Shell body of convection heater

A heater and shell technology, which is applied in the shell field of convection heaters, can solve the problems of poor natural convection effect of heaters and inconvenient heating, and achieve the effects of comfortable heating, strong convection effect, and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

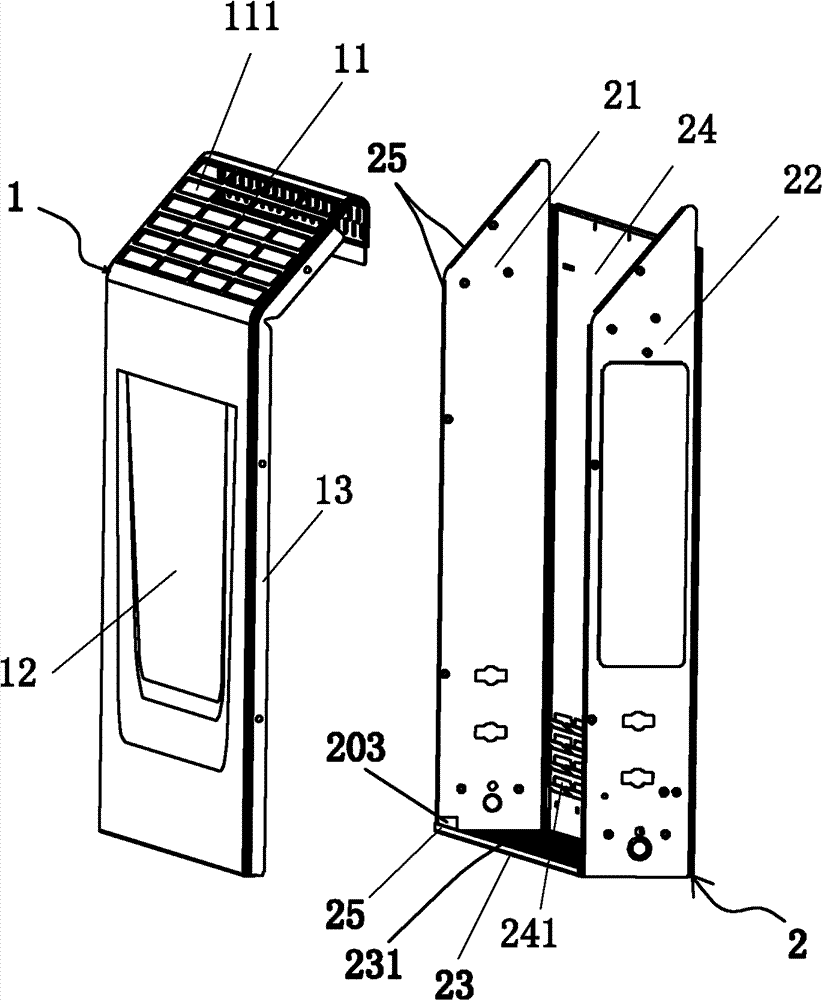

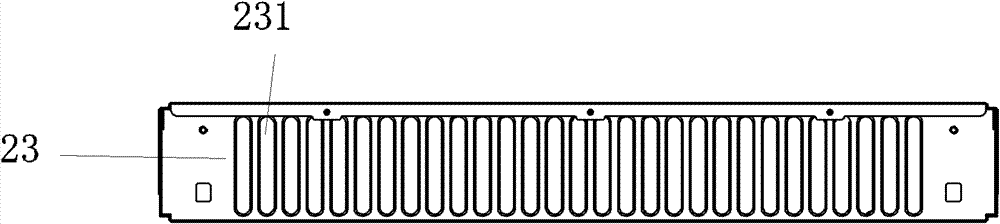

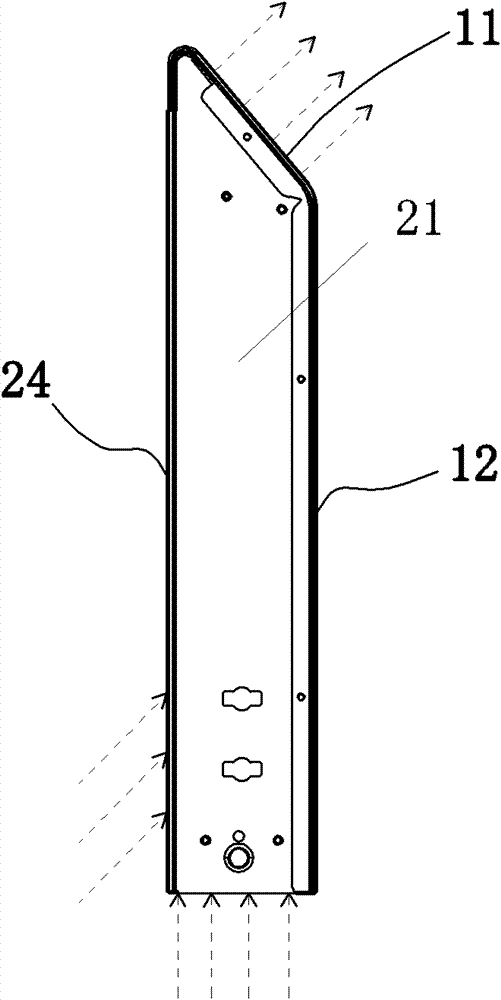

[0018] Such as figure 1 As shown, the housing of the convection heater provided in this embodiment includes a first housing member 1 and a second housing member 2 . The first shell member 1 is made of cold-rolled sheet (preferably 0.6 mm cold-rolled sheet), and includes a top panel 11 , a front panel 12 and a side flange structure 13 integrally formed. The top panel 11 is an inclined retaining surface, on which an air outlet 111 is opened, and the side flange structures 13 are arranged on both sides of the top panel 11 and both sides of the front panel 12 . The second shell member 2 is also made of cold-rolled sheet (preferably 0.6mm cold-rolled sheet), including integrally formed left side panel 21, right side panel 22, bottom panel 23, rear end panel 24, bottom And the side edge flanging structure 25. Wherein, the joint area 203 among the left side panel 21 , the right side panel 22 and the bottom panel 23 is welded to ensure the strength of the entire second shell member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com