Foot warming heating element and method of manufacturing foot warming heating element

A heat-generating body and foot technology, applied in the direction of heating element shape, heat exchange material, ohmic resistance heating, etc., can solve the problems of production equipment operating time, operator working time limitation, poor flow value, and productivity decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

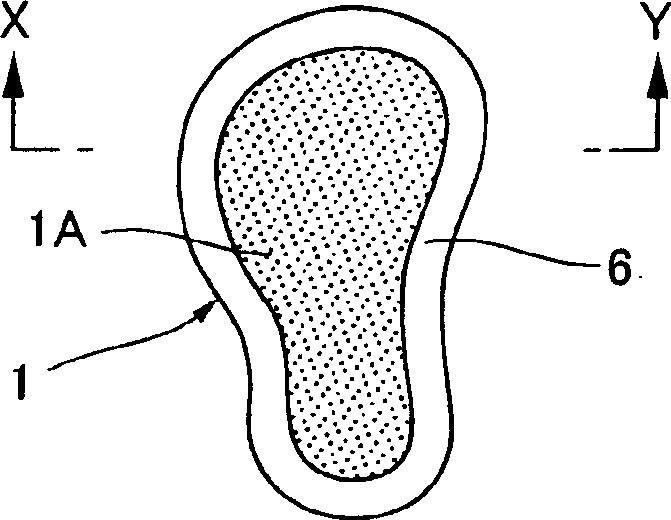

[0391] The heat generating body for heating a foot shown in FIG. 1 is a heat generating body for heating a foot having the shape of the entire foot, having a heat generating component sandwiched between a base material and a covering material, And the base material and the covering material are sealed 6 at a width of 10 mm on the periphery of the heat generating body component 1A.

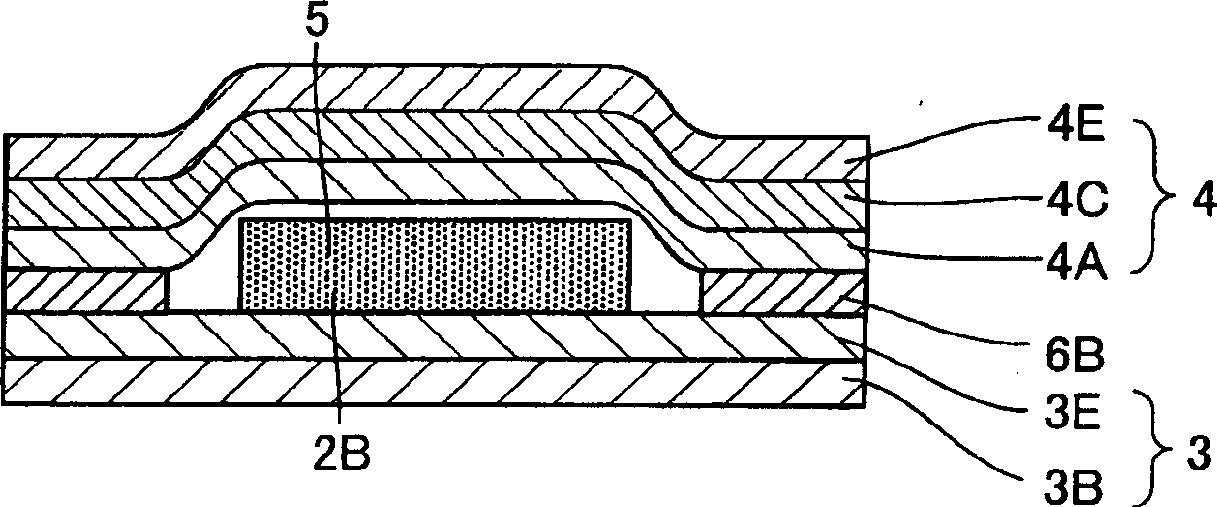

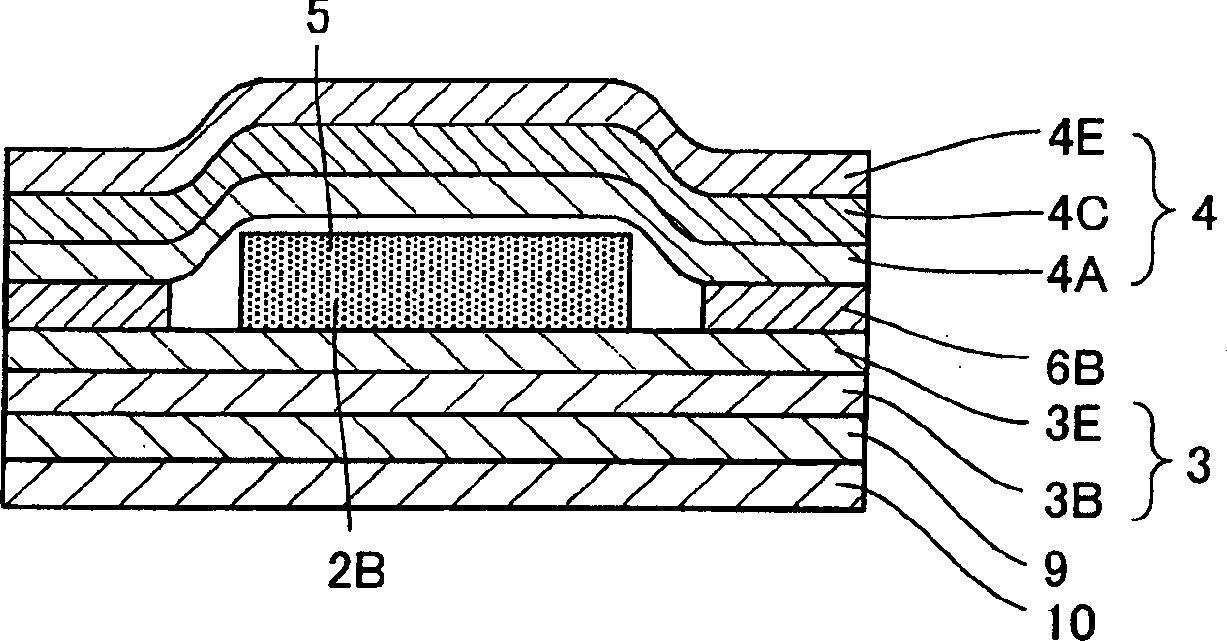

[0392] Its cross-sectional diagram is figure 2 shown in . As the base material 3, a corrugated fiberboard liner 3E having a thickness of 100 μm and a laying layer having a thickness of 50 μm and having air-impermeability and water-impermeability, made of metallocene catalyst-produced polyethylene 3B were provided. On base material 3, a non-adhesive heat-generating component with excess moisture is molded on a corrugated fiberboard liner by a mold in direct contact.

[0393] The covering material 4 is made by laminating a porous film 4C with a thickness of about 50 μm on a corrugated fiberboard li...

example 2

[0405] exist Figure 4 In the heat generating body for heating the foot shown in the plan view, the non-adhesive heat generating component with excess moisture is molded to increase the arch portion and extend from the arch portion to Example 1 by through-molding The form obtained from the shape of , and said part, except for the non-adhesive heat-generating component with excess moisture, is sealed 6 by adhesive, as in example 1.

[0406] Unlike the base material of Example 1, a rayon-polyester hybrid nonwoven fabric having a thickness of 140 μm and a rayon fiber weight of 60% was laminated on both surfaces of a polyethylene film having water absorption and a thickness of 80 μm instead of paper.

[0407] As the covering material, the same non-adhesive heat generating component with excess moisture and adhesive layer as in Example 1 were used.

example 3

[0409] exist Figure 5 In the heat-generating body for heating feet shown in the plan view of , (a) heat-generating component 1A is formed by through-molding on two areas at the approximate center of the shape as in Example 1, and except having Said part outside the non-adhesive heat-generating component 1A of excess moisture is sealed by bonding 6 . At the approximate center position where the heat generating component 1 is not laminated, the heat generating body for heating the foot can be folded so as to be compact. Since the surface area can be reduced during storage, deterioration of heat-generating components due to splashing of water can be reduced. (b) is a product that has perforated line 7A in the area without heat-generating components to facilitate folding. (c) is a product in which a portion protruding from the arched portion is increased.

[0410] The heat generating body 1 for heating the foot shown in the plan view of FIG. 6 shows Figure 5 (b) The perspect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com