Patents

Literature

121results about How to "Improve liquid permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water absorbent resin composition and production method thereof

InactiveUS20050288182A1Promote absorptionInhibitionOther chemical processesBaby linensCross-linkAbsorption capacity

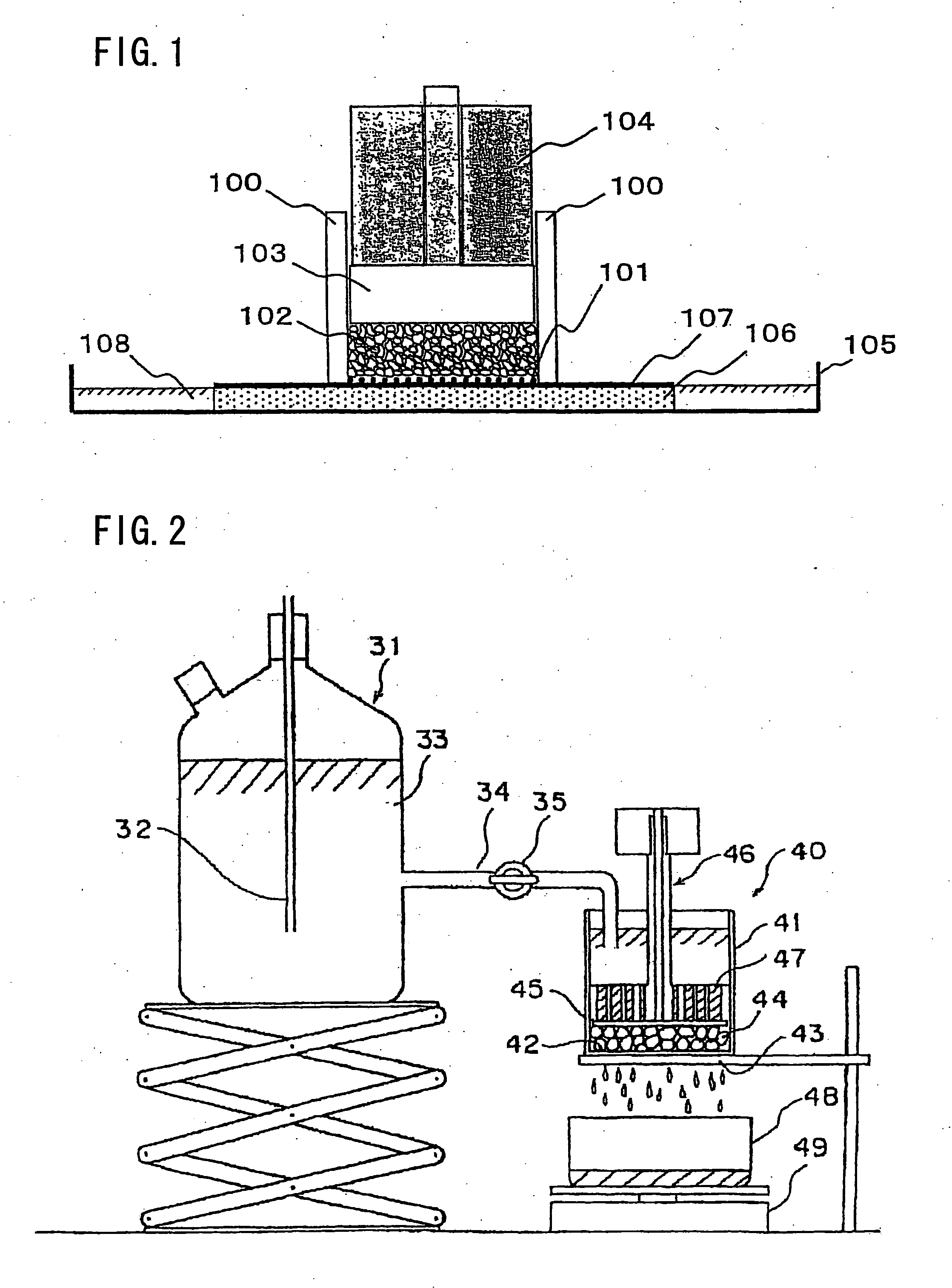

The water absorbent resin composition and the production method thereof according to the present invention are characterized by including: water absorbent resin particles having an internal cross-linked structure obtained by polymerizing a water-soluble unsaturated monomer; a nitrogenous ketone compound (A) (containing no carboxyl group) having a structure represented by formula (1); and a bivalent and / or trivalent and / or tetravalent water-soluble metal salt, wherein a total amount of the nitrogenous ketone compound (A) and the bivalent and / or trivalent and / or tetravalent water-soluble metal salt ranges from 0.01 to 100 parts by mass with respect to 100 parts by mass of the water absorbent resin particles, thereby providing a water absorbent resin composition, having an excellent absorption capacity represented by a centrifuge retention capacity (CRC), an absorbency against pressure of 4.83 kPa (AAP) etc., having excellent liquid permeability and liquid diffusion properties, having excellent fluidity at the time of moisture absorption, having an excellent damage resistance property, effectively suppressing occurrence of dusts, hardly bringing about permeation of added metal compounds into water absorbent resin particles, hardly bringing about segregation of added metal compounds.

Owner:NIPPON SHOKUBAI CO LTD

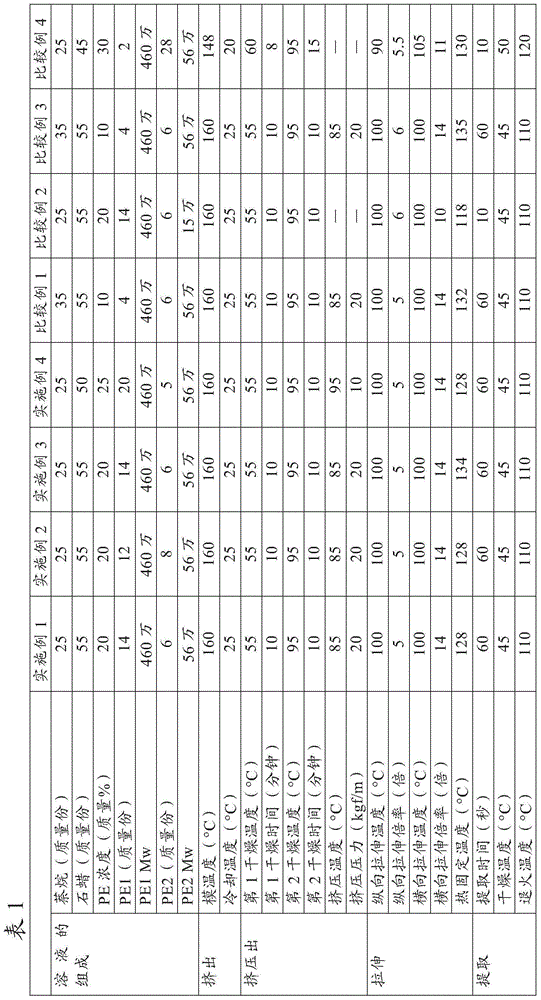

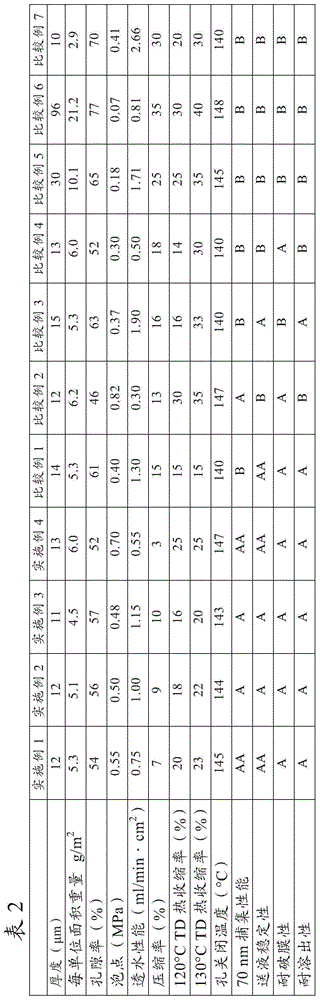

Lithium ion battery diaphragm, preparation method of lithium ion battery diaphragm and lithium ion battery

ActiveCN104157812ARequirements to ensure the strength of the diaphragmMeet the requirements of diaphragm strengthCell seperators/membranes/diaphragms/spacersSecondary cellsPorosityElectrical battery

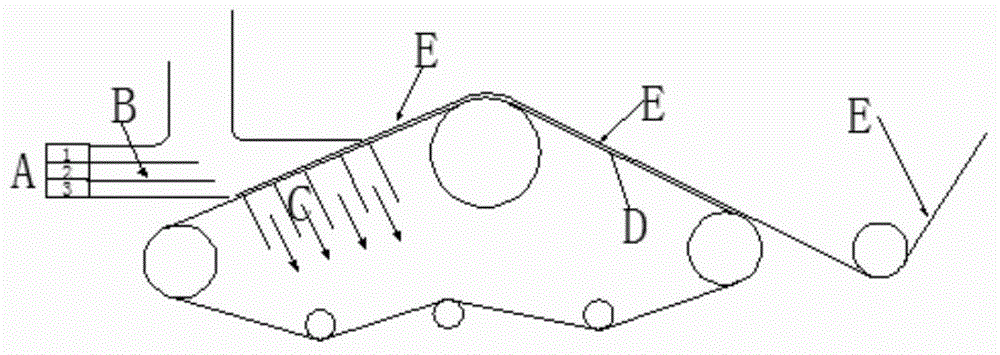

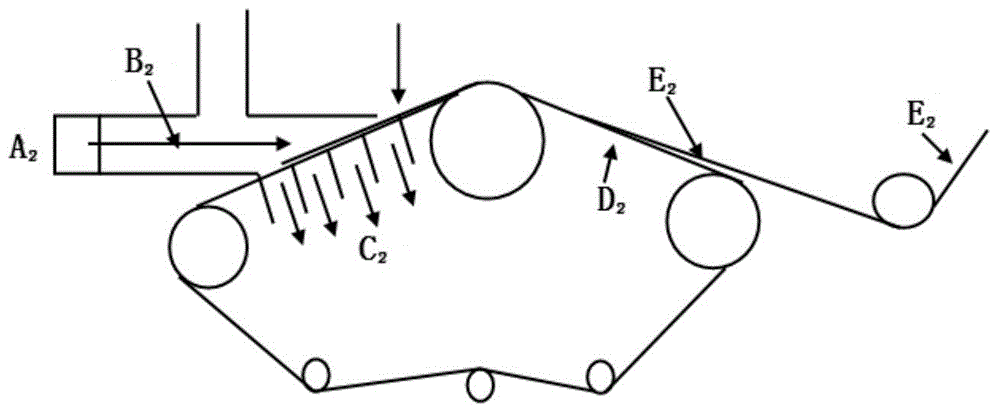

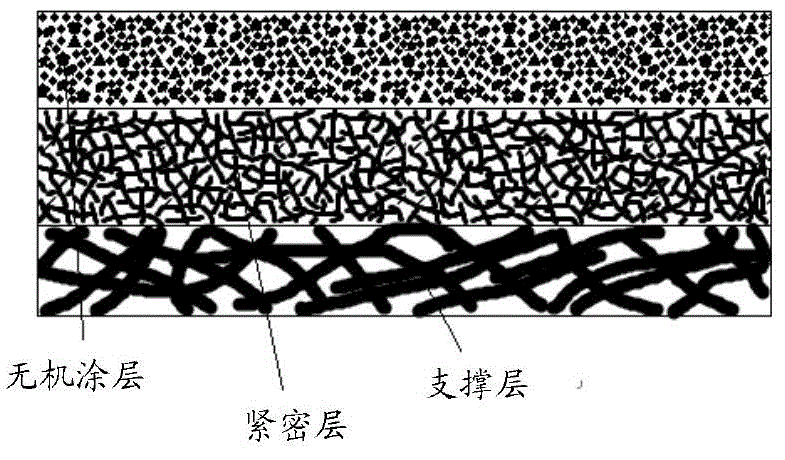

The invention provides a lithium ion battery diaphragm, a preparation method of the lithium ion battery diaphragm and a lithium ion battery. The lithium ion battery diaphragm comprises a support layer, wherein either or both of a dense layer or an inorganic coating are compounded on the support layer; the average quantity of the lithium ion battery diaphragm is 8-25g / m<2>, the thickness is 15-60 mu m, the average aperture is 50-500nm, and the porosity is 78-82%. The lithium ion battery diaphragm provided by the invention is good in isolating property and excellent in electrolyte absorbing property, is further relatively high in tension strength, is capable of realizing high power capacity of a battery, and can meet the requirement of rapid large-current charge and discharge of the lithium ion battery.

Owner:SOUTH CHINA UNIV OF TECH

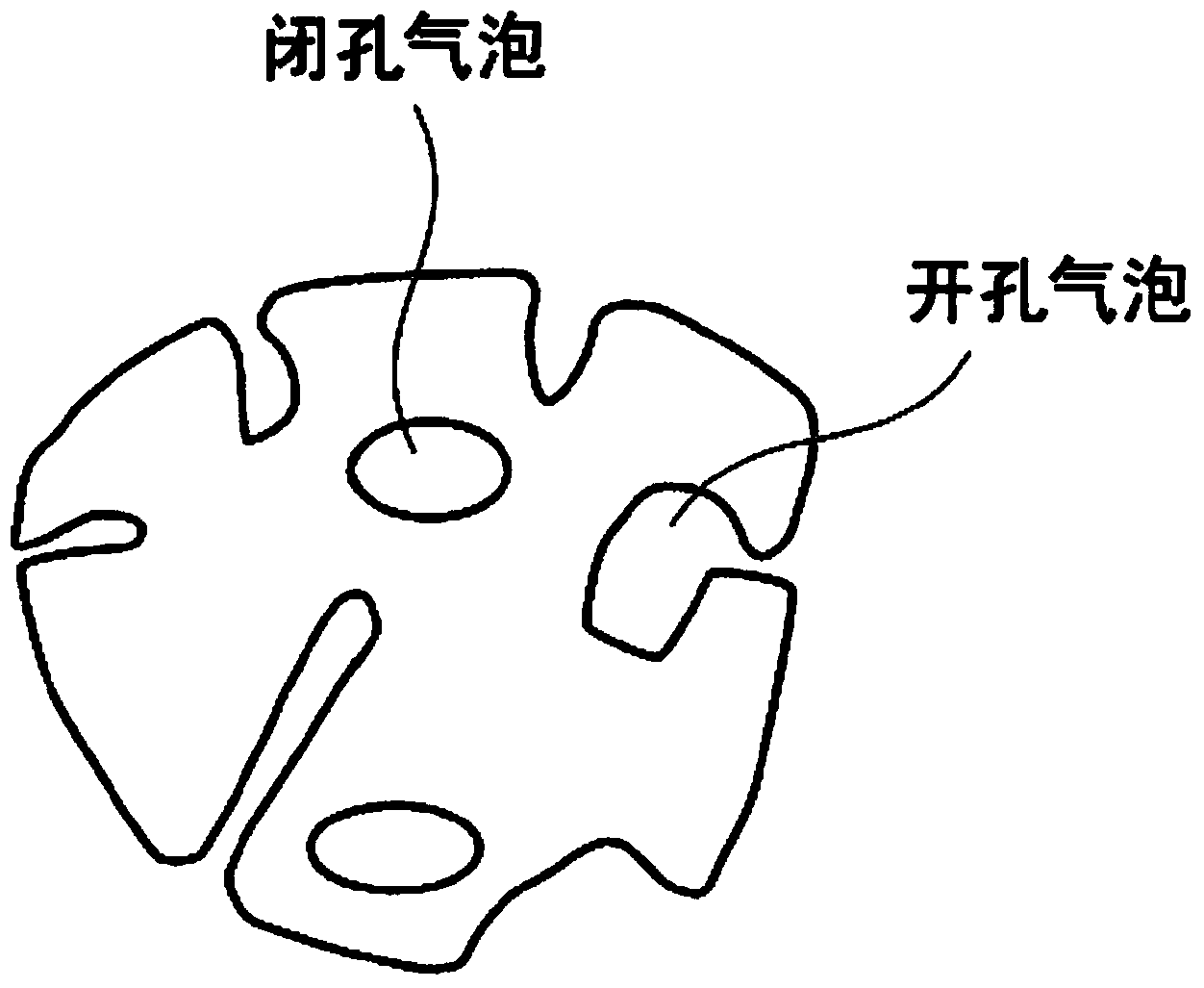

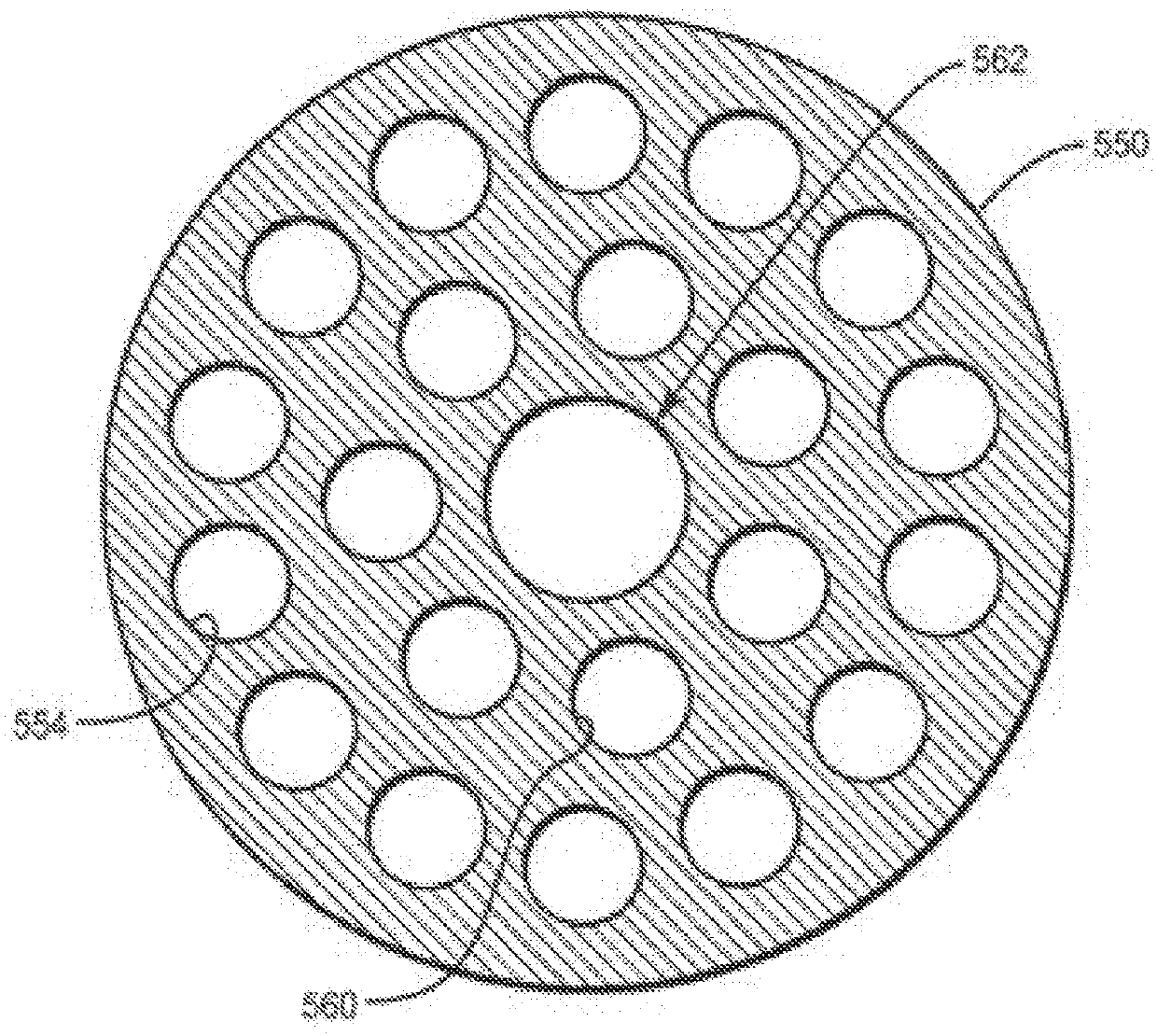

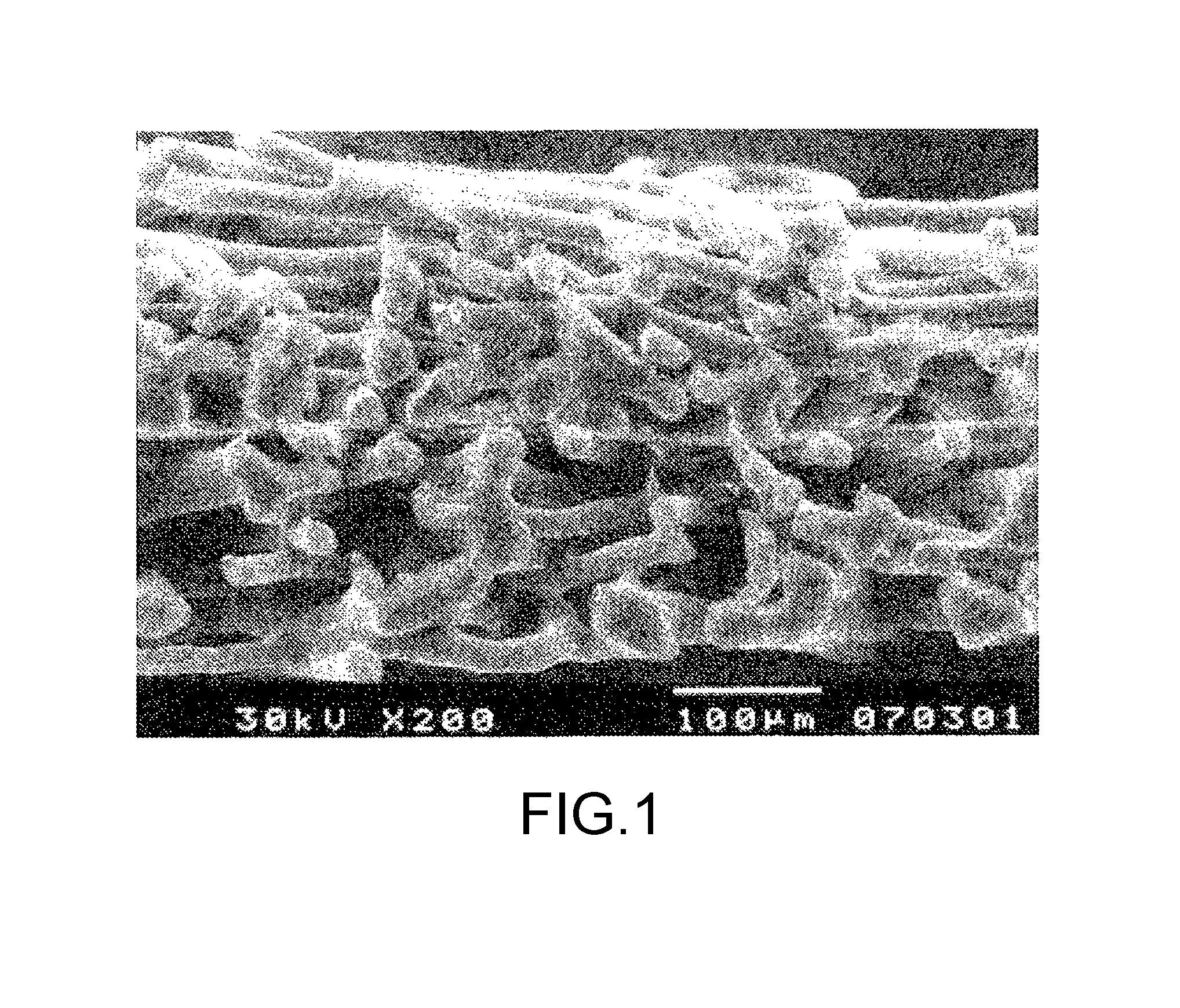

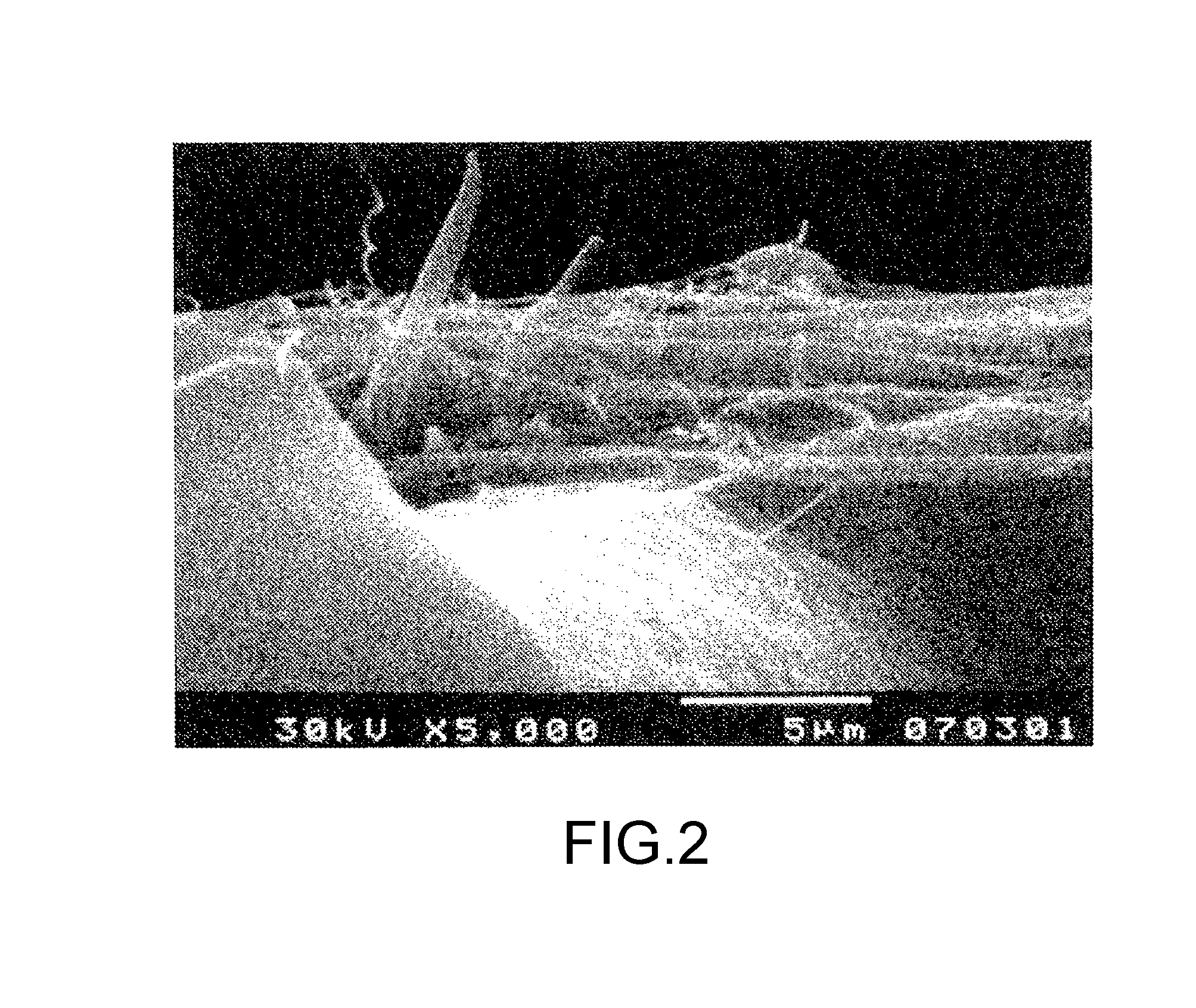

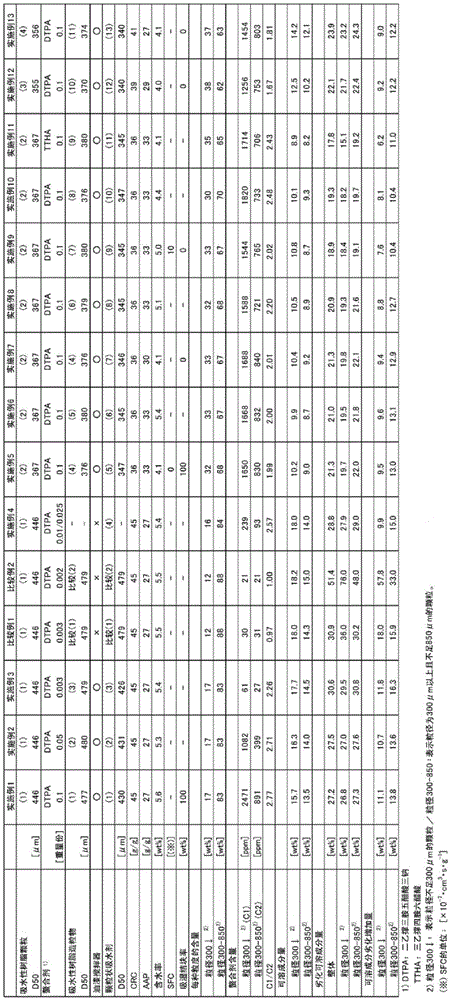

Particulate water absorbing agent with irregularly pulverized shape

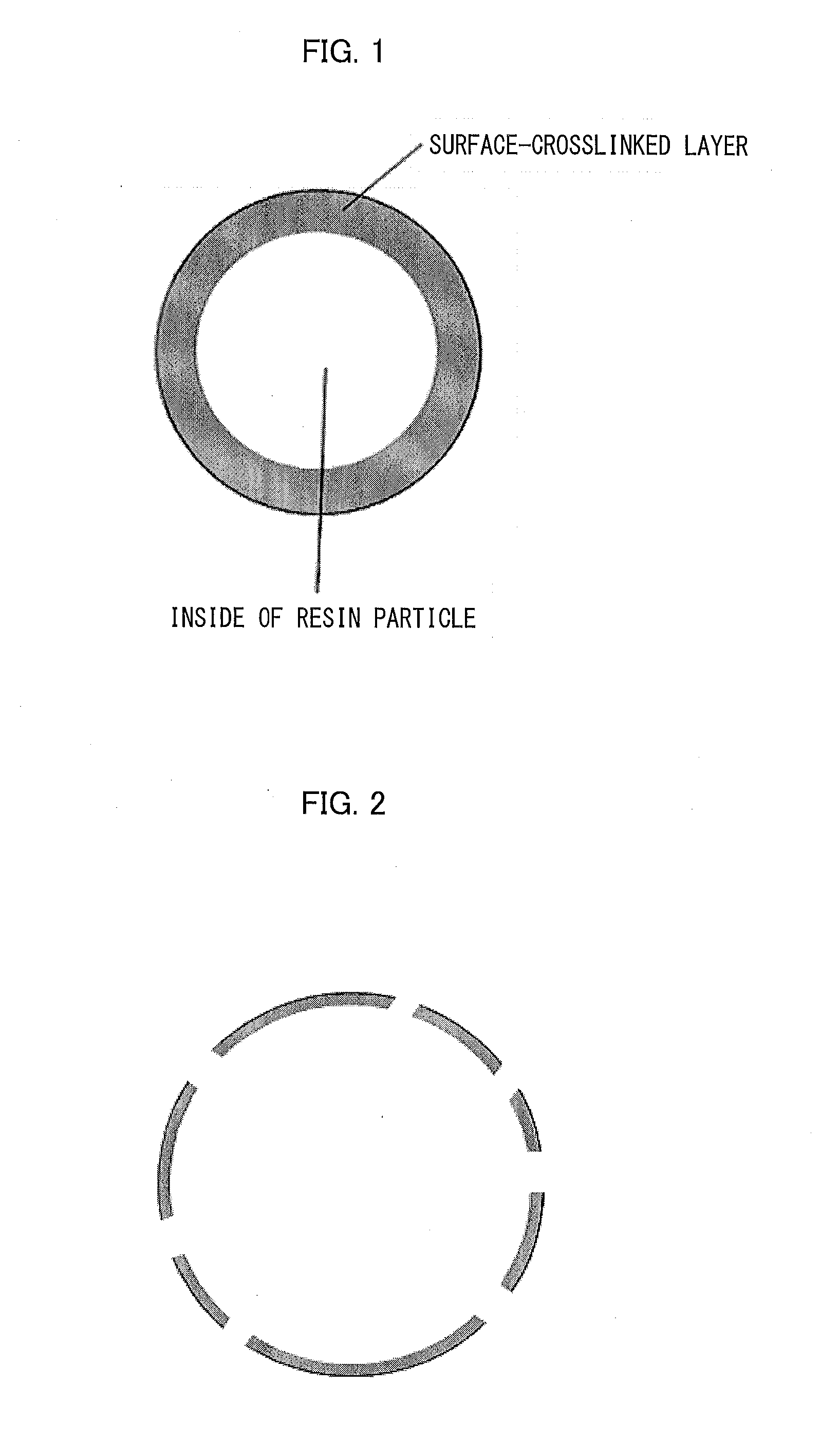

ActiveUS20070141338A1Improve surface drynessUnpleasant feelingOther chemical processesSynthetic resin layered productsParticulatesPermeation

The present invention provides a particulate water absorbing agent for a thin type absorbing substrate suitable for actual use. A particulate water absorbing agent having irregularly pulverized shape, characterized by comprising, a surface crosslinked water-absorbing resin obtained by crosslinking polymerization of an unsaturated monomer with an acid group and / or salts thereof, which absorbing agent contains agglomerated particles therein and further satisfies (i) centrifuge retention capacity (CRC) in a physiological saline solution of not lower than 32 g / g, (ii) mass median particle size (D50) of 200 to 400 μm, and (iii) particles smaller than 600 μm and not smaller than 150 μm of 95 to 100% by weight. By using the particulate water absorbing agent, such absorbing articles can be obtained as have few rugged surface after water absorption, excellent liquid permeation property.

Owner:NIPPON SHOKUBAI CO LTD

Water absorbent and producing method of same

ActiveUS20070123658A1Improve gel performanceMaintain good propertiesOther chemical processesAbsorbent padsCross-linkPolymer science

An object of the present invention is to provide a water absorbent having excellent gel properties and showing excellent properties when used in a water-absorbing material of a sanitary / hygienic material such as paper diaper. Moreover, another object of the present invention is to provide a water absorbent which is safe and excellent in liquid permeability, and in which an amount of liquid permeability improver for improving the liquid permeability is reduced. The water absorbent is made from a water-absorbing resin prepared by a specific polymerization method and having a high degree of cross-linking, a high liquid holding property and a high gel strength (its swelling pressure of gel layer of is 35 kdyne / cm2 or more). This water absorbent is further processed to have a particular particle size distribution (95 wt % or more of its particles are less than 850ƒÊm but not less than 106ƒÊm, and logarithmic standard deviation (ƒĐƒÄ) is in a range of 0.25 to 0.45) and then surface cross-linked. After that, a liquid permeability improver is added therein.

Owner:NIPPON SHOKUBAI CO LTD

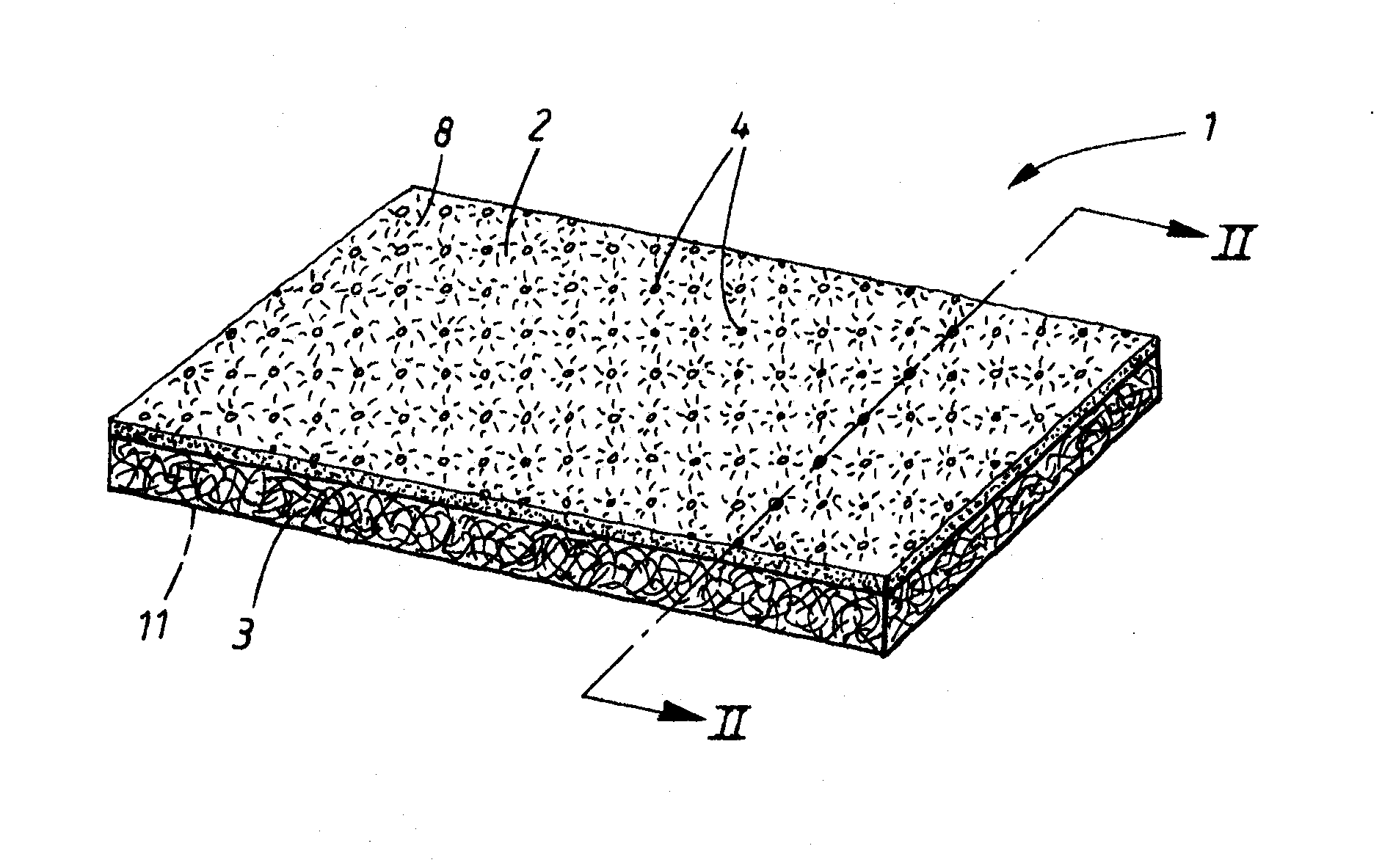

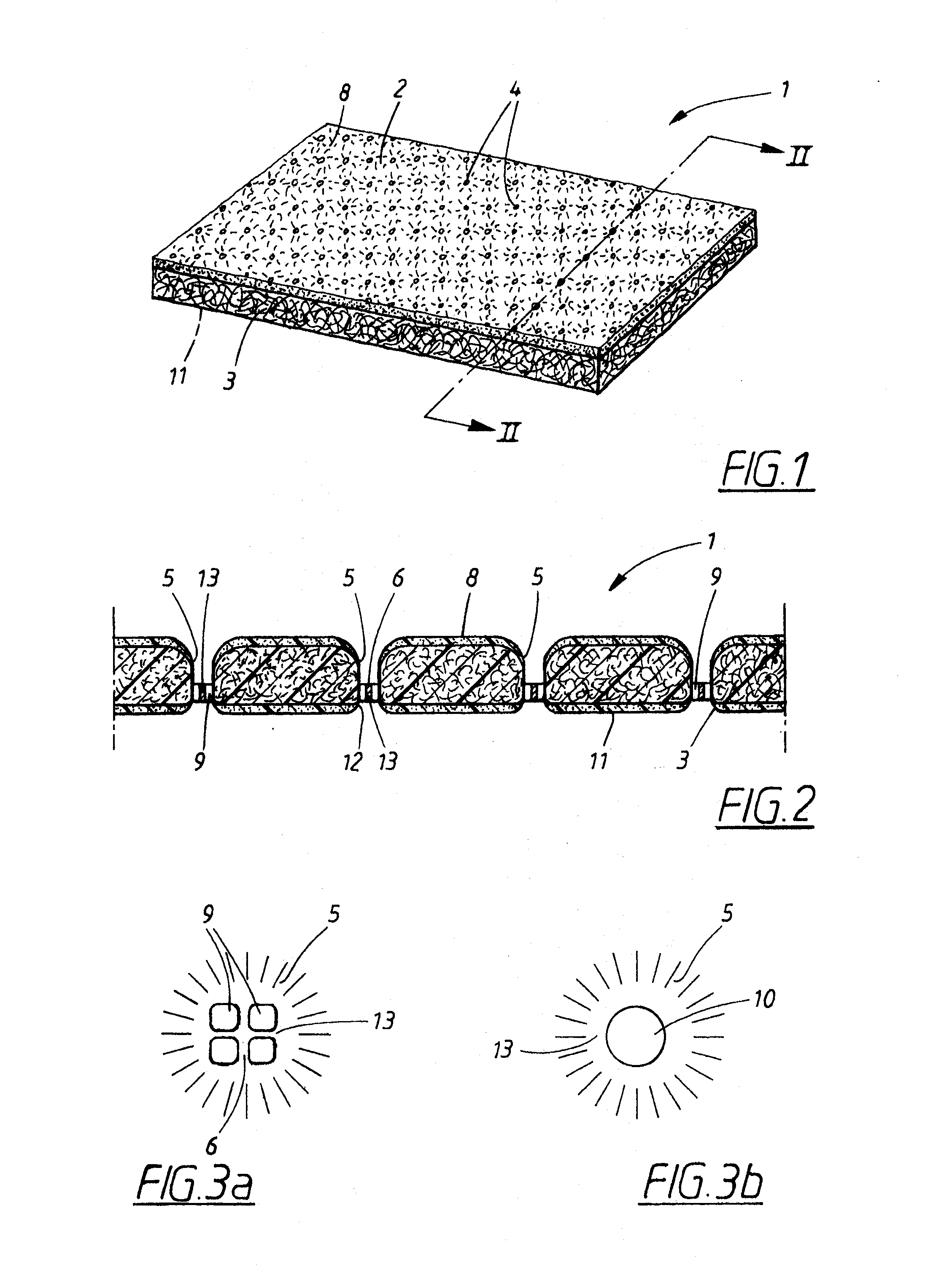

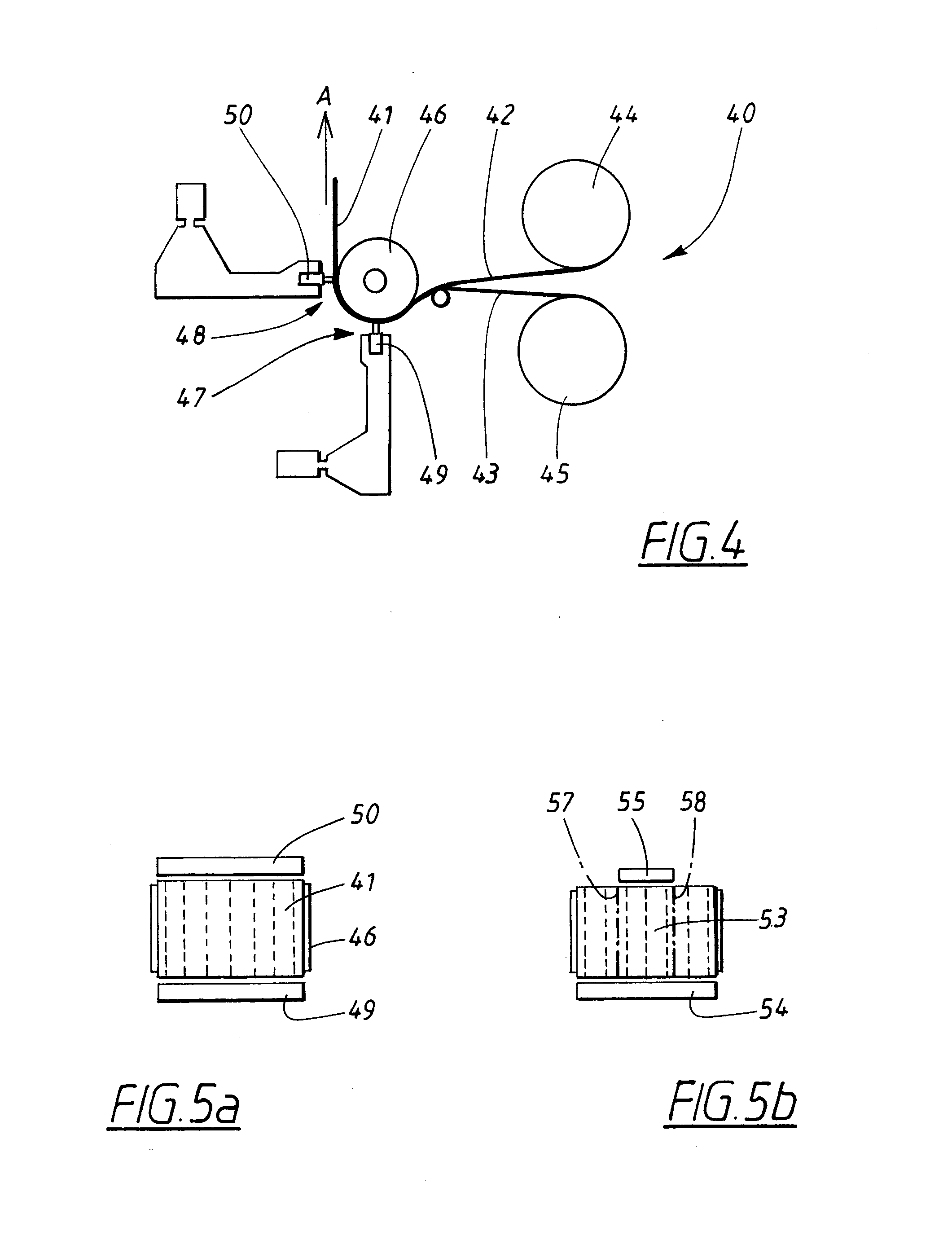

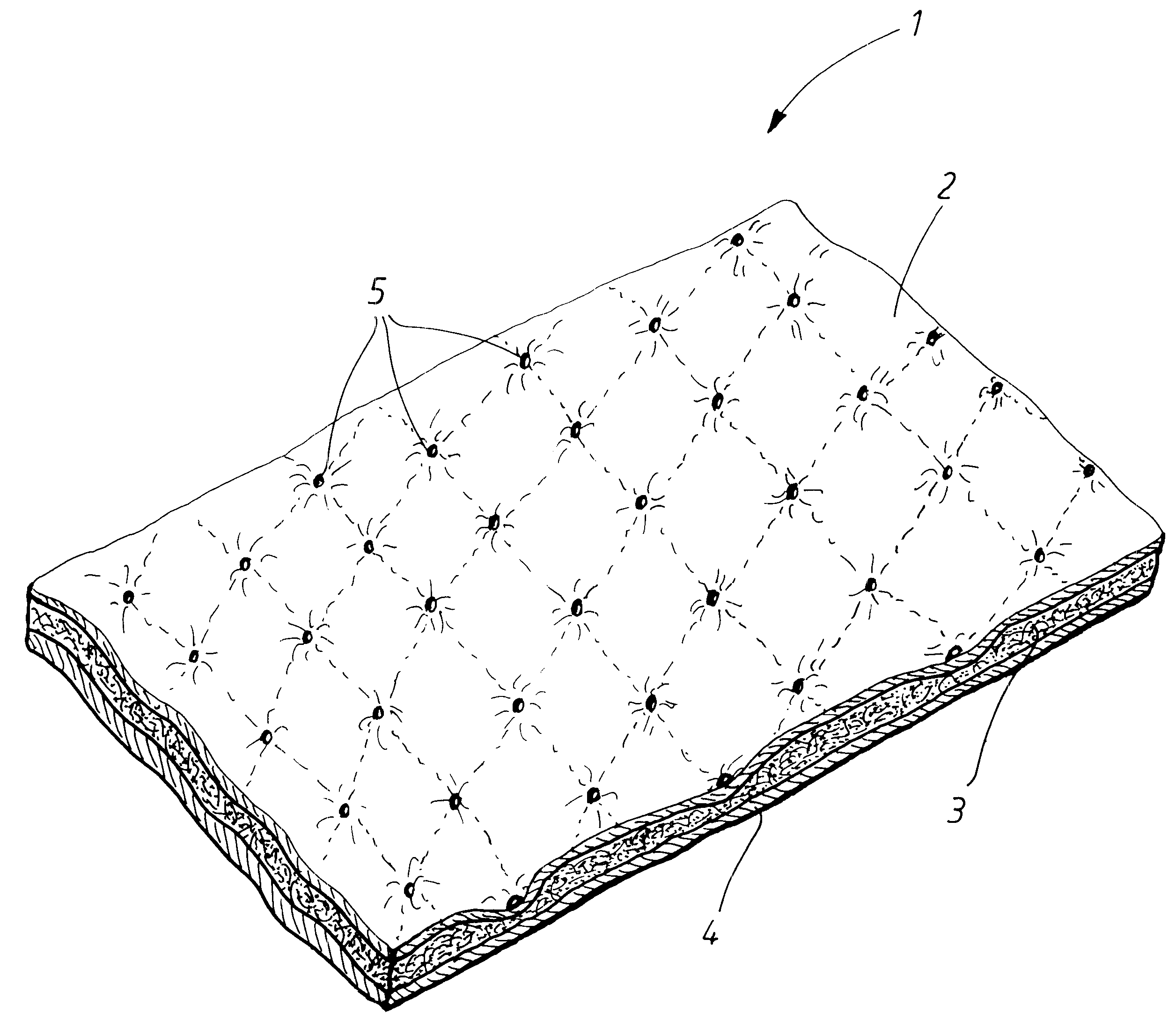

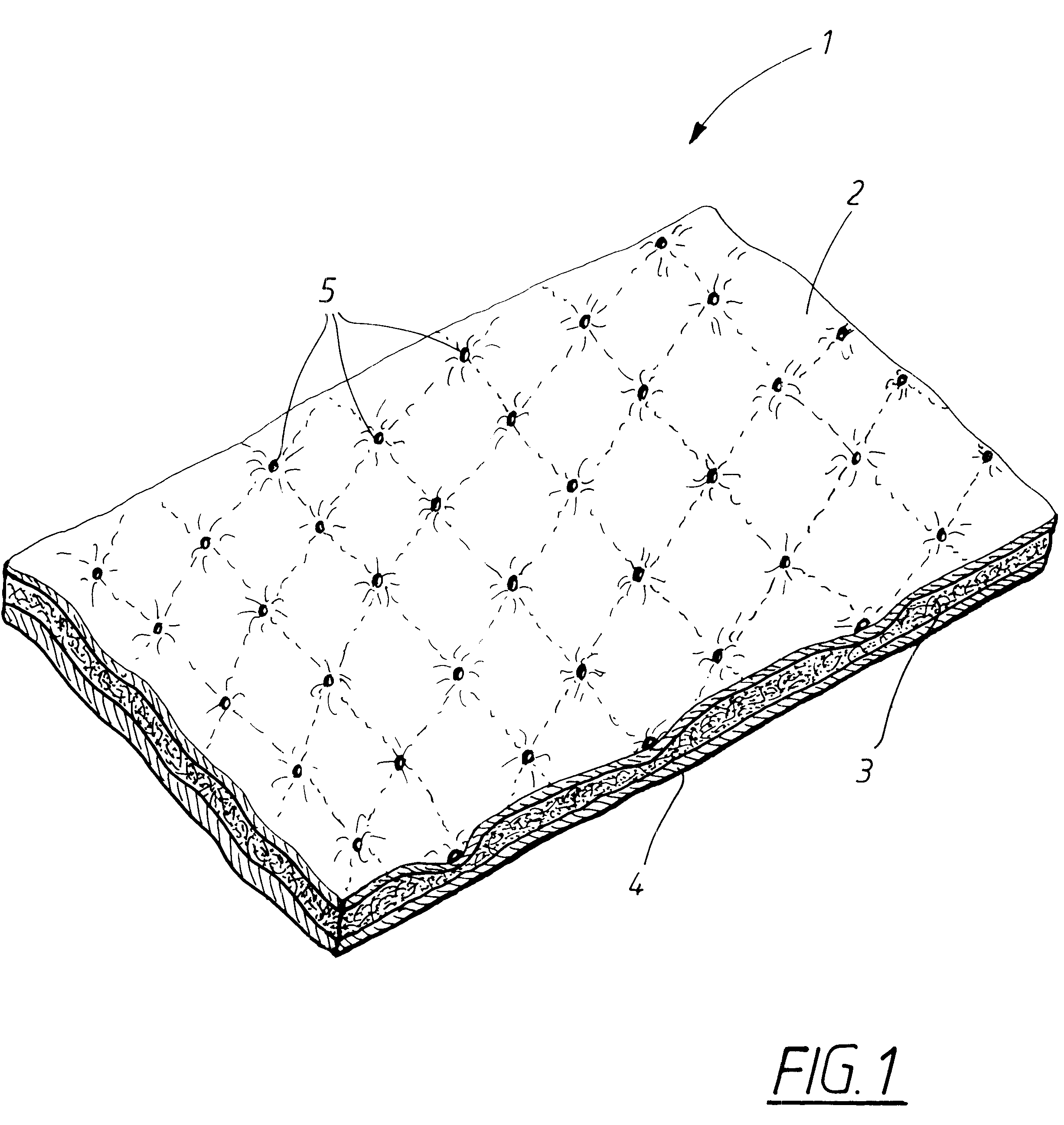

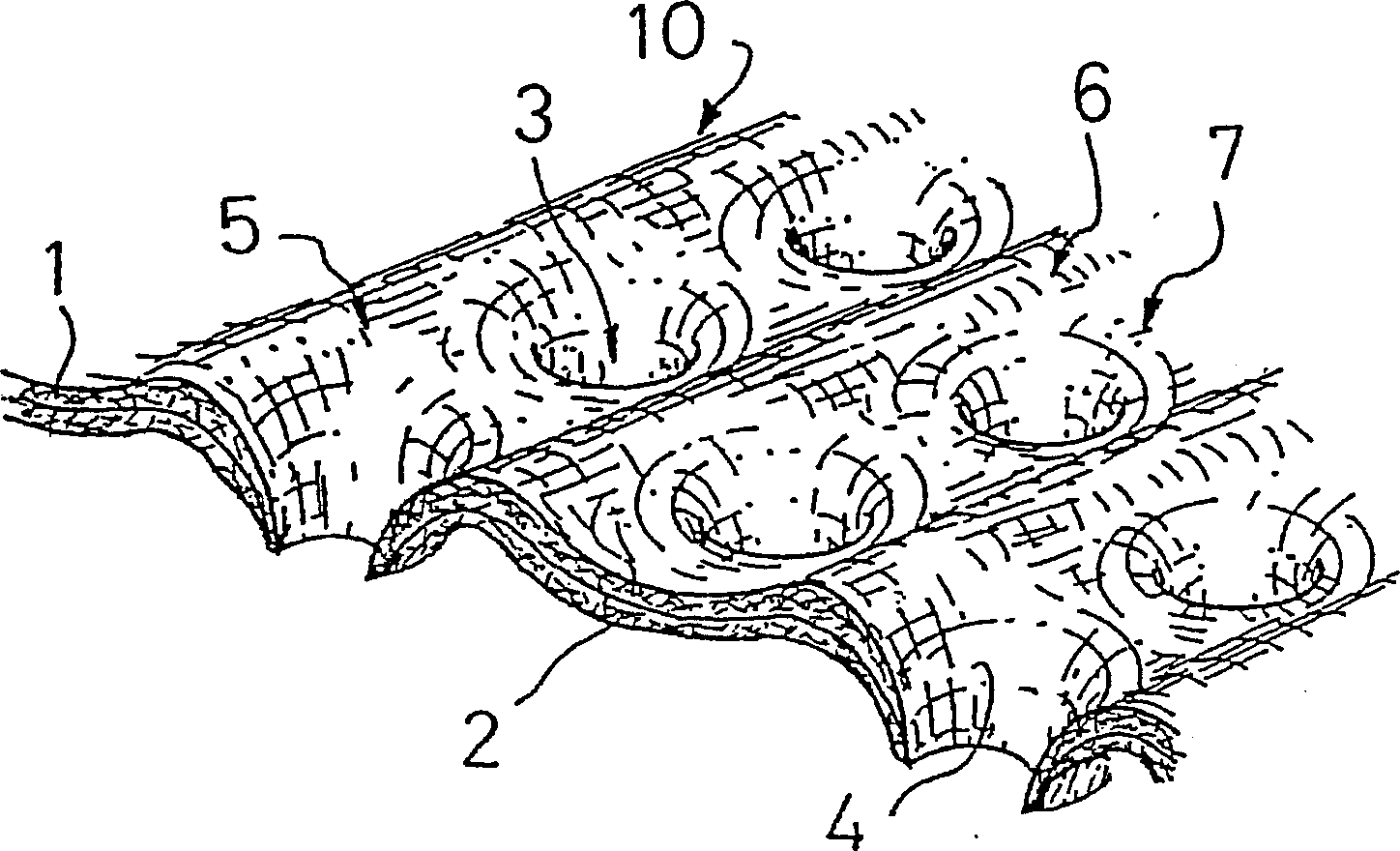

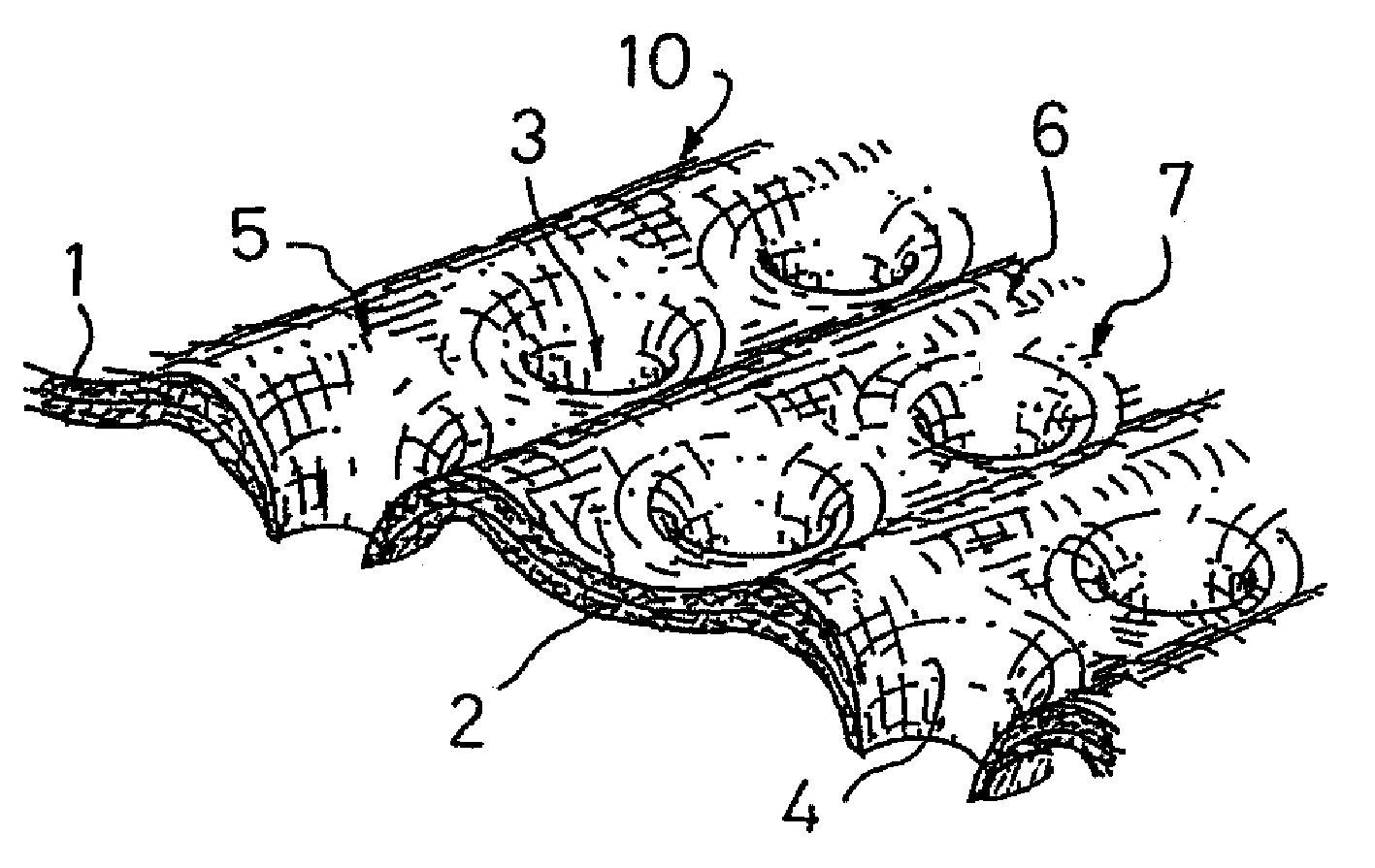

Material web for use in an absorbent article

InactiveUS20110004176A1Improve liquid permeabilityImprove ventilationLamination ancillary operationsPersonal careFiberBiomedical engineering

Owner:SCA HYGIENE PROD AB

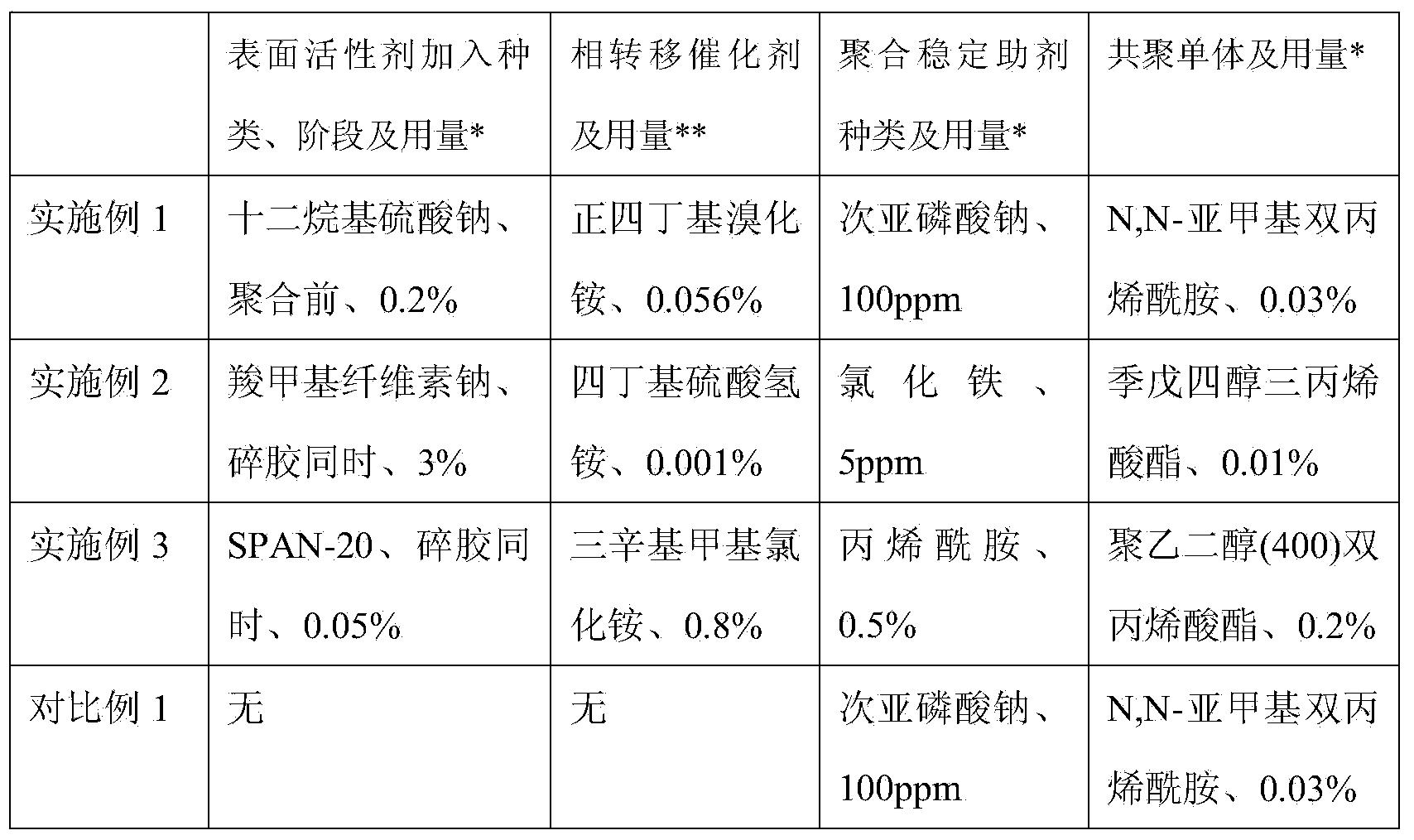

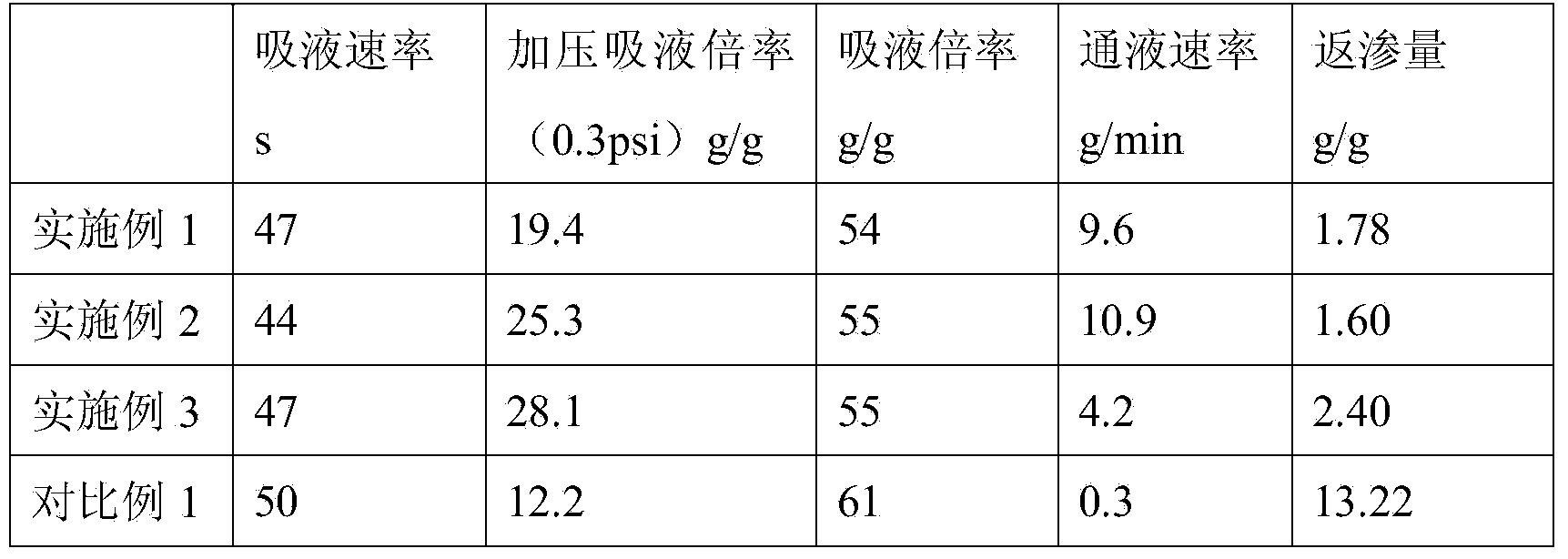

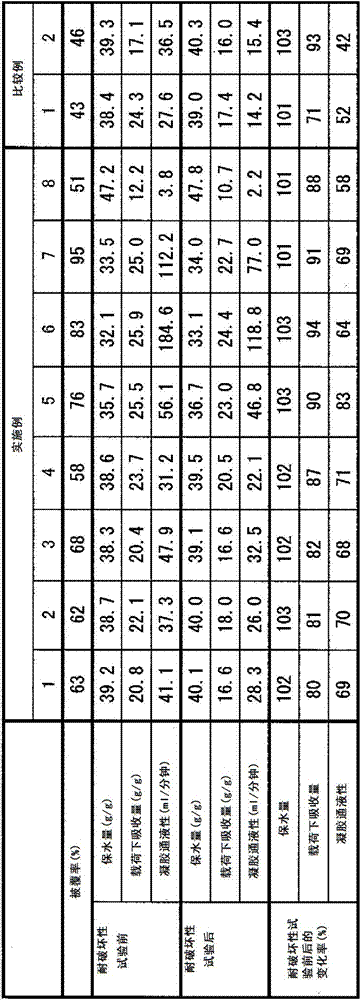

Preparation method of macromolecular water-absorbent resin with low reverse osmosis

ActiveCN103910896AImprove liquid absorption capacityImprove anti-reverse seepage abilityCoatingsPolymer scienceReverse osmosis

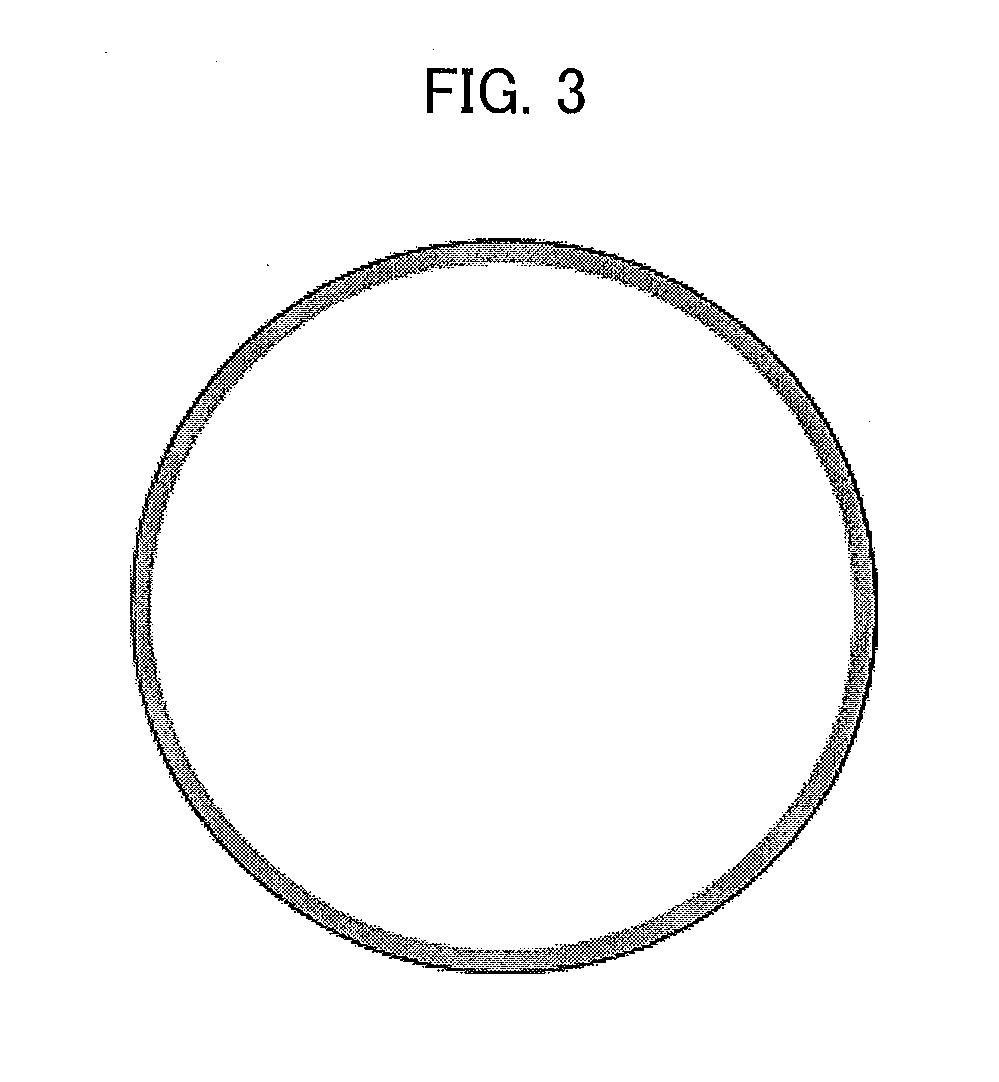

The invention provides a preparation method of macromolecular water-absorbent resin with low reverse osmosis. According to the method, a polymerization stabilizing additive is added and process conditions are reasonably controlled during a polymerization process, so that the polymerization reaction is stable and the process is simple. A surfactant is added before the surface crosslinking of water-absorbent resin powder; meanwhile, a phase transfer catalyst is added during the surface crosslinking. Thus, the phenomenon of caking of the water-absorbent resin powder during the surface crosslinking is avoided, so that surface crosslinking solution is uniformly distributed. Therefore, the solution absorbing ability and the reverse osmosis resisting ability of the water-absorbent resin are greatly improved. The water-absorbent resin is suitable for physical hygiene products.

Owner:WANHUA CHEM GRP CO LTD +1

Water absorbent and producing method of same

ActiveUS20100308263A1Improve gel performanceMaintain good propertiesOther chemical processesAbsorbent padsCross-linkPolymer science

An object of the present invention is to provide a water absorbent having excellent gel properties and showing excellent properties when used in a water-absorbing material of a sanitary / hygienic material such as paper diaper. Moreover, another object of the present invention is to provide a water absorbent which is safe and excellent in liquid permeability, and in which an amount of liquid permeability improver for improving the liquid permeability is reduced. The water absorbent is made from a water-absorbing resin prepared by a specific polymerization method and having a high degree of cross-linking, a high liquid holding property and a high gel strength (its swelling pressure of gel layer of is 35 kdyne / cm2 or more). This water absorbent is further processed to have a particular particle size distribution (95 wt % or more of its particles are less than 850ƒÊm but not less than 106ƒÊm, and logarithmic standard deviation (ƒĐƒÄ) is in a range of 0.25 to 0.45) and then surface cross-linked. After that, a liquid permeability improver is added therein.

Owner:NIPPON SHOKUBAI CO LTD

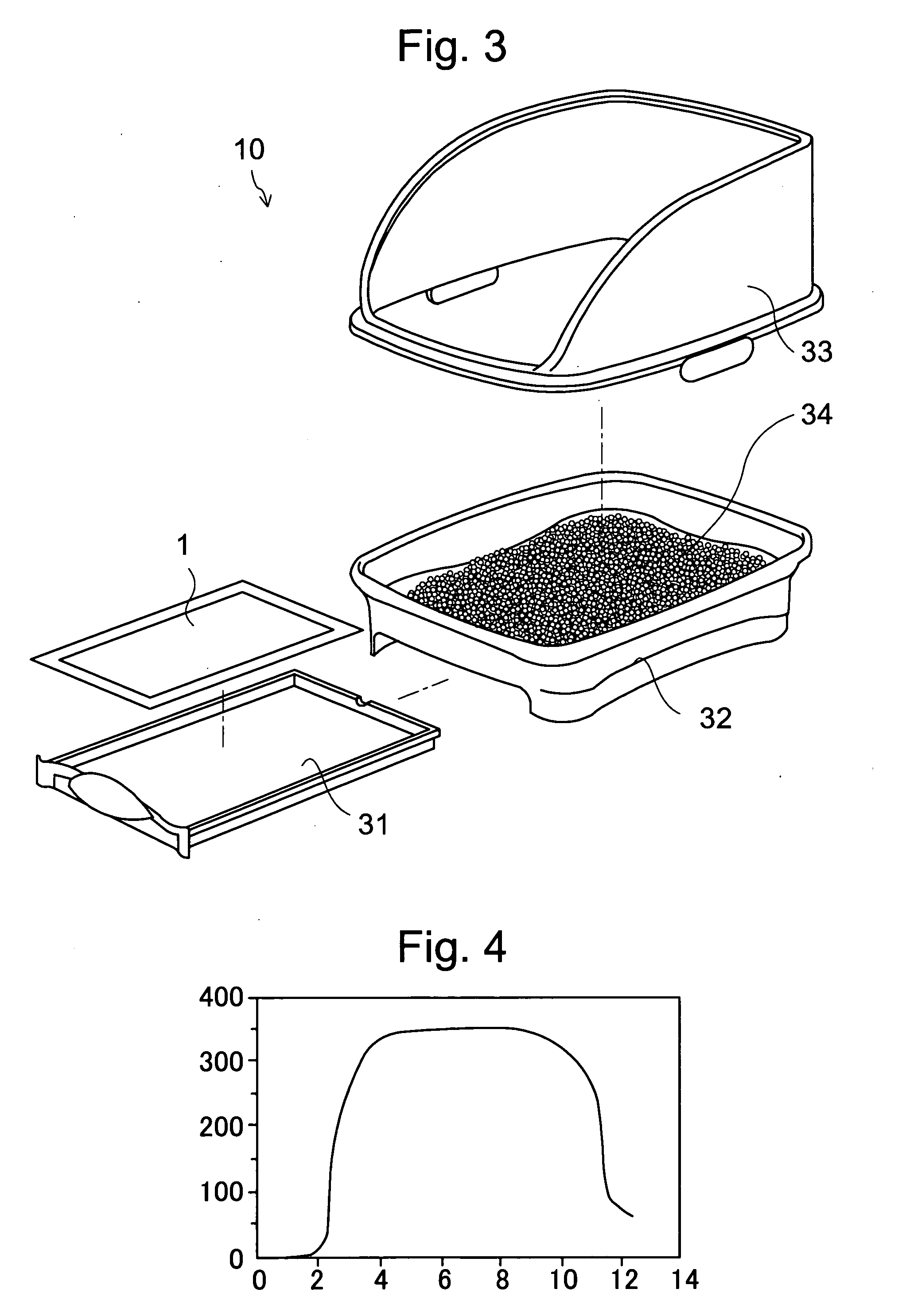

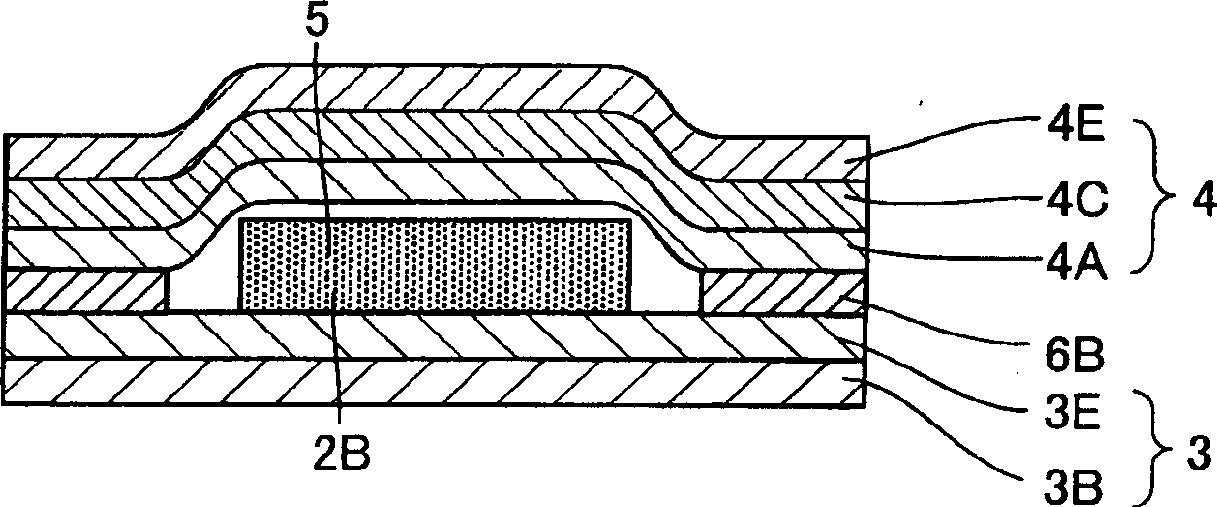

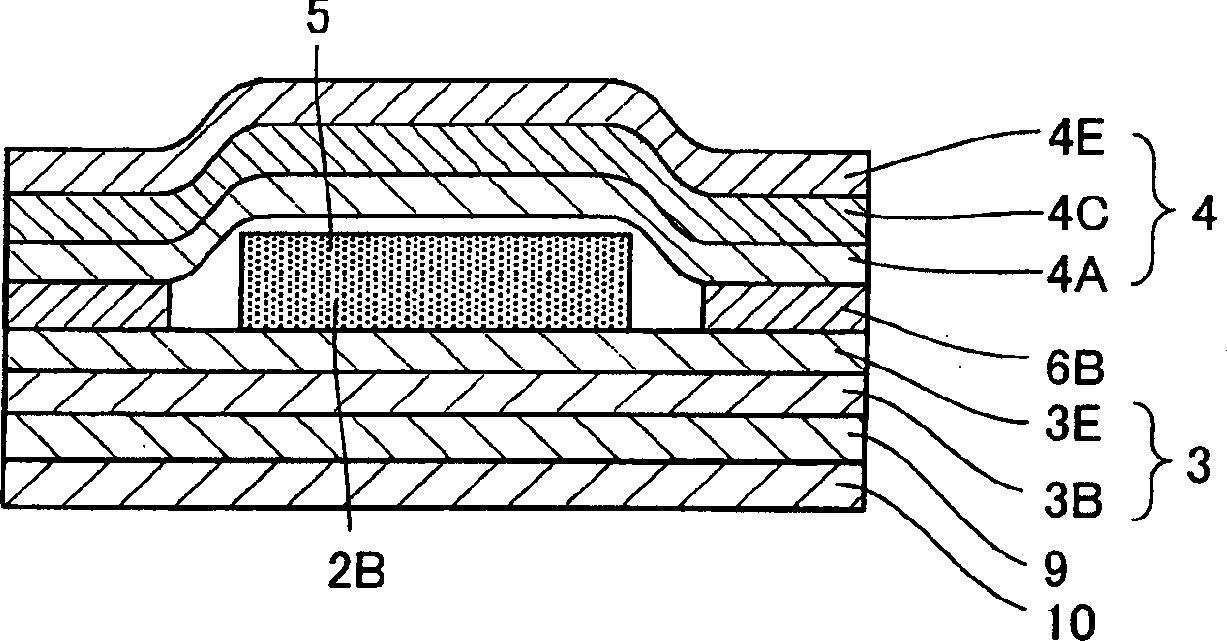

Liquid-absorbing sheet for animal litter box

InactiveUS20040255869A1Inhibit growth and proliferationAvoid it happening againAnimal housingOther apparatusAnimal scienceOdor

An animal litter box system that can be used for a long time about 3 to 10 days and can prevent the occurrence of undesirable odors is to be provided, particularly to provide a liquid-absorbing sheet used for the animal litter box system. A liquid-absorbing sheet used for an animal litter box is characterized by comprising an antimicrobial and bacteriostatic part having both an antimicrobial property and a bacteriostatic property; or both of an antimicrobial part having an antimicrobial property and a bacteriostatic part having a bacteriostatic property.

Owner:UNI CHARM PETCARE

Water absorbent and producing method of same

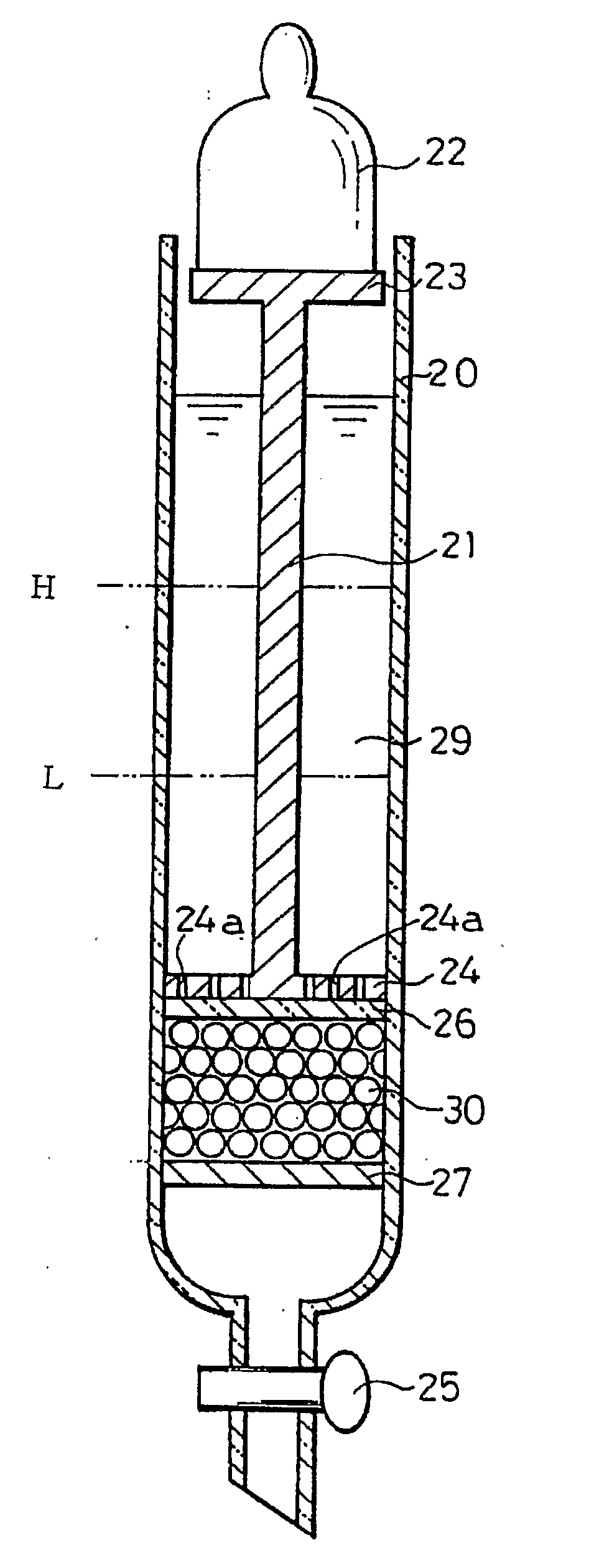

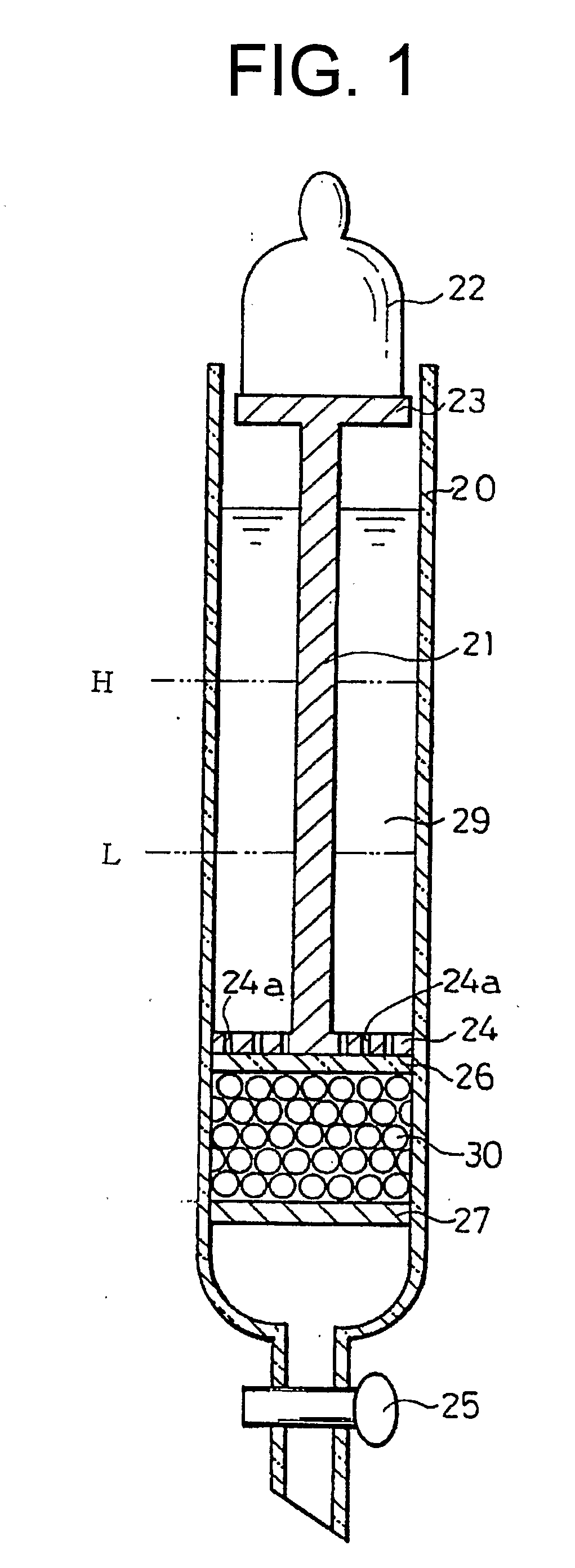

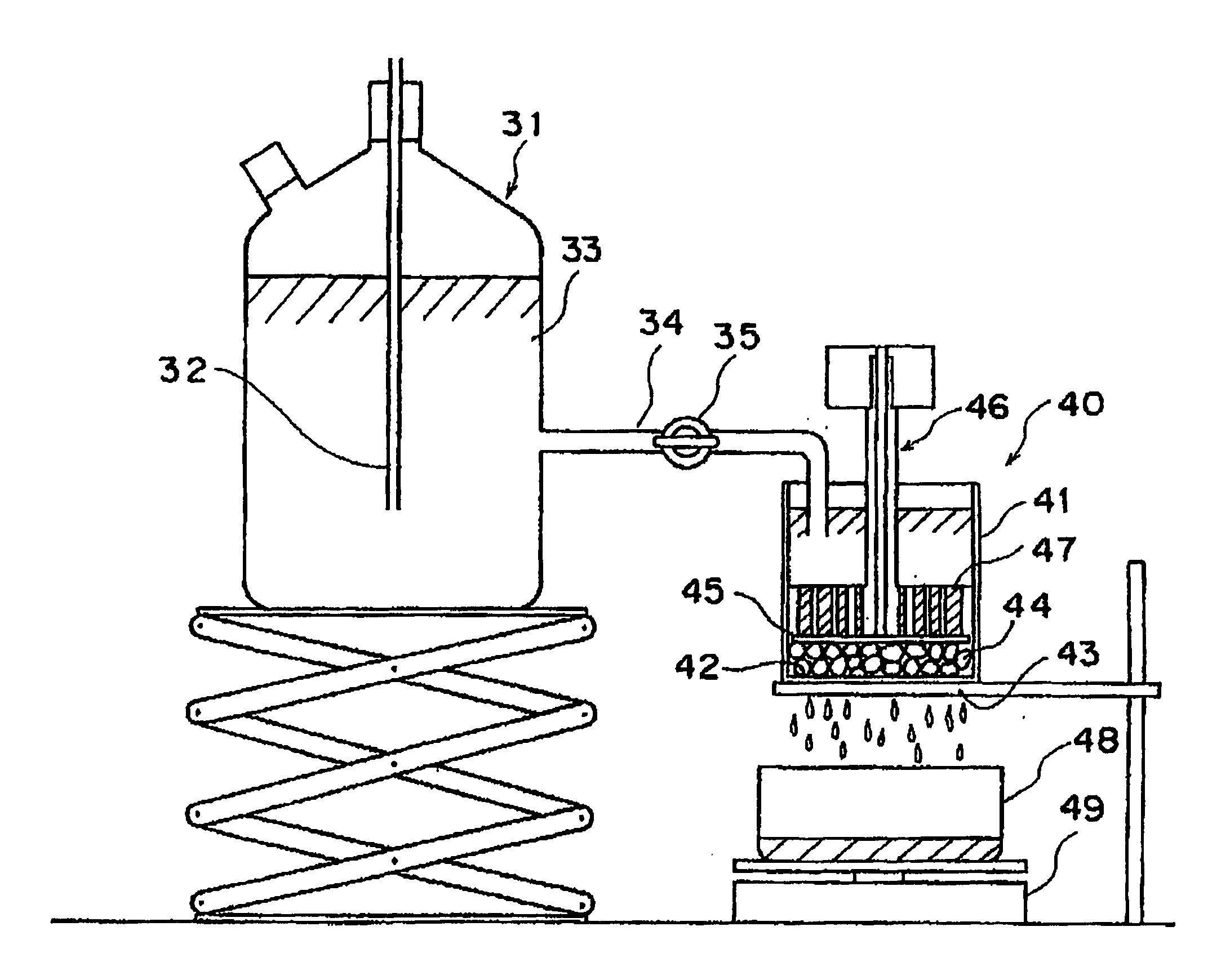

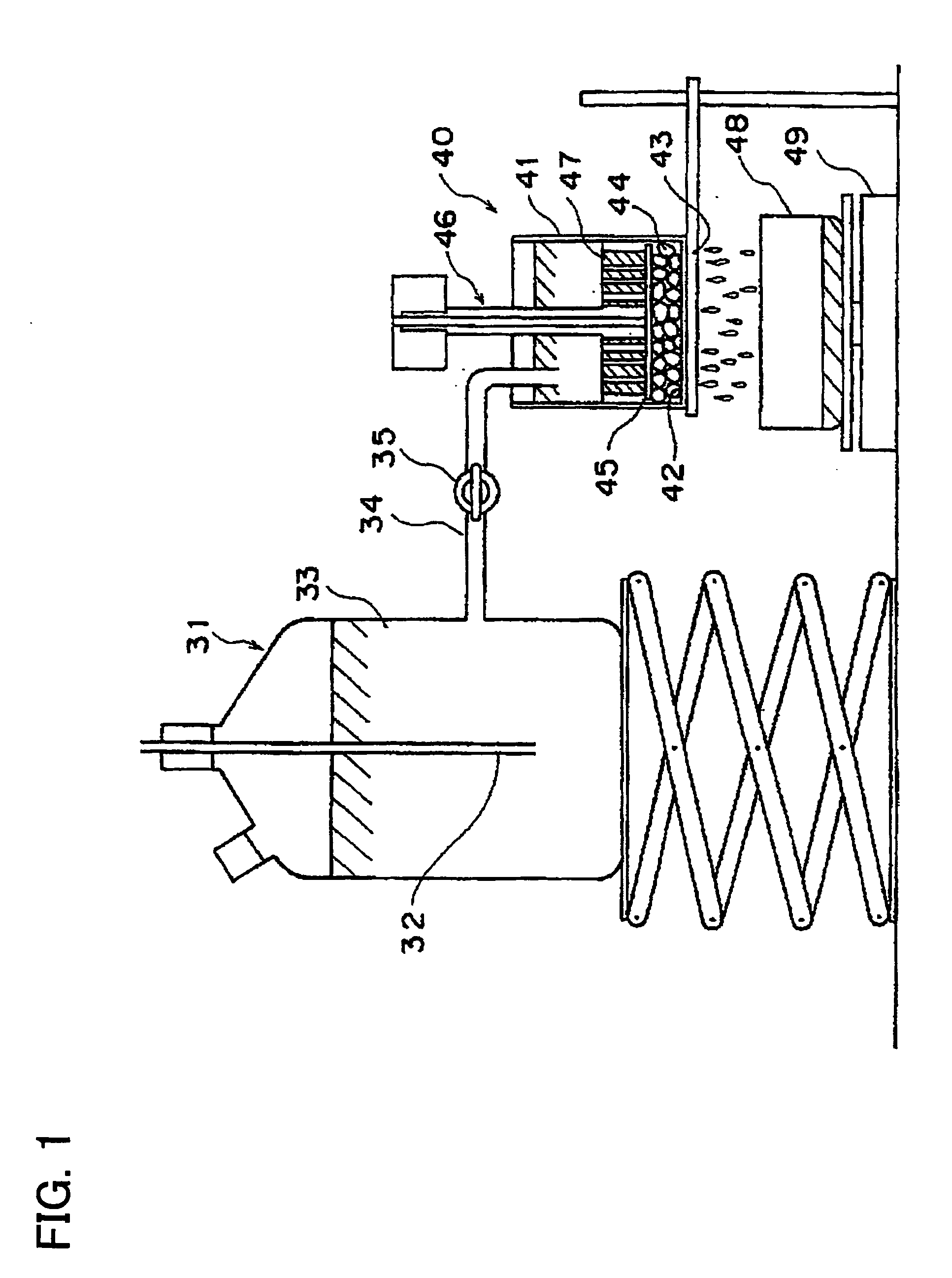

ActiveUS7803880B2Improve gel performanceMaintain good propertiesOther chemical processesAbsorbent padsCross-linkPolymer science

An object of the present invention is to provide a water absorbent having excellent gel properties and showing excellent properties when used in a water-absorbing material of a sanitary / hygienic material such as paper diaper. Moreover, another object of the present invention is to provide a water absorbent which is safe and excellent in liquid permeability, and in which an amount of liquid permeability improver for improving the liquid permeability is reduced. The water absorbent is made from a water-absorbing resin prepared by a specific polymerization method and having a high degree of cross-linking, a high liquid holding property and a high gel strength (its swelling pressure of gel layer of is 35 kdyne / cm2 or more). This water absorbent is further processed to have a particular particle size distribution (95 wt % or more of its particles are less than 850ƒÊm but not less than 106ƒÊm, and logarithmic standard deviation (ƒĐƒÄ) is in a range of 0.25 to 0.45) and then surface cross-linked. After that, a liquid permeability improver is added therein.

Owner:NIPPON SHOKUBAI CO LTD

Preparation method of superabsorbent polymer

ActiveUS20160311985A1Good physical propertiesReduction in centrifuge retention capacityAbsorbent padsProsthesisPolymer scienceSuperabsorbent polymer

Provided is a method of preparing a superabsorbent polymer. According to the method of preparing the superabsorbent polymer of the present invention, provided is a superabsorbent polymer having improved physical properties, in which the superabsorbent polymer has improved absorption rate and liquid permeability without reduction in centrifuge retention capacity or absorbency under load.

Owner:LG CHEM LTD

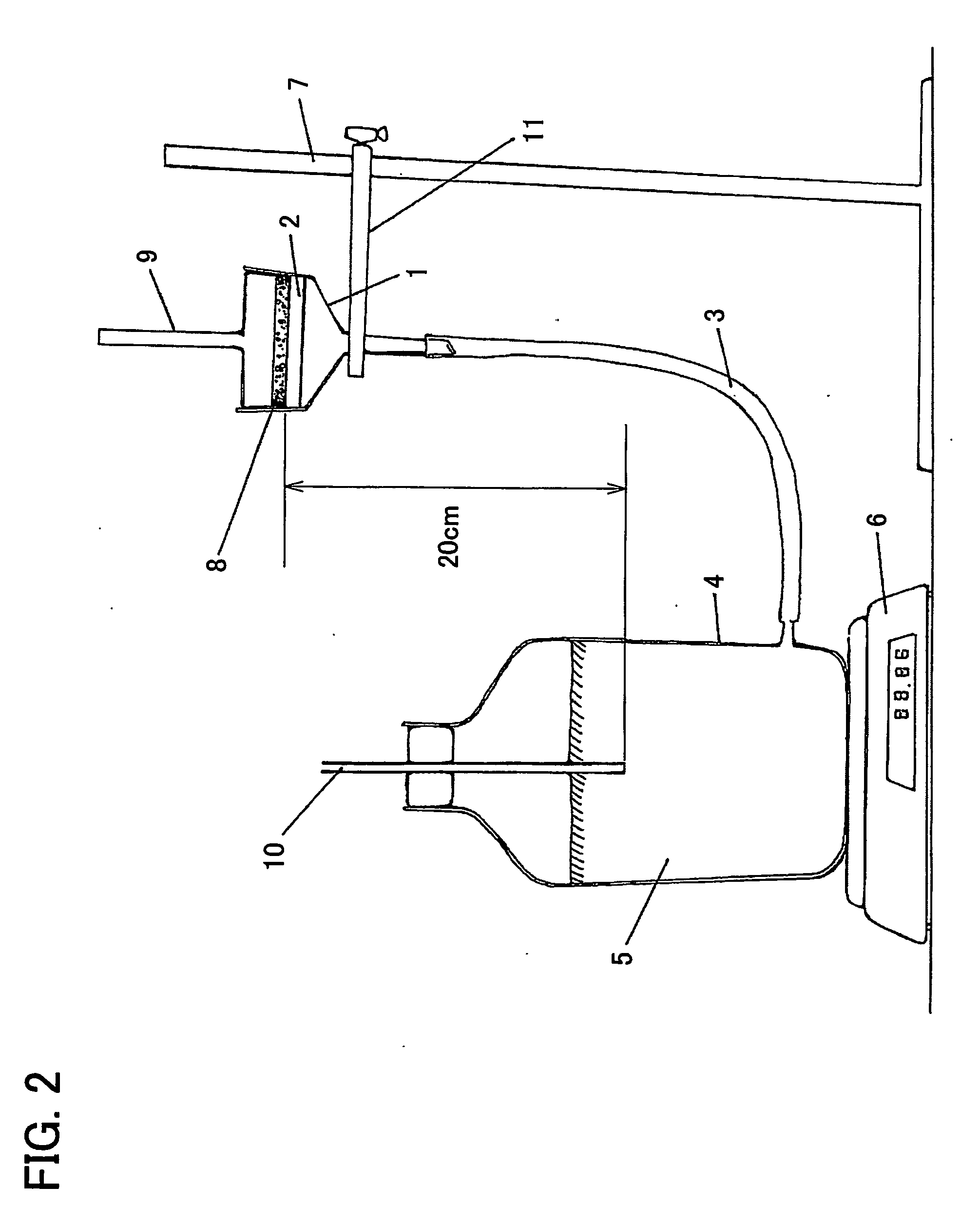

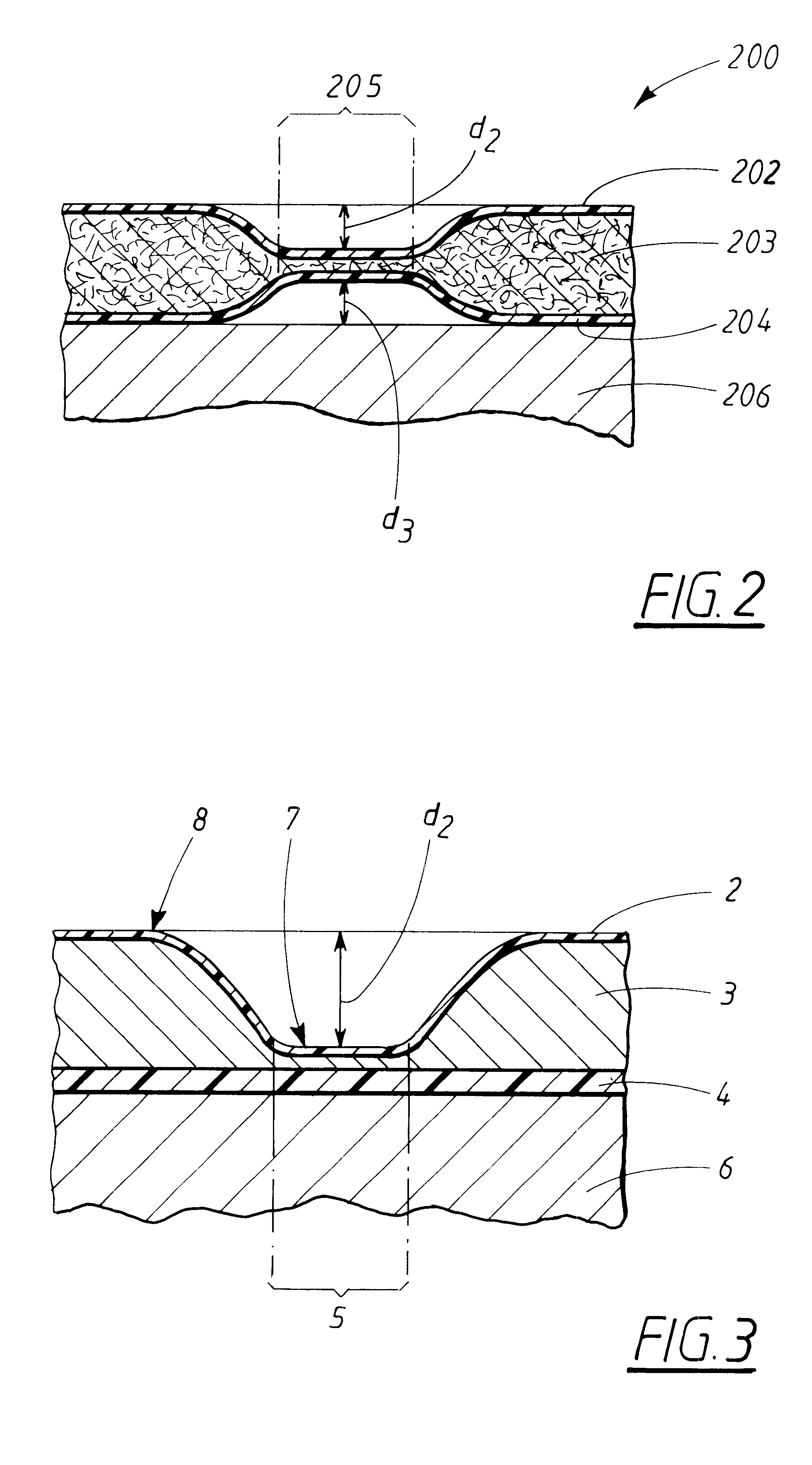

Absorbent product comprising at least one thermoplastic component to bond layers

InactiveUS6462253B1Improve liquid permeabilityLarge capacityLayered productsFibre treatmentFiberEngineering

An absorbent product comprising a liquid-permeable casing layer (402), a liquid-barrier layer (413) and an absorption element (416) which is enclosed between the liquid-permeable casing layer (402) and the liquid-barrier layer (413), and a liquid-transfer layer (403) which is disposed between the liquid-permeable casing layer (402) and the absorption element (406). The envelope layer (402) is bonded in a pattern of distinct thermally produced bonds (405) to the liquid-transfer layer (403). The liquid-transfer layer (403) comprises 40-65% by weight network-creating function fibres which are substantially intact following the bonding-together of the envelope layer (402) and the liquid-transfer layer (403) and which have a fibre coarseness ranging from 6 denier to 12 denier and 35-60% by weight fibres comprising a weldable, thermoplastic component and having a fibre coarseness of at least 3 denier.

Owner:SCA HYGIENE PROD AB

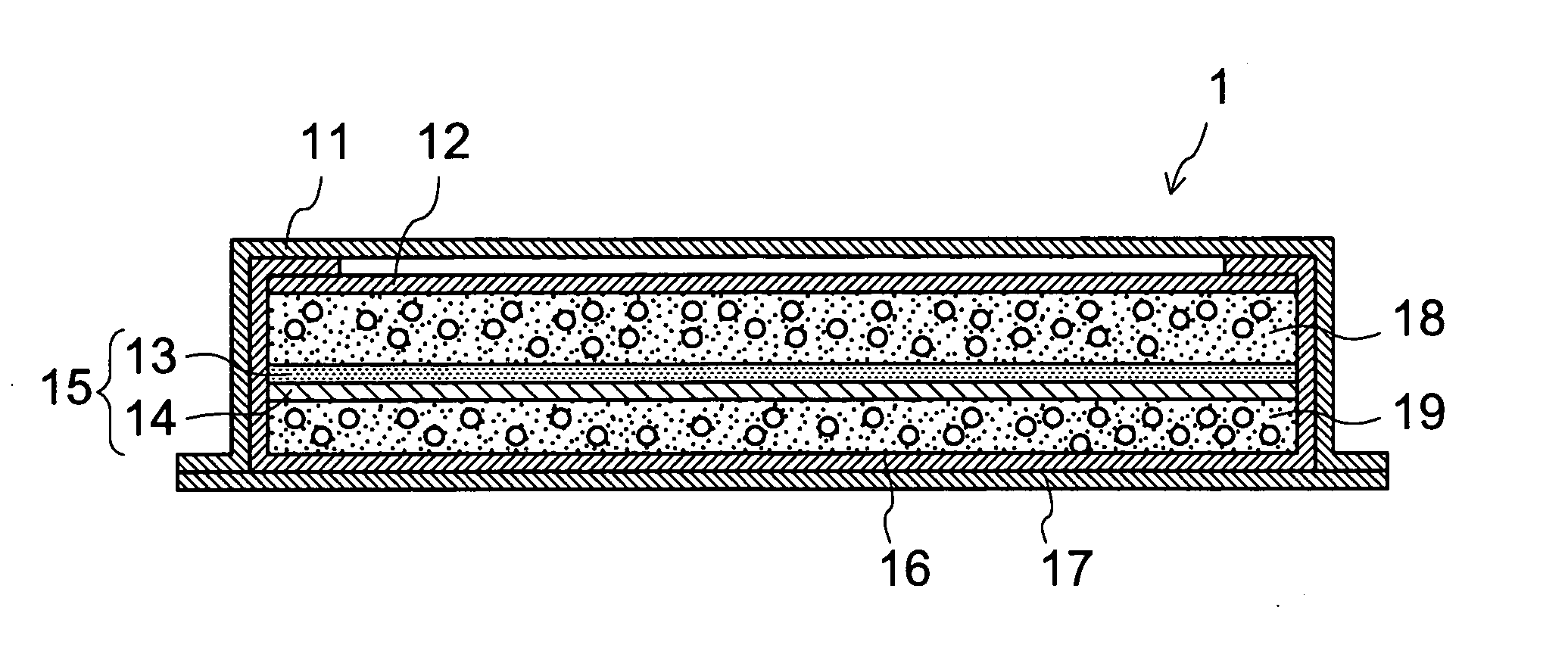

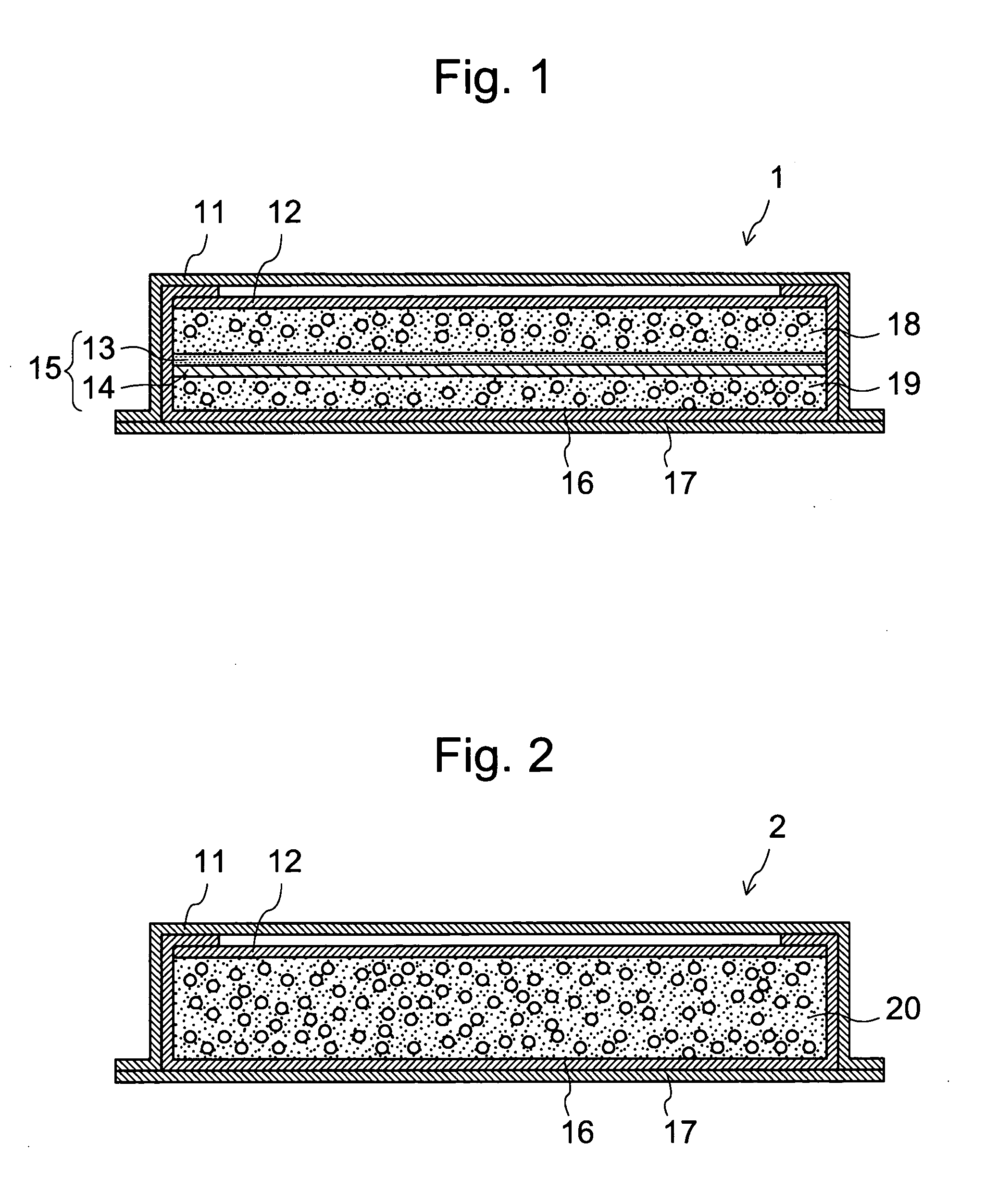

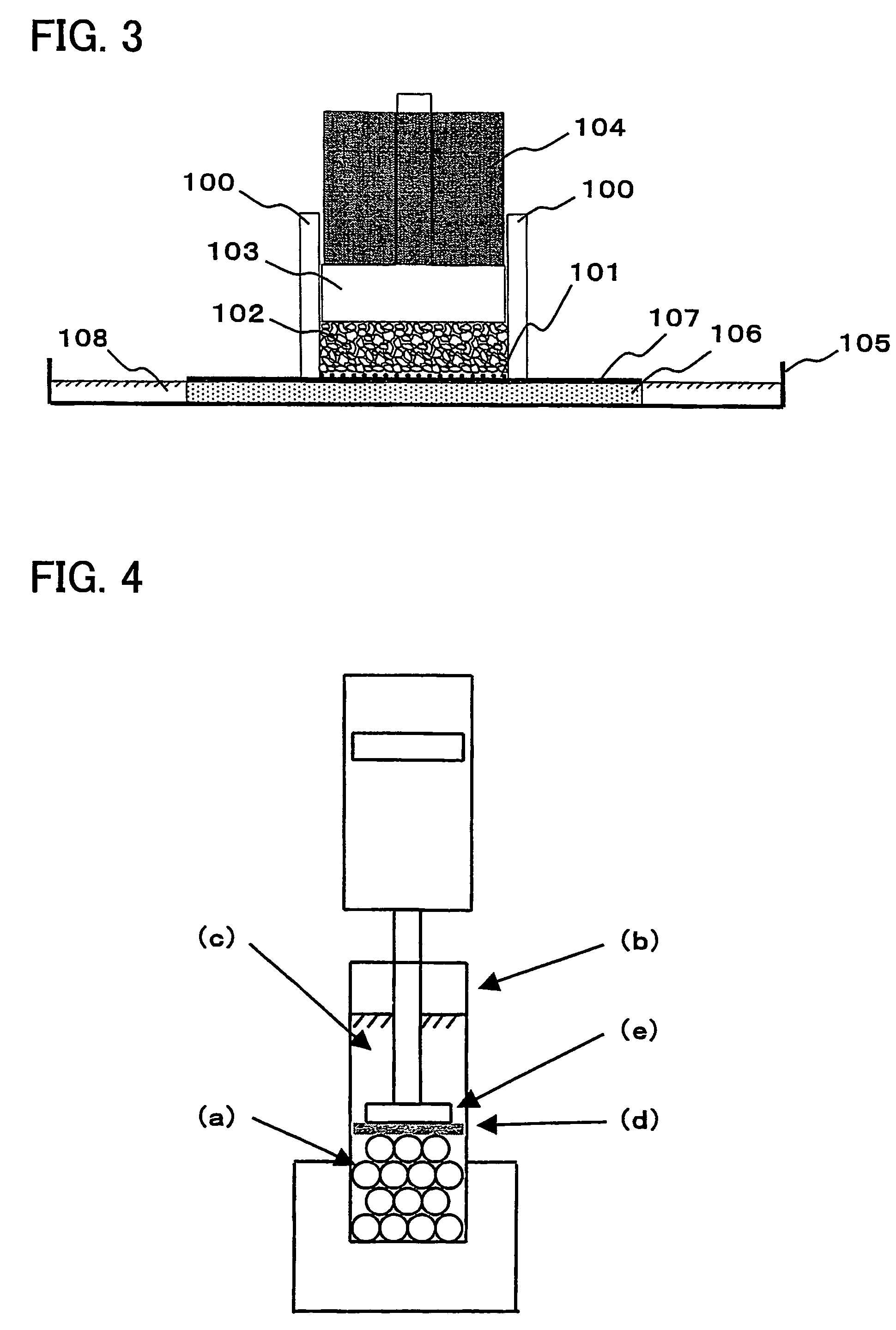

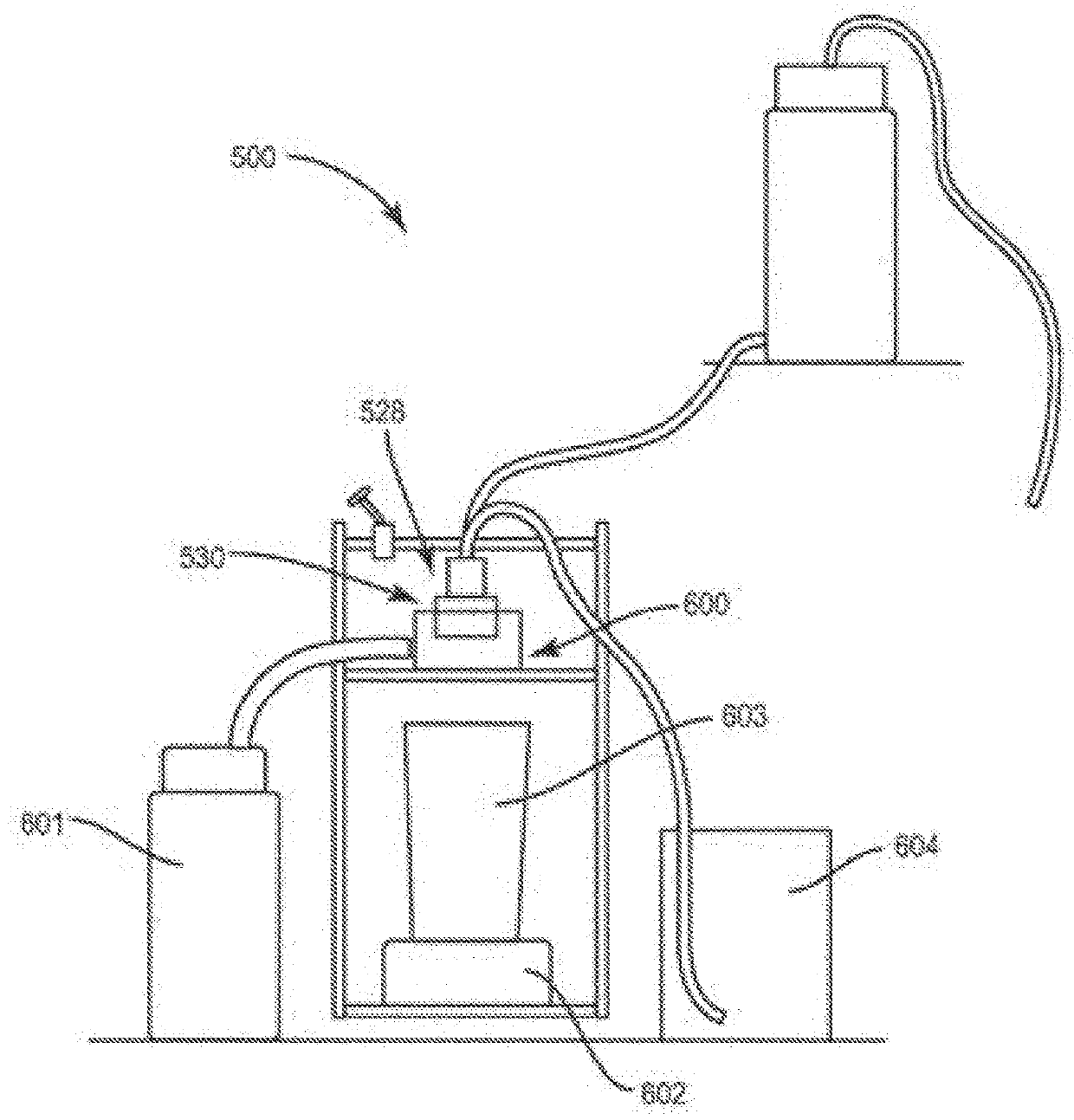

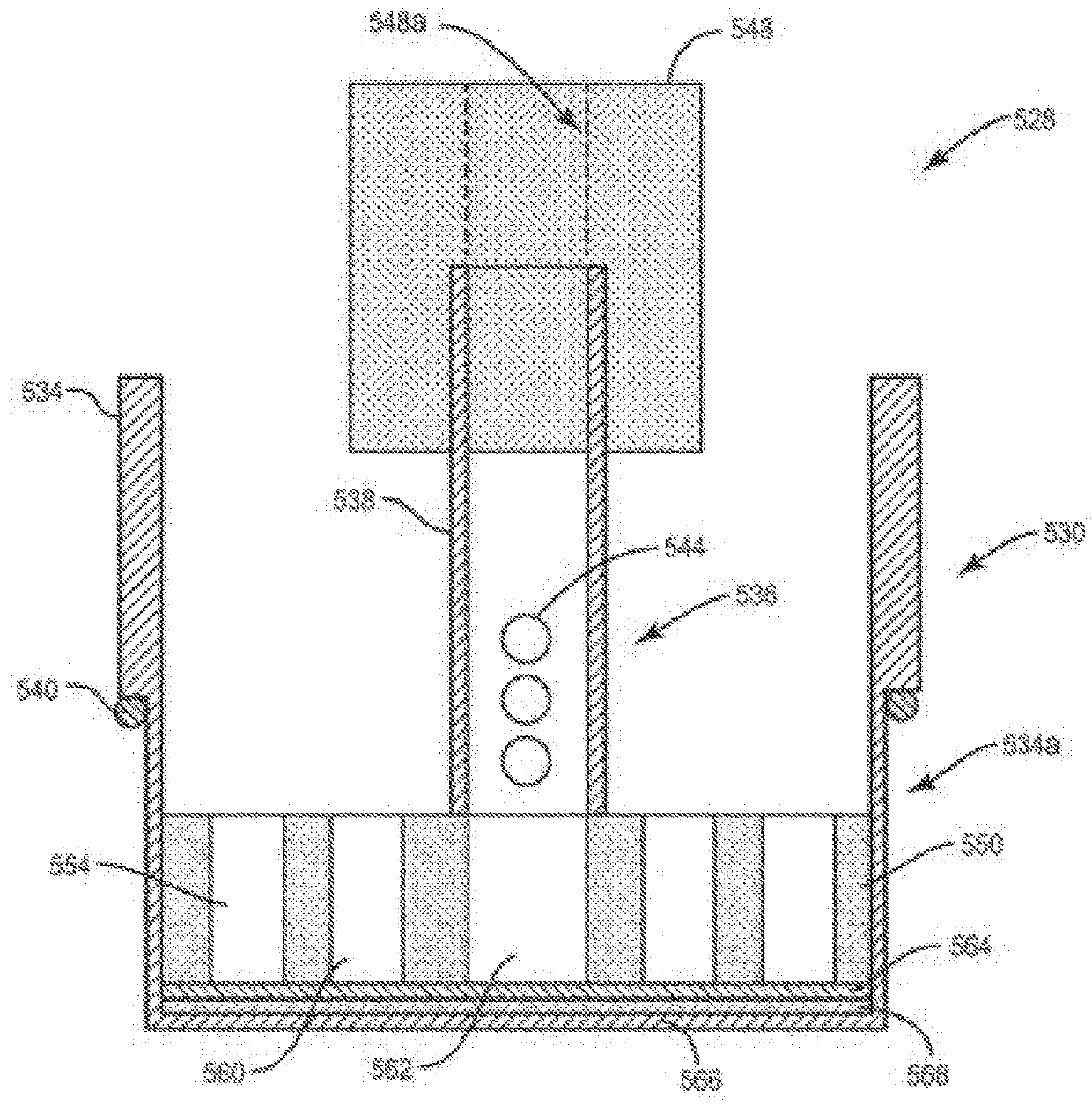

Process for producing aqueous-liquid-absorbing resin particles, aqueous-liquid-absorbing resin particles, absorbent, and absorbent article

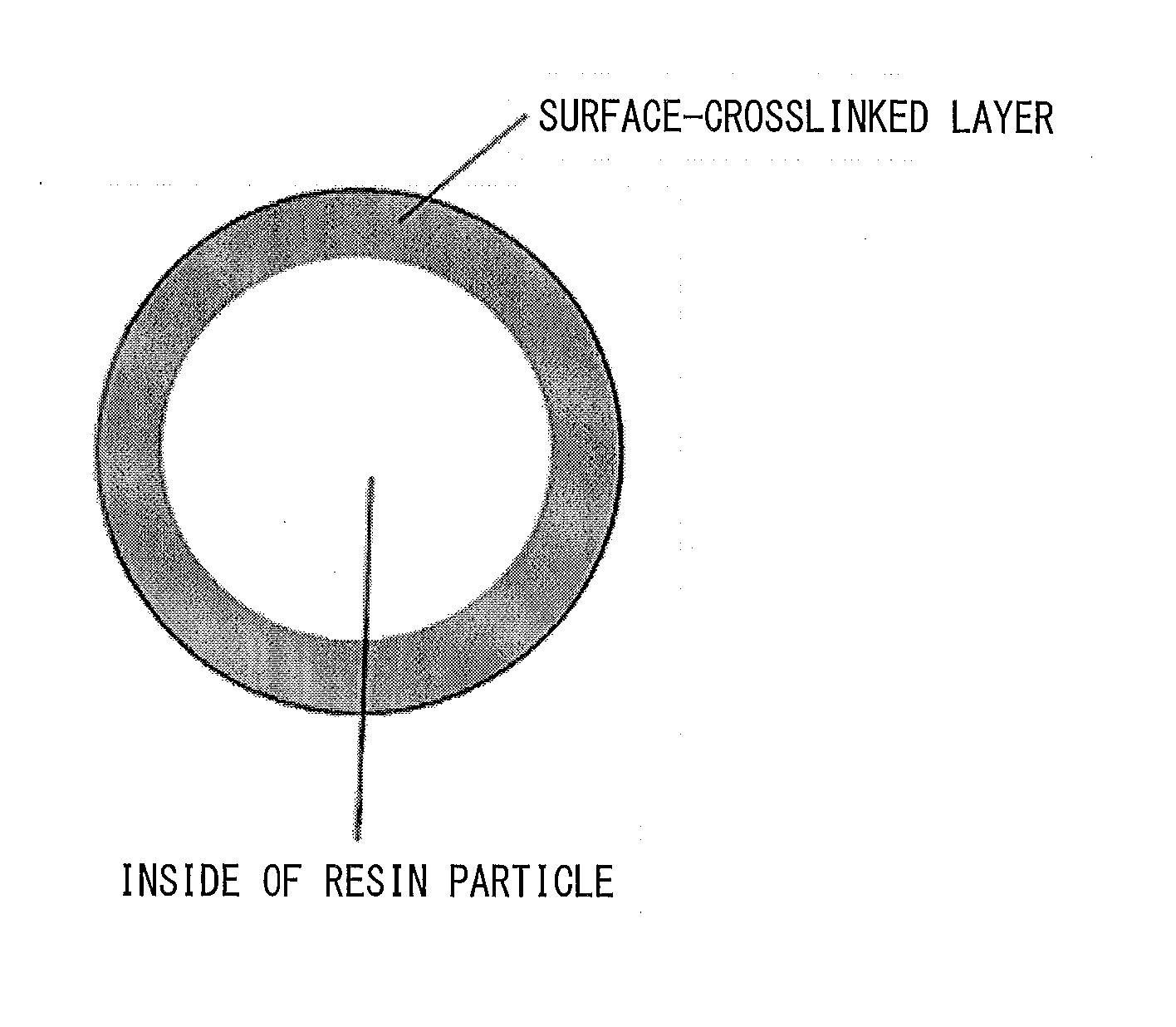

Provided is a process for producing aqueous-liquid-absorbing resin particles which, even after transportation or a diaper production step, are capable of combining the property of enabling liquid passing through interstices among the swollen gel particles with absorption performance under load. The present invention is: a process for producing aqueous-liquid-absorbing resin particles (P), characterized by subjecting resin particles (B) that comprise a crosslinked polymer (A) comprising essential constituent units derived from a water-soluble vinyl monomer (a1) and / or a vinyl monomer (a2) which becomes a water-soluble vinyl monomer (a1) upon hydrolysis and from a crosslinking agent (b), to a surface treatment by a specific method using a C4 or lower polyhydric alcohol (c), a polyvalent-metal salt (d), and a polyvalent glycidyl compound (e); and the aqueous-liquid-absorbing resin particles (P).

Owner:SDP GLOBAL

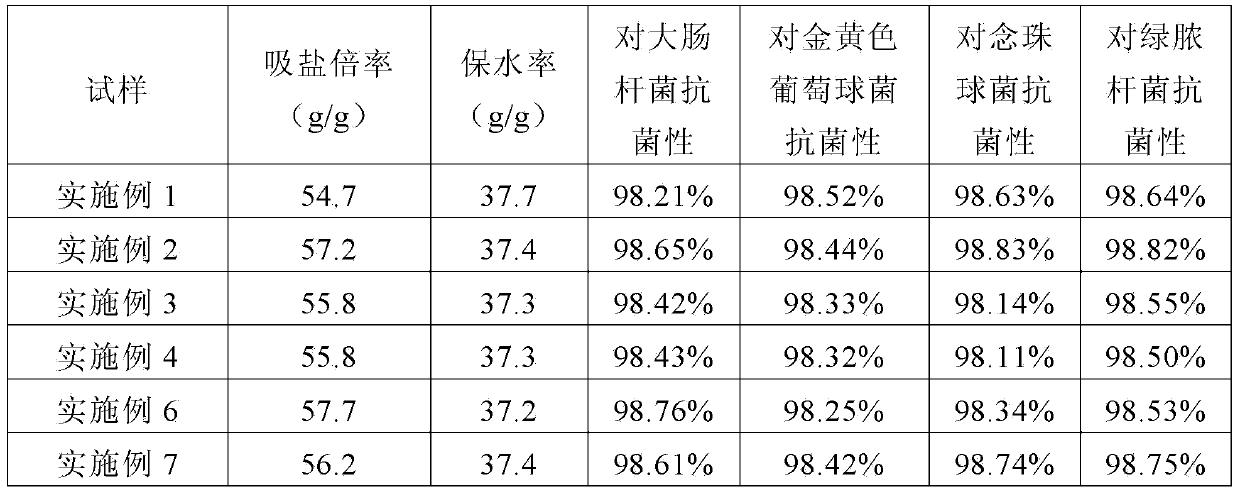

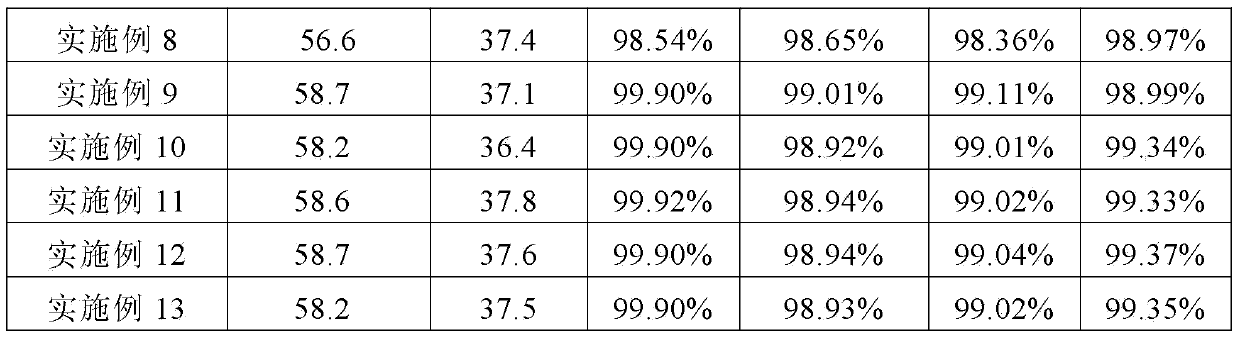

Bacterium resisting type high water absorption resin and preparation method thereof

The present invention relates to bacterium resisting type high water absorption resin and a preparation method thereof. The resin is a functional polymer material prepared by redox initiation system water solution polymerization method, the resin has a long chain containing allyl structures, a side chain containing carboxylic acid groups and carboxylic acid sodium, and an inner-crosslinking porous network structure, and the internal or external of particles contains a solubilizing quaternary ammonium salt positive ion monomer, an oxidizing agent is sodium persulfate and ammonium persulfate, a reducing agent is sodium sulfite or sodium bisulfite, and a crosslinking agent is N, N '-methylene bis acrylamide or polyethylene glycol diacrylate. The prepared high water absorbent resin has excellent water absorption and water retention properties, high liquid passing performance and high liquid absorption speed, most prominently has good antibacterial properties, and is applicable to the production of adult diapers, sanitary napkins, baby diapers and other water absorption hygiene materials.

Owner:浙江卫星新材料科技有限公司

Manufacturing method for polyacrylic acid (salt) -based water-absorbent resin powder

Owner:NIPPON SHOKUBAI CO LTD

Method for producing polyacrylic acid (SALT)-based water absorbing agent, and water absorbing agent

InactiveUS20150225514A1Reduce surfaceHigh liquid permeabilityAbsorbent padsBandagesChemical compoundDew point

An object of the present invention is to provide a method for producing a water absorbing agent, whereby the ability to produce the water absorbing agent is enhanced or the amount of a residual surface crosslinking agent is reduced (or Anti-Caking property are enhanced) in the production of a water absorbing agent having high physical properties (particularly, high liquid permeability and Anti-Caking property), whereas the surface crosslinking step tends to be a rate-determining step in the current state of the art. In this method for producing a water absorbing agent, an additive selected from a polyvalent metal cation-containing compound, water-insoluble inorganic fine particles, and a cationic polymer compound is used, and surface crosslinking, particularly surface crosslinking with an alkylene carbonate compound, is performed under conditions where a temperature in a heat treatment system is controlled to be in a range from 100° C. to 300° C., and a dew point in the heat treatment system is controlled to be lower than 45° C.

Owner:NIPPON SHOKUBAI CO LTD

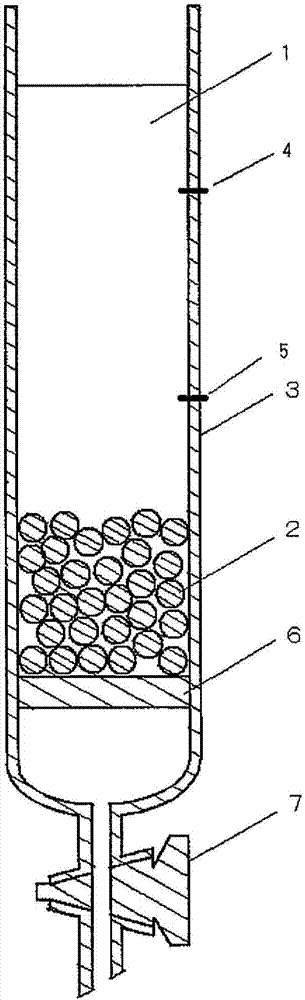

Charging method for blast furnace burden

The invention provides a method for mixed-loading blast furnace materials, ironstone and coke are loaded into the furnace hierarchically, characterized in that the ironstone loaded into the furnace is ore having two or more than two different alkalinity, and the ore is mixed according to the matching proportion of furnace alkalinity requirement prior to entering into the blast furnace. The invention solves the problem that each material layer in the original blast furnace owes the diverse formed softening, fusing, falling starting temperatures to diverse alkalinities, causing the bad air and liquid permeability of material post at the lower part of the blast furnace so as to have an influence on the stable operation of the blast furnace. The invention has the characteristics of reducing the alkalinities of initial slag and bosh slag of the high alkalinity sinter, dropping the melting point of the initial slag, promoting the fluidities of the initial slag and the bosh slag, thus improving the air and liquid permeability of material post at the lower part of the blast furnace and creating advantageous conditions for further increased production and coke saving.

Owner:ANGANG STEEL CO LTD

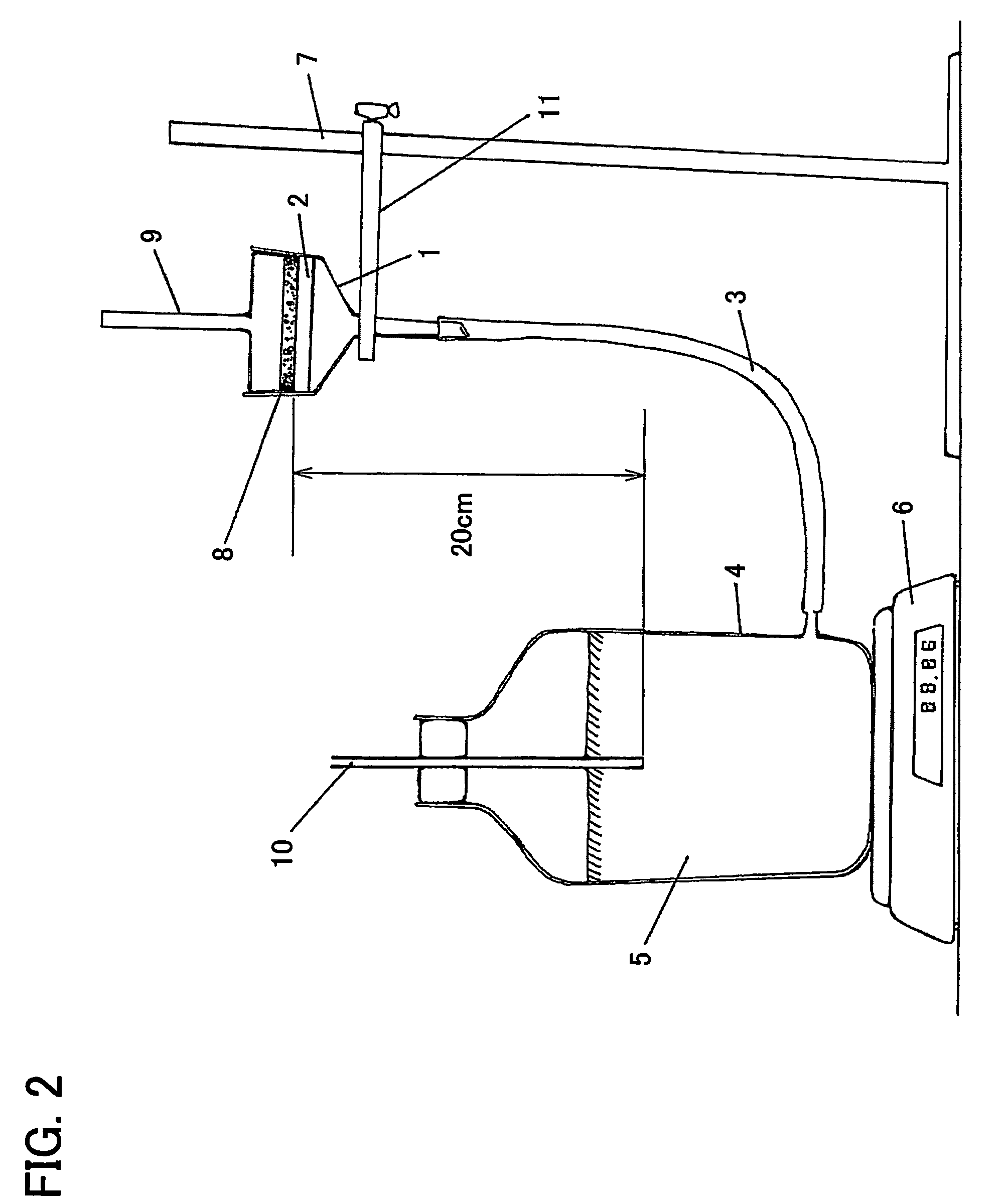

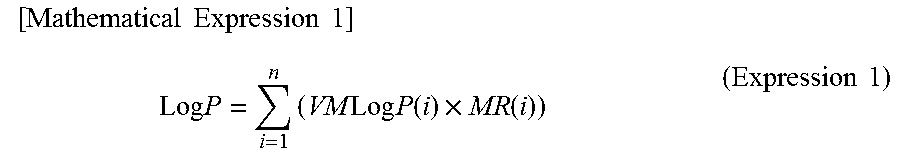

Water absorbent resin material, and method for producing same

ActiveUS20150360204A1Increase capacityImprove liquid permeabilityOther chemical processesAbsorbent padsWater dispersibleWater soluble

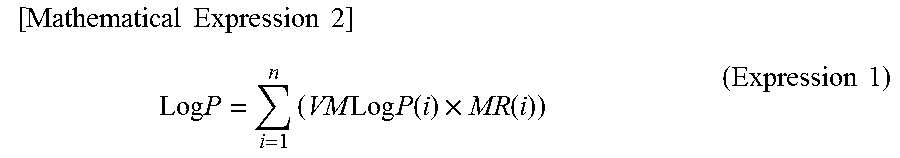

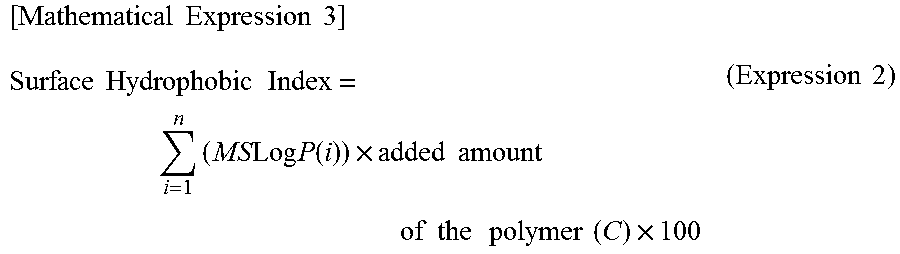

An object of the present invention is to provide a water absorbent resin which attains high liquid permeability and water absorbing speed, and which does not have problems of coloring and odor. The water absorbent resin includes: (A) a water absorbent resin particle having a carboxyl group; (B) a covalent surface crosslinking agent in which the number of carbons is not more than 10; (C) 0.001 mass % to 0.2 mass % of a water-soluble or water-dispersible polymer whose Log P is not less than 1.0; and (D) 0.001 mass % to 1 mass % of a water-soluble polyvalent cation. The water absorbent resin has not less than 20 g / g of a fixed height absorption (FHA) at a height of 20 cm.

Owner:NIPPON SHOKUBAI CO LTD

Nonwoven fabric

Nonwoven fabric (10) having a multilayer structure including first layer (1) constituting one outer layer and second layer (2) constituting the other outer layer, which nonwoven fabric (10) is comprised of split type conjugate fibers and hot melt fibers. Split type conjugate fibers are contained in an amount of 20 wt.% or less in the first layer (1) and contained in greater amount in the second layer (2). The nonwoven fabric (10) is provided with a multiplicity of openings (3). The split type conjugate fibers lying at the periphery of openings (3) have constituent resins thereof split and spaced, and the extent of splitting and spacing thereof is greater than that of split type conjugate fibers at other parts of the nonwoven fabric (10)

Owner:KAO CORP

Method for producing polyacrylic acid (SALT)-based water absorbing agent, and water absorbing agent

ActiveUS20150210843A1Simple designImprove liquid permeabilityAbsorbent padsBandagesAbsorption ratioALLYL SUCROSE

The present invention relates to an absorbent suitable for use in a thin sanitary material / absorbent article having a high absorbent content and not prone to gel blocking, the absorbent having excellent liquid diffusibility (e.g. SFC) and minimal decrease in absorption ratio under pressure (e.g., AAP or PUP) even when a liquid permeation enhancer is added, and to a method for manufacturing the high-performance absorbent stably during actual production. The method is a method for manufacturing a polyacrylic acid (salt)-based absorbent, having a surface-crosslinking agent addition step for adding a solution of a surface-crosslinking agent, and a liquid permeation enhancer addition step for adding a liquid permeation enhancer, the liquid permeation enhancer addition step being performed after and / or at the same time as the surface-crosslinking agent addition step, the method characterized in that a surface crosslinking step for performing heat treatment in an atmosphere having a dew point of 45° C. to 100° C. is performed after or at the same time as the surface-crosslinking agent addition step.

Owner:NIPPON SHOKUBAI CO LTD

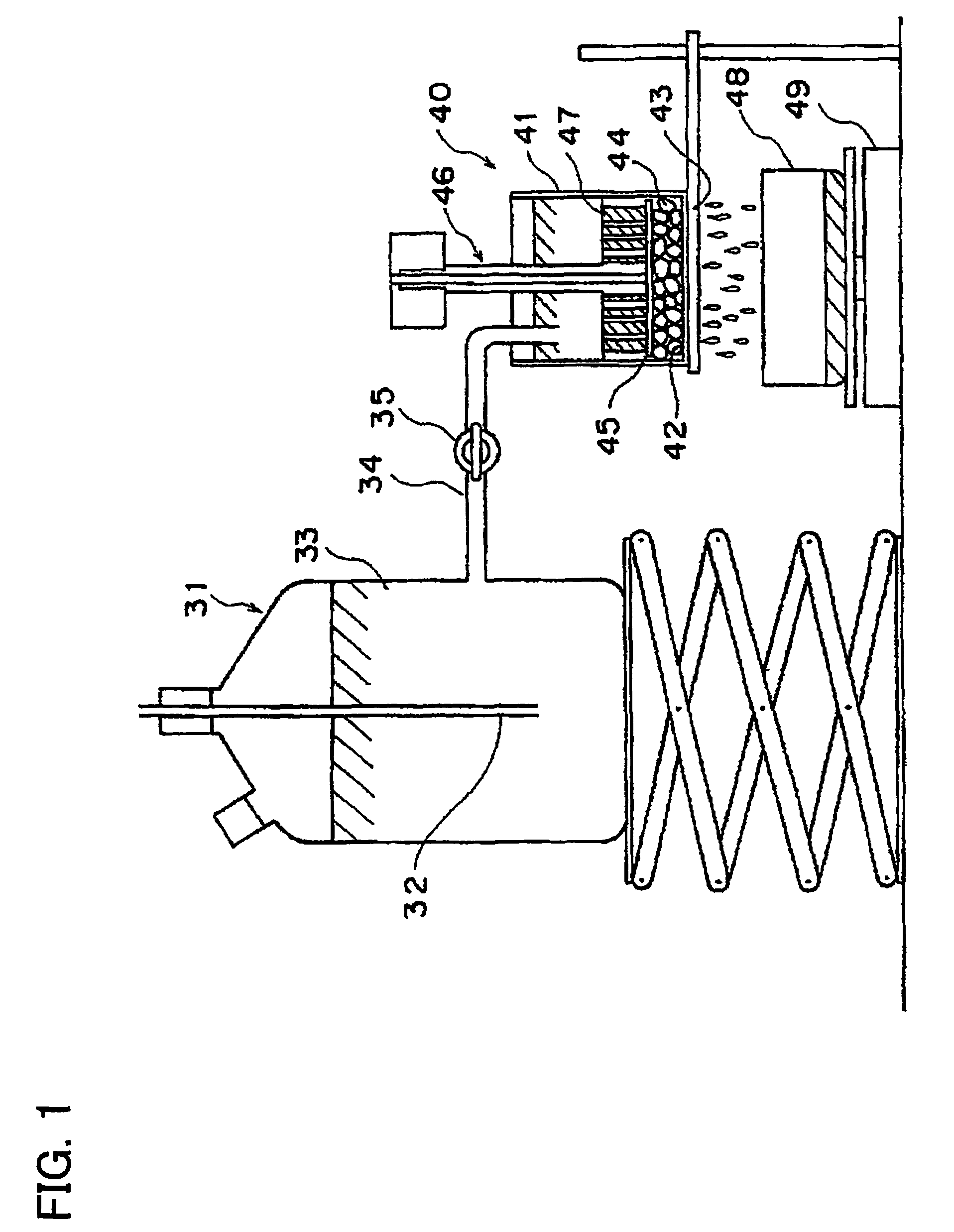

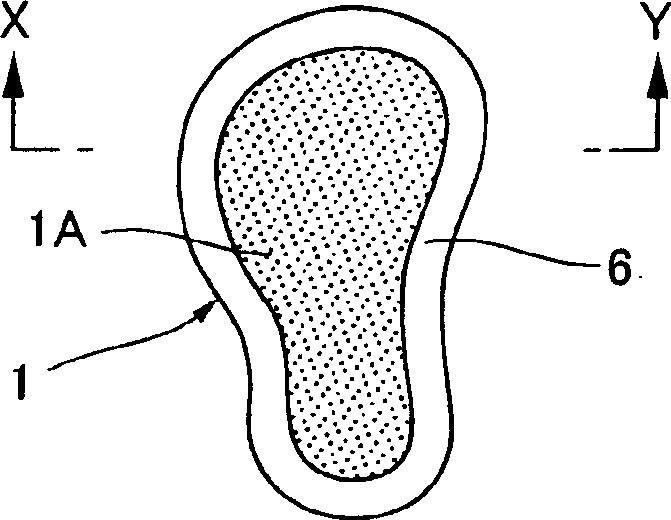

Foot warming heating element and method of manufacturing foot warming heating element

InactiveCN1518435AHeating comfortBroaden your optionsHeat-exchange elementsHeating element shapesSOCKSEngineering

A foot warming heating element capable of preventing a heating composition from moving by fixing a part or all of the composition in a packaging materi al by using the shape maintainable heating composition and capable being suitably fitted to the shape of a foot at the time of installation to efficiently war m the specified portions of the foot for a long time irrespective of an air pressure in a storage bag when the heating element is used by sticking on th e foot, footware, and socks, characterized in that a heating formed product causing heating reaction under the presence of air and having a shape maintaining degree of 70 or higher is sealed in the storage bag formed of a substrate material and a cover material, and at least a part of the storage bag is a permeable.

Owner:MYCOAL

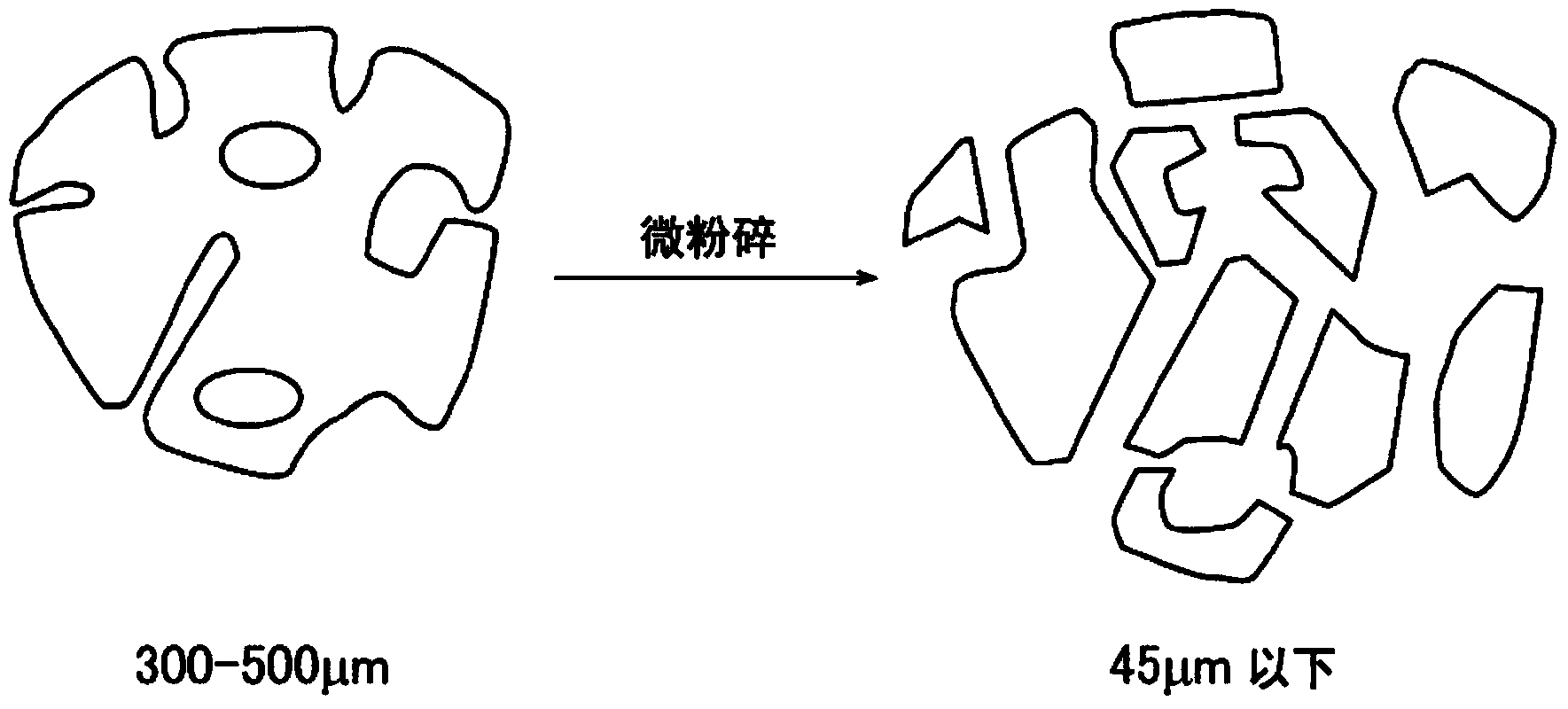

Method for preparing superabsorbent polymer, and superabsorbent polymer prepared thereby

ActiveUS20180265646A1Minimizing deteriorationExcellent basic absorption performanceAbsorbent padsBandagesPolymer scienceSuperabsorbent polymer

The present invention relates to a method for preparing a superabsorbent polymer, and a superabsorbent polymer prepared thereby. A superabsorbent polymer prepared by the preparation method exhibits minimized deterioration of physical properties after being pulverized, and thus basic absorbance performance is excellent and an excellent liquid permeability and absorbance rate can be exhibited.

Owner:LG CHEM LTD

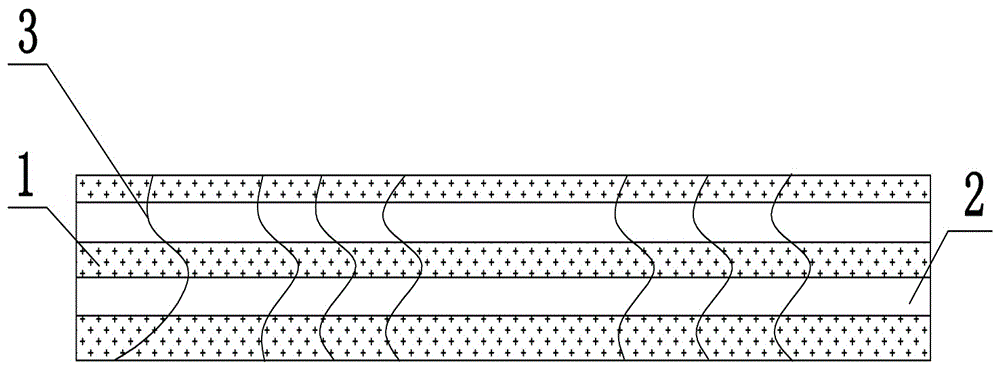

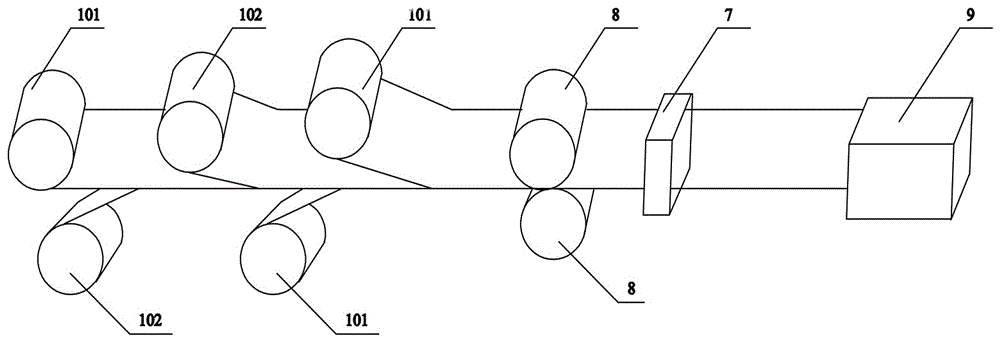

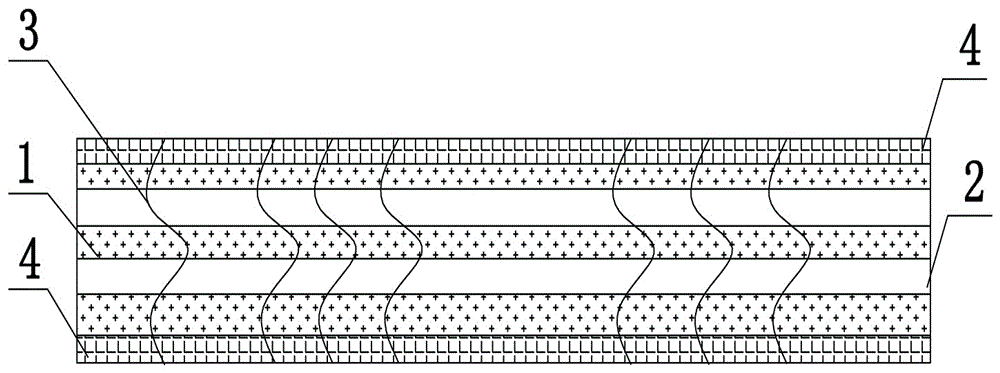

Thermoplastic continuous fiber composite material and preparation method thereof and production device

InactiveCN106113811AImprove breathabilityImprove liquid permeabilitySynthetic resin layered productsGlass/slag layered productsNonwoven fabricFibrous composites

The invention provides a preparation method of thermoplastic continuous fiber composite material. Paving parts; pre-pressing the paving parts to obtain preforms; subjecting the preforms to hot pressing and melting molding to obtain thermoplastic continuous fiber composite materials. The preparation method has simple process and is suitable for automatic production. The present invention also provides a thermoplastic continuous fiber composite material prepared by the method and a device for producing the composite material. The layers of the thermoplastic continuous fiber composite material are tightly bonded, and the provided device is simple in composition and easy to adjust. process steps.

Owner:ZHENGZHOU UNIV

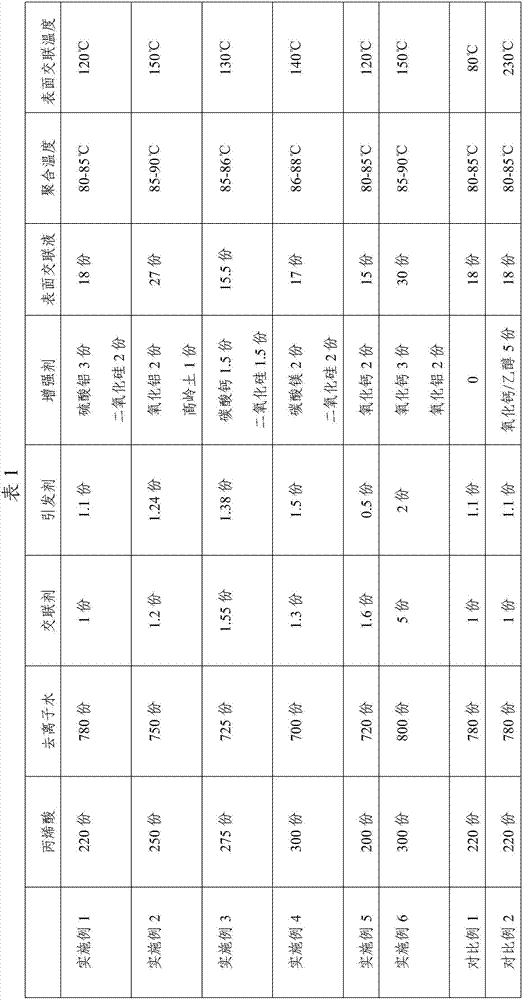

Preparation method of super absorbent resin resistant to moisture absorption and caking

The invention relates to a preparation method of super absorbent resin resistant to moisture absorption and caking. The preparation method comprises the following steps: introducing nitrogen to removal oxygen after mixing acrylic acid, water and a cross-linking agent, then adding an initiating agent until the temperature is not increased, and then preserving the temperature to obtain a product; treating the obtained product to obtain resin particles; adding reinforcing agent powder into the resin particles to be mixed uniformly, then adding a surface cross-linking solution to be stirred uniformly, preserving the temperature at the temperature of 120 to 200 DEG C to obtain the super absorbent resin, wherein the reinforcing agent is selected from one or more of calcium oxide, kaoline, silica, aluminum sulfate, aluminum oxide, calcium carbonate and magnesium carbonate. The super absorbent resin synthesized by using the method is highly uniform in surface cross-linking degree and high in strength, is not easy for moisture absorption and caking in air, can be stored for longer time, is unlikely to cause gel blockage after liquid absorption, and has good liquid flowing performance and conduction performance.

Owner:SHANDONG NUOER BIOLOGICAL TECH

Liquid filter substrate

ActiveCN105188895AImprove the capture effectImprove liquid permeabilityMembranesSemi-permeable membranesPolyolefinPolymer science

This liquid filter substrate comprises a polyolefin microporous film, the water permeation performance of the polyolefin microporous film being 0.51-1.20 ml / min.cm2, the bubble point of the polyolefin microporous film being 0.45-0.70 MPa inclusive, and the bulk compressibility of the polyolefin microporous film being less than 15%.

Owner:TEIJIN LTD

Fibrous laminate containing ultrafine fibers and filter comprising same

InactiveUS20160288034A1Large specific surface areaIncreased durabilityLayered productsMembrane filtersPolymer scienceHot melt

To provide a fibrous laminate having excellent secondary processability in processing into a filter or the like by laminating a fibrous layer composed of ultrafine fibers with another fibrous layer and strongly adhering and uniting each interlayer while reduction of characteristics of the ultrafine fibers is suppressed at a minimum to compensate insufficiency of mechanical strength and rigidity of a layer of ultrafine fibers.The fibrous laminate includes fibrous layer I composed of ultrafine fibers having a mean fiber diameter of 10 to 1,000 nm and fibrous layer II composed of thermo-fusible conjugate fibers having a mean fiber diameter of 5 to 100 μm, in which contact points between the ultrafine fibers and the thermo-fusible conjugate fibers are bonded by melting of the thermo-fusible conjugate fibers composing the fibrous layer II, and the fibrous layer I and the fibrous layer II are laminated and united by the formed bonding points.

Owner:JNC CORP +1

Particulate water absorber comprising water-absorbing resin as main component and process for manufacturing same

ActiveCN105658323AImprove stabilityStability deviation is smallOther chemical processesAbsorbent padsSolid componentPolymer science

The invention aims to provide a water absorber which exhibits high gel stability, little scattering in gel stability among particle sizes, and good water absorption characteristics. A particulate water absorber which comprises a water-absorbing resin as the main component and a chelating agent and in which the constituent particles comprise particles having particle diameters of less than 300[mu]m and particles having particle diameters of 300 to less than 850[mu]m, each particle diameter being determined by JIS standard sieves, characterized in that: the content of the chelating agent is 0.001 to 5 parts by weight relative to 100 parts by weight of the solid matter of the water-absorbing resin; and the relationship (1) 1.2<C1 / C2<4.0 is satisfied.

Owner:NIPPON SHOKUBAI CO LTD

Azithromycin detection molecular imprinting monolithic micro column and preparation method thereof

InactiveCN104829774AImprove solubilityImprove liquid permeabilityComponent separationFunctional monomerMicro column

The invention discloses an azithromycin detection molecular imprinting monolithic micro column and a preparation method thereof, and belongs to the technical field of material chemistry. The preparation method of the azithromycin detection molecular imprinting monolithic micro column comprises the following steps: a template, a mixed pore forming agent, a functional monomer, a crosslinking agent and an initiator are polymerized at 50-80 DEG C for 48h, and the template is removed to obtain the azithromycin detection molecular imprinting monolithic micro column. The azithromycin recovery rate of the prepared molecular imprinting monolithic micro column is more than 90%, the prepared molecular imprinting monolithic micro column shows high cross reactivity, high selectivity and specificity, and has a broad application prospect in use as a purification and pretreatment material for analysis of a sample of azithromycin in animal tissues, feeds and environmental water, and other matrix.

Owner:SOUTH CHINA AGRI UNIV

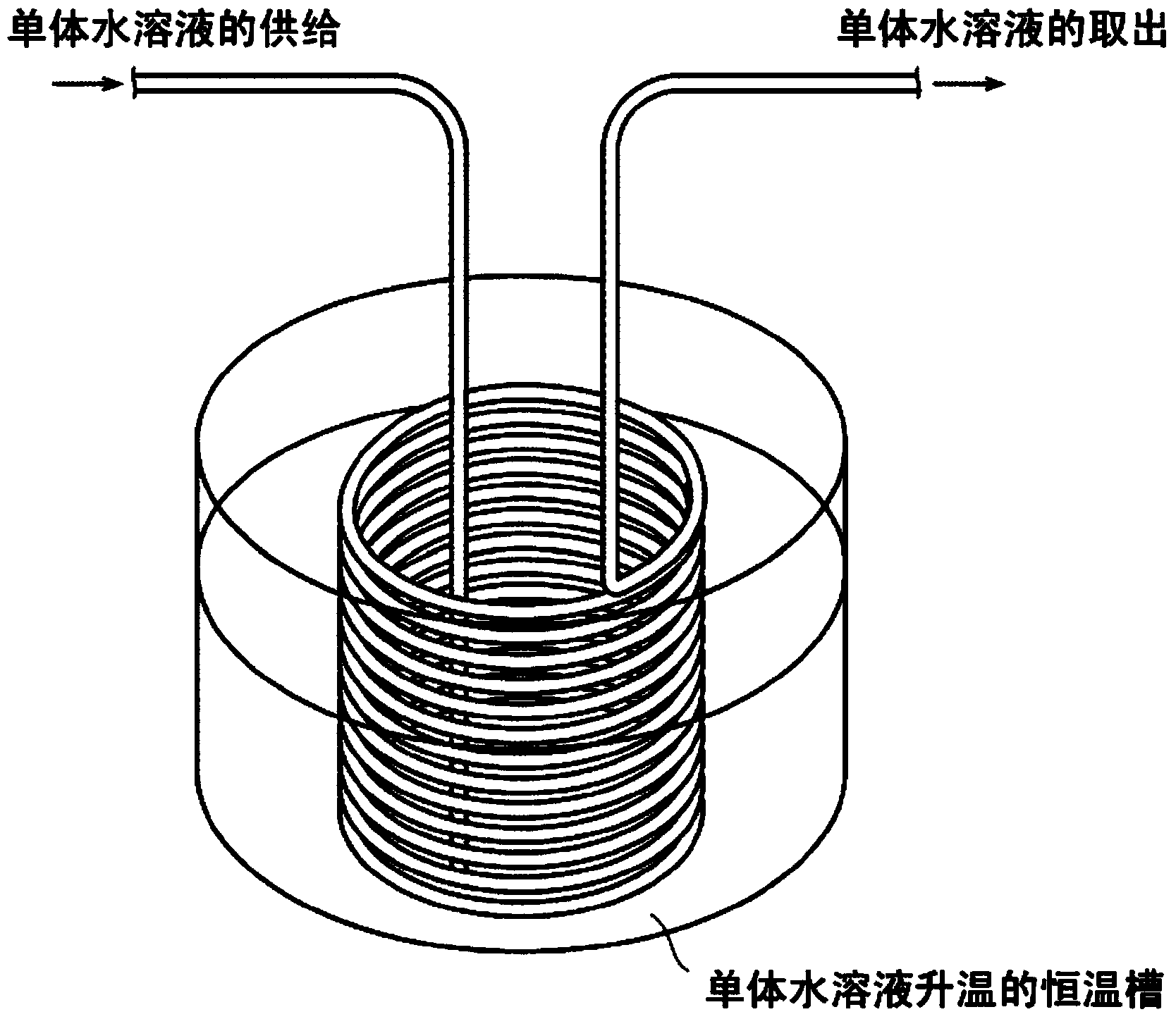

Process for producing water-absorbing resin

ActiveCN103429624AImprove liquid permeabilityAbsorbent padsThin material handlingCross-linkPolymer science

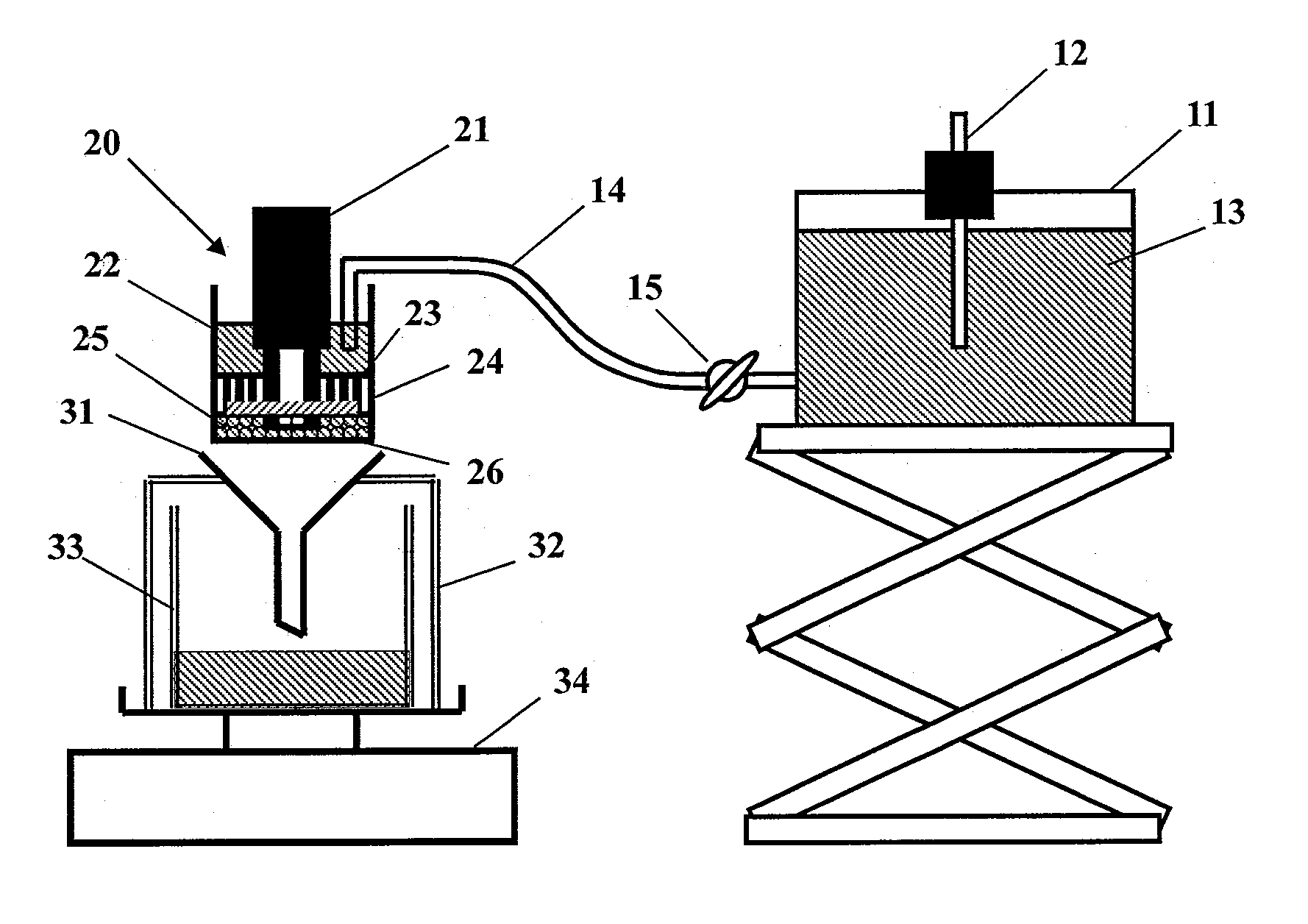

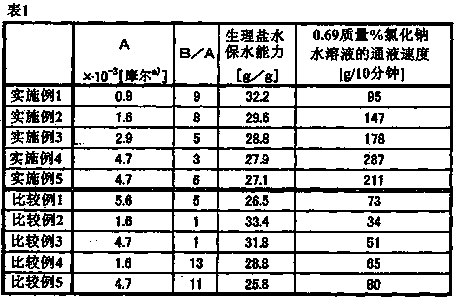

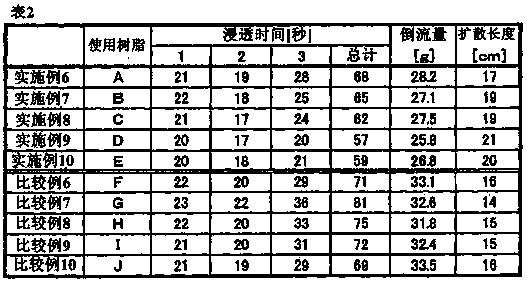

Provided is a process for producing a water-absorbing resin using a water-soluble ethylenically unsaturated monomer unit to which an internal cross-linking agent has been added, and in the process, primary particles obtained in a first inverse suspension polymerization step are aggregated in a second inverse suspension polymerization step. If the added amount of the internal cross-linking agent in the first polymerization step is set at A moles in relation to 100 moles of the water-soluble ethylenically unsaturated monomer unit used in the first polymerization step, and the added amount of internal cross-linking agent of the second polymerization step is set at B moles in relation to 100 moles of the water-soluble ethylenically unsaturated monomer unit used in the second polymerization step, the production process is characterized by A and B satisfying the relationships A<=5.0*10-3 and 2<=B / A<=10. This process can provide a water-absorbing resin with excellent liquid permeability, as well as an absorbent material and absorbent article comprising the same.

Owner:SUMITOMO SEIKA CHEM CO LTD

Water-absorbent resin and preparation method thereof

The invention discloses a water-absorbent resin and a preparation method, the method comprises the following steps: 1)adding a cross-linking agent and a polymerization initiator in an acrylic acid monomer alkaline aqueous solution; 2)applying microwave to initiate a polymerization; 3)performing polymerization for 3-10 minutes at 100-140 DEG C, increasing the temperature of 10-30 DEG C and slaking for 10-20 minutes to obtain a polymer gel; 4)sprinkling water vapor on the surface of the polymer gel to obtain the water-absorbent gel, by metering weight of the polymerization material, wherein the water vapor amount is 1-3weight%; and 5)using microwave for irradiate the water-absorbent gel under temperature which is lower than water boiling temperature.

Owner:SHANGHAI HUAYI NEW MATERIAL

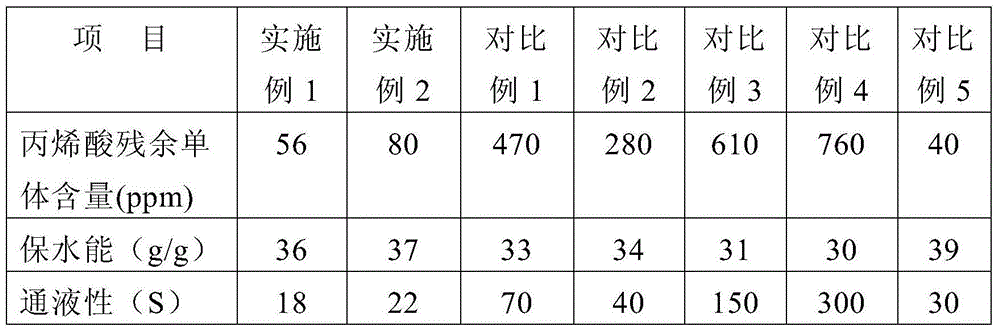

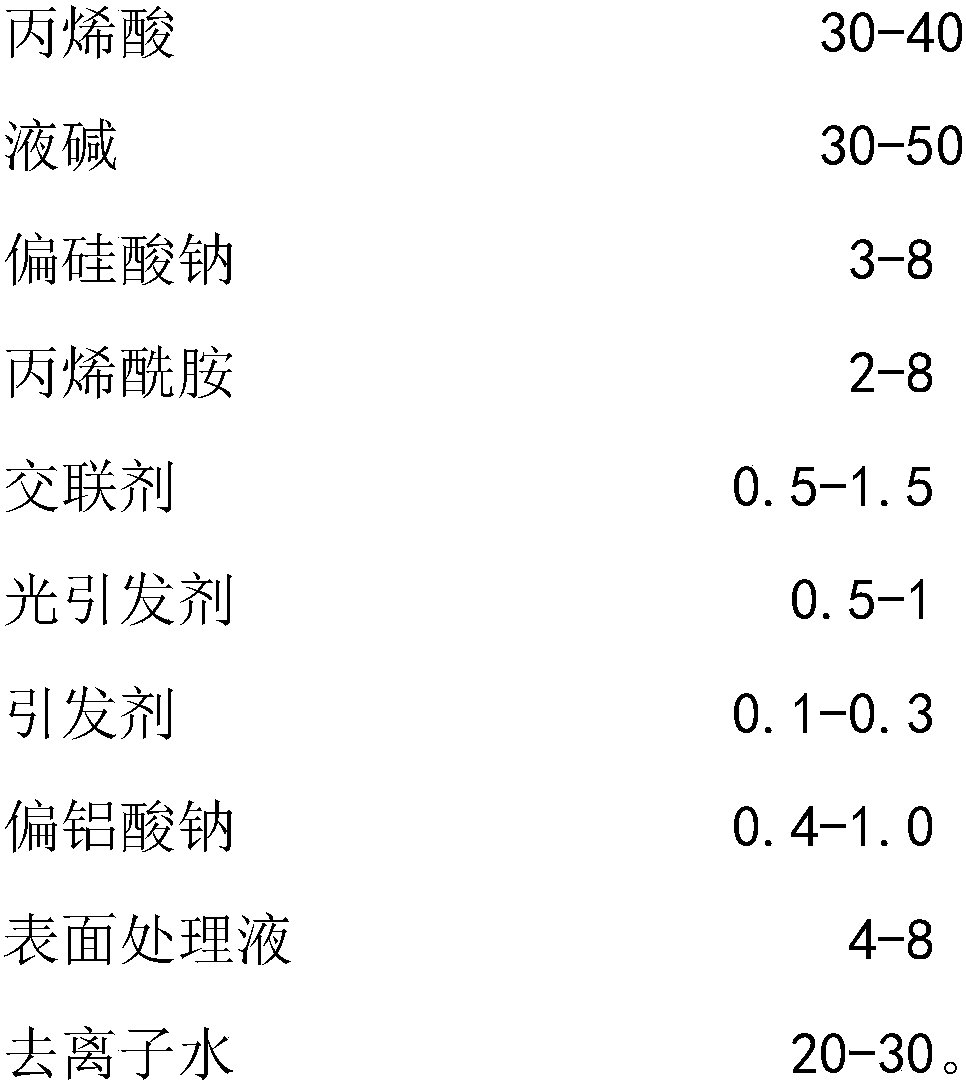

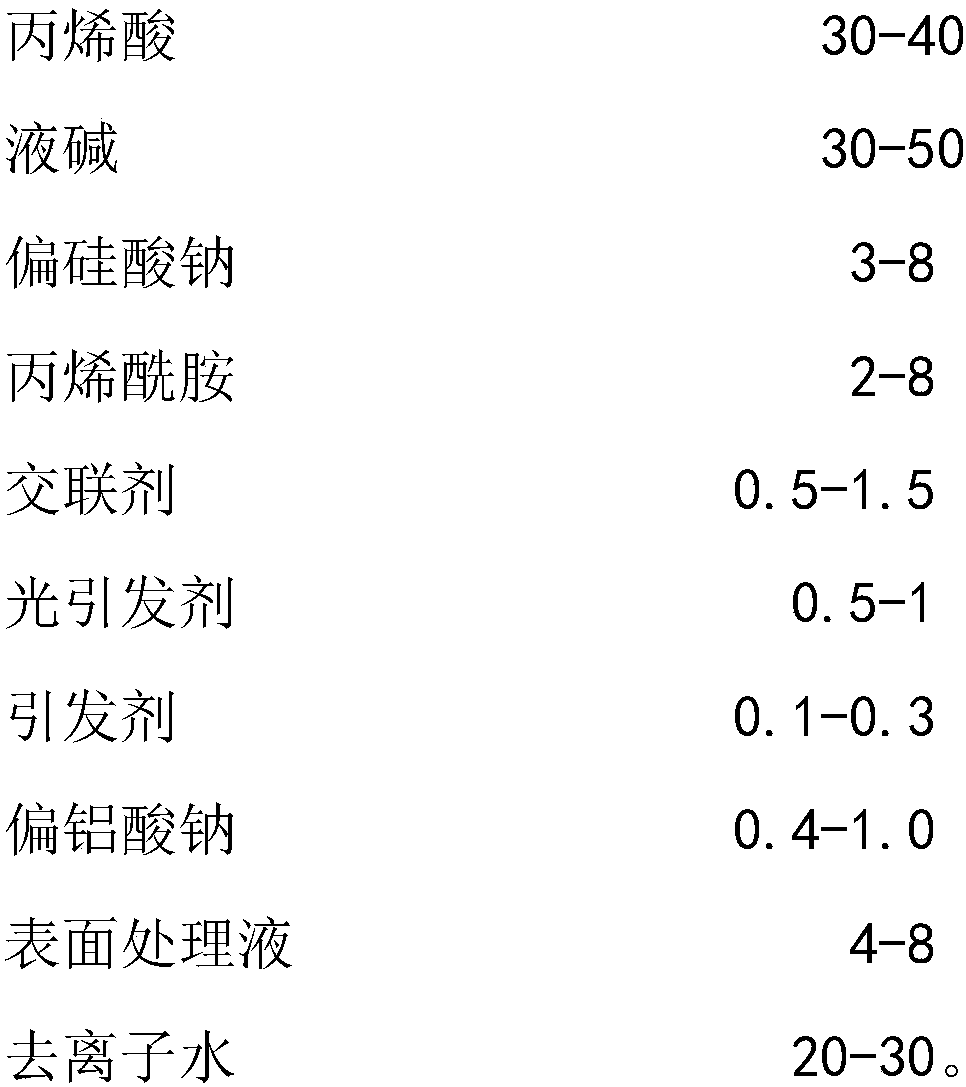

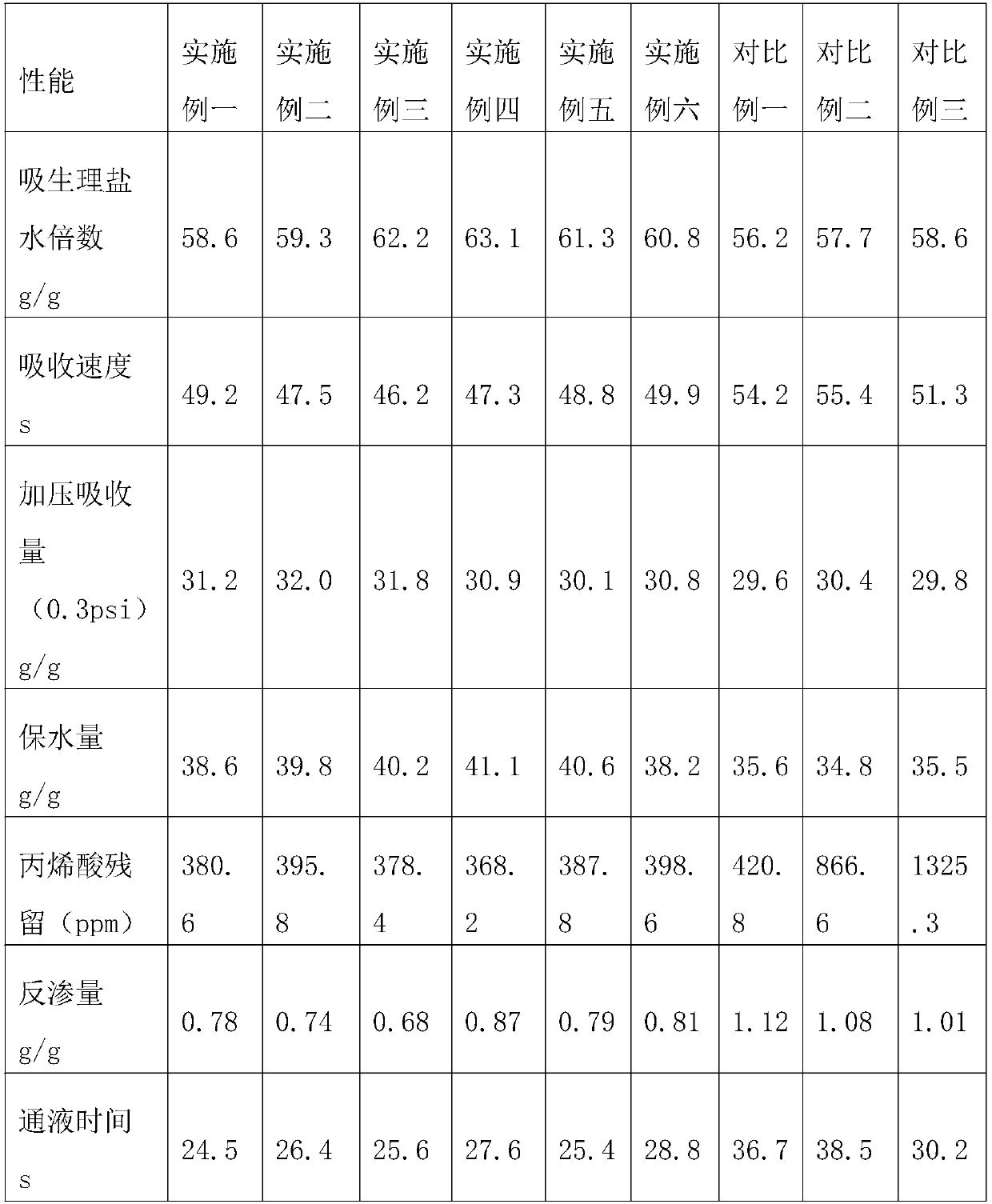

Water absorbent resin suitable for wood-pulp-core paper diaper and preparing method thereof

ActiveCN107854223AModerate water absorption speedResidue reductionAbsorbent padsBaby linensCross-linkSodium metasilicate

The invention discloses a water absorbent resin suitable for a wood-pulp core and a preparing method thereof. The preparing method includes the following steps that after acrylic acid and deionized water are mixed, then a neutral reaction is carried out with a sodium hydroxide solution, the reaction is completed, then a sodium metasilicate water solution, acrylamide, a cross-linking agent and an initiating agent are sequentially added, and a milk-white mixed solution is obtained; nitrogen is introduced, mixed liquid is subjected to a polymerization reaction under ultraviolet rays, and transparent colloid is obtained; the colloid is granulated, dried and smashed, and resin powder is obtained; the resin powder is taken and evenly stirred with sodium metaaluminate, surface treatment liquid isadded for treatment, and the product is obtained. According to the water absorbent resin suitable for the wood-pulp core and the preparing method thereof, nanoscale silicon dioxide is generated in the neutral process and evenly dispersed in a reaction system and is capable of improving the liquid passing performance and the diffusivity of the water absorbent resin; the water absorbent resin prepared with the method is low in residual monomer, small in reverse osmosis amount, large in water retaining capacity, high in particle strength after water absorption, loose and particularly suitable for a wood-pulp-core paper diaper.

Owner:LUNALER HEALTH TECH GUANGZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com