A kind of electric heating film and its production process

A production process, electric heating film technology, applied in the direction of electric heating system, electric heating device, ohmic resistance heating, etc., can solve the problems such as poor heating effect of electric heating film, achieve the effect of shortening the production process, good flexibility and good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

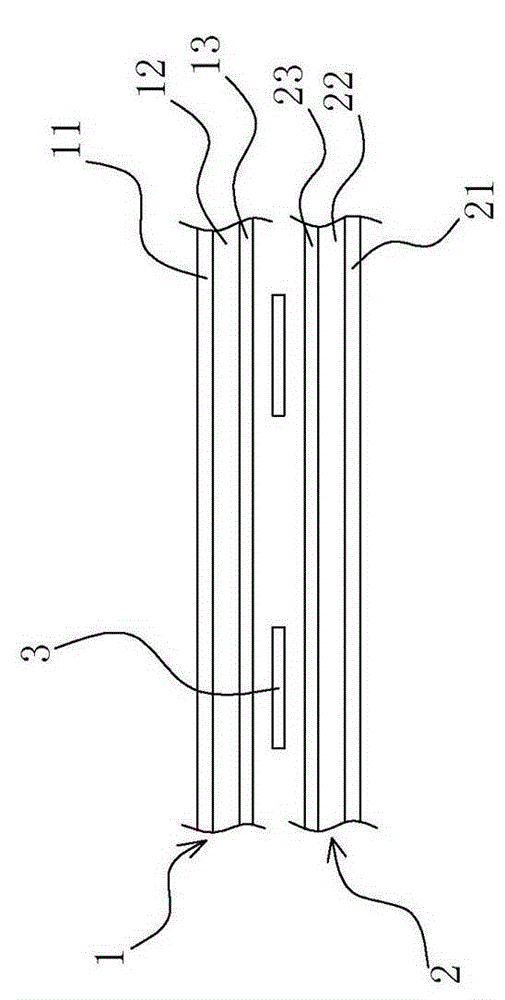

[0025] Such as figure 1 As shown, the electric heating film includes an upper layer 1 and a lower layer 2. The upper layer 1 includes an upper PET film 11, an upper non-woven fabric 12 and a PVC film 13 pasted together by glue, and the upper non-woven fabric 12 is pasted on the upper PET film 11 and PVC film. Between the films 13; the lower layer 2 includes the lower non-woven fabric 22, the heat-conducting layer 23 and the lower PET film 21 pasted on the reverse side of the lower non-woven fabric 22 by glue, and the front side of the lower non-woven fabric 22 is covered with carbon pulp and the lower non-woven fabric The gaps of 22 are filled with carbon paste, and the heat conduction layer 23 is formed after the carbon p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com