End mill

An end mill and tool technology, applied in milling cutters, forming knives, milling machine equipment, etc., can solve problems such as difficulty in reducing processing efficiency and cost, wear or defect of end mills, and reduced chip discharge, etc. Effect of roughening, preventing roughening, and suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

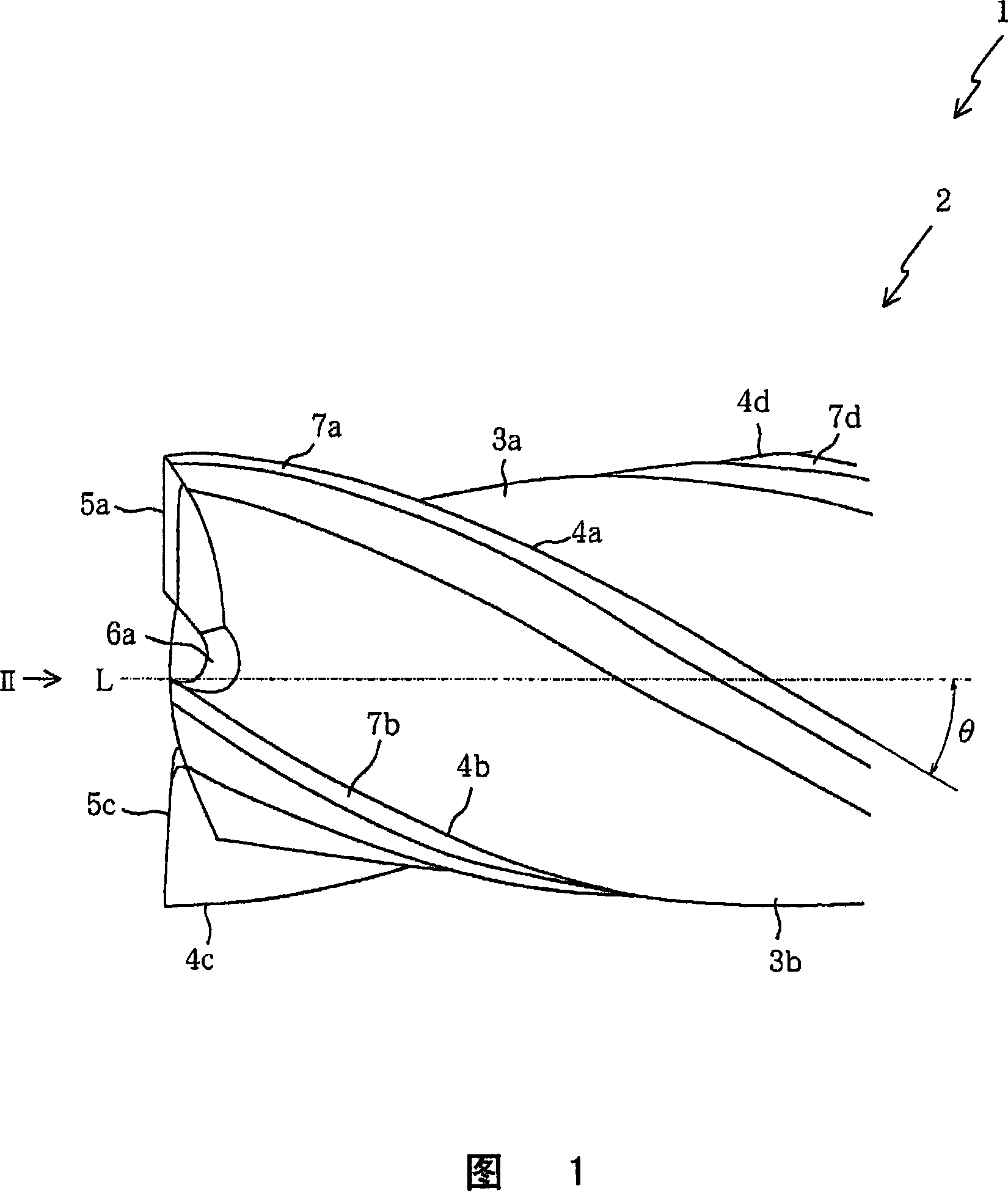

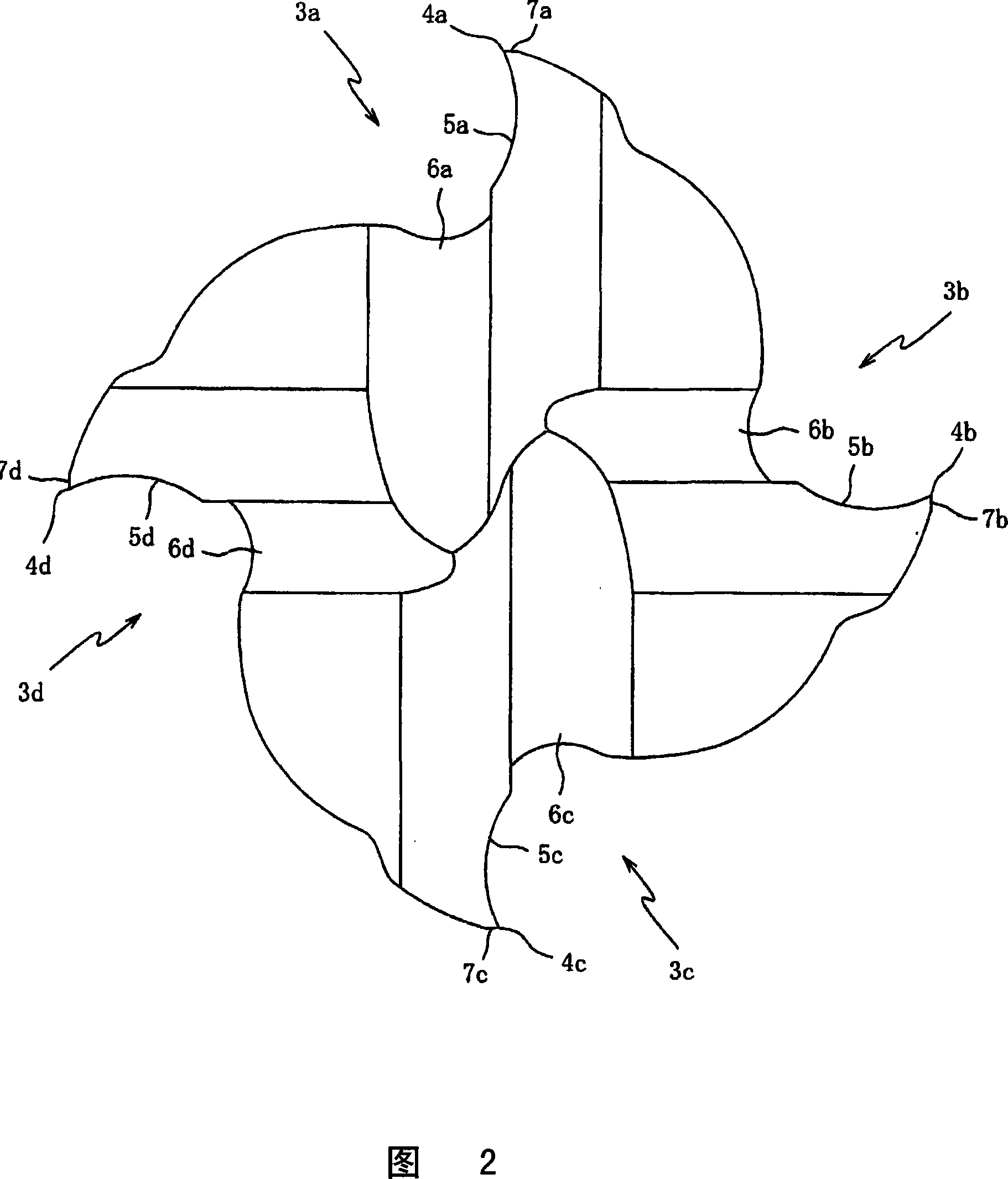

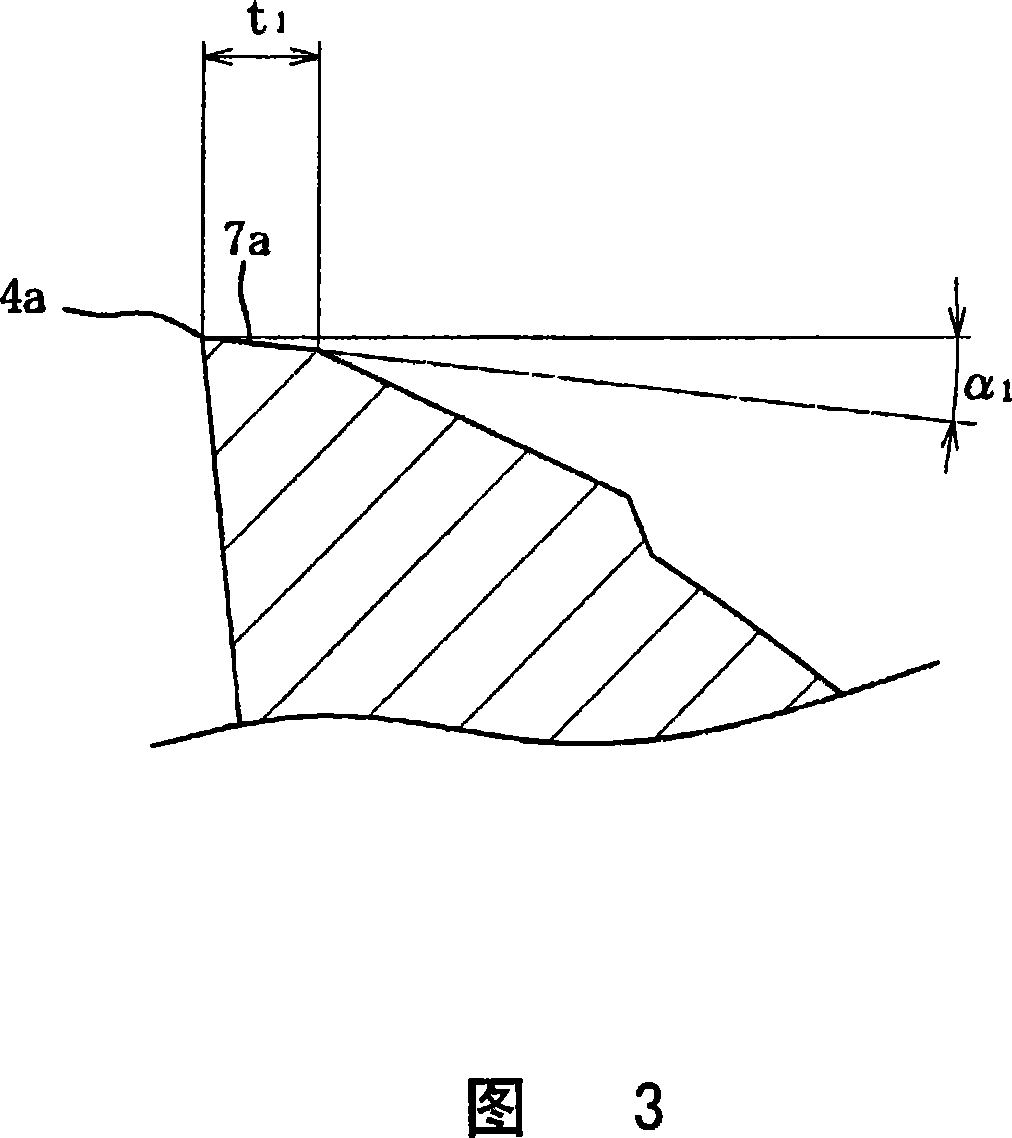

[0035] Hereinafter, embodiments of the present invention will be described based on the drawings. Fig. 1 is an enlarged front view of an end mill 1 according to an embodiment of the present invention, Fig. 2 is a side view of the end mill 1 viewed from the direction of arrow II in Fig. 1 , and Fig. 3 is a peripheral edge of the end mill 1 4a is a cross-sectional view at right angles to the axis. First, the overall structure of the end mill 1 will be described with reference to FIGS. 1 to 3 .

[0036] The end mill 1 is a solid square end mill including a tool body 2 having an axis L. As shown in FIG. The tool body 2 is made of cemented carbide after tungsten carbide (WC) is pressurized and sintered. ˜6d, the first relief surfaces 7a-7d of the peripheral cutting edges 4a-4d, and a cylindrical shank (not shown) formed on the other end side.

[0037] In addition, in this embodiment, titanium aluminum nitride (TiAlN) is coated on the peripheral cutting edges 4 a to 4 d and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com