALOY CORP

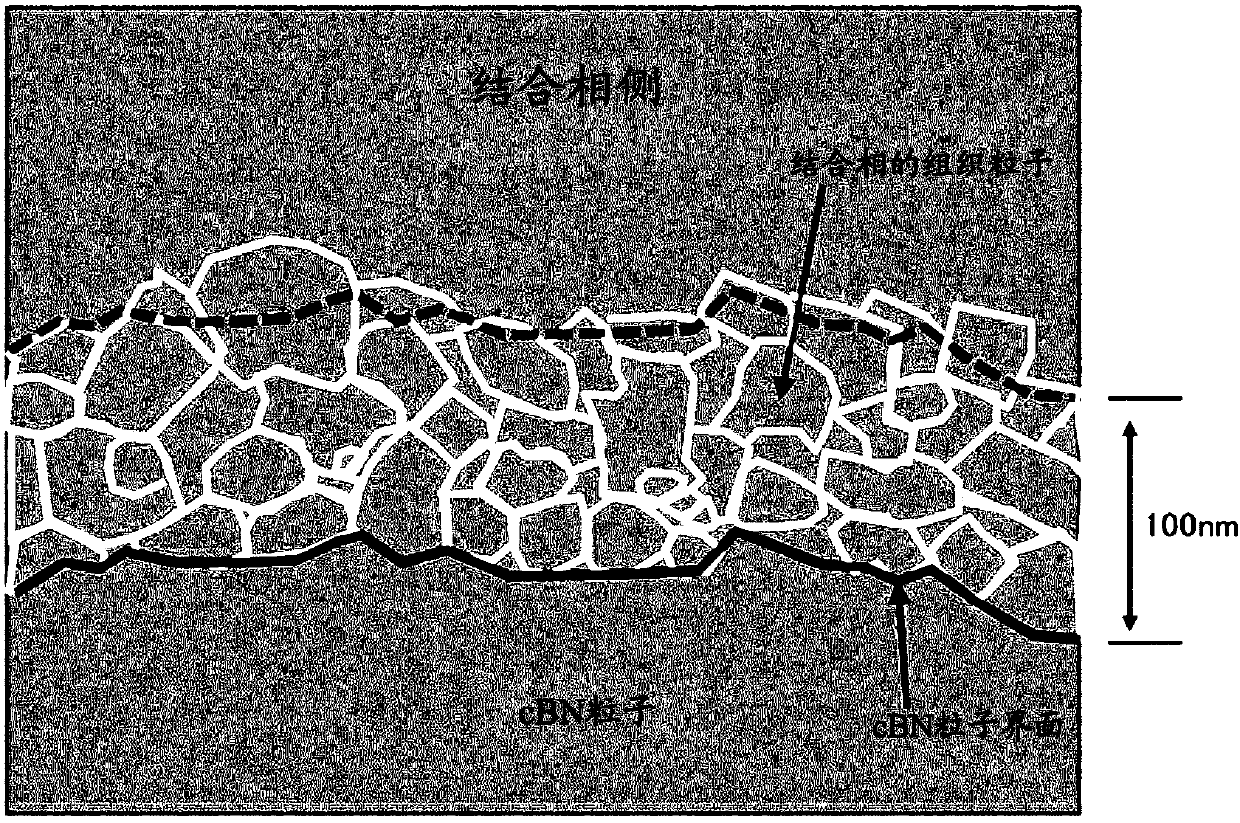

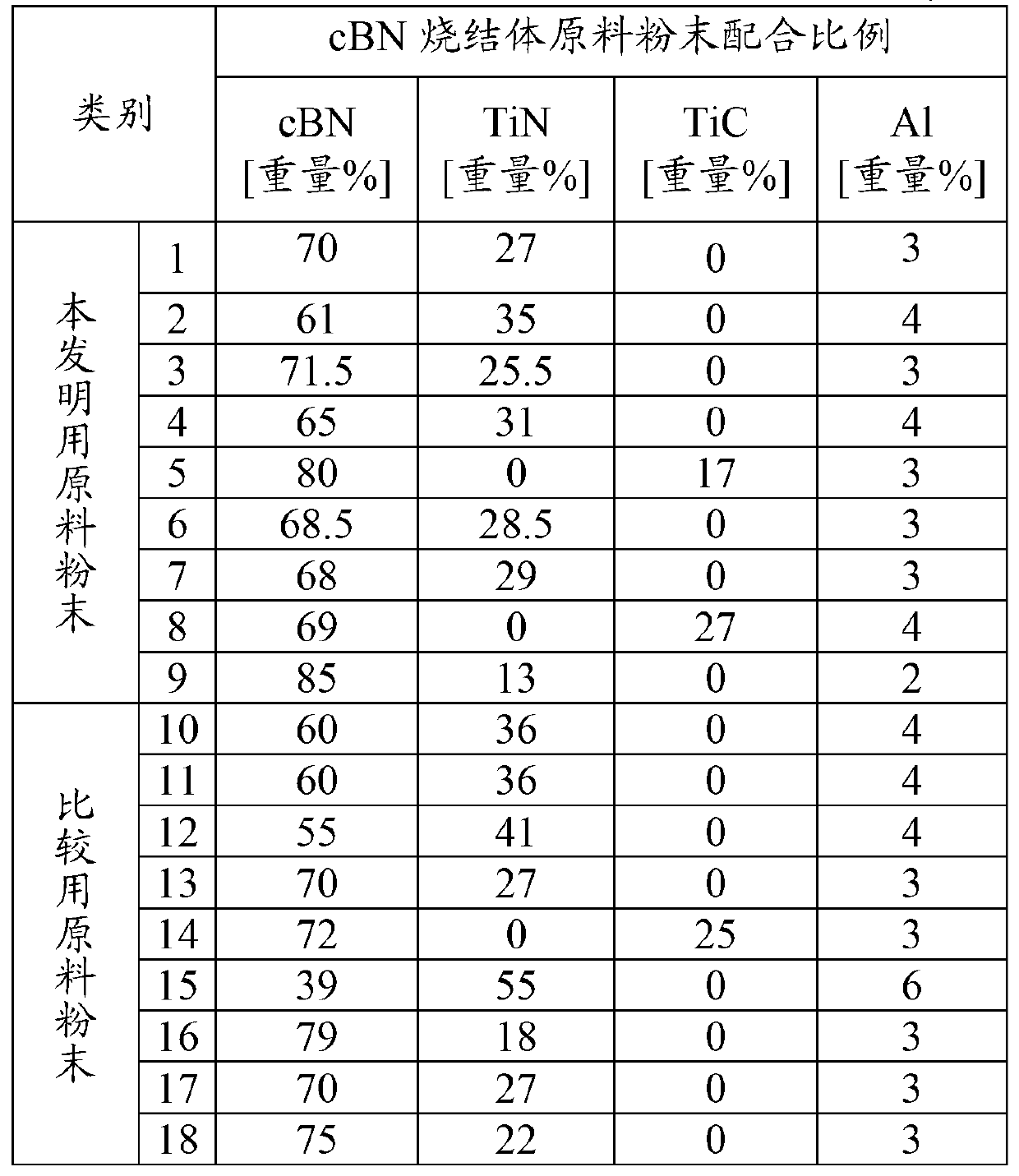

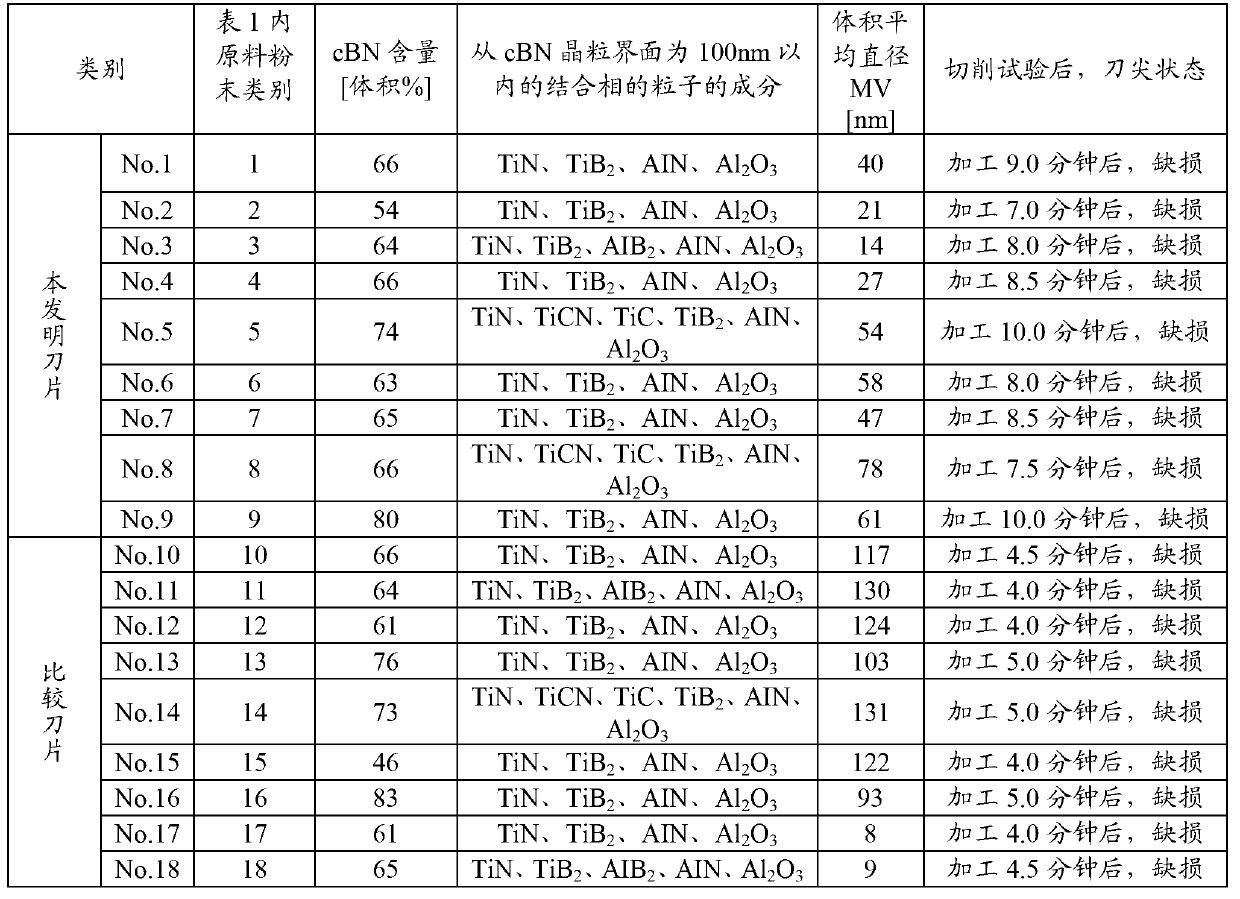

CBN sintered body cutting tool with excellent toughness

An object of the present invention is to provide a cBN sintered body cutting tool with excellent toughness. While being used for interrupted cutting of high-hardness steel even if in the situation requiring high-load cutting conditions, the cutting tool provided by the invention is prevented from proneness to the cracks and defects of the blade and has excellent cutting performance which can be maintained for a long term. The cBN sintered body cutting tool comprises a sintered body including cubic boron nitride and a binder phase as a tool substrate, wherein a binder phase structure is existed in the area within 100nm from the grain boundary of the cubic boron nitride towards the binder phase, and is composed of one or more than two selected from the group of nitrides, carbides, carbon nitrides and borides of Ti, nitrides, borides and oxides of Al, and solid solution of more than two of them, and inevitable impurities, and has fine structures with an average volume diameter MV of 10-80 nm. Thus, the object of the present invention is achieved.

Owner:MITSUBISHI MATERIALS CORP

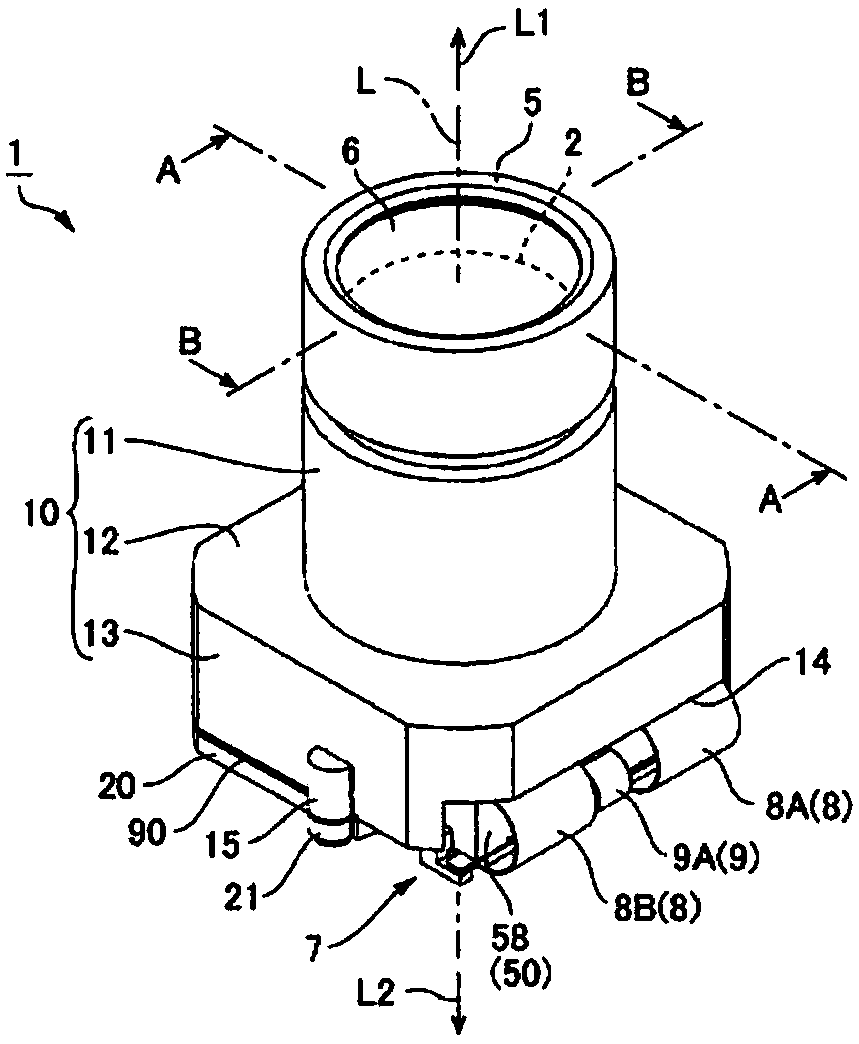

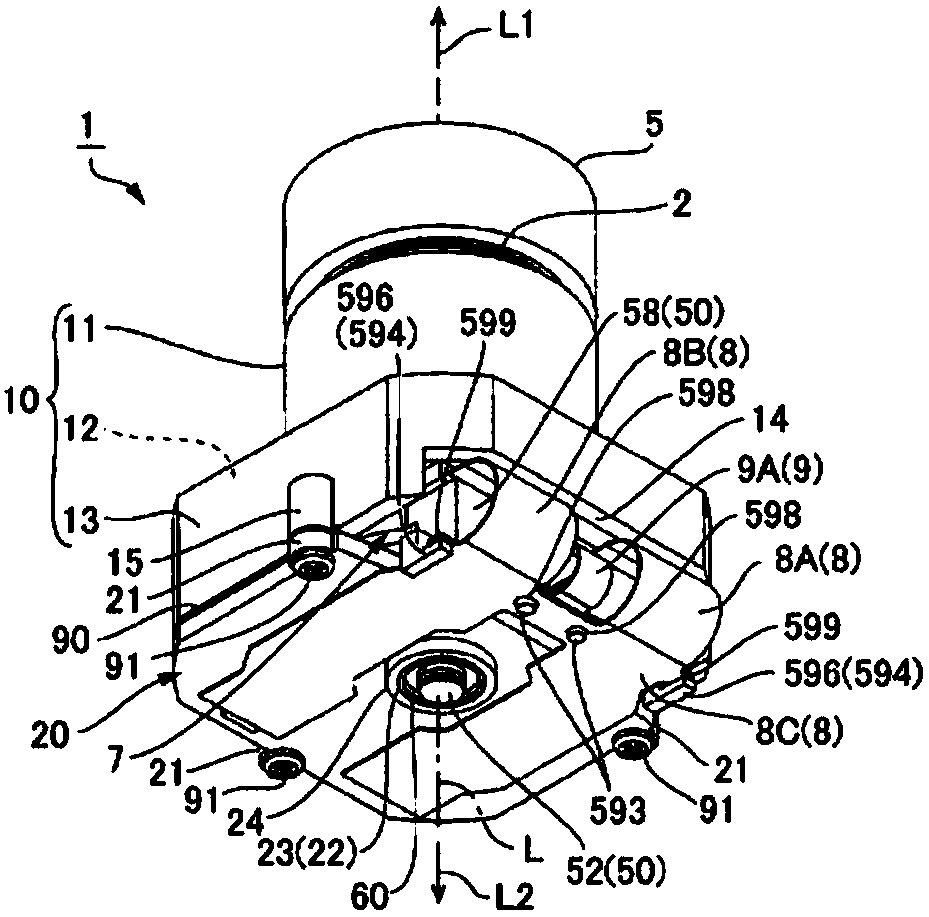

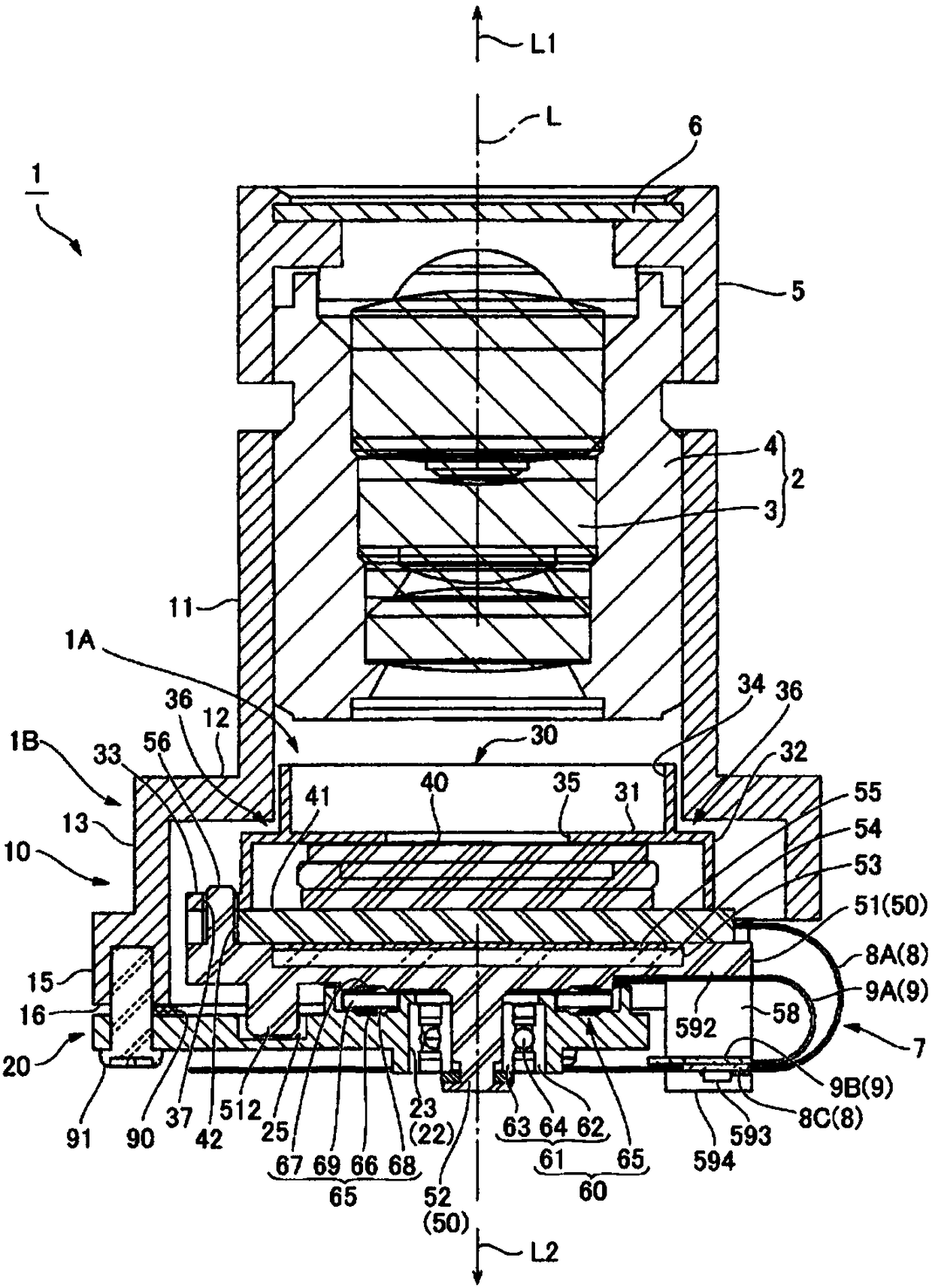

Optical unit and optical unit with 3-axis shake correction function

ActiveCN108693681ASuppression defectReduce power consumptionPrintersProjectorsBall bearingOptical axis

The present invention provides an optical unit and an optical unit with a 3-axis shake correction function. An optical unit including a roll correction mechanism is miniaturized. The optical unit fixes a substrate on which an imaging element is mounted to a rotating pedestal that is separated from a lens unit and a lens holder, so that the rotating pedestal rotates to perform roll correction. A coil of a magnetic drive mechanism for roll and at least a part of the projection area in the optical axis L direction of the magnet overlap with the substrate on which the imaging element is mounted. Further, since a rotation support mechanism includes a bearing portion and a rotation support portion, and the rotation support portion is disposed radially outside the bearing portion, compared with aconfiguration in which two sets of ball bearings such as the bearing portion are arranged to overlap each other in the optical axis L direction, the thickness in the optical axis L direction is small. Therefore, the optical unit can be miniaturized, and the optical unit can be made lighter.

Owner:SANKYO SEIKI MFG CO LTD

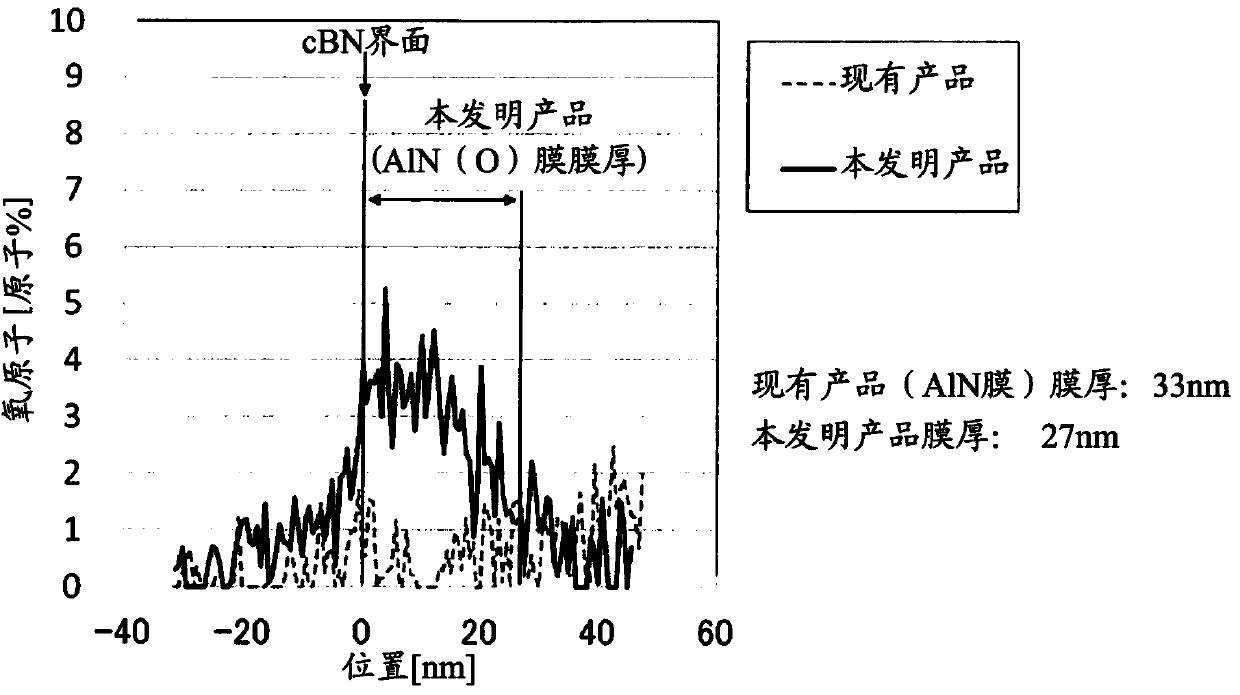

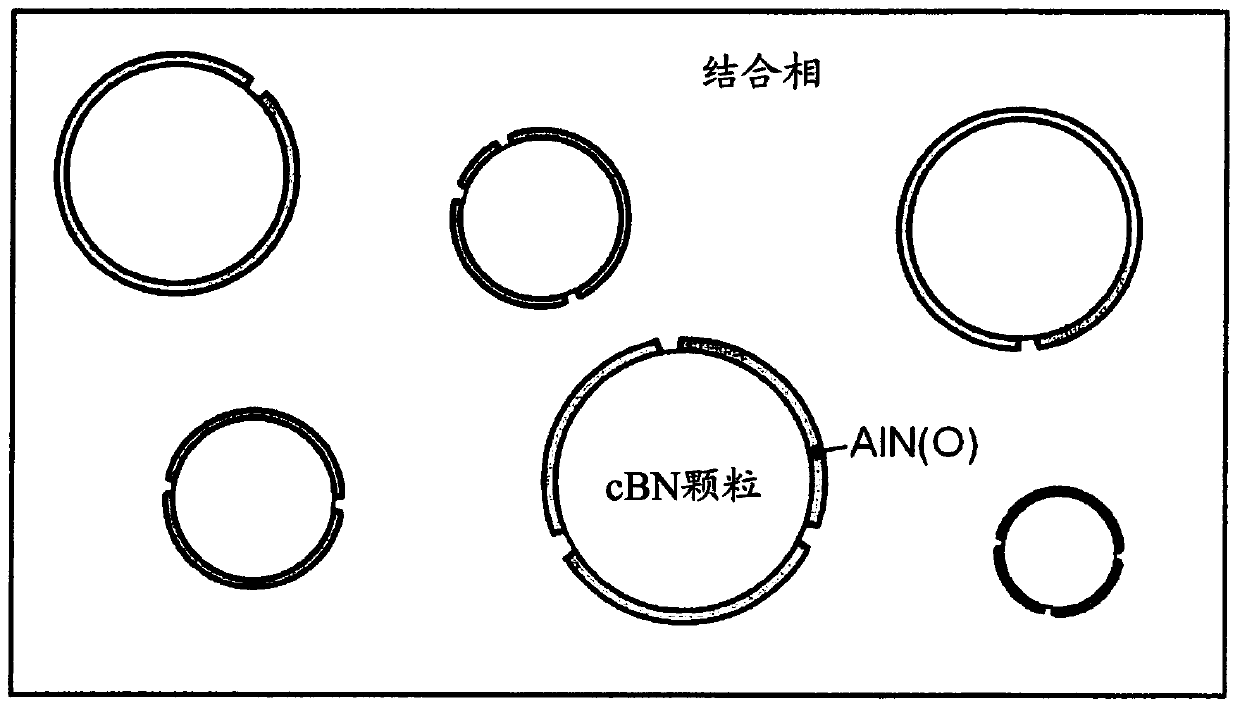

Cutting tool made from cubic boron nitride sintering material

ActiveCN103964858AImprove interfacial adhesion strengthIncreased interfacial adhesion strengthHardnessBoron nitride

The invention provides a cutting tool made from a cubic boron nitride sintering material which demonstrates excellent resistance to defects in intermittent cutting machining of high-hardness steel. According to the cutting tool made from the cubic boron nitride sintering material, optimally an average particle size of a cubic boron nitride particle is 0.5 to 8 [mu]m; at least pat of the surface of the cubic boron nitride particle is coated by an oxygen-containing aluminum nitride film with the average thickness of 10 to 100 [mu]m and an everage oxygen concentration being 1 to 15 atom%; furthermore, the oxygen-containing aluminum nitride film covering the surface of the cubic boron nitride particle has a local crack; and the average formation proportion of the local crack h / H satisfies 002<=h / H<=0.08, with h representing the length of the crack of the oxygen-containing aluminum nitride film and H representing the perimeter of the cubic boron nitride particle.

Owner:MITSUBISHI MATERIALS CORP

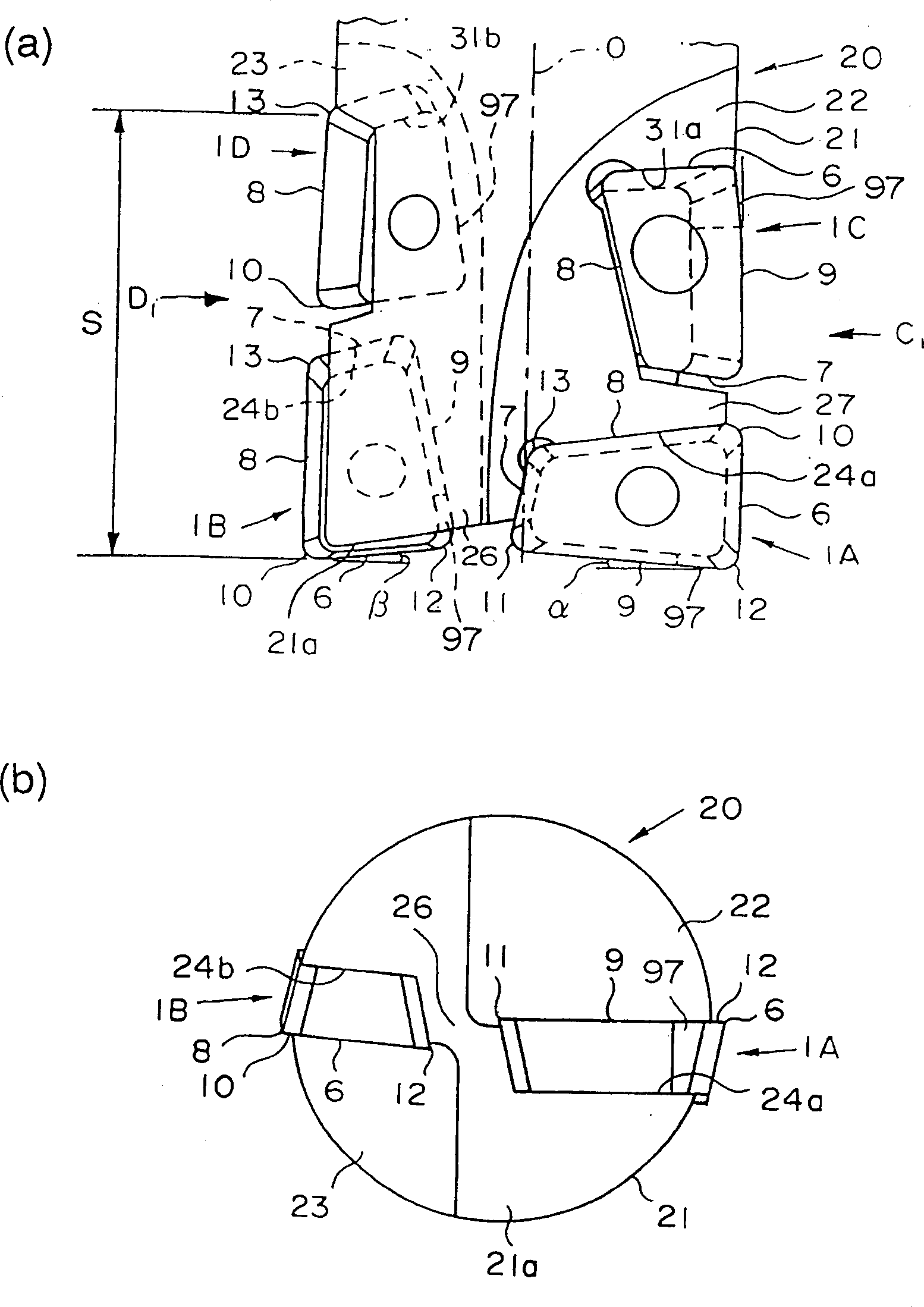

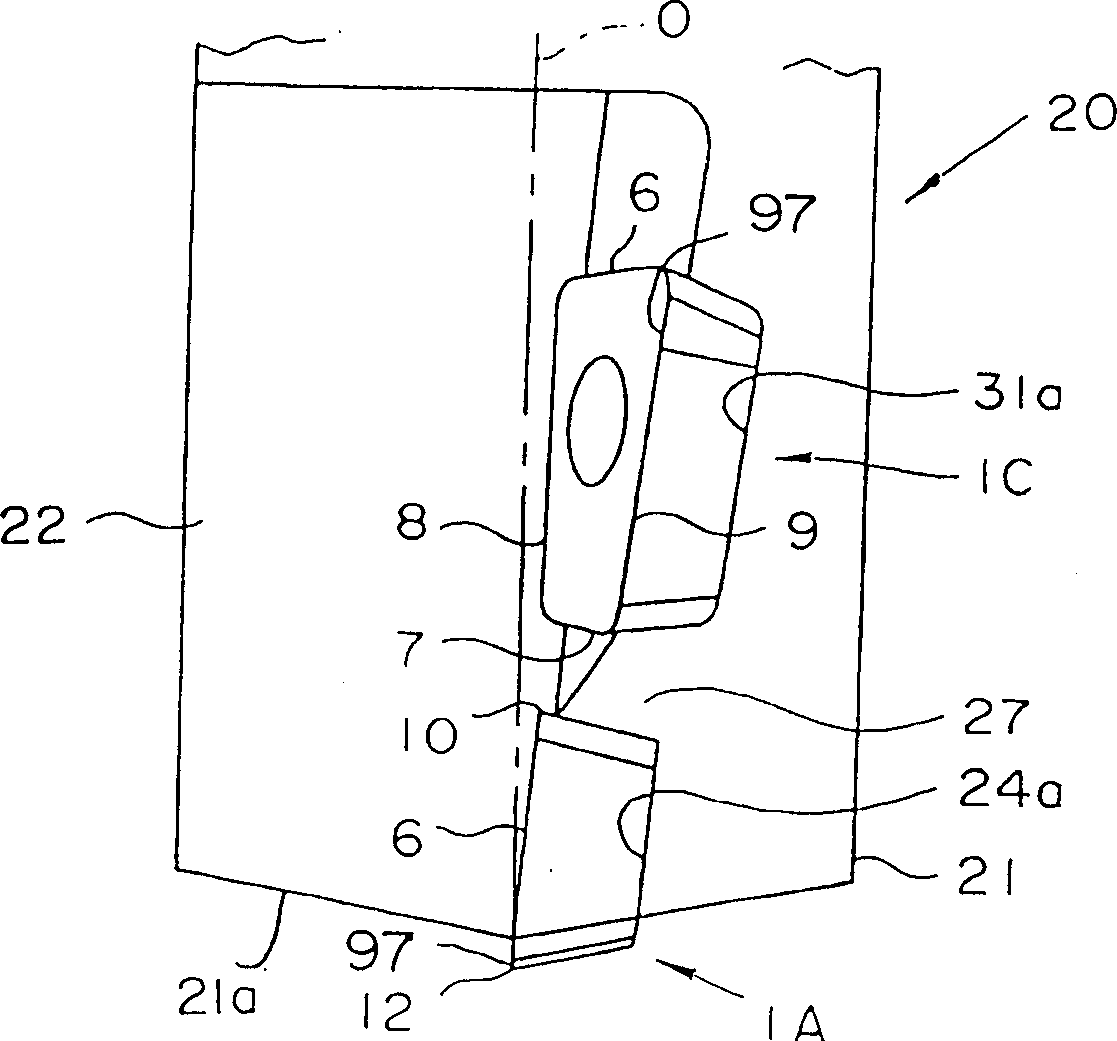

Cutting insert and indexable rotary cutting tool

InactiveCN102947035ASmooth replacementEasy to installTransportation and packagingMilling cuttersEngineeringMetal mold

Provided are a cutting insert suitable for pocket machining of metal molds and the like, and an indexable cutting tool that uses the cutting insert. The cutting insert (10) is provided with: a rake face (14); a flank face (15); and a major cutting edge (11) that is formed on the intersecting ridge of the rake face (14) and the flank face (15), and that extends in the direction that intersects with the cutting direction of the rotary cutting tool. At least one partitioning section (12) that is not involved in cutting is provided in the middle of said major cutting edge (11) in a direction along the major cutting edge (11). The major cutting edge (11) is composed of two first cutting edges (11a) and second cutting edges (11b) separated by the partitioning section (12), and is configured in such a manner that, when the cutting insert is attached to the tool body (1) of the cutting tool, the cutting angles ([kappa]1, [kappa]2) between the first cutting edge (11a) and the second cutting edge (11b) falls in a range of 5 DEG and 20 DEG .

Owner:TUNGALOY CORP

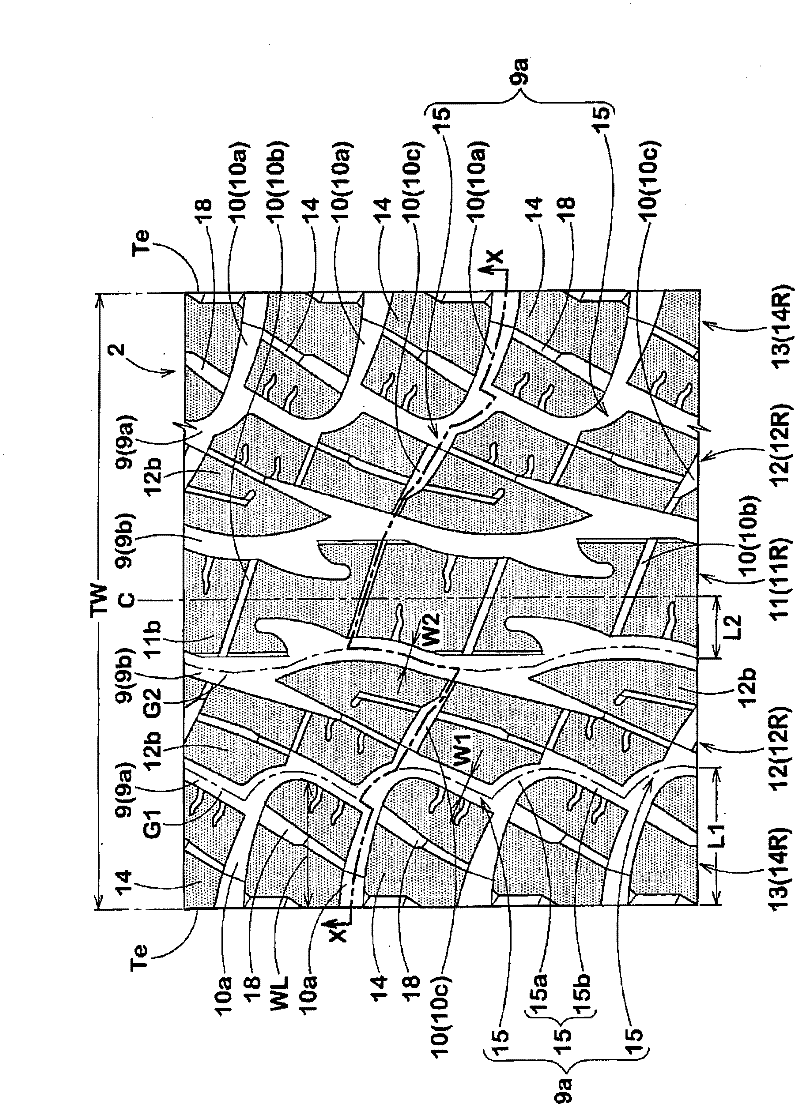

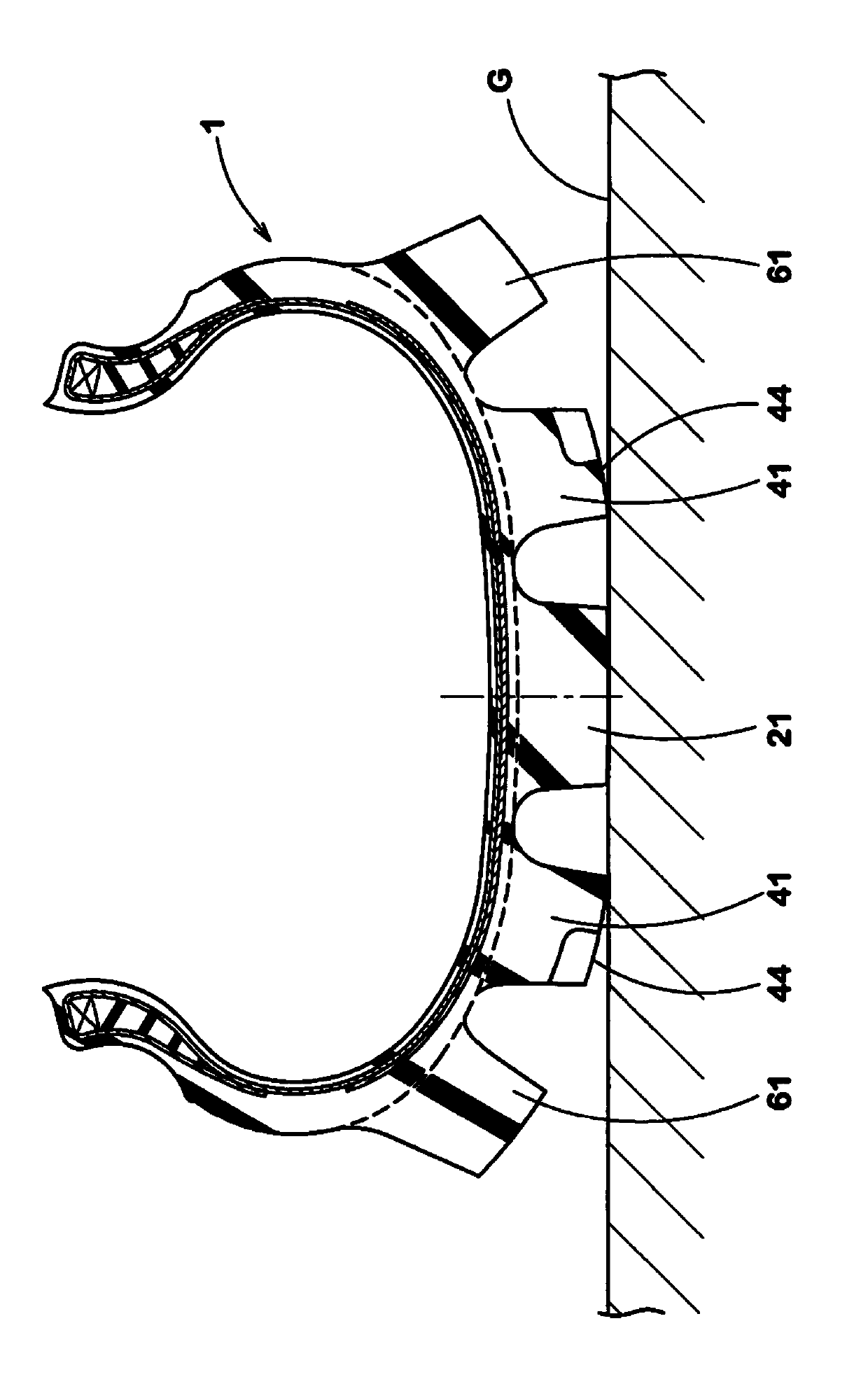

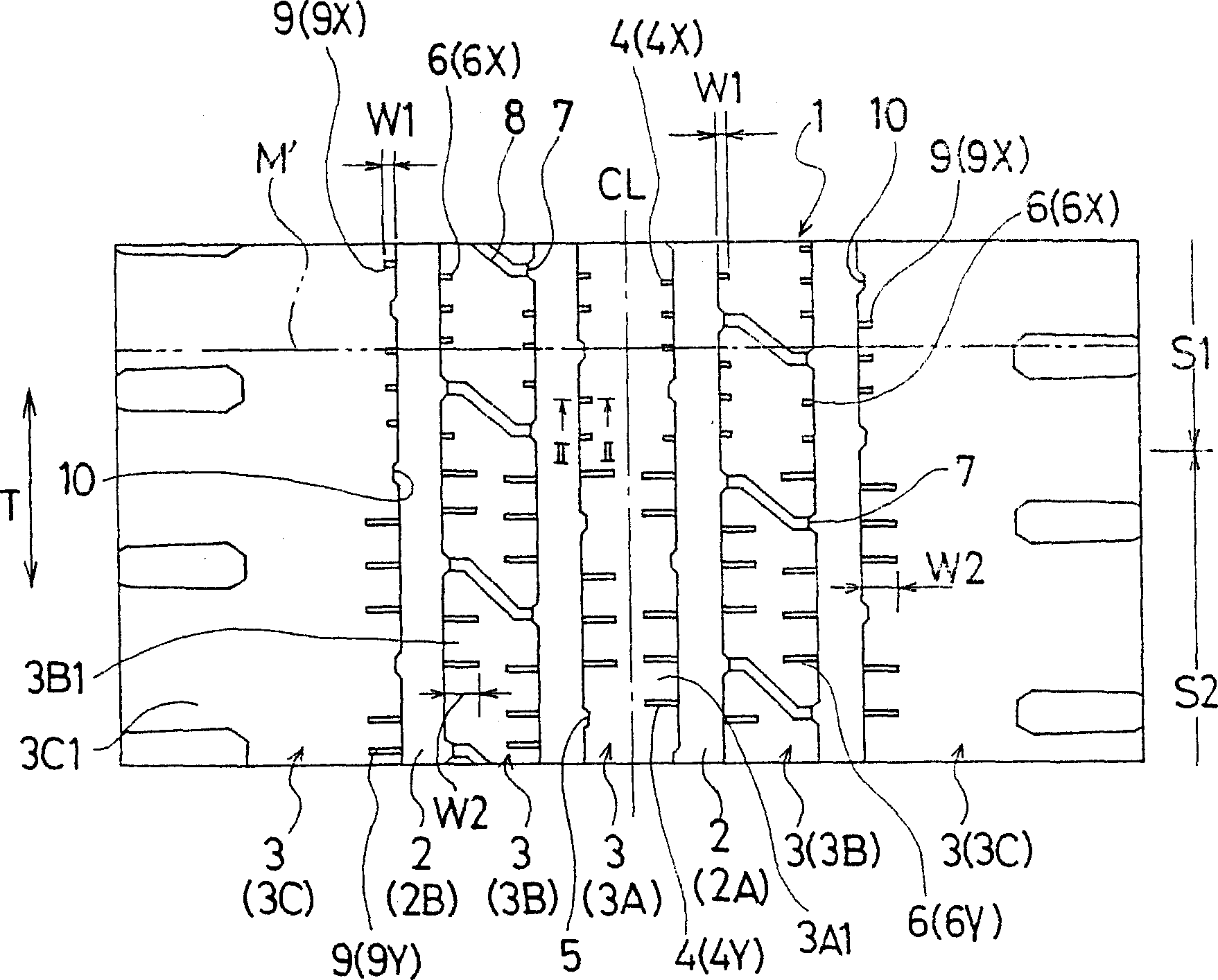

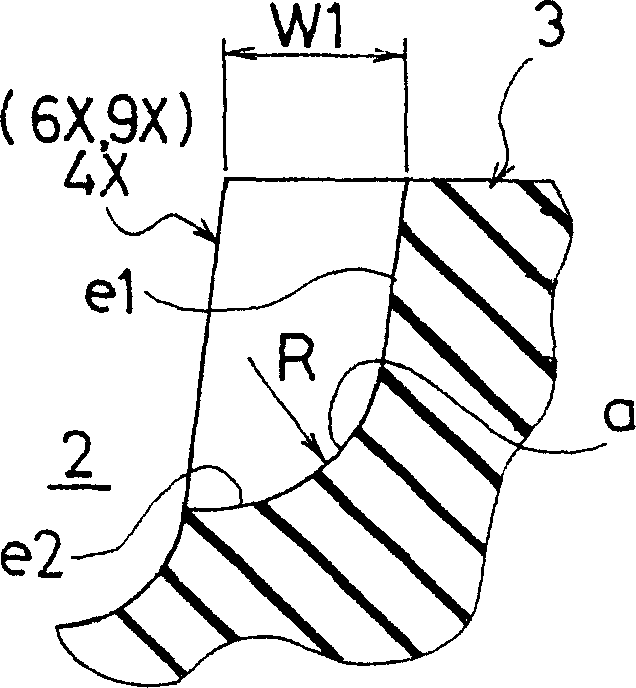

Pneumatic tire and tire mold

InactiveCN1636770ASuppression defectOptimize the extraction processTyresTyre tread bands/patternsEngineeringMechanical engineering

The present invention is a pneumatic tire vulcanized and molded by a split type tire mold composed of a plurality of sectors formed by dividing an annular side mold having a tread forming surface for forming a tread in the circumferential direction. . On the tread having the first region formed by the region near the sector division position of the sideform and the second region formed by the region far from the sector division position of the sideform, there is at least one tire extending in the circumferential direction of the tire. The land portion formed by dividing the circumferential grooves. In at least one of the land portions, fine lines extending from at least one of the circumferential grooves and extending from at least one of the land portions are arranged at predetermined intervals in the tire circumferential direction. The fine lines include first fine lines located in the first region and second fine lines located in the second region. The length W1 in the tire width direction of the first sipe is shorter than the length W2 in the tire width direction of the second sipe.

Owner:YOKOHAMA RUBBER CO LTD

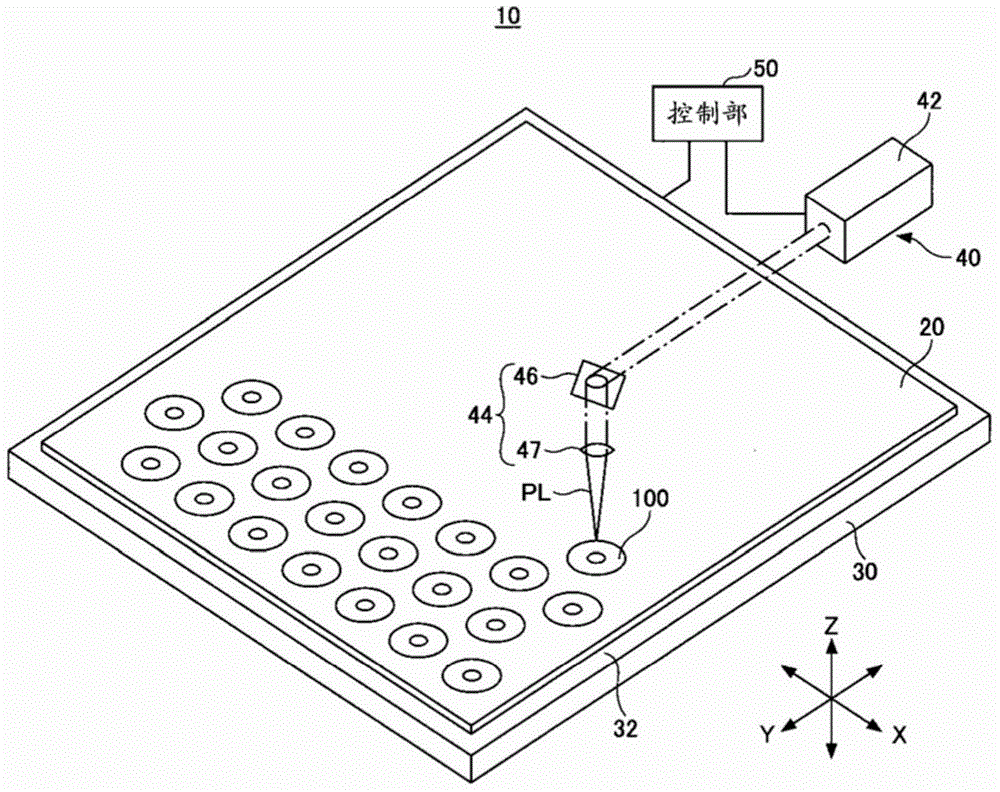

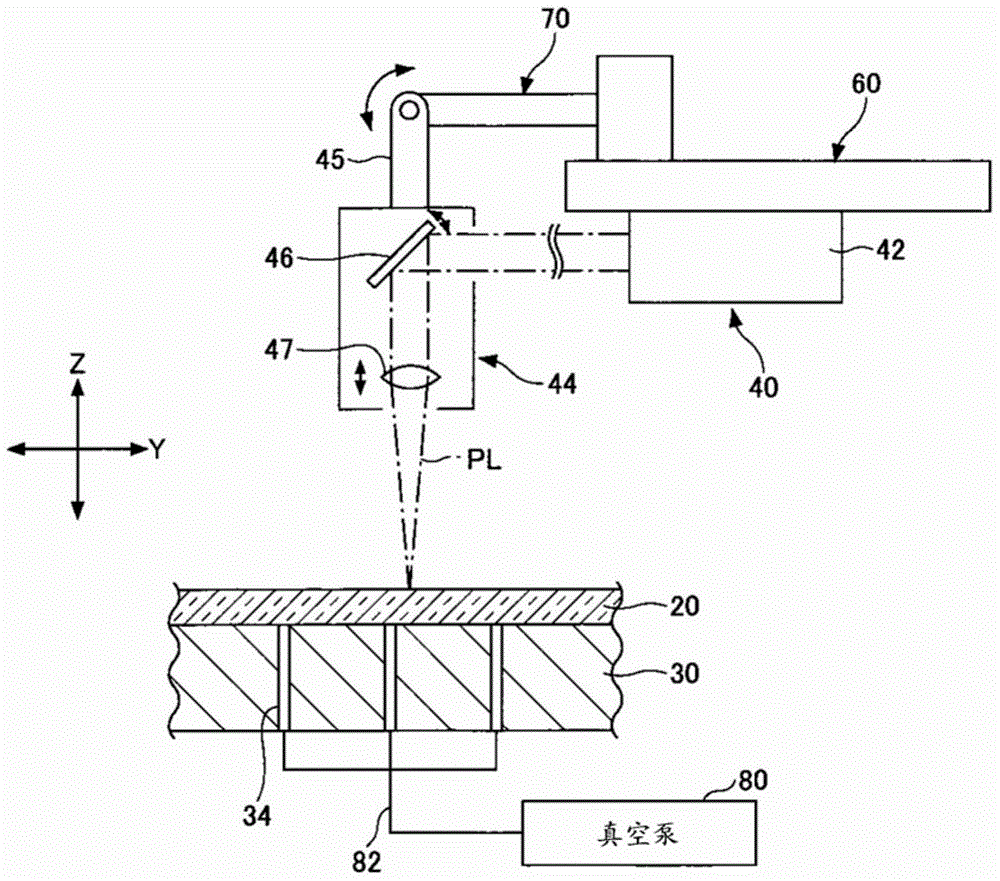

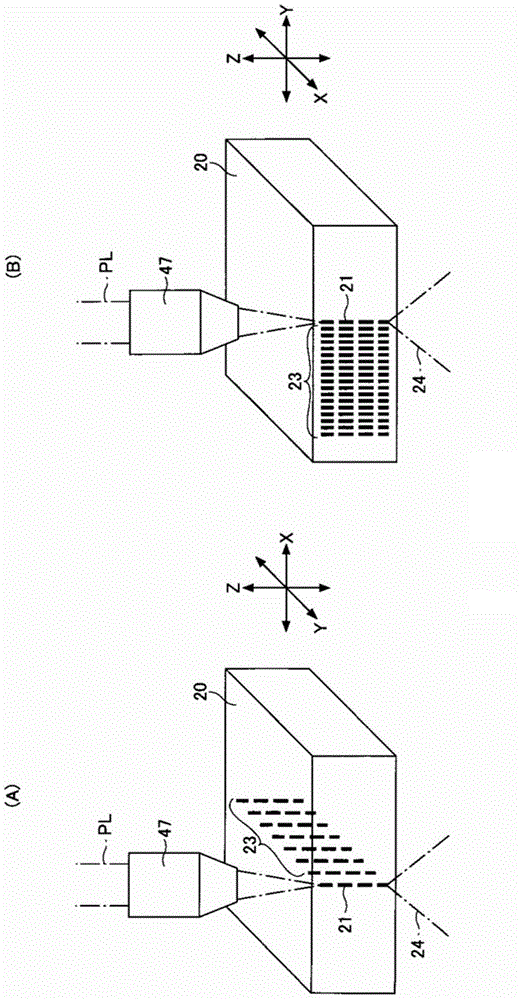

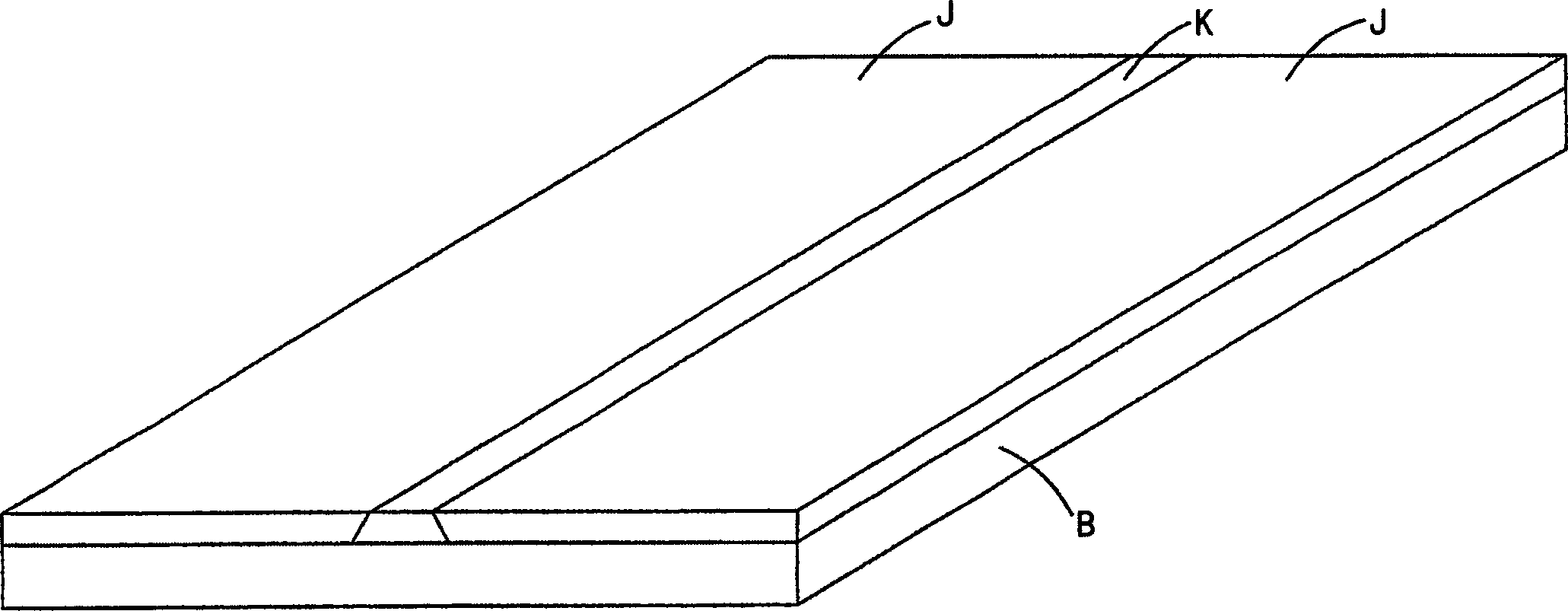

Disk-like glass substrate with magnetic recording medium and manufacturing method thereof

InactiveCN104551412AIncrease the number of sheetsSuppression defectRecord information storageDisk carriersNanosecondMicrometer

A disk-like glass substrate with magnetic recording medium and a manufacturing method thereof aim to improve productivity. The disk-like glass substrate does not contact with a wall surface of a cutting slot when being cut out from a glass blank. The method comprises a cutting step, a polishing step, and a cleaning step. In the cutting step, the substrate is cut out of the glass blank along a circular contour in the surface by means of a pulse laser beam with an irradiation pulse width greater than 1 femtosecond and less than 1 nanosecond, so that the cutting slot wider than 10 micrometer is formed along the contour. In the polishing step, a main surface of the substrate is polished. In the cleaning step, the surface of the substrate is cleaned.

Owner:ASAHI GLASS CO LTD

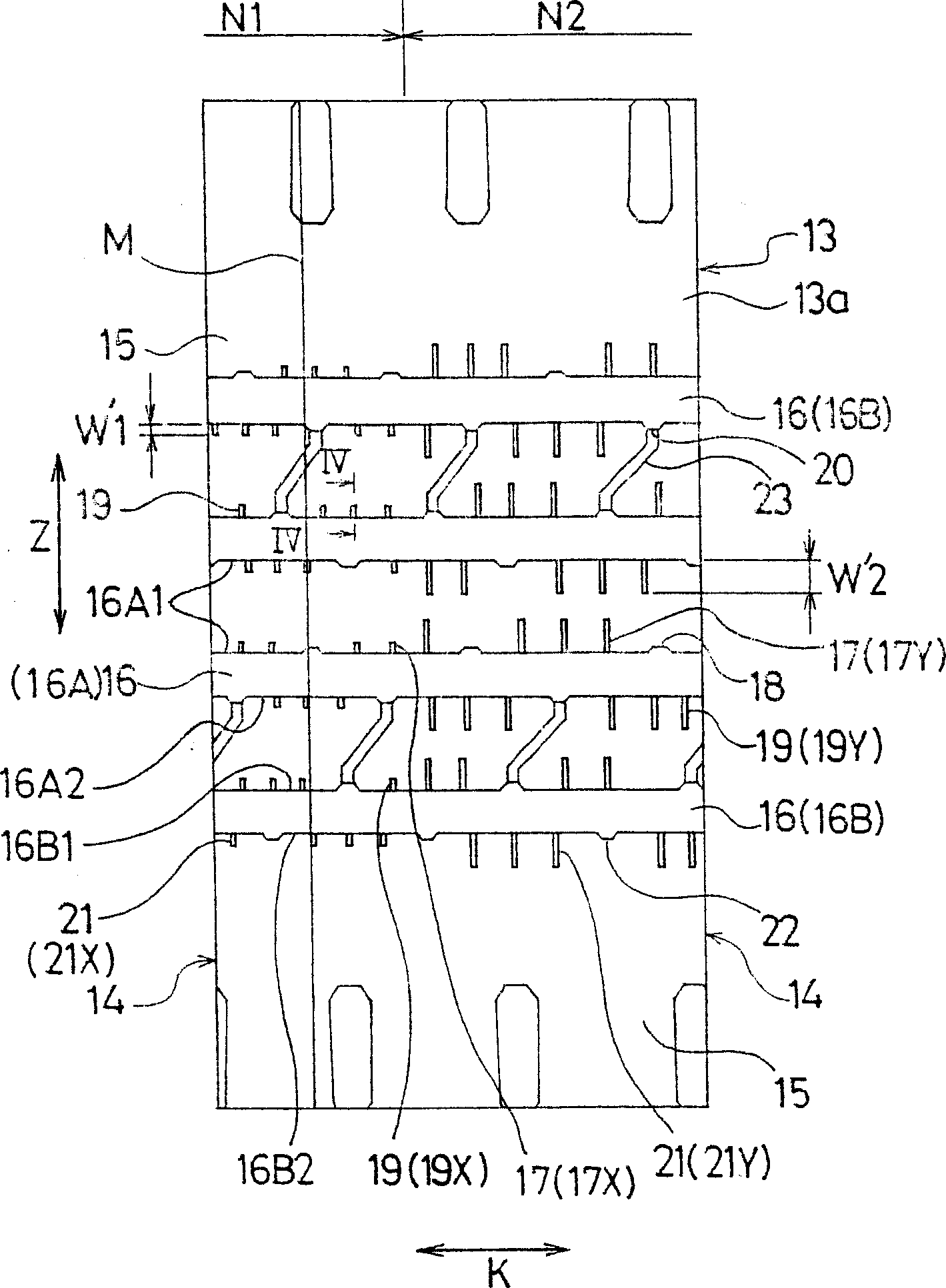

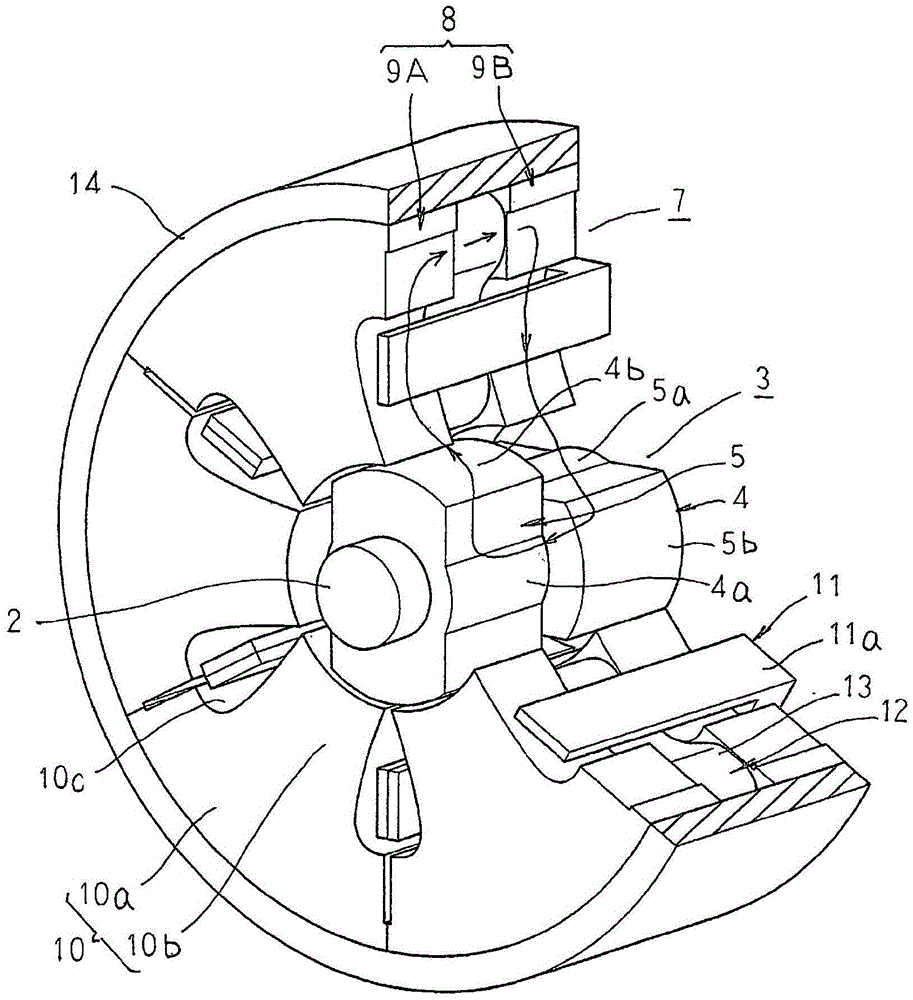

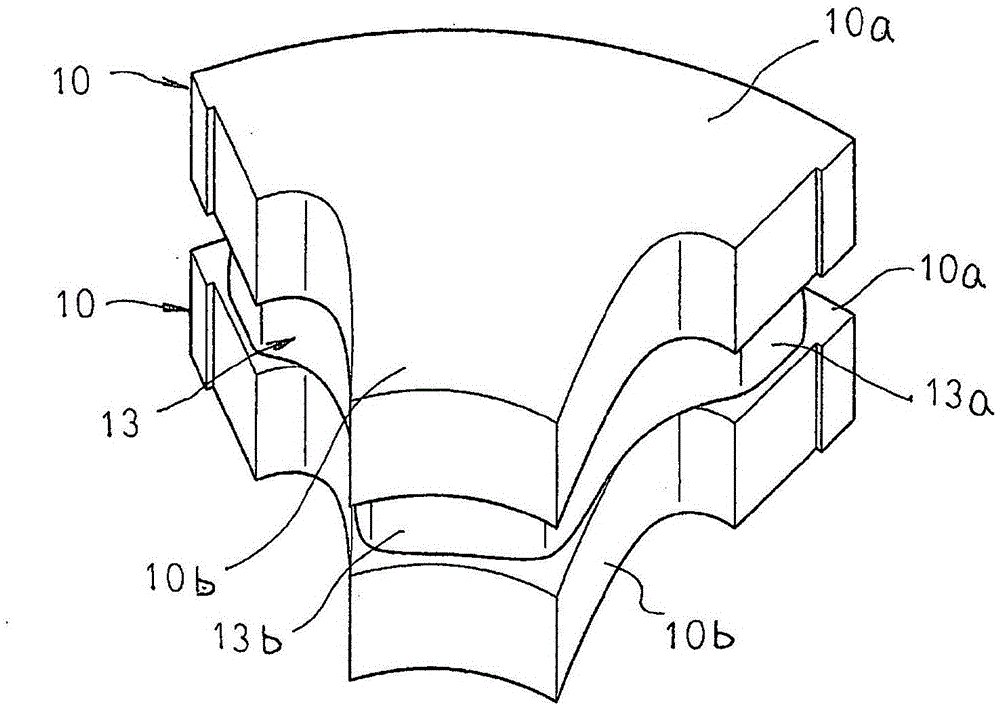

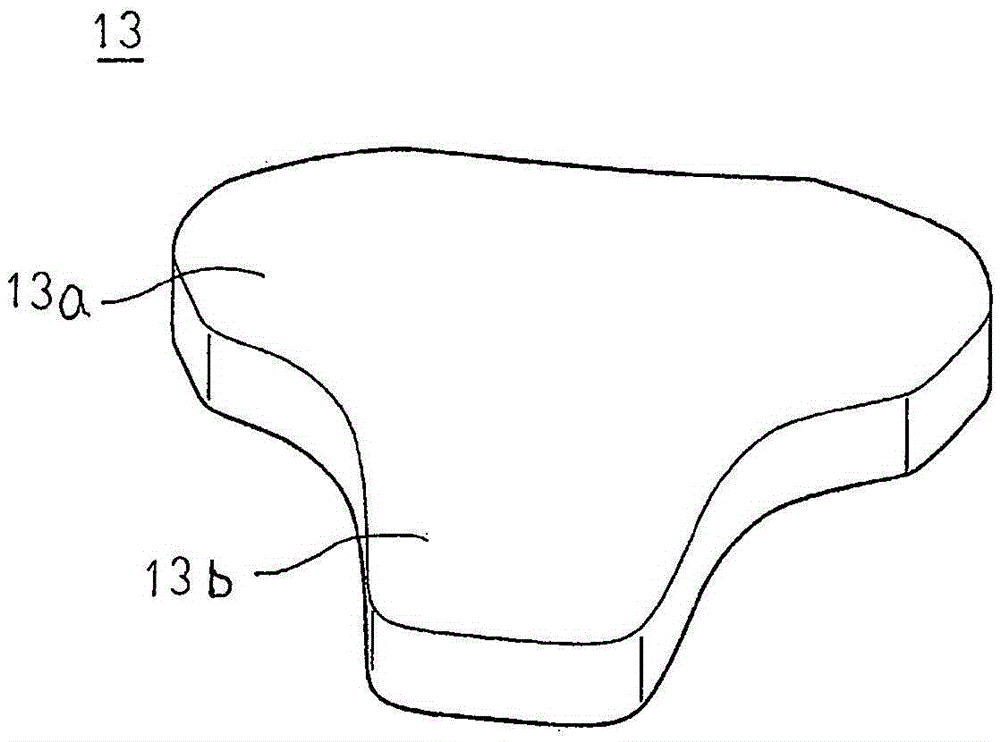

Magnetic induction motor

ActiveCN105580255AAvoid contactInhibition of ruptureMagnetic circuit rotating partsSynchronous machinesInduction motorMagnet

The present invention obtains a magnetic induction motor that, when core block pairs that sandwich magnet blocks are arrayed in an annular shape and are integrated, eliminates contact between magnet blocks and is able to suppress the occurrence of cracks or chips in the magnet blocks. In the present invention: a first stator core (9A) and a second stator core (9B) cause core block (10) pairs, which are configured by separating and superposing in the axial direction an arc-shaped core back section (10a) and core blocks (10) comprising teeth (10b) protruding inwards in the radial direction from the inner peripheral surface of the core back section (10a), to be configured arrayed in an annular shape in a manner such that the lateral surfaces in the peripheral direction of the core back sections (10a) contact each other; permanent magnets (12) are configured in a manner split respectively to the plurality of magnet blocks (13) sandwiched between the core block (10) pairs in a manner so as to fit within the core block (10) pairs; and the magnet blocks (13) have a base section (13a) sandwiched between the core back sections (10a) and of which the two lateral surfaces in the peripheral direction have an outer shape positioned at the inside in the peripheral direction from the two lateral surfaces in the peripheral direction of the core back sections (10a).

Owner:MITSUBISHI ELECTRIC CORP

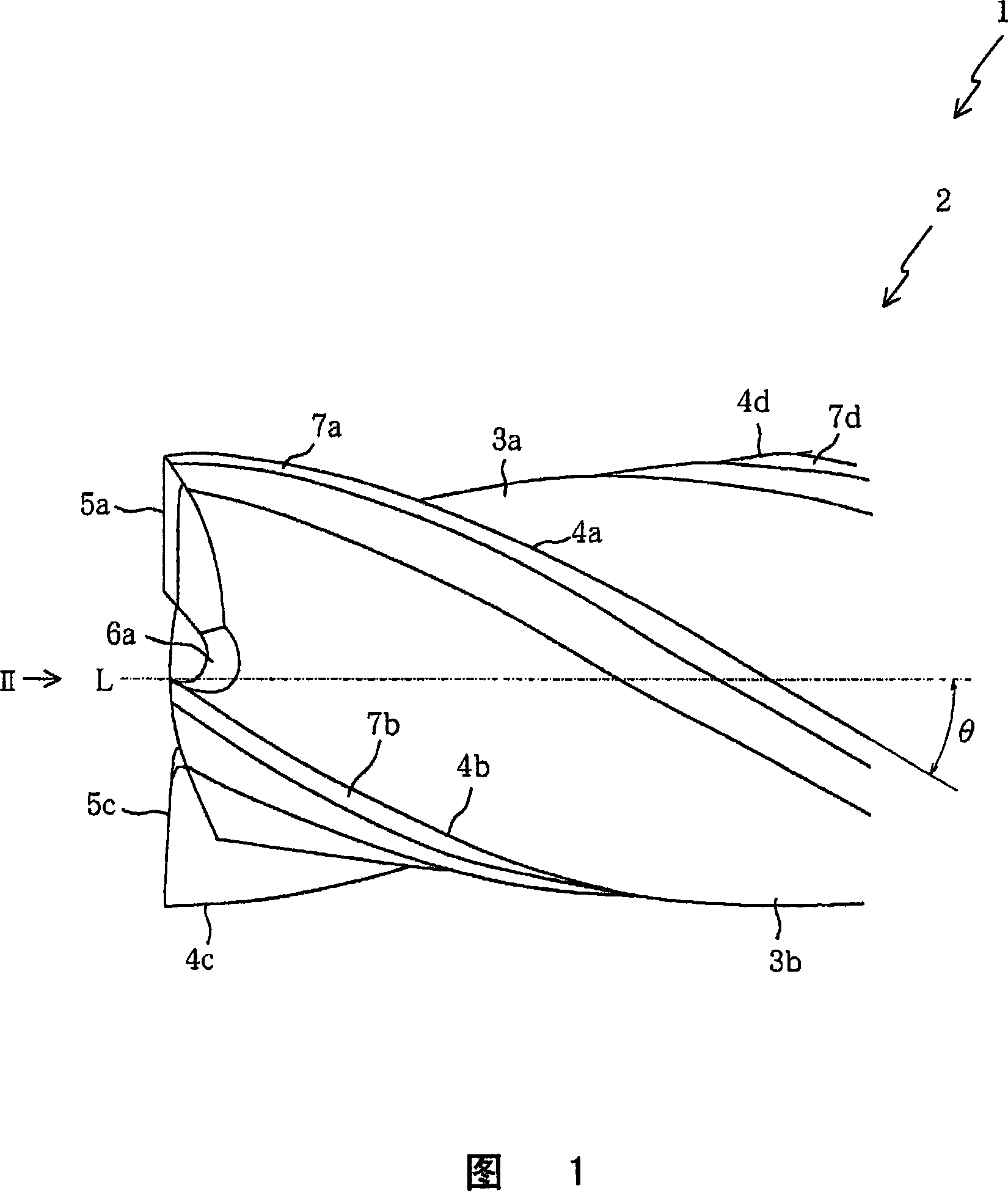

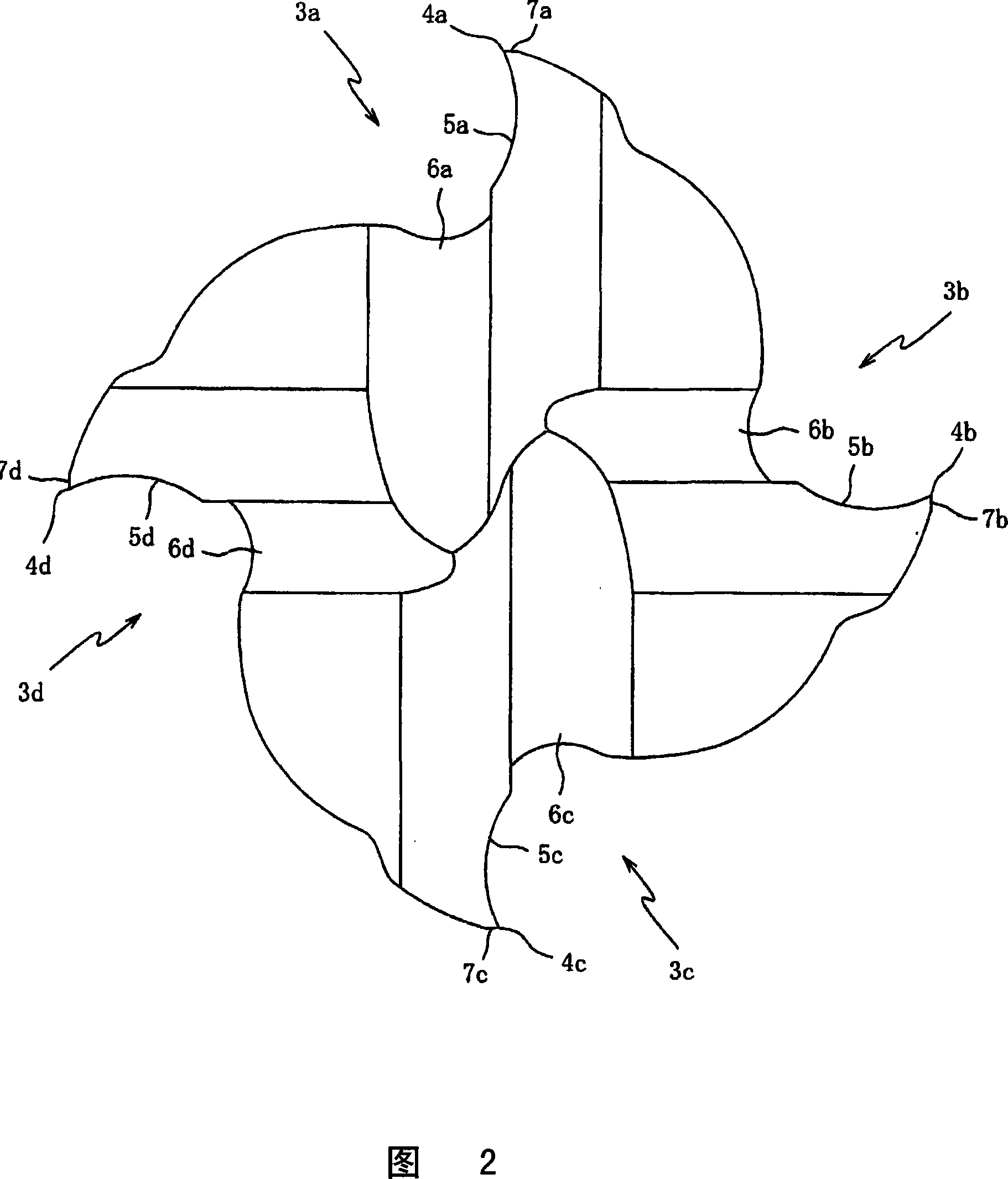

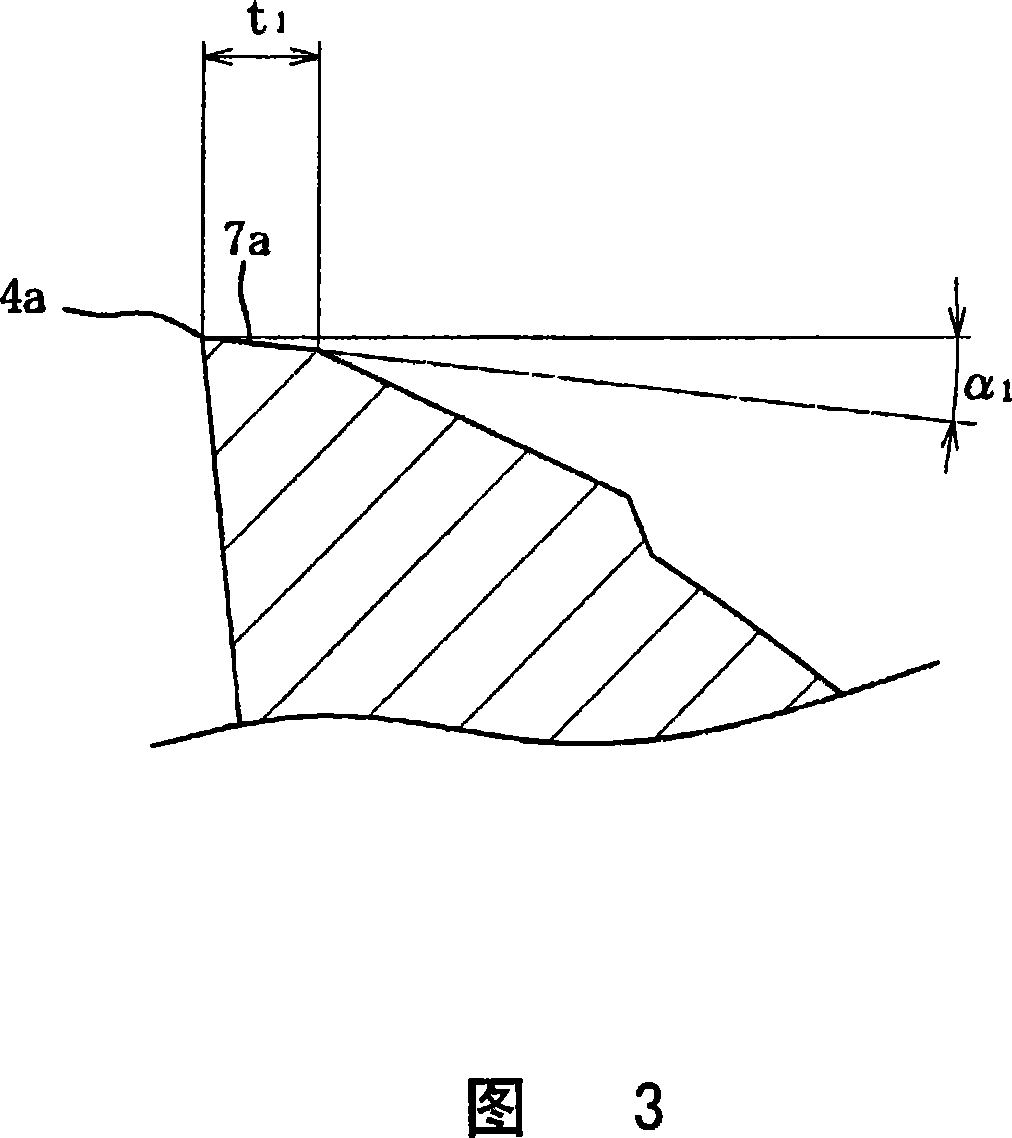

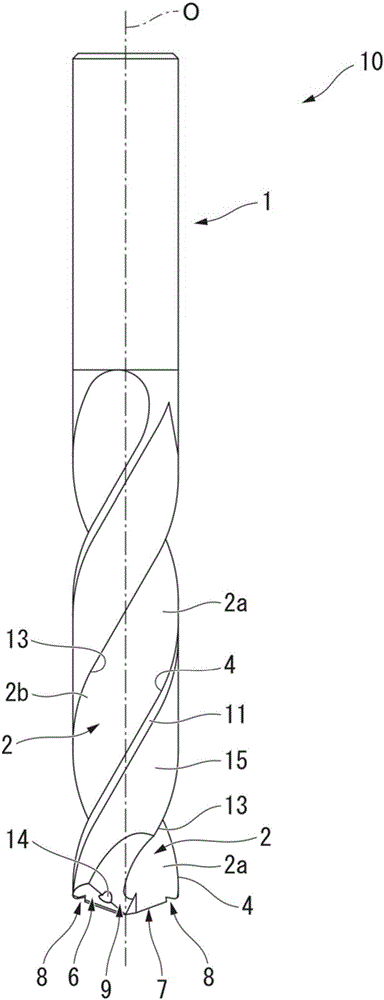

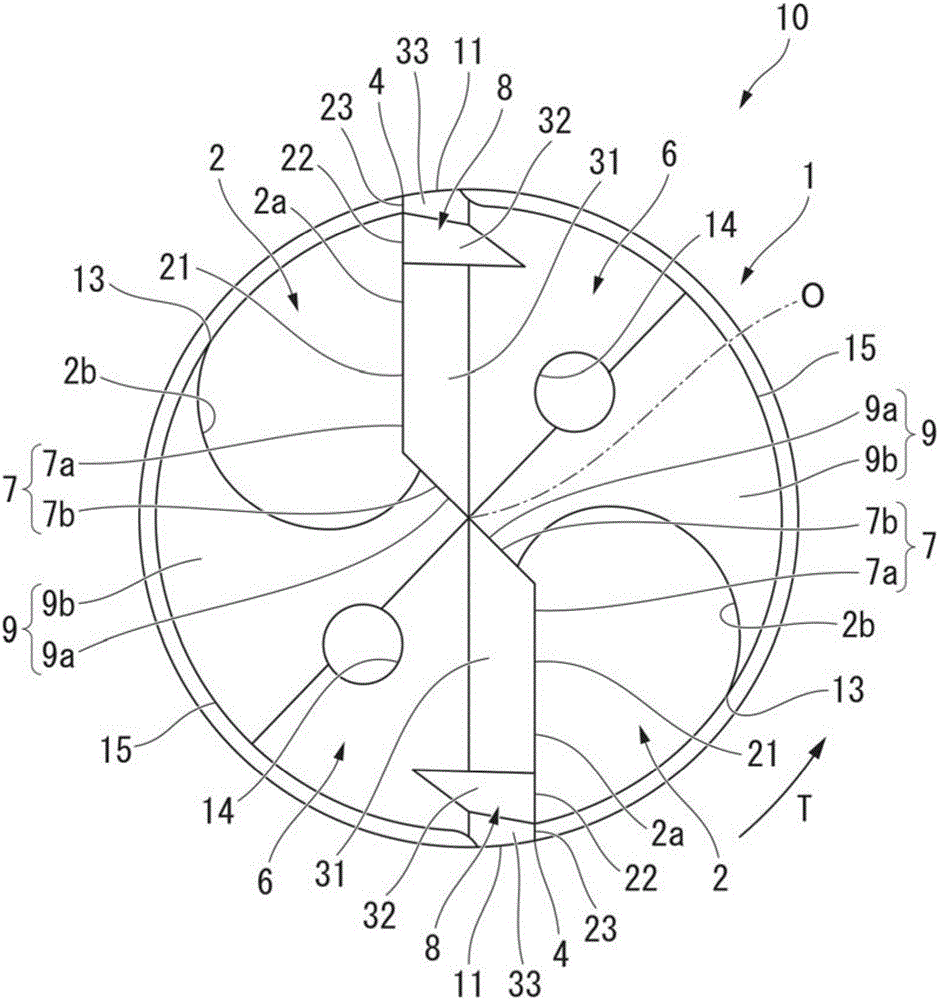

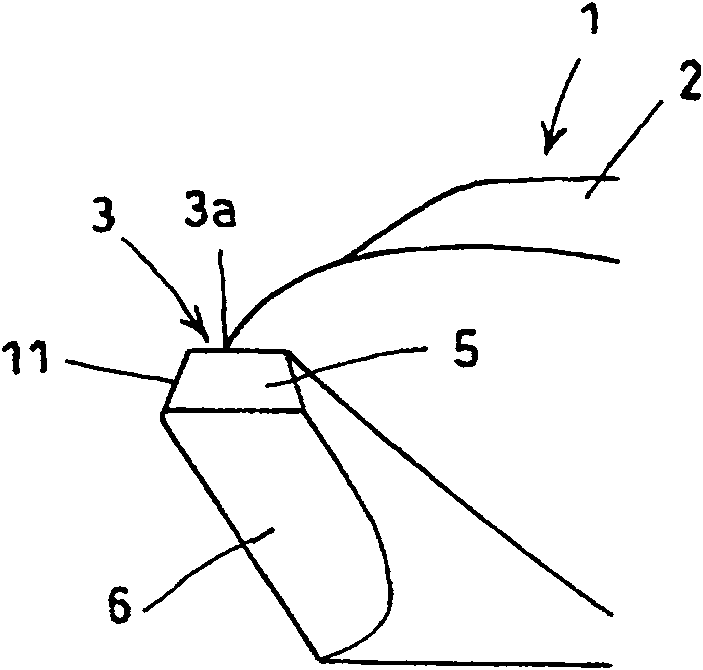

Drill and drill head

InactiveCN106660141AEvenly dispersedUniform and stable flowTransportation and packagingWorkpiecesFluteEngineering

A drill is provided with a drill body that is rotated around the axial line, chip-discharging flutes (2) formed on the periphery of the drill body, and tip edges (7) formed on the intersection ridges between the chip-discharging flutes (2) and the tip surfaces of the drill body. The tip edges (7) have a first lip (21), which extends toward the base end of the axial direction as one follows the lip radially outward, and a second lip (22), which is disposed outside of the first lip (21) in the radial direction. The second lip (22) extends toward the tip in the axial direction or is perpendicular to the axis line as one follows the lip radially outward. The radially inside end of the second lip (22) is disposed on the axially base end side of the radially outside end of the first lip (21), and the radially outside end of the second lip (22) is disposed on a virtual extension (VL) of the first lip (21) that extends radially outward.

Owner:MITSUBISHI MATERIALS CORP

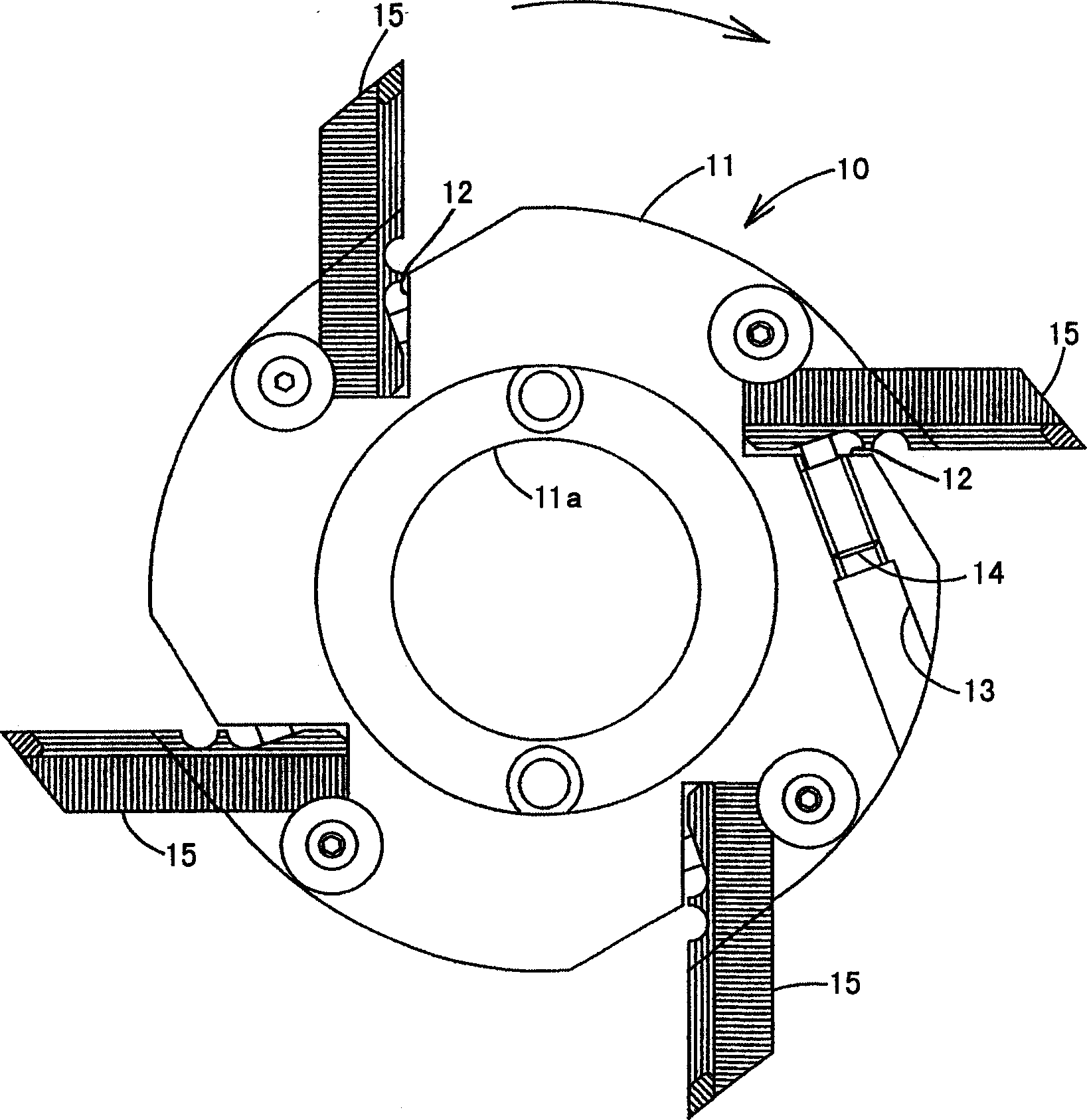

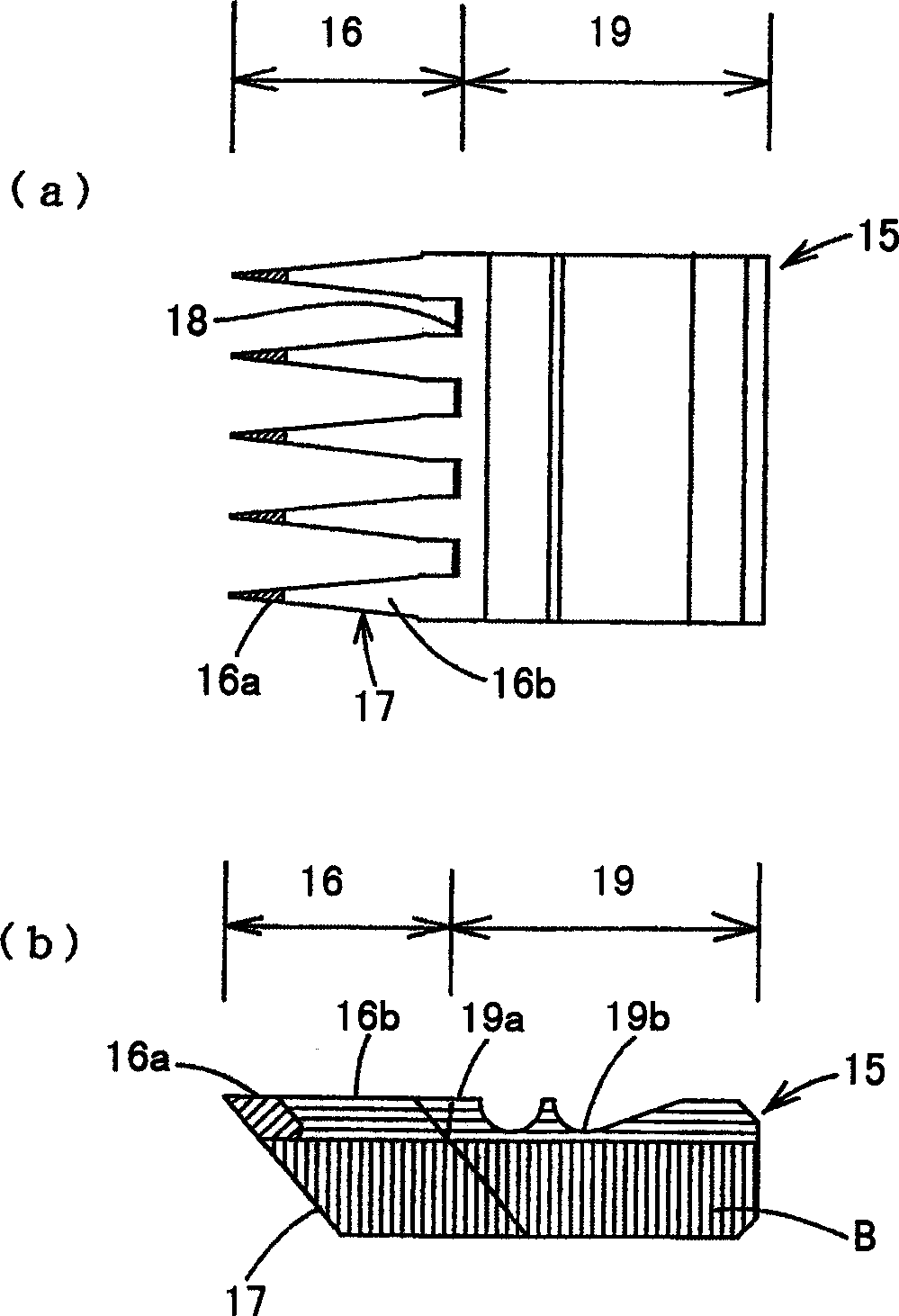

Finger cutter

InactiveCN1538899AInhibit wearSuppression defectRotary cutting toolsFinger joining apparatusMilling cutterFinger joint

Cutting portion regions 16 of replaceable blades 15 that extrude outward in a radial direction at a plurality of portions in a peripheral direction of an outer periphery of a body 11 of a finger joint cutter are arranged in that, as for a cutting portion material that comprises cutting edge, tip end cutting portions 16a are formed of a steel material of high hardness and base portion side cutting portions 16b, which are the remaining portions, are formed of a steel material that exhibits a higher toughness than that of the tip end cutting portions. It is possible to improve the wear resistance through the tip end cutting portions and to improve the chipping resistance by the base portion side cutting portions. The steel material of high hardness comprising the tip end cutting portions and the steel material of high toughness comprising the base portion side cutting portions are successively joined through forge welding.

Owner:KANEFUSA HAMONO KOUGIYOU KK

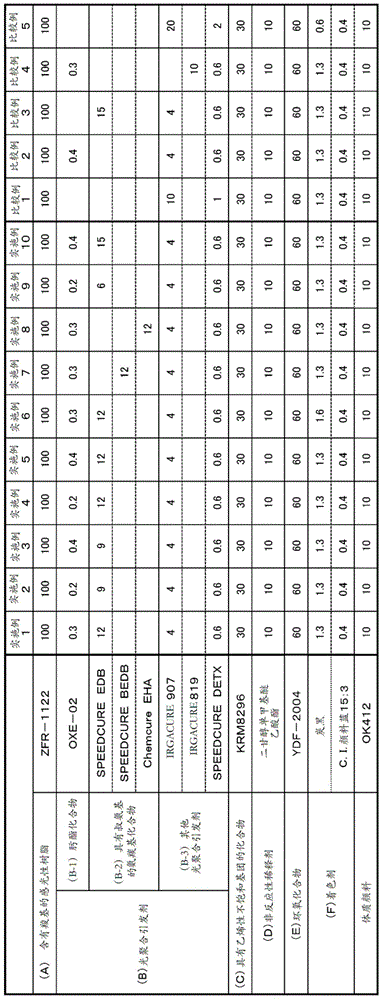

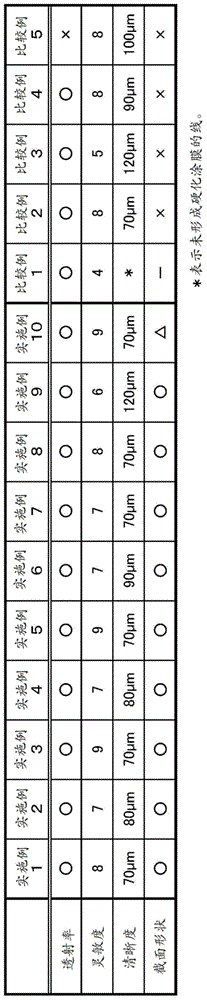

Photosensitive resin composition

InactiveCN104076603AAffect the transmittanceAffect sensitivityPrinted circuit detailsPrinted circuit aspectsReactive diluentOxime

A photosensitive resin composition includes a carboxyl group-containing photosensitive resin, a photopolymerization initiator, a compound having an ethylenic unsaturated group, a non-reactive diluent, and an epoxy compound. The photopolymerization initiator includes an oxime ester compound and an aminocarbonyl compound having a tertiary amino group.

Owner:TAMURA KK

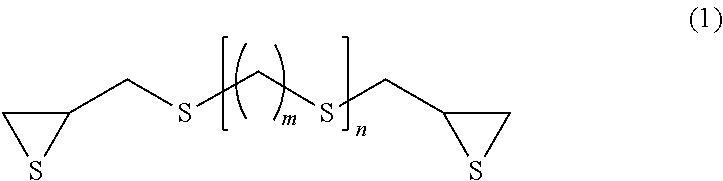

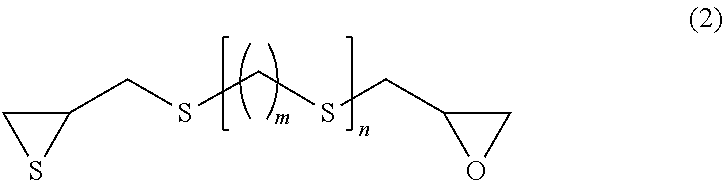

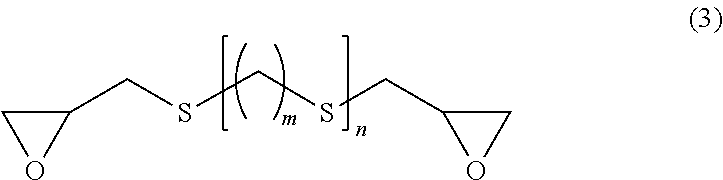

Composition for optical material, and method for producing same

ActiveUS9447226B2High refractive indexReduce yieldOptical elementsPolymer sciencePolymerization catalysts

Owner:MITSUBISHI GAS CHEM CO INC

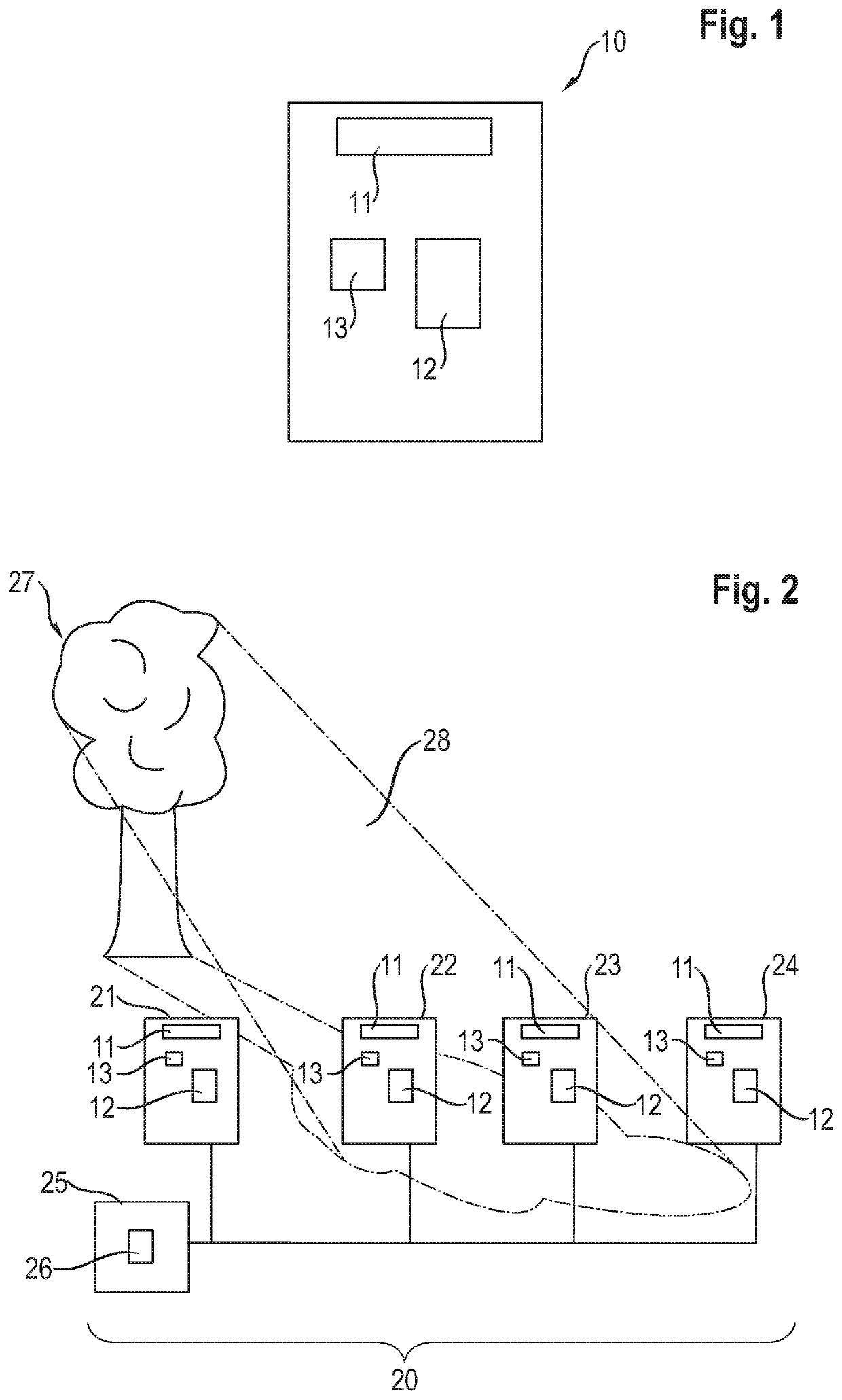

Lighting concept for a charging park

ActiveUS20200001737A1Improve cooling effectExcessive heatingCharging stationsElectrical apparatusDisplay deviceEngineering

A method for operating a charging system for charging electric vehicles, wherein the charging system has a charging station and at least two charging columns which are physically separate from one another and each have at least one charging connection. Each charging column has a light sensor and also a light and / or a display. The method includes receiving signals of the individual light sensors and also collectively evaluating the signals and adjusting the brightness of the light and / or the display of at least one of the charging columns depending on a result of collectively evaluating the received signals. Also described herein is a corresponding charging system.

Owner:DR ING H C F PORSCHE AG

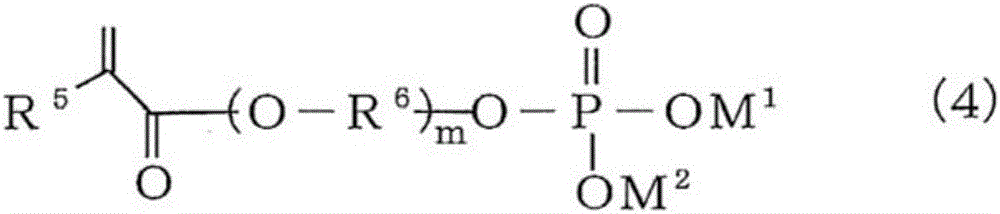

Anchor layer formation composition, anchor layer, optical film provided with adhesive layer, and image display device

InactiveCN106414634AIncreased durabilityExcellent reworkabilityLiquid surface applicatorsAntifouling/underwater paintsDisplay devicePolymer

Owner:NITTO DENKO CORP

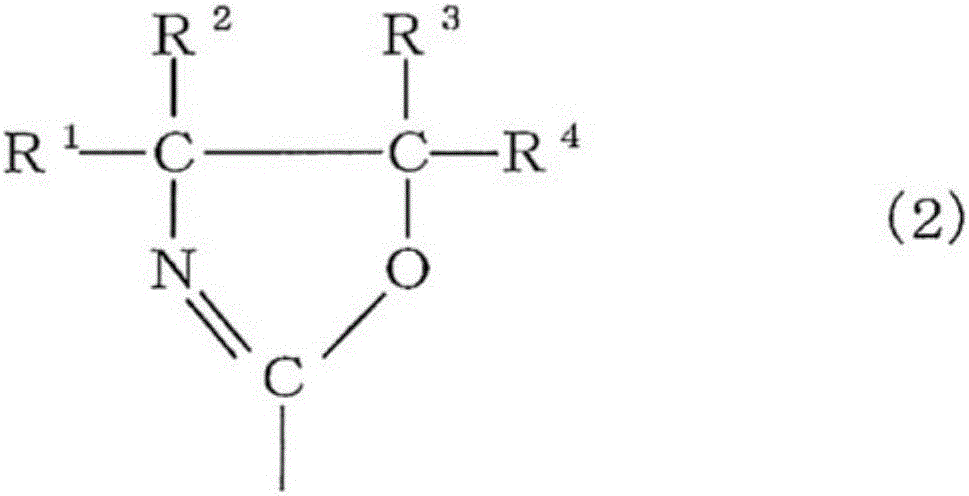

Photocurable resin composition for transferring surface free energy and method for producing substrate using same

ActiveUS20170204285A1Inhibition defectAvoid defectsPhotomechanical apparatusPretreated surfacesFree energiesTransmittance

The present application provides a photocurable resin composition for transferring surface free energy, the photocurable resin composition including a first compound exhibiting low surface free energy, a second compound exhibiting surface free energy higher than the surface free energy of the first compound, and a photopolymerization initiator, wherein a difference in transmittance of the photocurable resin composition to a wavelength of 450 nm between before and after addition of the first compound is less than 79.3%, and a method for producing a substrate using the photocurable resin composition.

Owner:DEXERIALS CORP

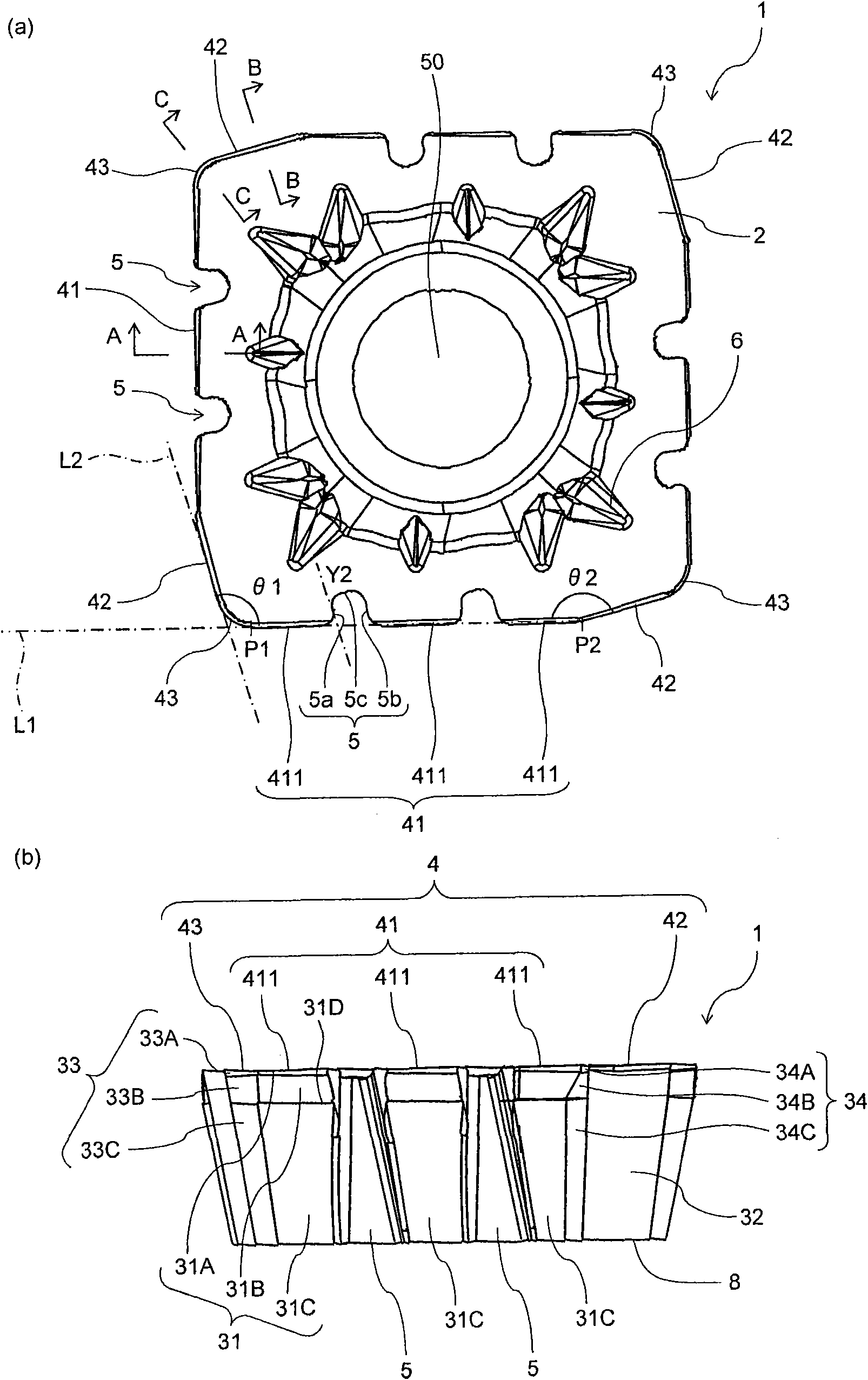

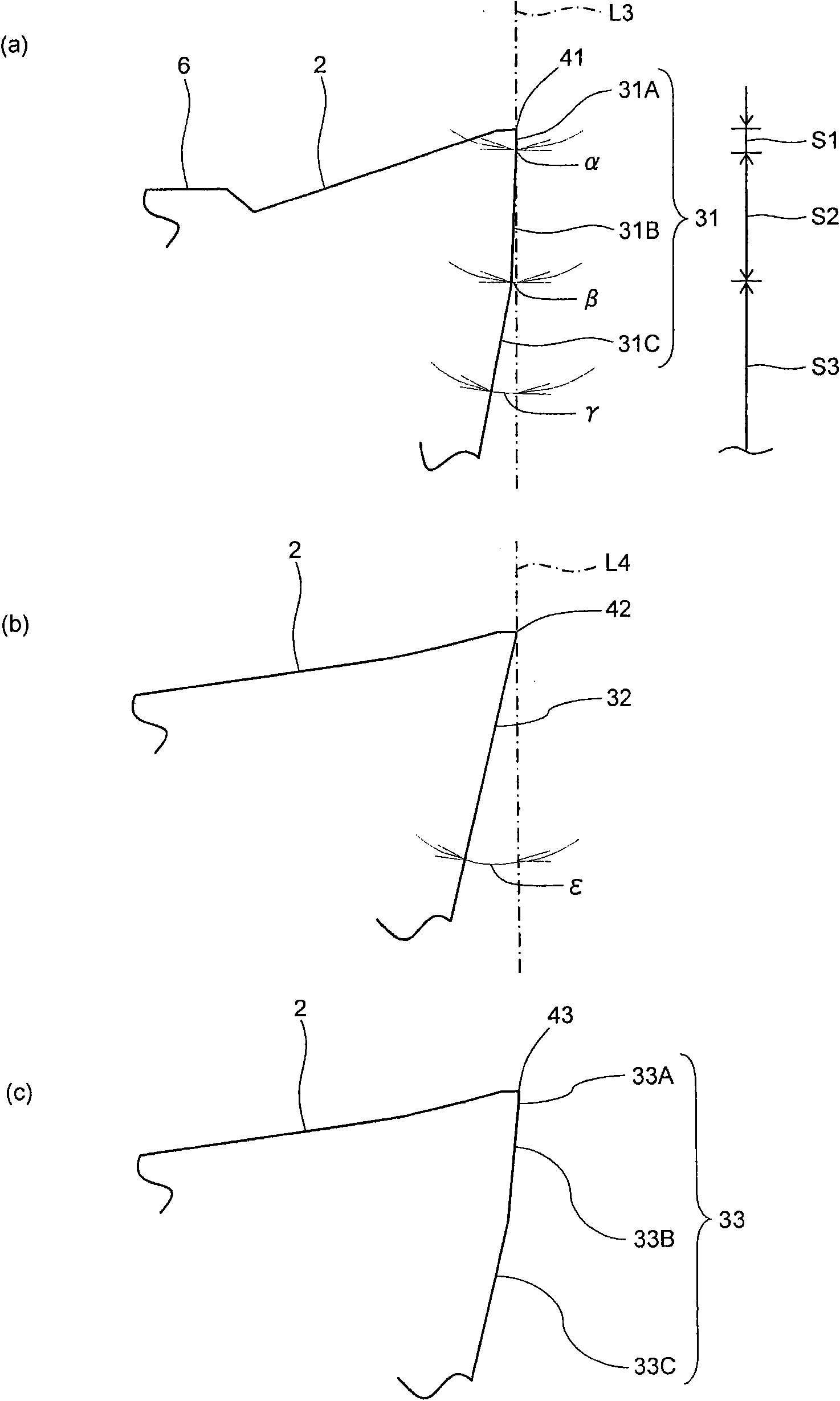

Cutting insert and cutting tool and cutting method employing it

ActiveCN101678465ASuppression defectExcellent machining accuracyMilling cuttersTurning toolsEngineeringMechanical engineering

A cutting insert having a substantially polygonal upper surface, a lower surface, a side face with a flank, and a cutting edge formed at the intersection of the upper surface and the side face.The cutting edge has a first cutting edge, a second cutting edge, and a third cutting edge located between the first and second cutting edge at the corner of the polygon. The flank has a first flank corresponding to the first cutting edge, and a second flank corresponding to the second cutting edge. The first flank has an upper flank connected with the first cutting edge, a middle flank located on the lower surface side of the upper flank, and a lower flank located on the lower surface side of the middle flank.Assuming the clearance angle of the upper flank is alpha, the clearance angle of the middleflank is belta, the clearance angle of the lower flank is gamma, and the clearance angle of the second flank is epsilon, the alpha, belta, gamma and epsilon satisfy the relation alpha<belta<gamma<epsilon. The cutting insert is attached to a cutting tool, and a cutting method employs the cutting tool.

Owner:KYOCERA CORP

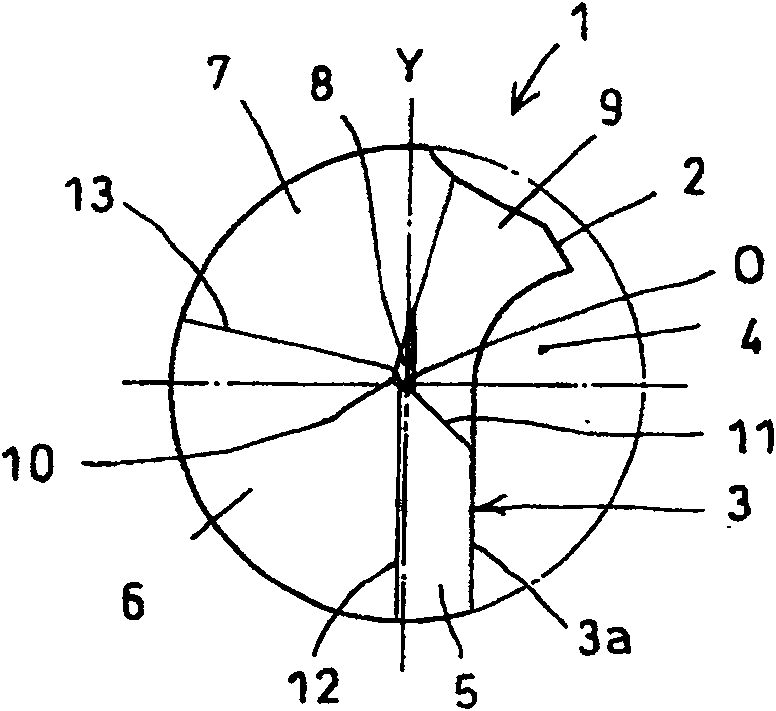

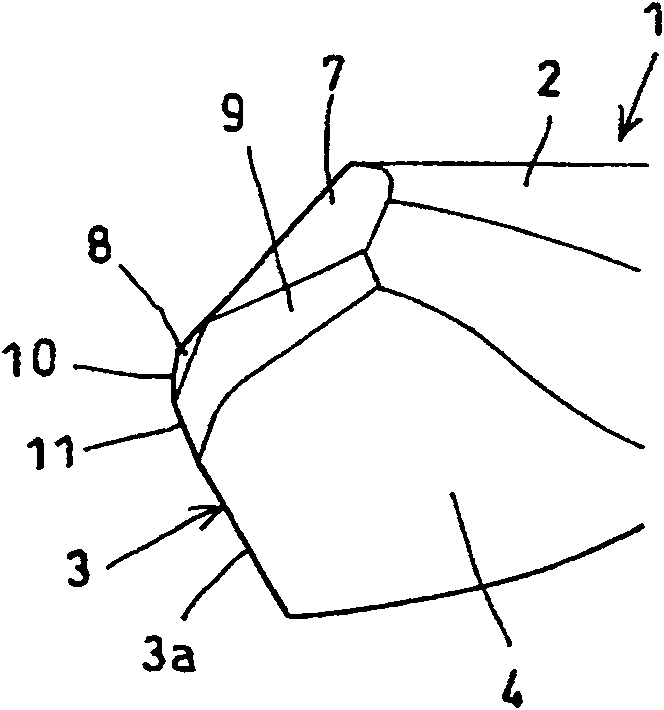

Single-lip drill

InactiveCN100563887CHigh strengthSuppression defectTransportation and packagingRecord carriers used with machinesFluteChisel

This invention is to provide a drill with a single cutting edge capable of stabilizing engagement with the work piece, preventing fractures of a chisel point to maintain high bore position accuracy over a long time, and causing less scatter of quality in manufacturing. The structure of this drill with a single cutting edge 3 and one chip flute 4 comprises multiple connected relief faces of the relief portion at the front end of the drill. At the foremost end of the drill is a first chisel edge, which is formed by the intersection of two relief faces and is perpendicular to the axial center and positioned at a rotary center of the drill. The first chisel edge is connected to the second chisel edge, which is formed by the intersection of two relief faces. The outer end of the second chisel edge is connected to the main cutting edge, where the opposite end of the second chisel edge is connected to the other end of the first chisel edge.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Pneumatic tires for trucks

ActiveCN102616090BReduce rigidityImprove anti-yaw performanceHeavy duty tyresHeavy duty vehicleTransverse grooveAgricultural engineering

The invention provides a high-capacity inflatable tire, which is capable of preventing rubber loss and damage and improving the nibbling performance. A tread part (2) of the high-capacity inflatable tire (1) has a main groove (3) and a land portion (4). The main groove (3) comprises a tire-shoulder main groove (3A). The land portion (4) comprises a central land portion (4A) and a tire-shoulder land portion (4B). The central land portion (4A) is spacedly provided with central pattern blocks (7). A tire-shoulder auxiliary groove (9) and a tire-shoulder transverse groove (10) are formed on the tire-shoulder land portion (4B). The tire-shoulder auxiliary groove (9) comprises an outer tire-shoulder auxiliary groove (9A) and an inner tire-shoulder auxiliary groove (9B). The tire-shoulder transverse groove (10) comprises an inner portion (10A), a central portion (10B) and an outer portion (10C). The tire-shoulder land portion (4B) is spacedly provided with an inner tire-shoulder pattern block row (11A), a central tire-shoulder pattern block row (11B) and an outer tire-shoulder pattern block row (11C). The spacing distance (P2) between the inner portion (10A), the central portion (10B) and the outer portion (10C) is smaller than the spacing distance (P1) of a central transverse groove (6).

Owner:SUMITOMO RUBBER IND LTD

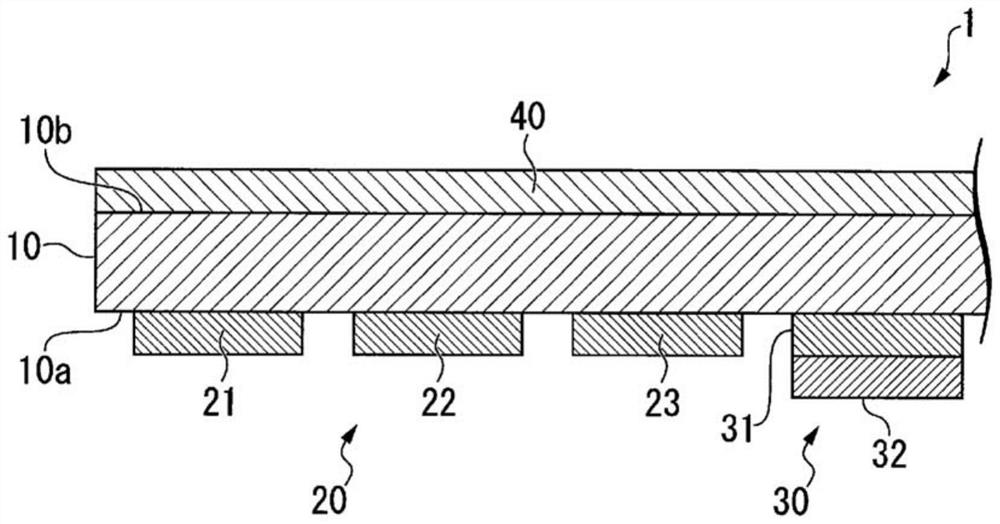

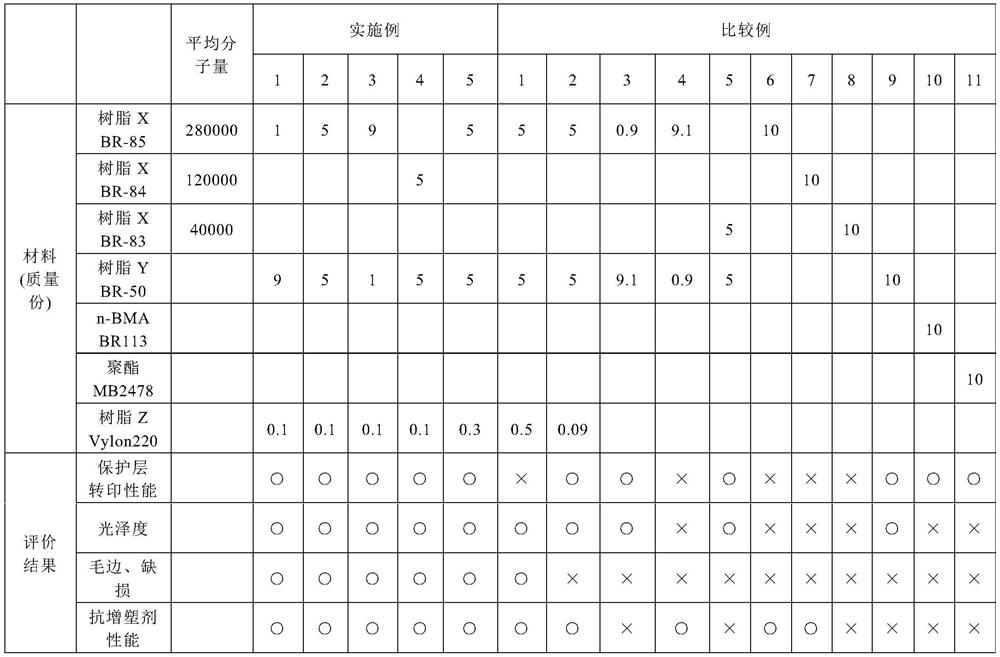

Thermal transfer ribbon

ActiveCN112654505AProperly protectedSuppression defectSynthetic resin layered productsThermographyPolymer scienceAcrylic resin

A transferable protective layer in a thermal transfer ribbon has a first layer formed upon a substrate and a second layer formed upon the first layer, said thermal transfer ribbon having a dye layer and the transferable protective layer repeatedly formed on one surface of the substrate. The first layer comprises: an acrylic resin (X) including a methyl methacrylate; an acrylic resin (Y) including a styrene-based resin; and a polyester resin (Z). The weight-average molecular weight of X is at least 120,000, the mass ratio between X and Y is 1:9-9:1, the mass of Z is 1%-3% of the total mass of X and Y.

Owner:TOPPAN PRINTING CO LTD

Replaceable cutter blade and replaceable cutter

The throwaway tip characterized that the shape is approximately square type plate late, and the corner angle of the another two corner tooth which adjoins each other of one face is made as 90 DEG or less, and the other two corner edge which counters respectively is made as non parallel cutting tooth, a corner angle of another corner cutting edge(11) is set to 90 deg.C or less. The throwaway type cutting tool characterized that two or more throwaway tip is the same as the throwaway tip, and the throwaway tips are arranged so that the other two corner tooth projects respectively to a perimeter side of a tip of a main part of a tool, in a throwaway type cutting tool that the two or more throwaway tips are arranged so that the tip is projected respectively to a tip side of a main part of a tool.

Owner:MITSUBISHI MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com