Patents

Literature

141results about How to "Heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

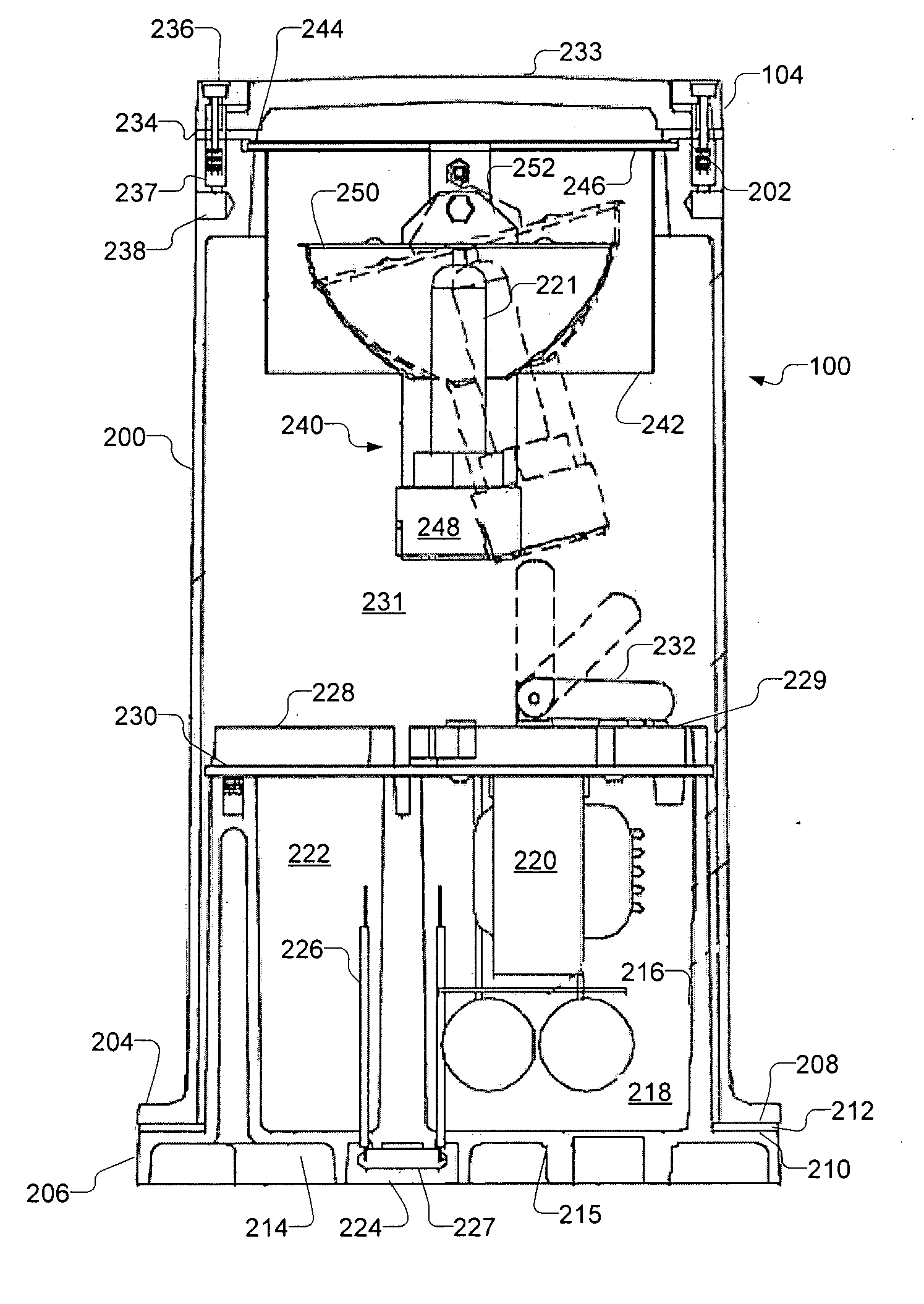

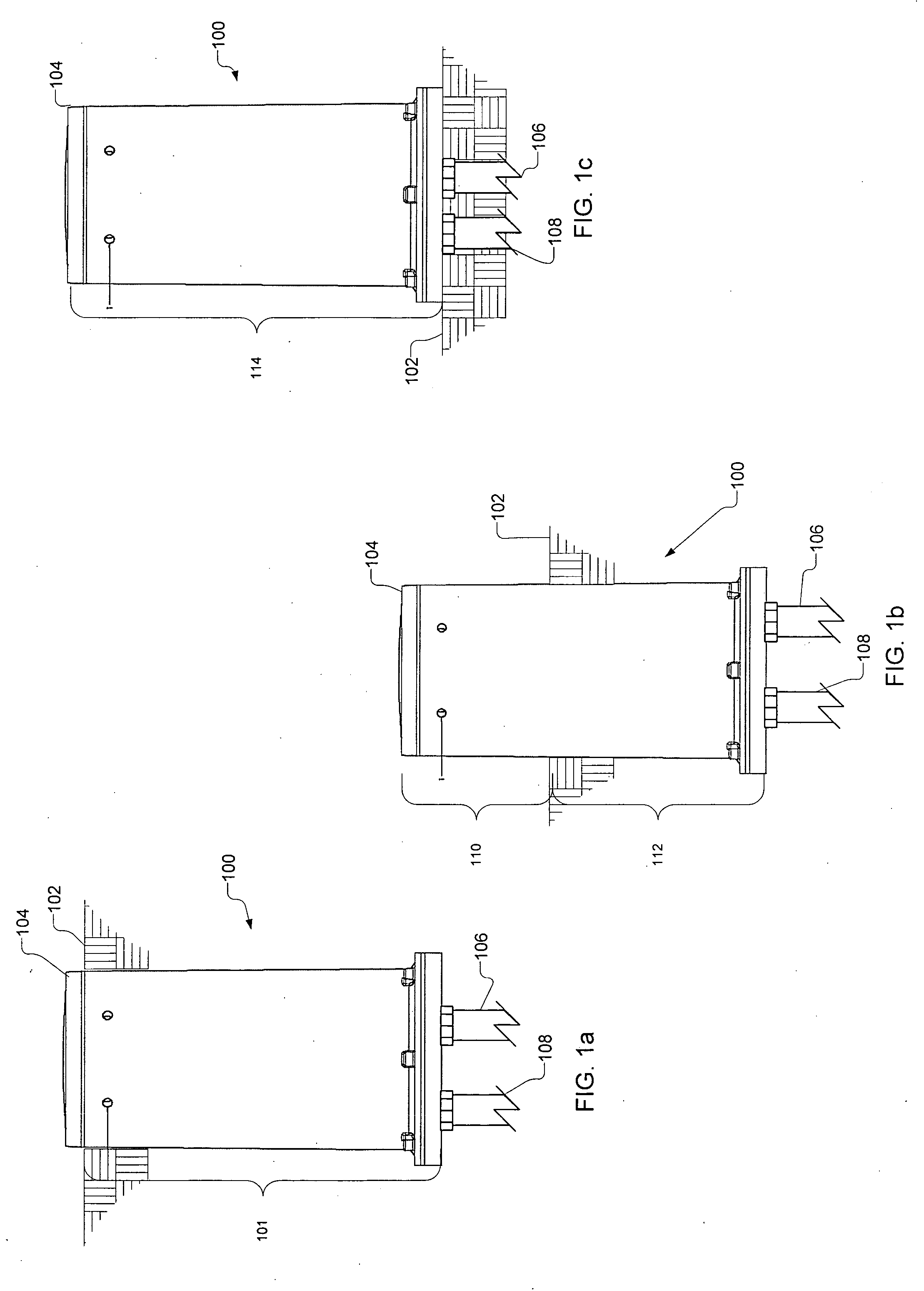

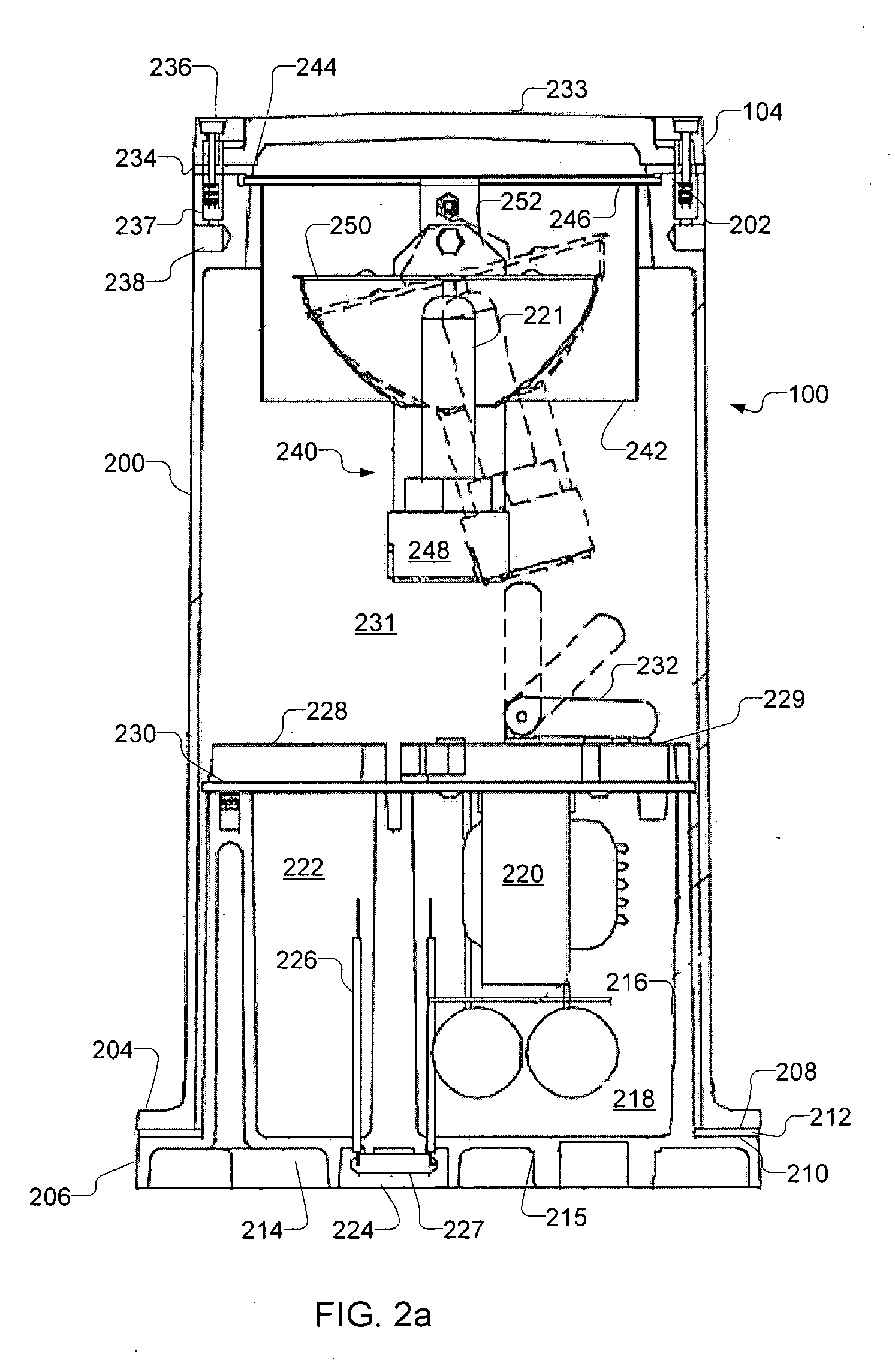

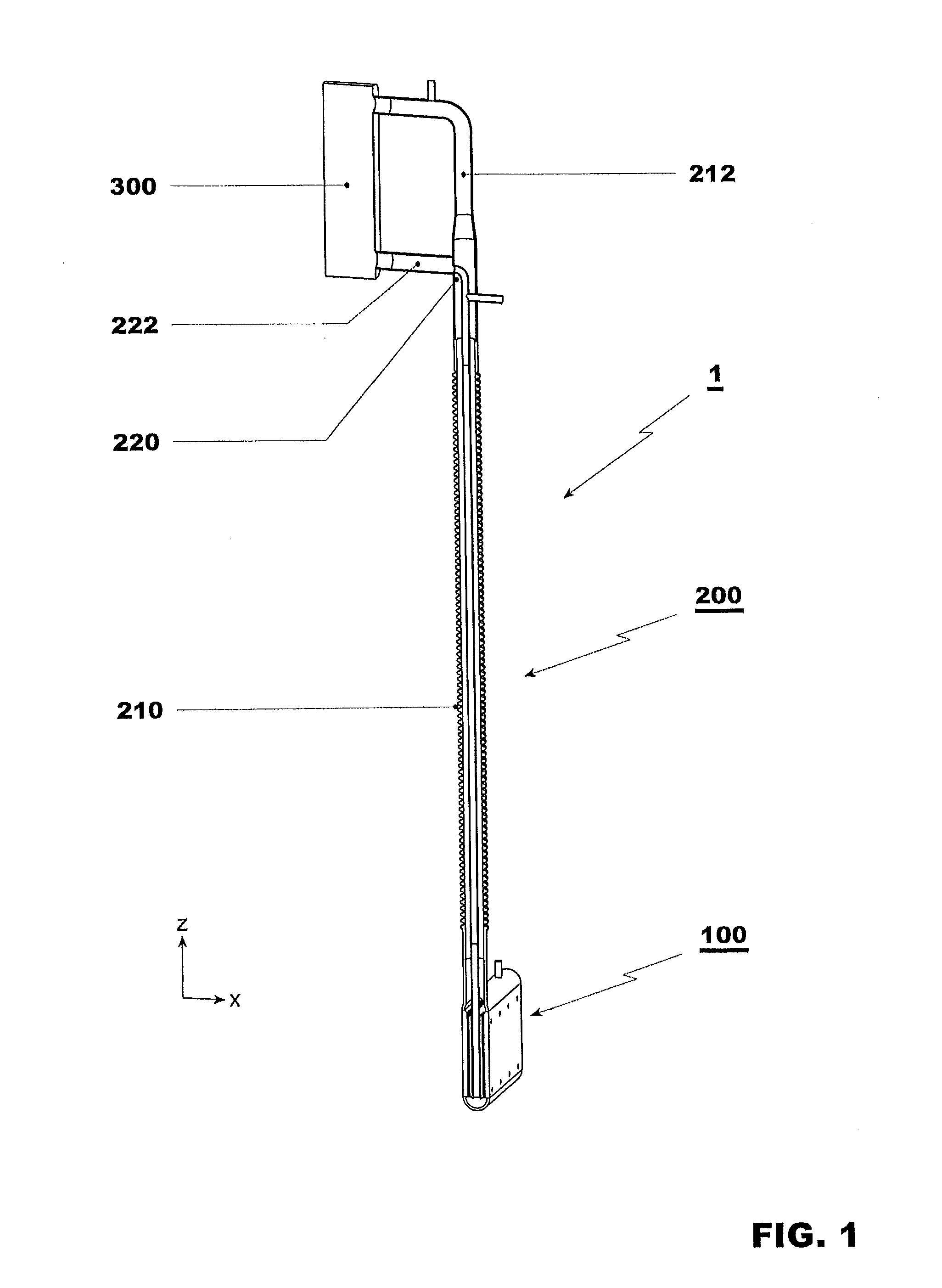

Modular landscape light fixture

InactiveUS20060262542A1Heat transferReduce heat transferMechanical apparatusPoint-like light sourceModularityLight source

A multi-use landscape light fixture is provided. The landscape light fixture includes a main housing, a lens assembly, a light source mount assembly and a base. The main housing has an upper flanged opening and a lower flanged opening. The upper opening is used for mounting a lens or the like using the lens ring. The lower opening has a flange used for mounting the base. The base has an upper portion that is inserted into the bottom opening of the main housing and a lower flanged bulkhead that mates with the flange of the main housing. Once mated, the flanged bulkhead forms a watertight seal with the lower flange of the main housing. The base includes power and signal connectors and separate compartments for ballast circuitry and junctions. The landscape light fixture may be mounted above, below or at any level in between grade.

Owner:JJI LIGHTING GROUP

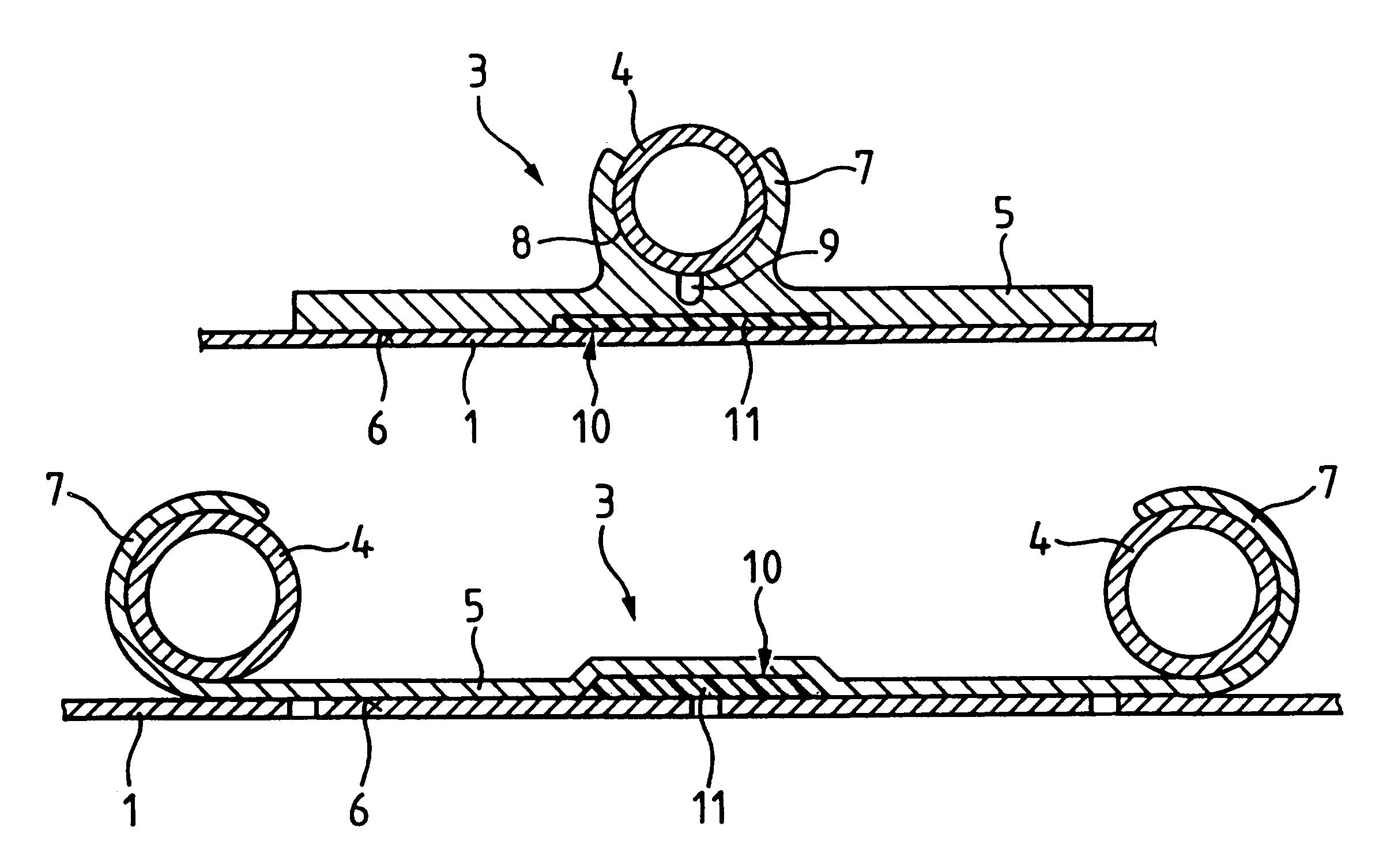

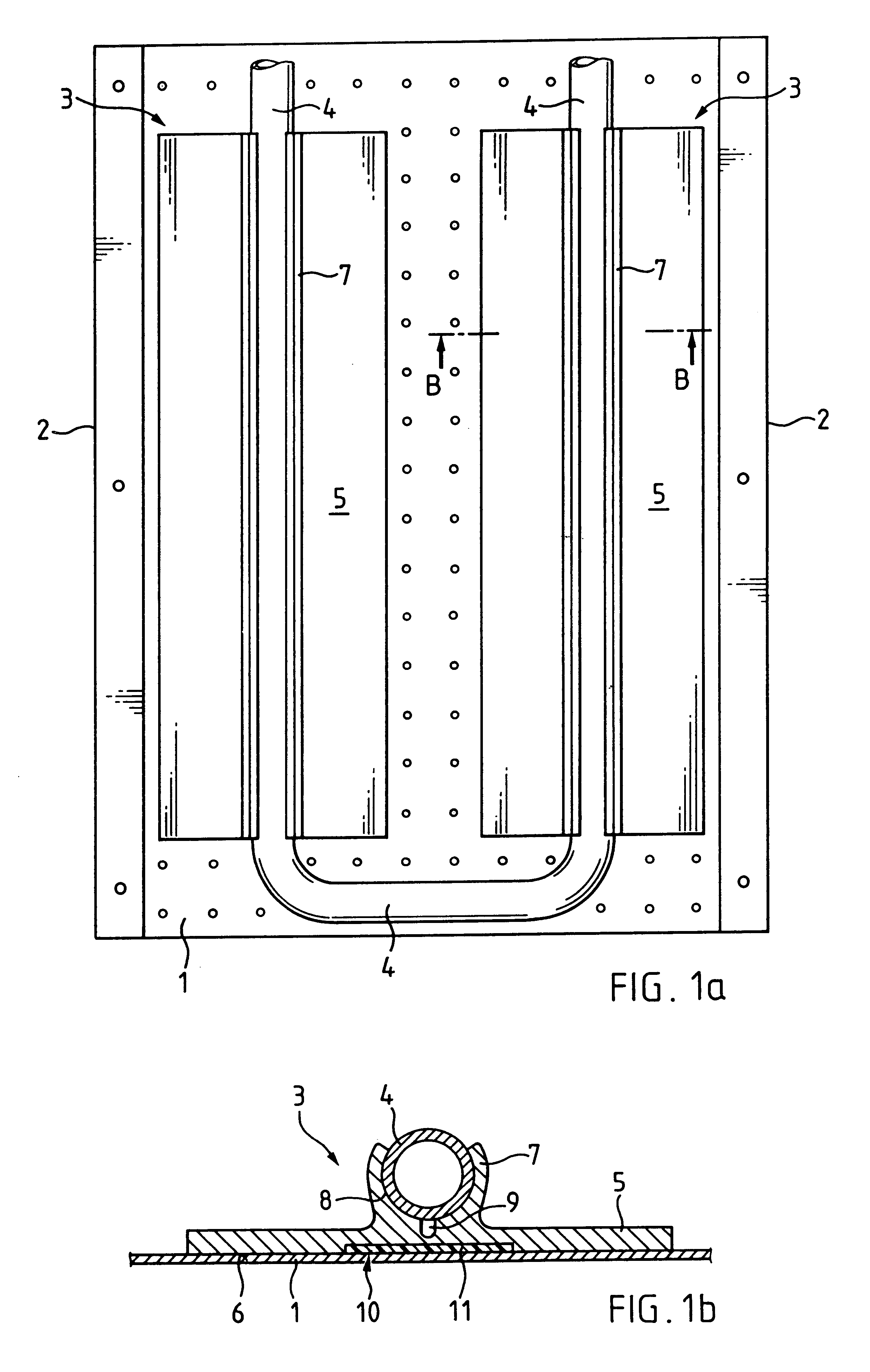

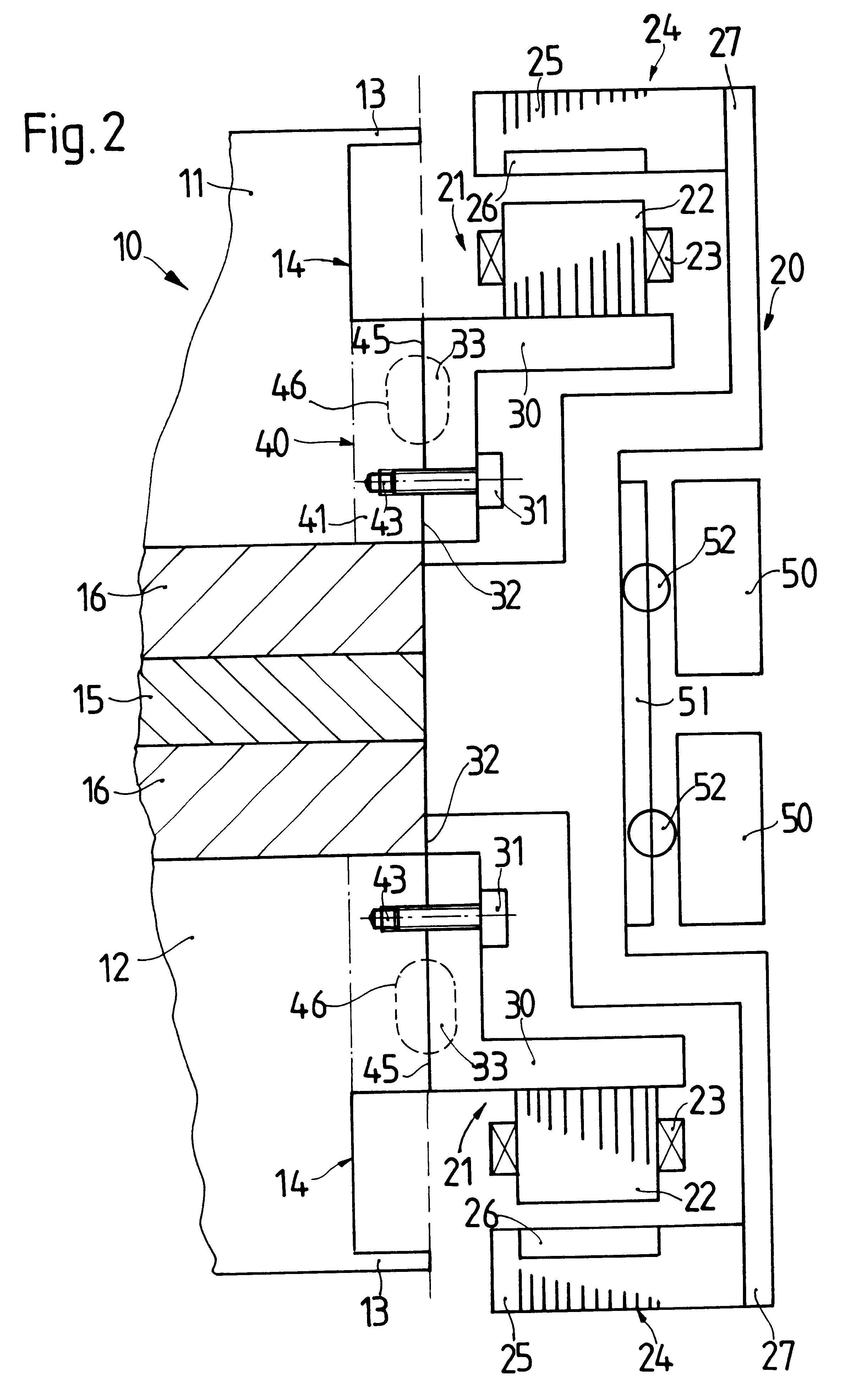

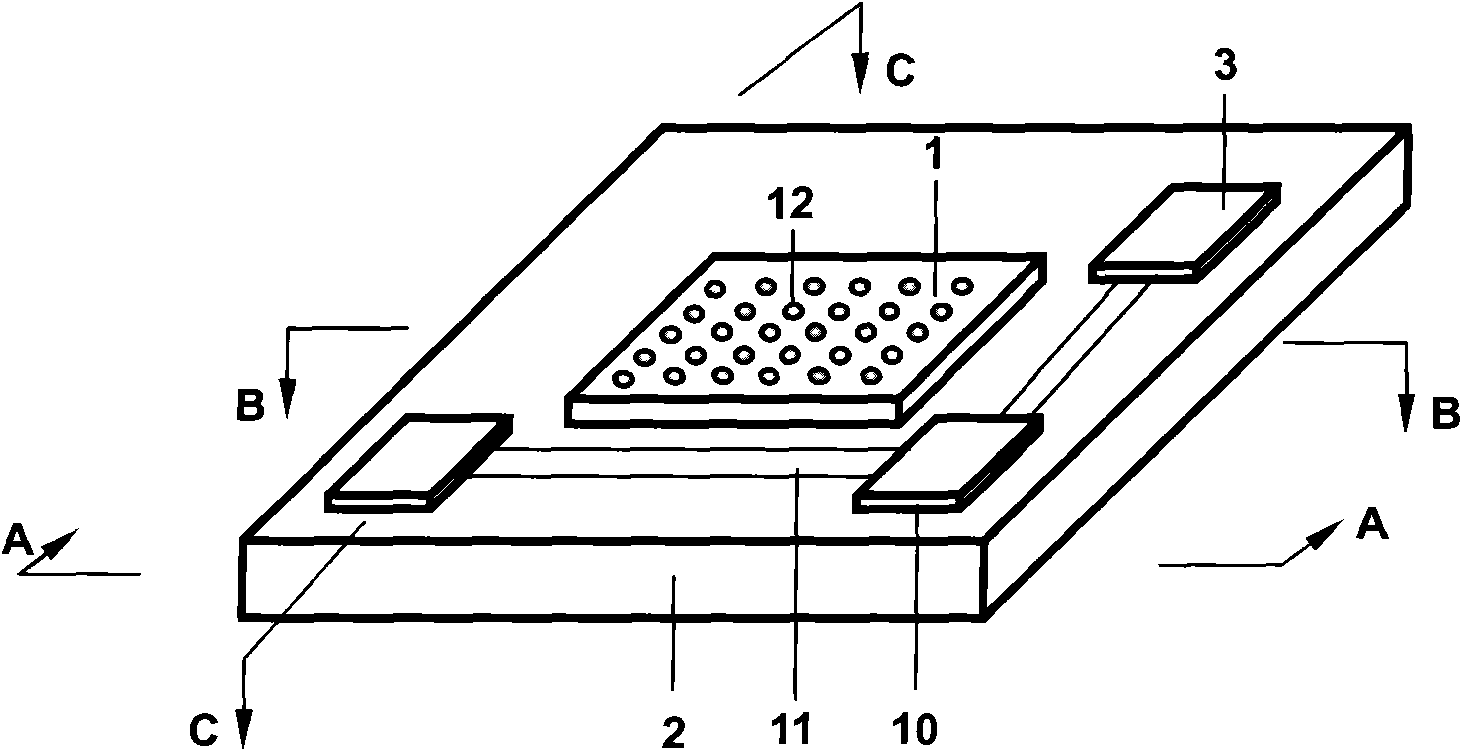

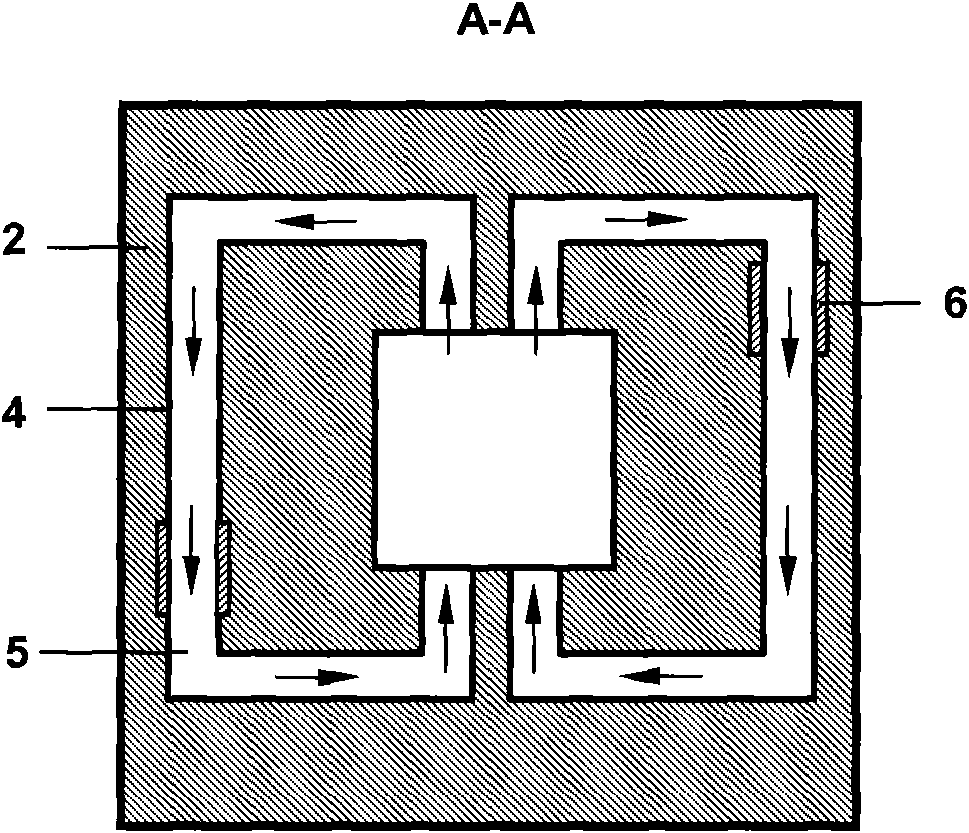

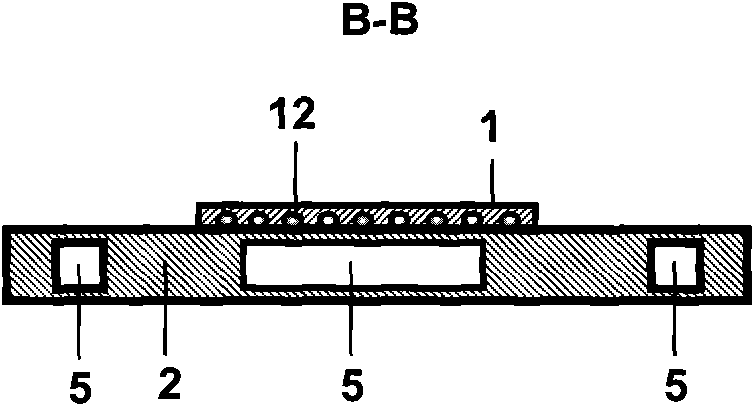

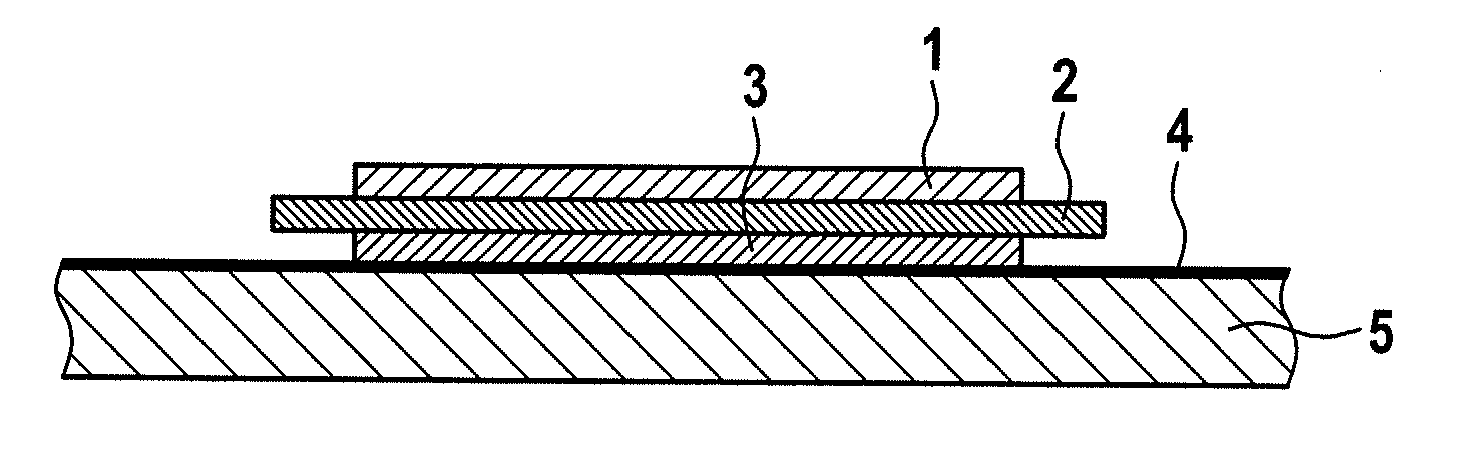

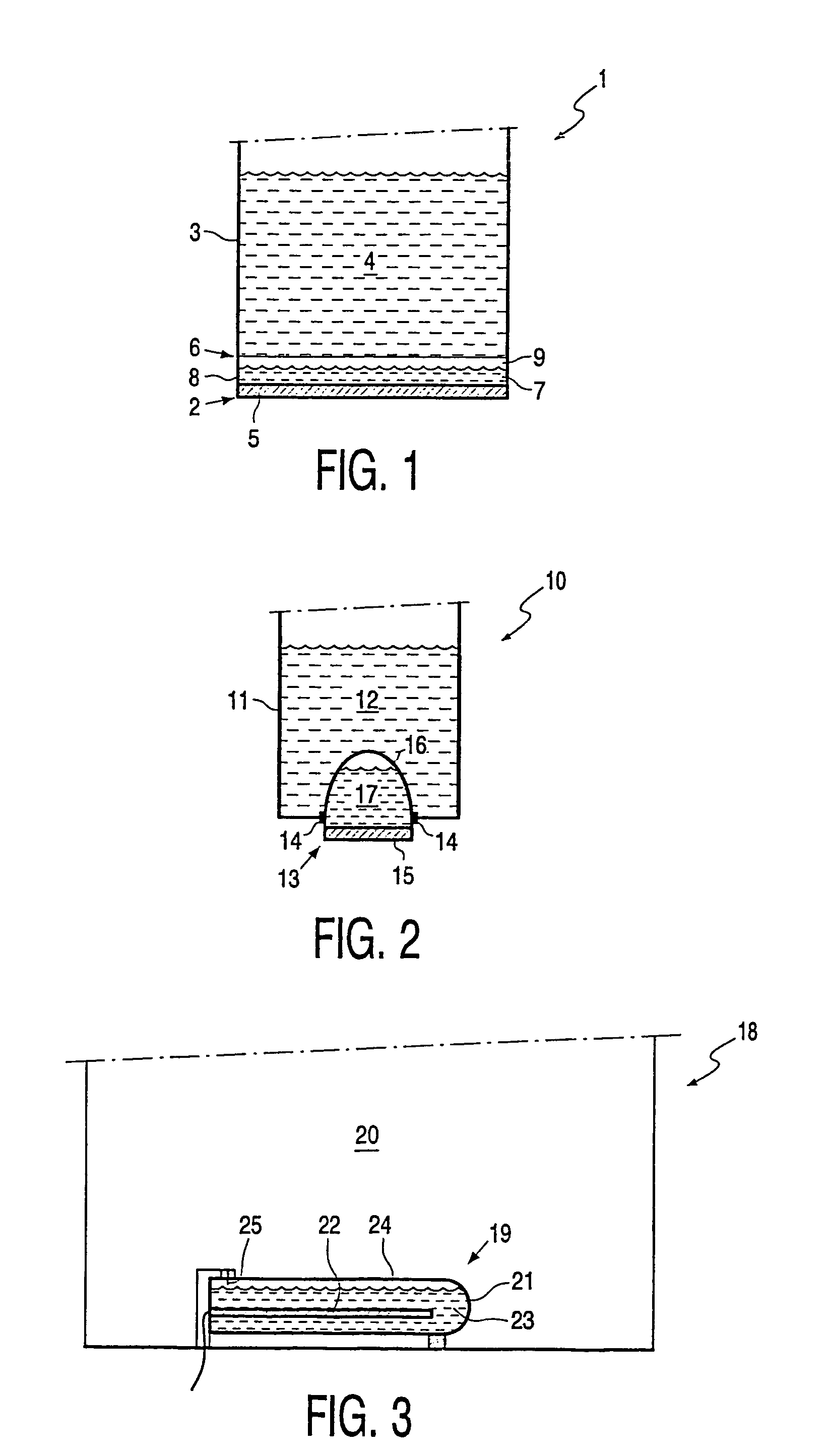

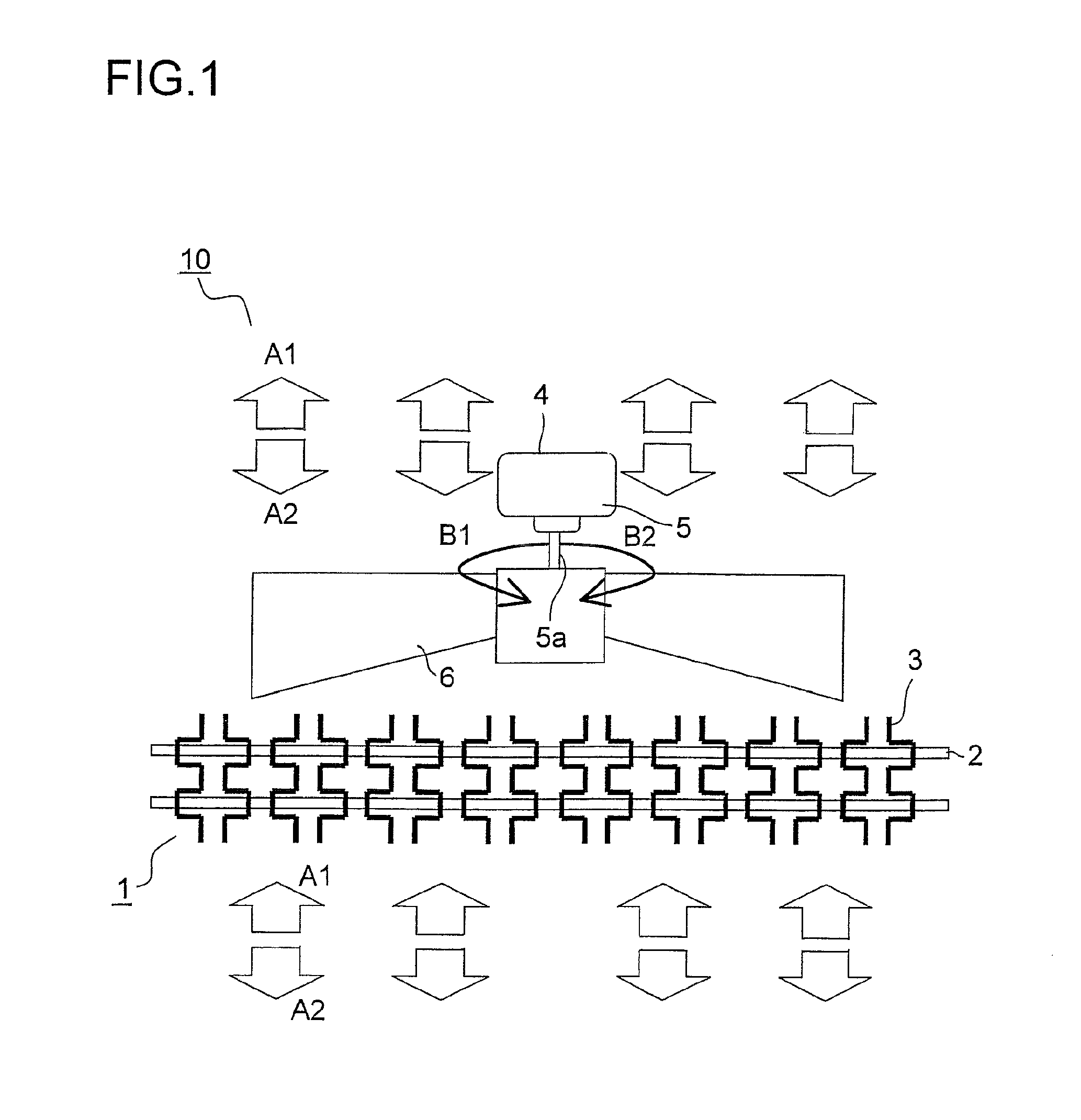

Contact element and ceiling element for a heating and cooling ceiling

InactiveUS6910526B1Heat transferEasy to useFluid heatersHot-air central heatingHeat conductingEngineering

In order to improve the heat-conducting connection between a contact element (3) and a ceiling panel (1) which are adhesively bonded to one another, the contact panel (5) of the contact element (3) is provided with an adhesive depression (10) in the contact surface (6), said depression taking up only part of said contact surface, while the remaining part of the latter rests directly against the upper side of the ceiling panel (1). The contact panel (5) may be elastically or plastically deformable, e.g. along a bending groove (9), with the result that it adapts more easily to irregularities, such as those caused, for example, by slight sagging of the ceiling panel (1). This permits larger widths of the contact panel (5) without impairing the thermal contact. In order to ensure close abutment of the parts of the contact surface (6) which are not adhesively bonded to the upper side of the ceiling panel (1), the contact panel (5) can be appropriately prestressed.

Owner:BARCOL AIR

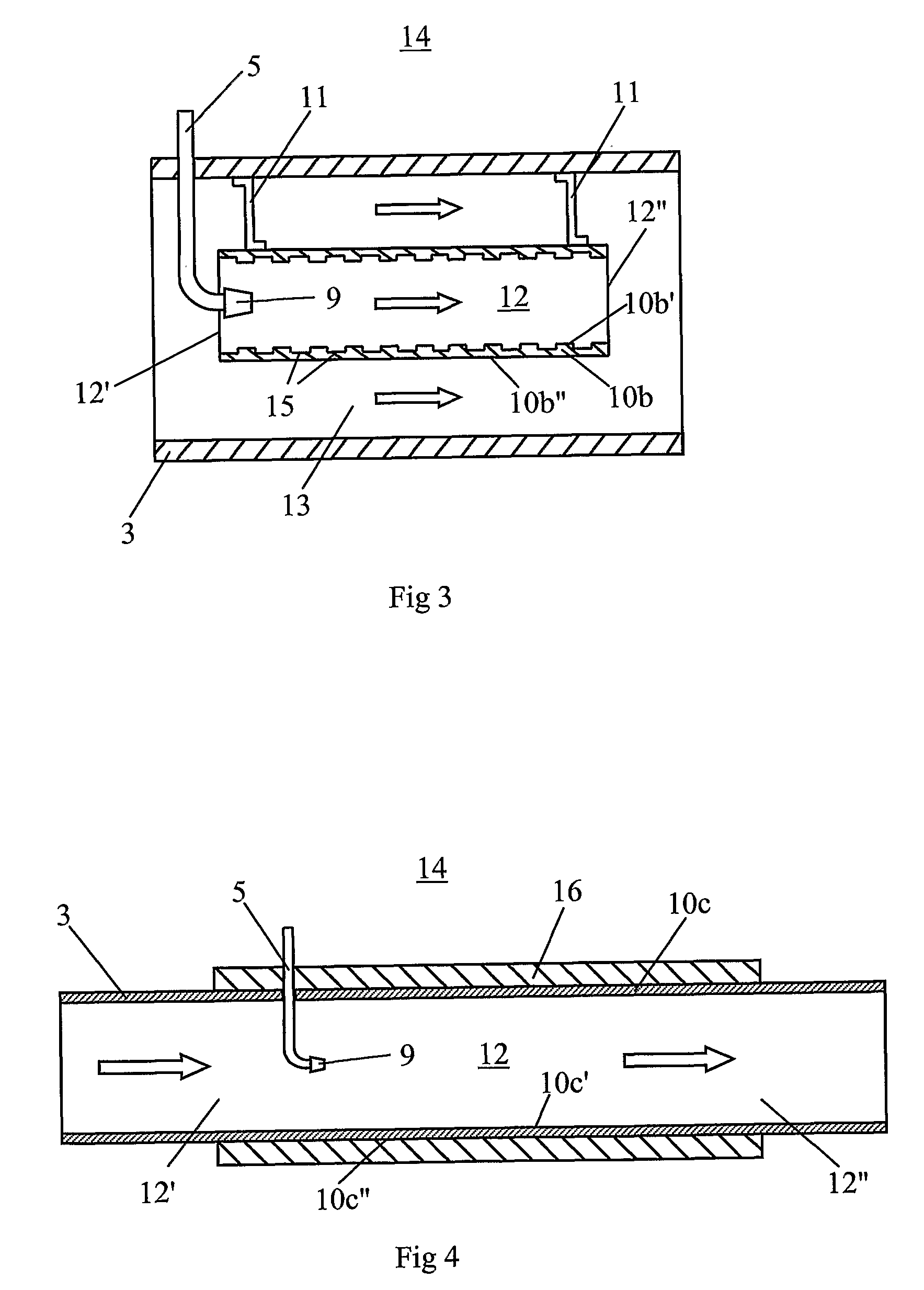

Arrangement for supplying a medium into an exhaust gas conduit in an internal combustion engine

InactiveUS7877983B2Heat transferHigher thermally insulating propertyNitrogen compoundsInternal combustion piston enginesLiquid mediumCombustion

An arrangement for supplying a medium to an exhaust line of a combustion engine. The arrangement comprises a first exhaust passage defined by at least a first wall surface of an element, and a dosing device supplying the medium to the first exhaust passage. The arrangement is adapted to maintaining a degree of heating of the first wall surface so that the latter will be at a higher temperature than the medium's vaporization point when the liquid medium is supplied in the first exhaust passage. Therefore, even the medium which reaches the first wall surface will vaporize in the first exhaust passage.

Owner:SCANIA CV AB

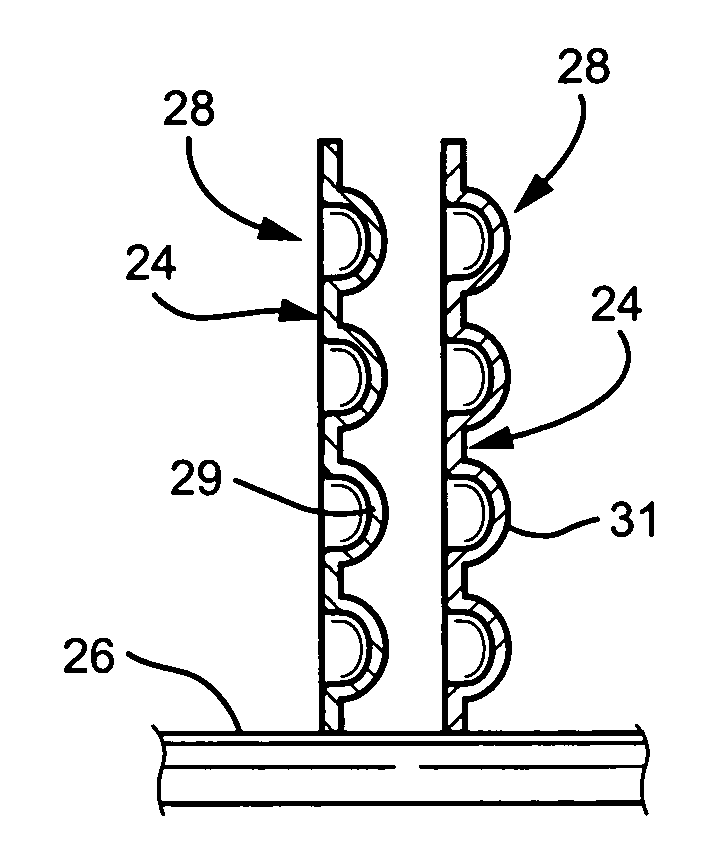

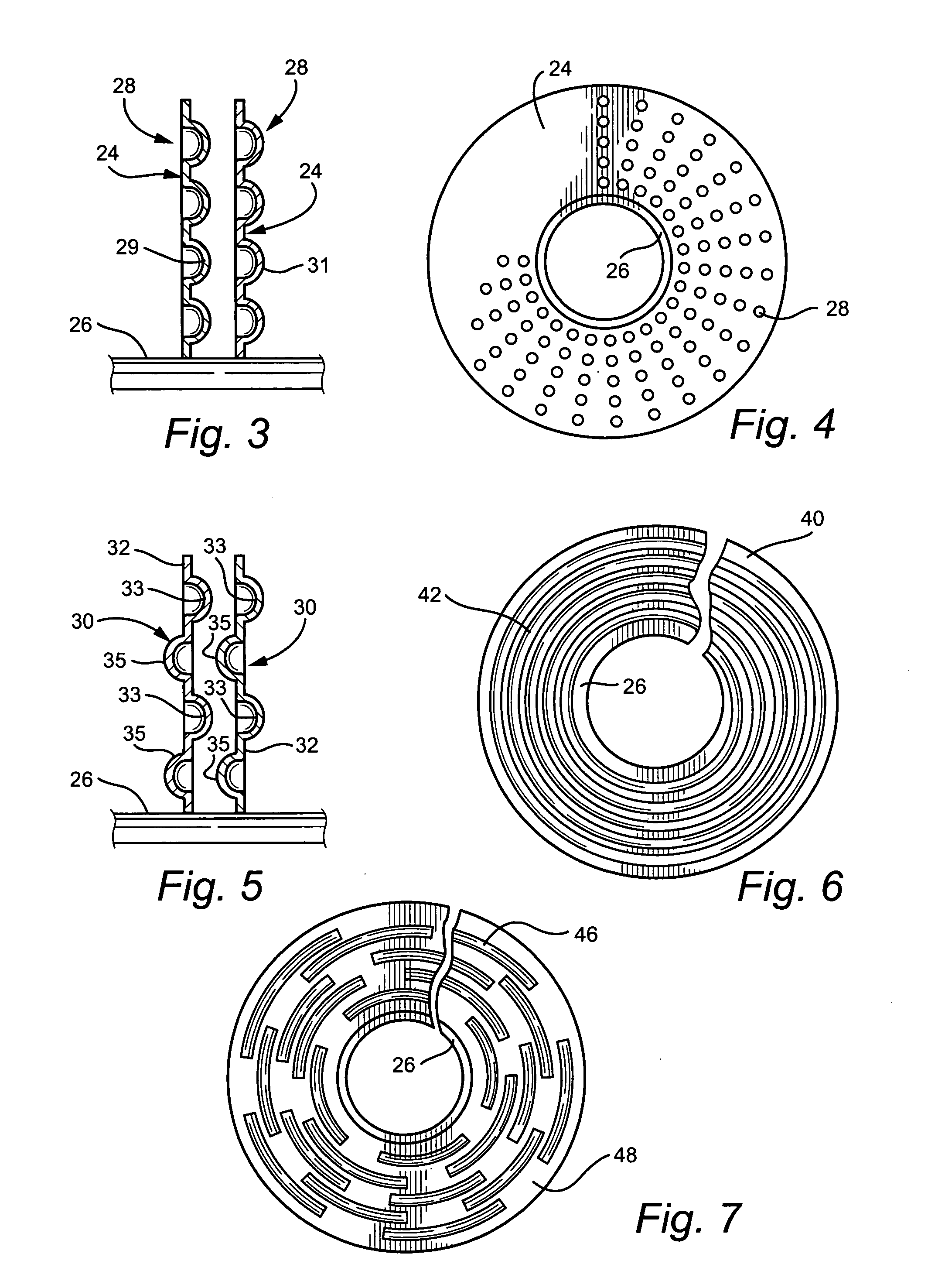

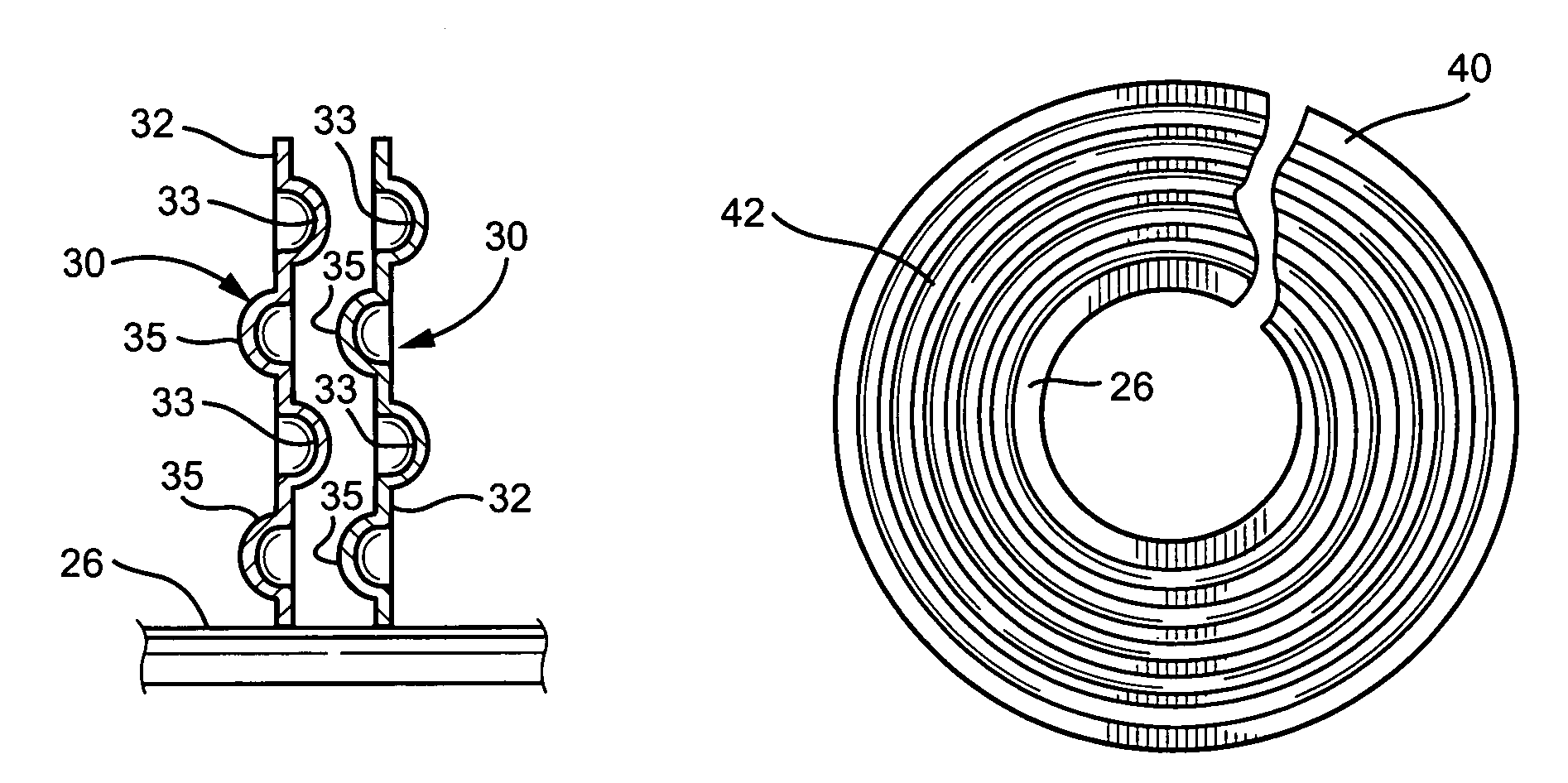

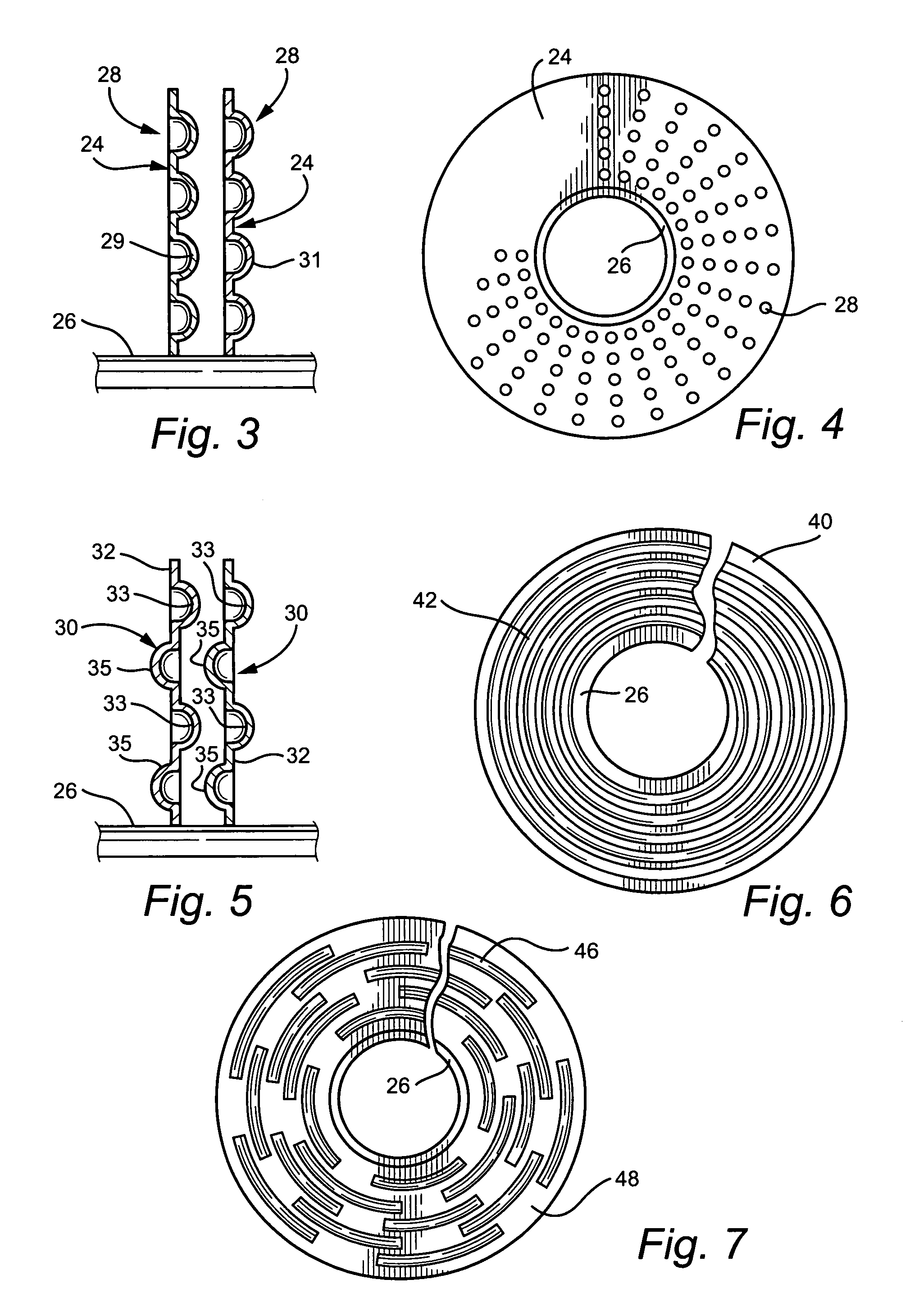

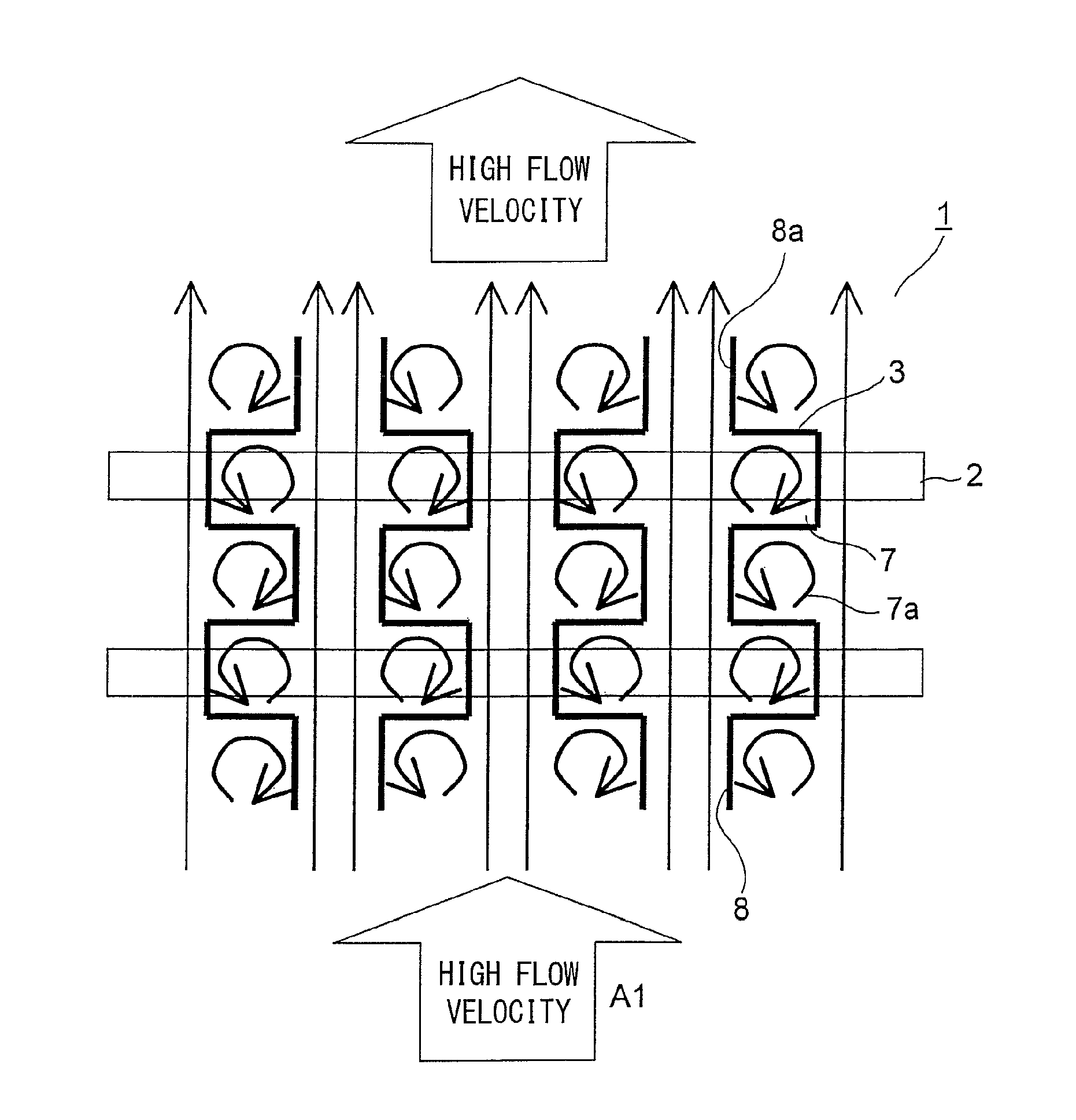

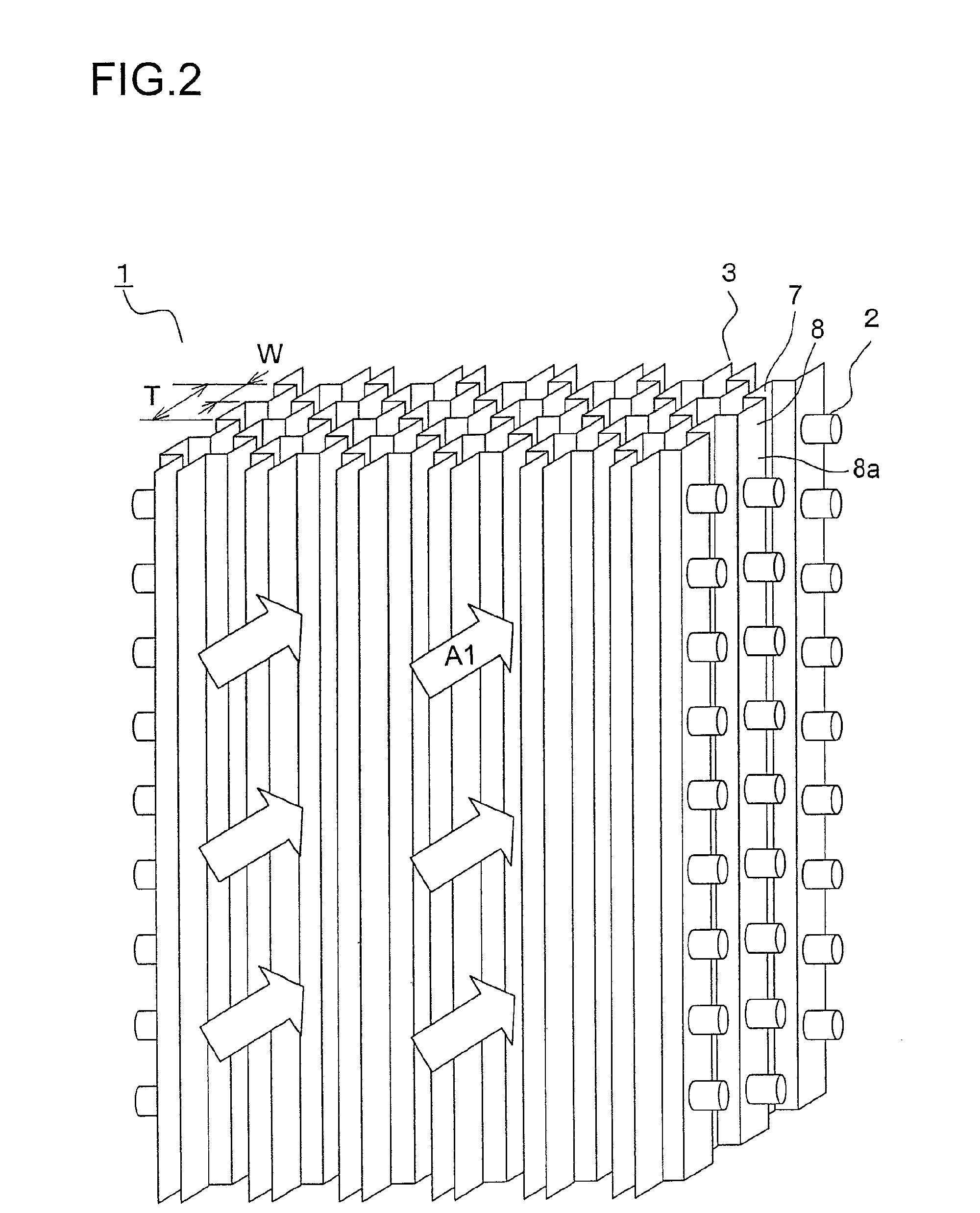

Air cooled heat exchanger with enhanced heat transfer coefficient fins

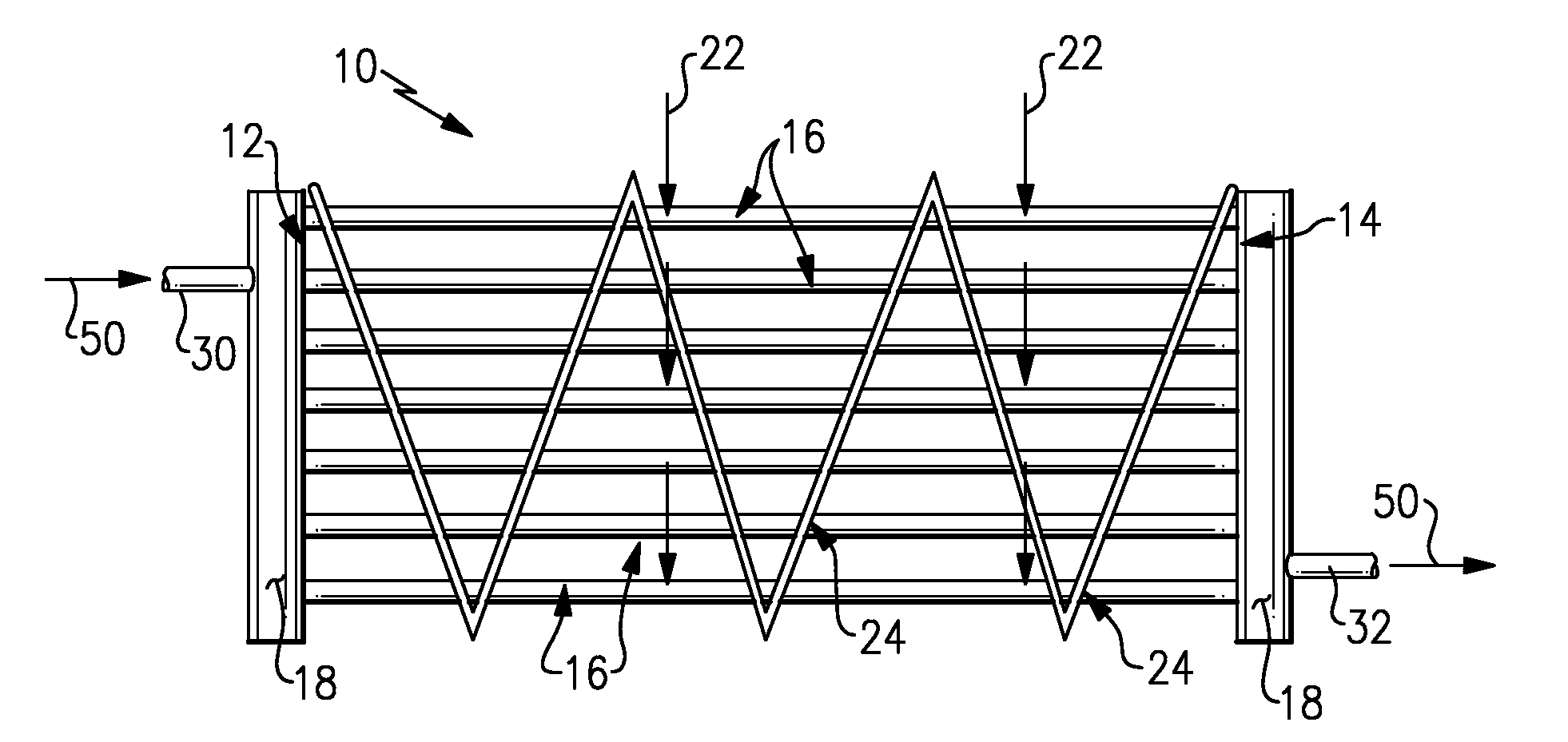

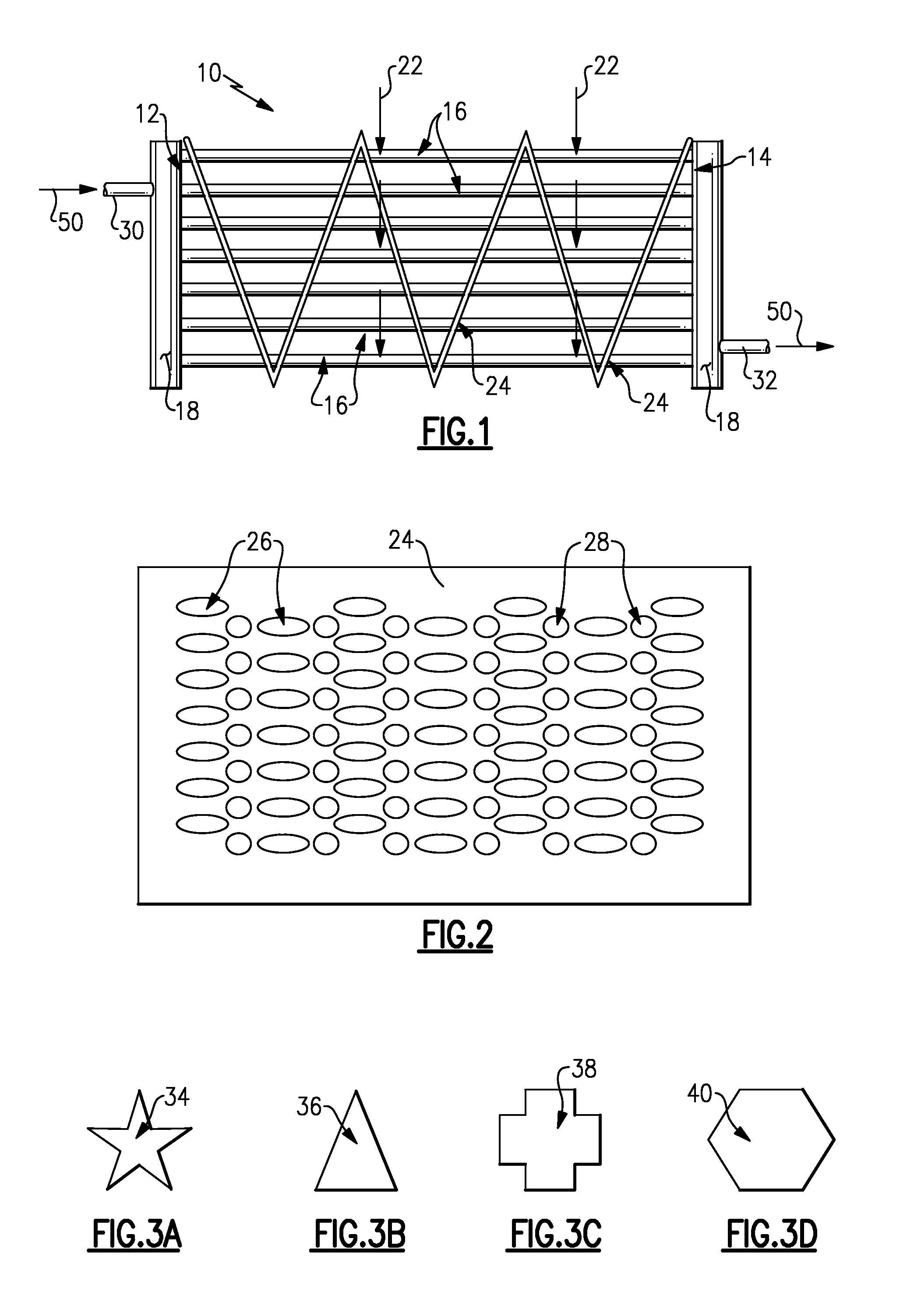

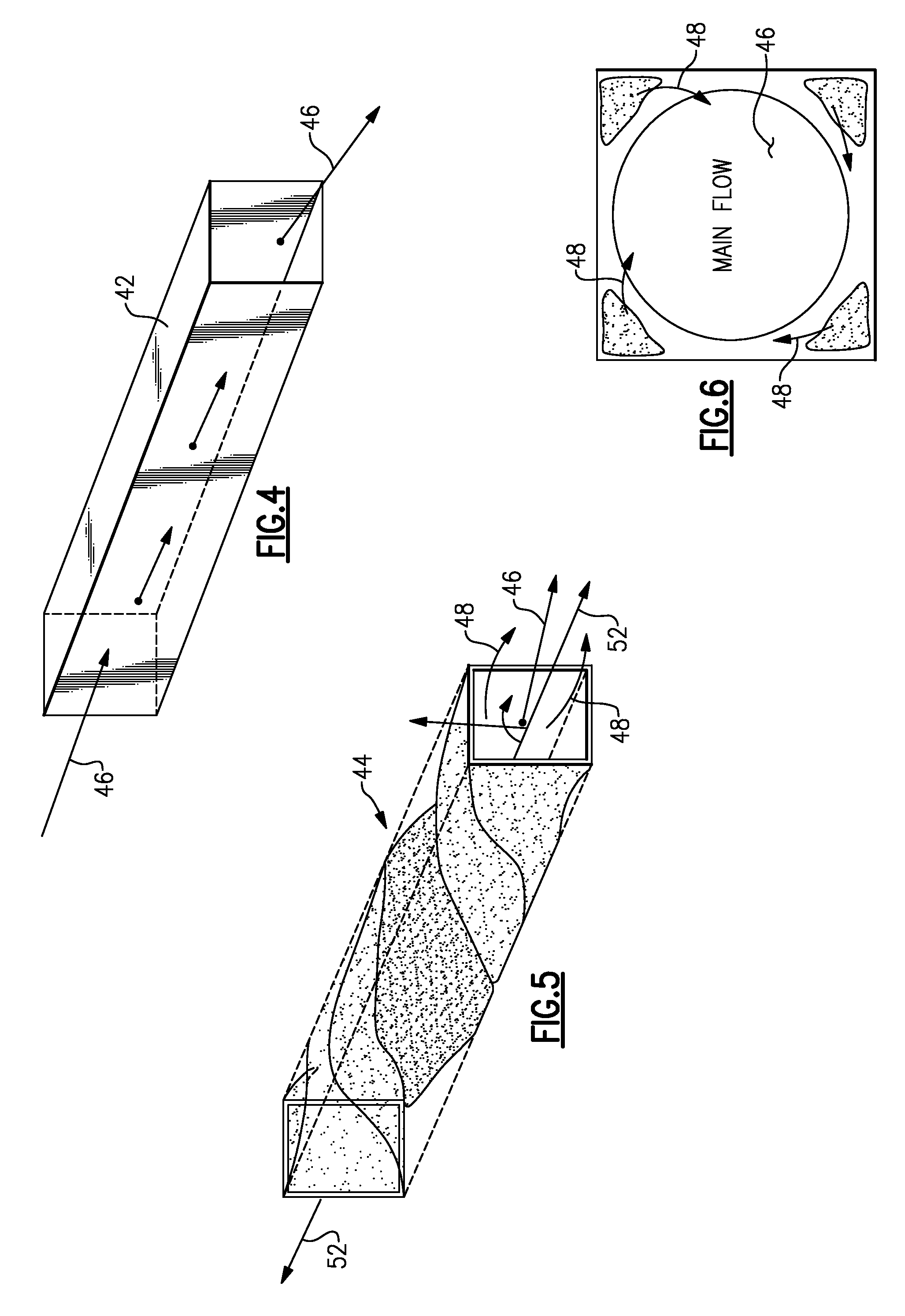

ActiveUS20080023180A1Heat transferMinimum pressure lossHeat transfer modificationTubular elementsEnhanced heat transferEngineering

The heat exchanger includes a tube having axially spaced fins or a continuously spirally wound fin about the tube. One or more of the fins are dimpled, mechanically or molded, to provide concavities and projections on opposite sides of the fins or alternating concavities and projections on opposite side of the fins. The dimples improve the heat transfer between the fluid flowing through the tubes and the air circulating about the tubes and through the fins. The dimples create vortices and turbulent flow between the fins and effectively increase the heat transfer rate.

Owner:NUOVO PIGNONE TECH SRL

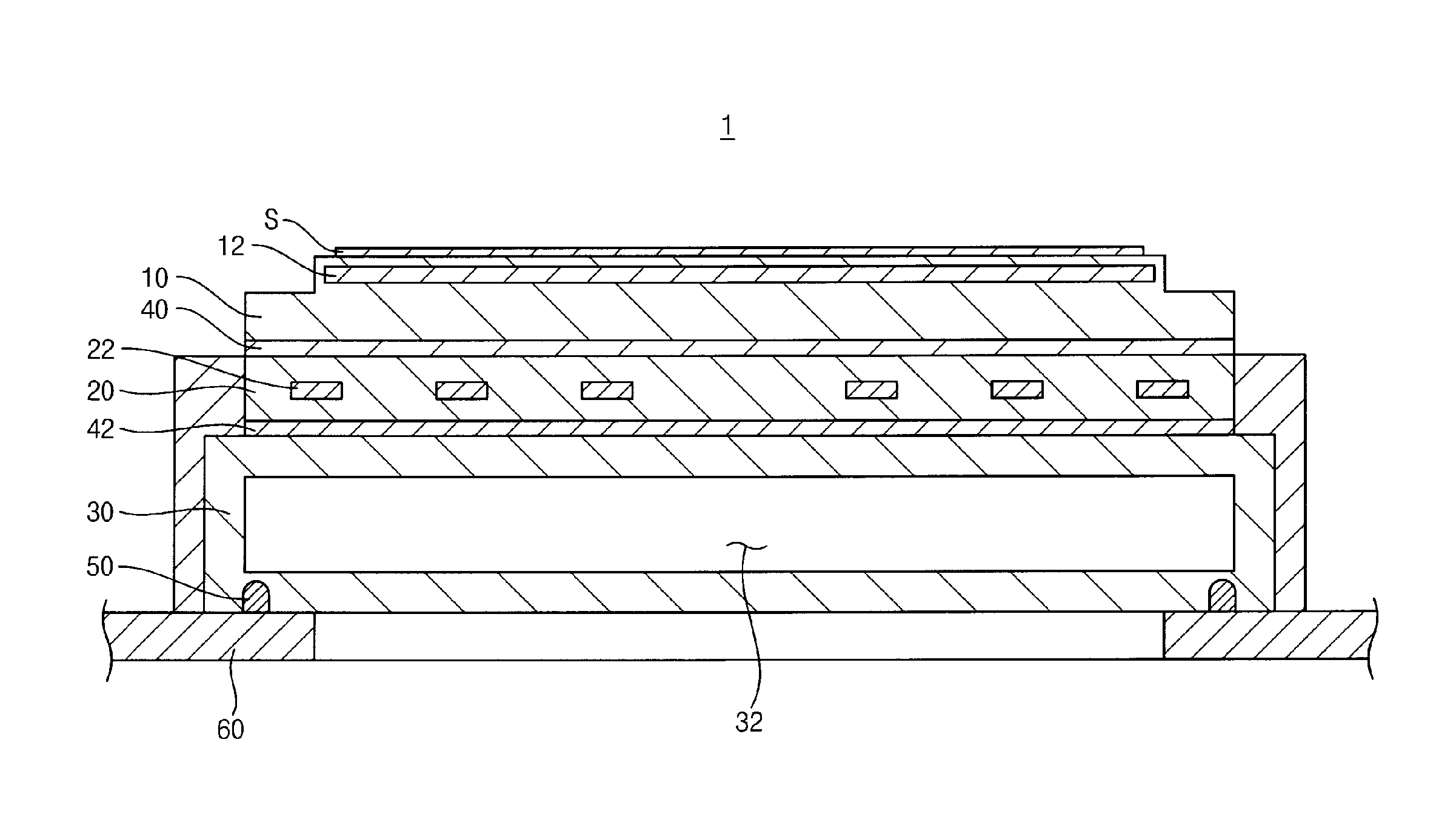

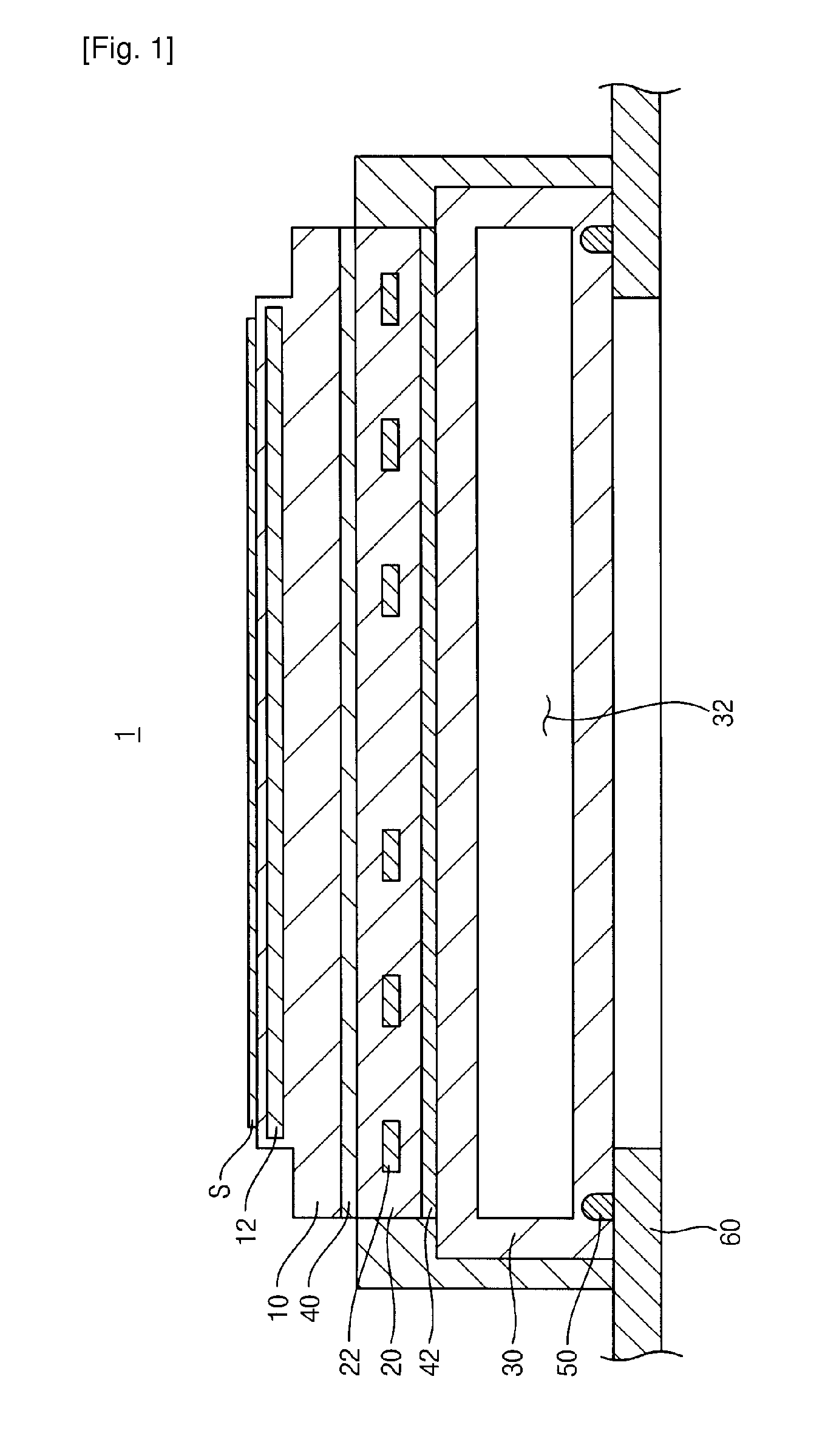

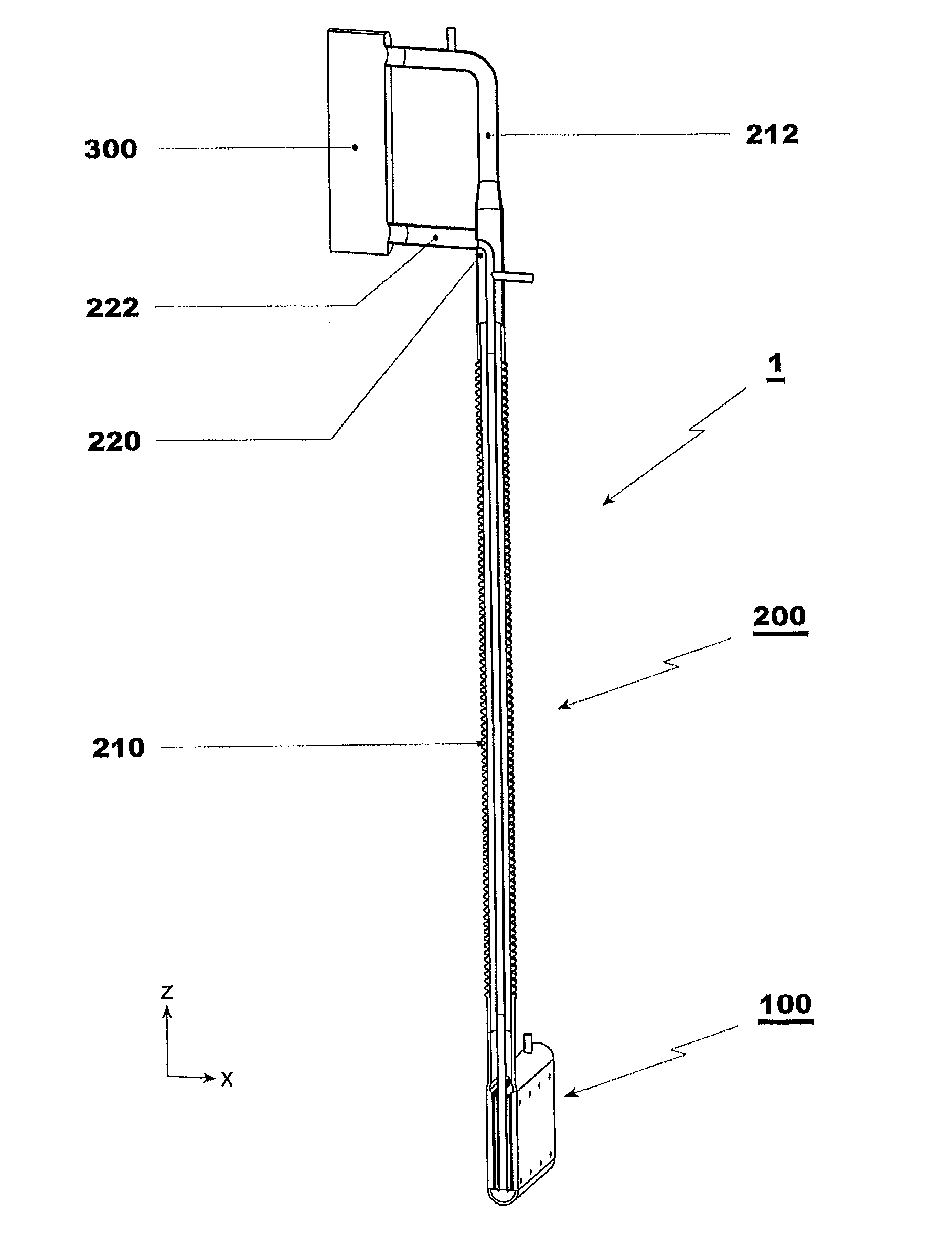

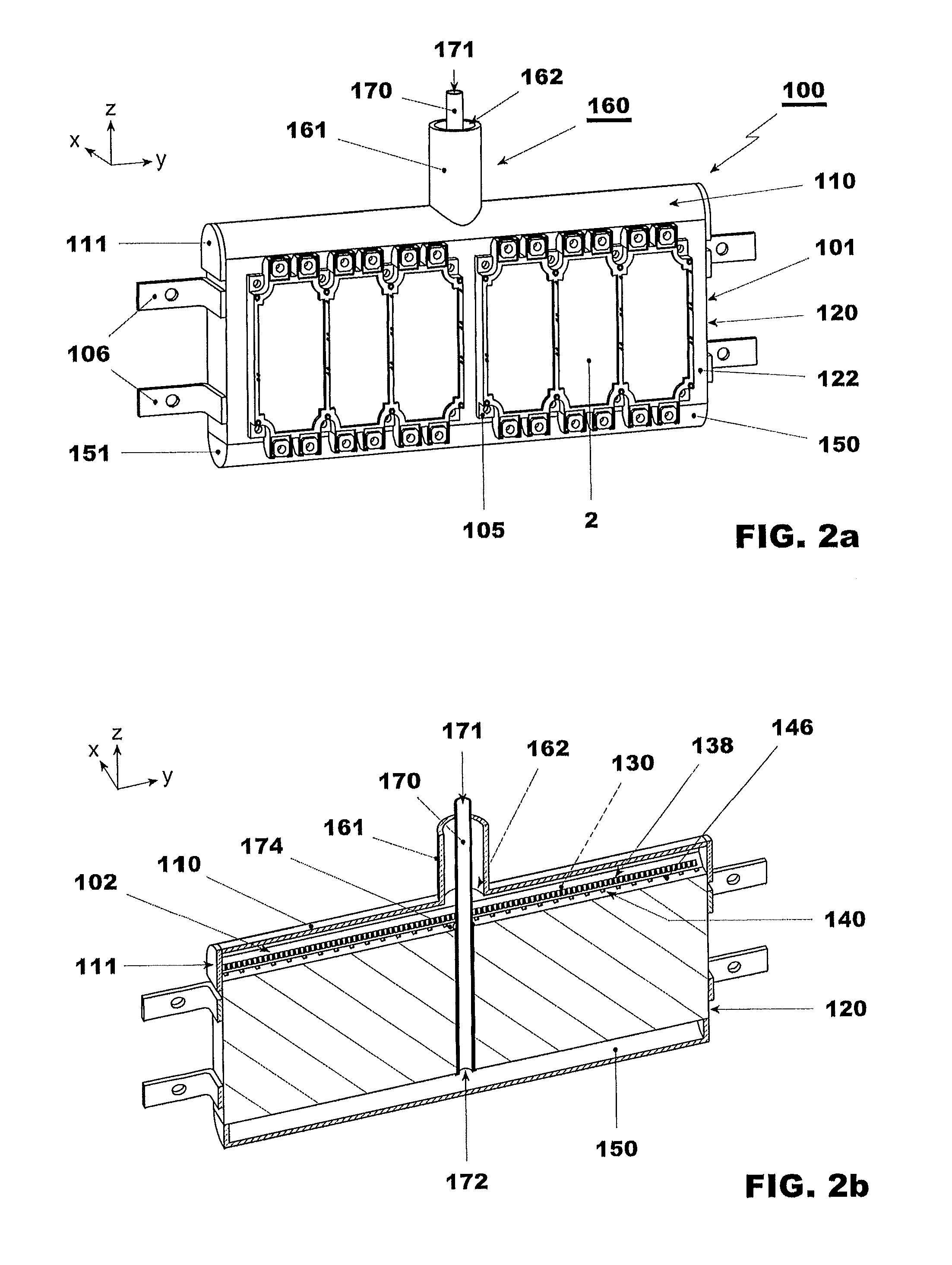

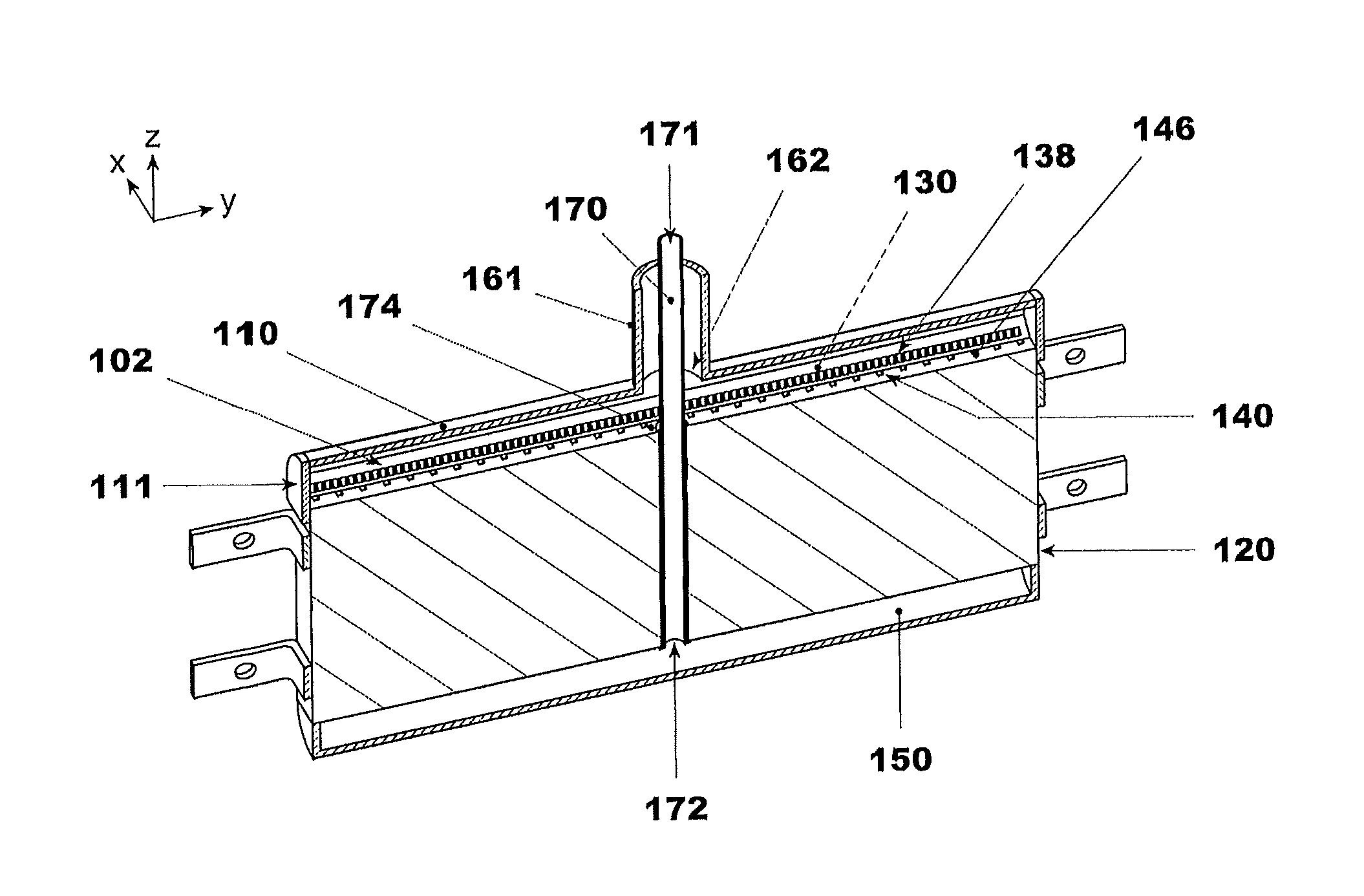

Unit for supporting a substrate and apparatus for processing a substrate having the same

InactiveUS20100193491A1Heat transferHeating effectively and uniformlyElectric heatingSemiconductor/solid-state device manufacturingBiomedical engineeringHeat transfer

A substrate support unit of a substrate processing apparatus includes a first support member, a second support member, a buffer member and a tube. The first support member has an electrode and a heater built-in and supports the substrate. The second support member is disposed beneath the first support member to support the first support member. The buffer member is disposed between the first support member and the second support member to form an air gap between the first support member and the second support member so as to reduce heat transfer between the first support member and the second support member. The tube is connected with a lower surface of the first support member. Further, the tube extends through the second support member and receives lines for applying power to the electrode and the heater.

Owner:KOMICO

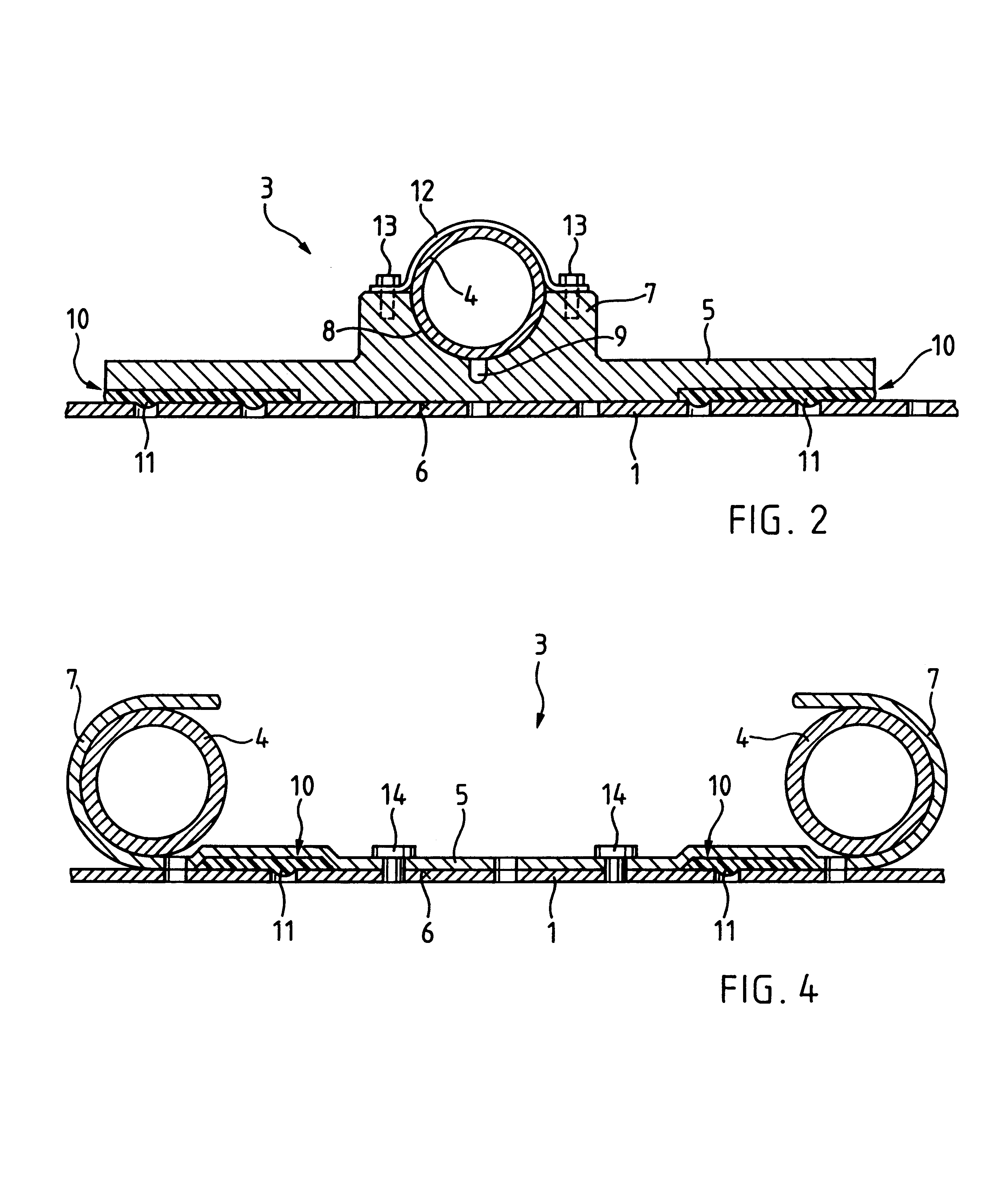

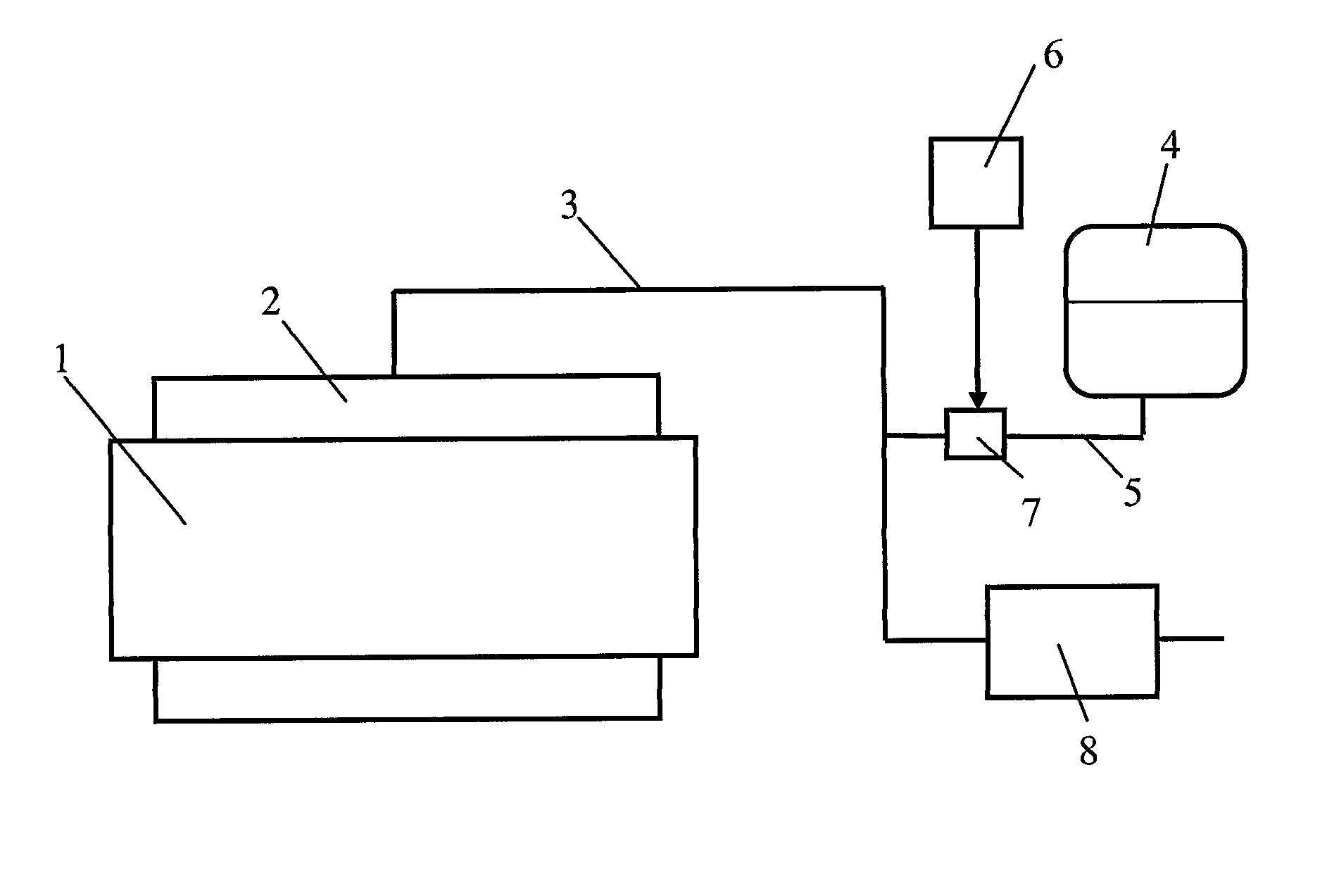

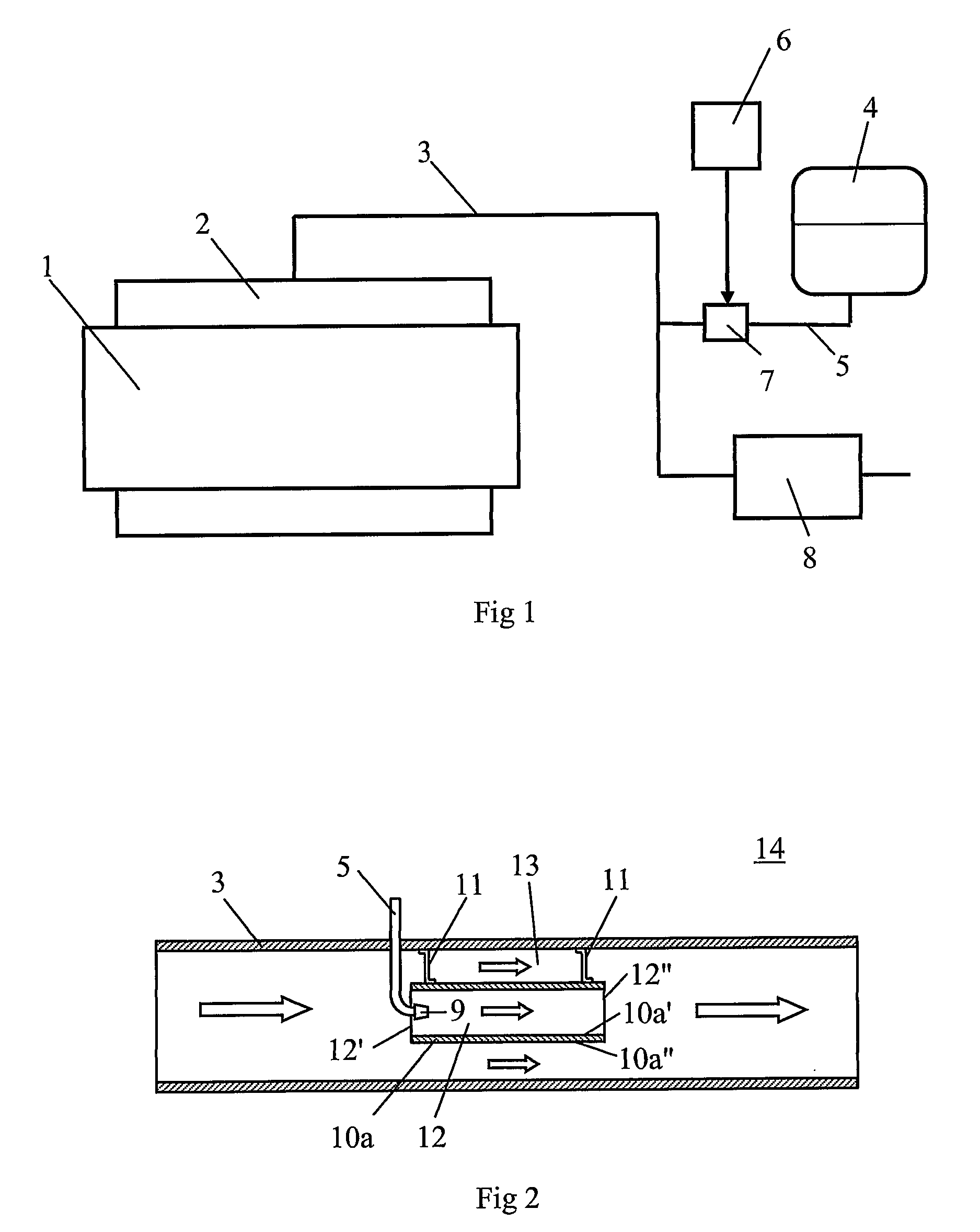

Evaporator and cooling circuit

ActiveUS20110030400A1Heat transferPromote fluid circulationEvaporators/condensersSolid-state devicesEvaporationEngineering

An evaporator for a cooling circuit is provided, for cooling at least one heat emitting device by evaporation of a cooling fluid. The evaporator includes a top collector, a bottom collector, and an evaporator body. The evaporator body includes at least one thermoconducting wall that is thermally connectable to the at least one heat emitting device, a plurality of evaporation channels, and a plurality of return channels.

Owner:ABB (SCHWEIZ) AG

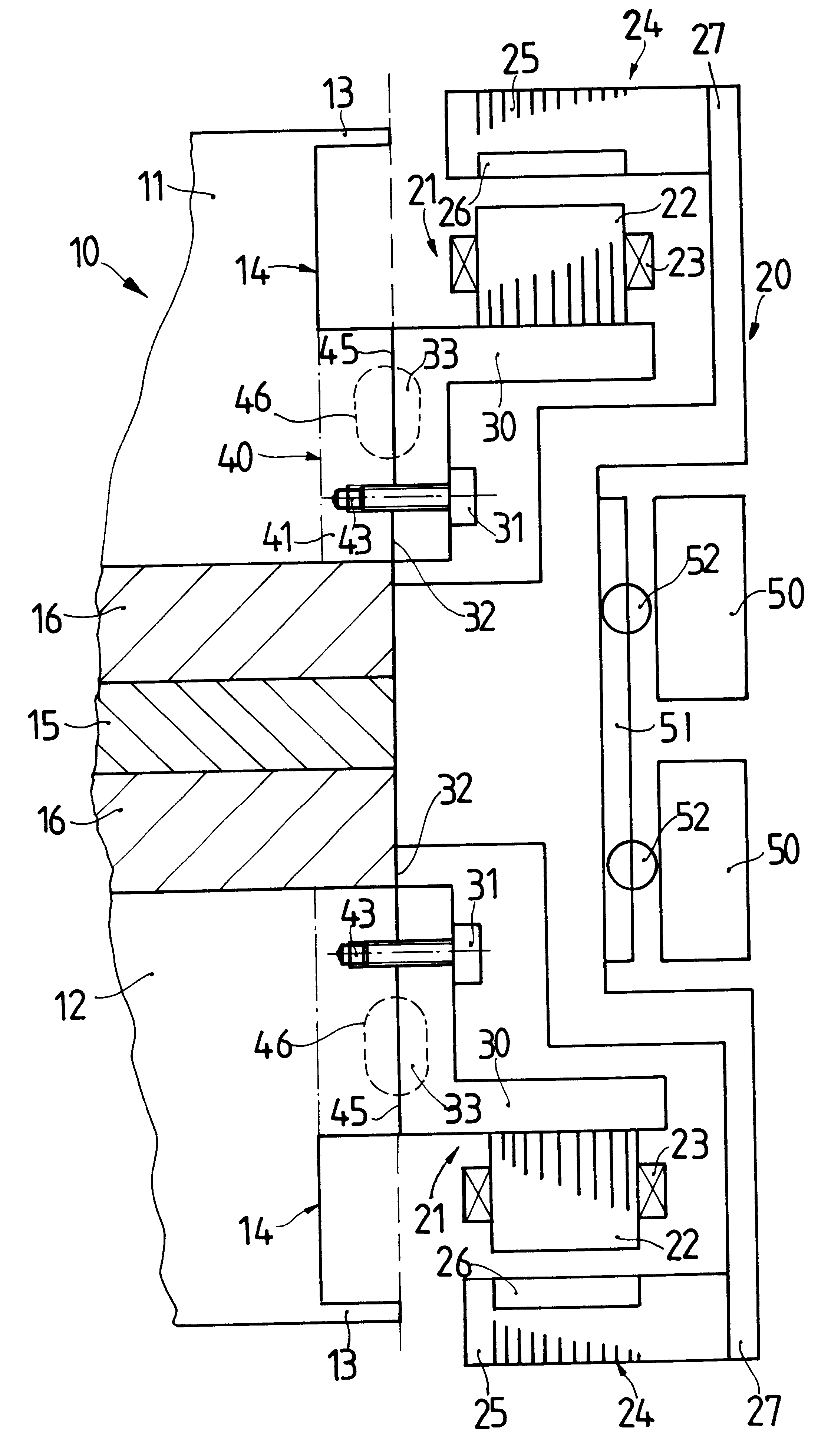

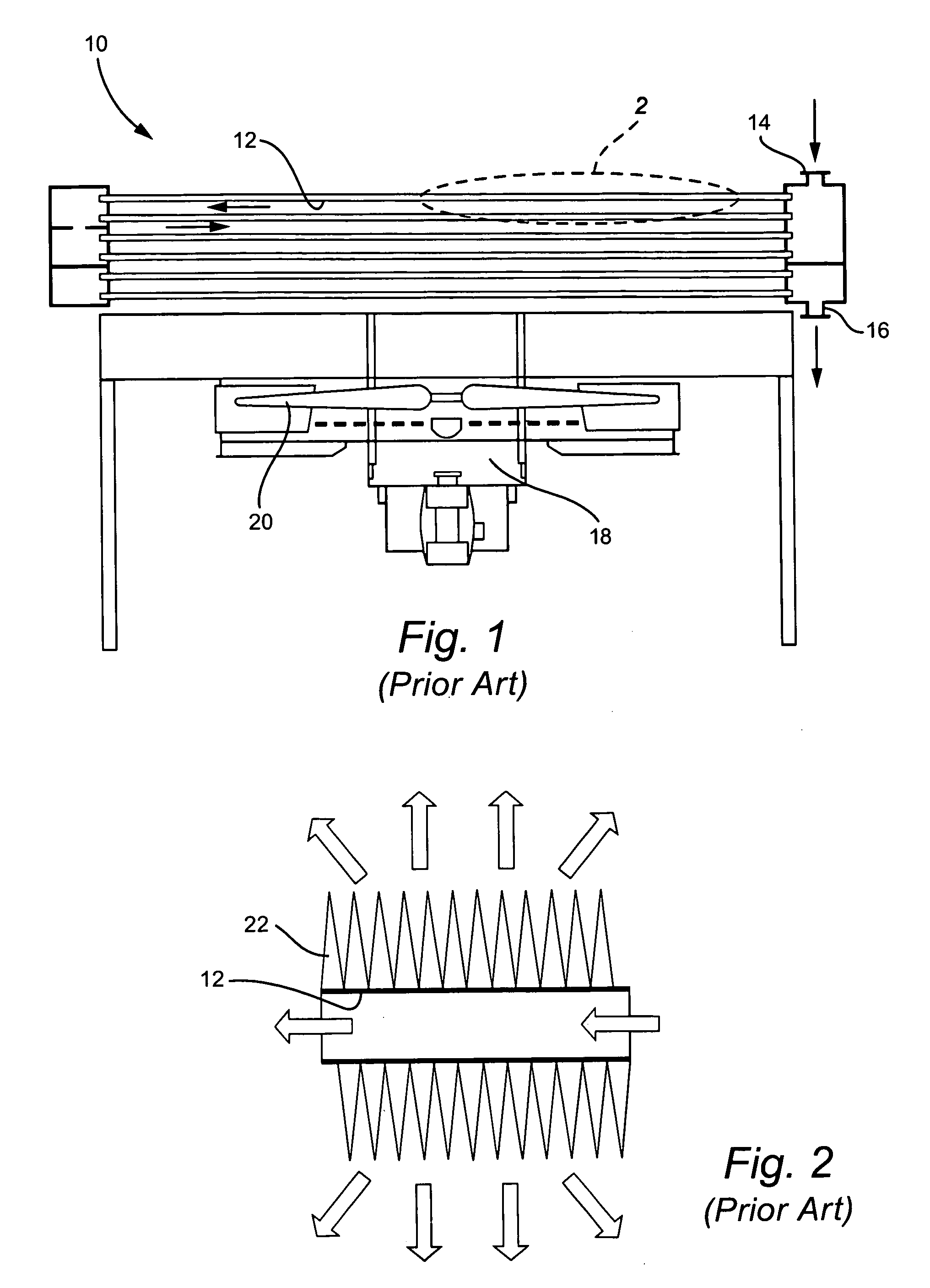

Cooling arrangement for an electrical machine of a vehicle

InactiveUS6455959B1Improve thermal conductivityHeat transferLiquid coolingMachines/enginesElectric machineEngineering

A cooling arrangement for an electrical machine-for example, a permanent-field synchronous machine of a vehicle. The electrical machine is connected to the engine block of the vehicle. In order to ensure cost-effective cooling of the electrical machine, the electrical machine includes a support element, and the engine block includes a cooling element. At least a region of the electrical machine is connected via the support element to the cooling element of the engine block such that the heat generated during operation of the electrical machine dissipates thermally into the engine block.

Owner:ZF FRIEDRICHSHAFEN AG

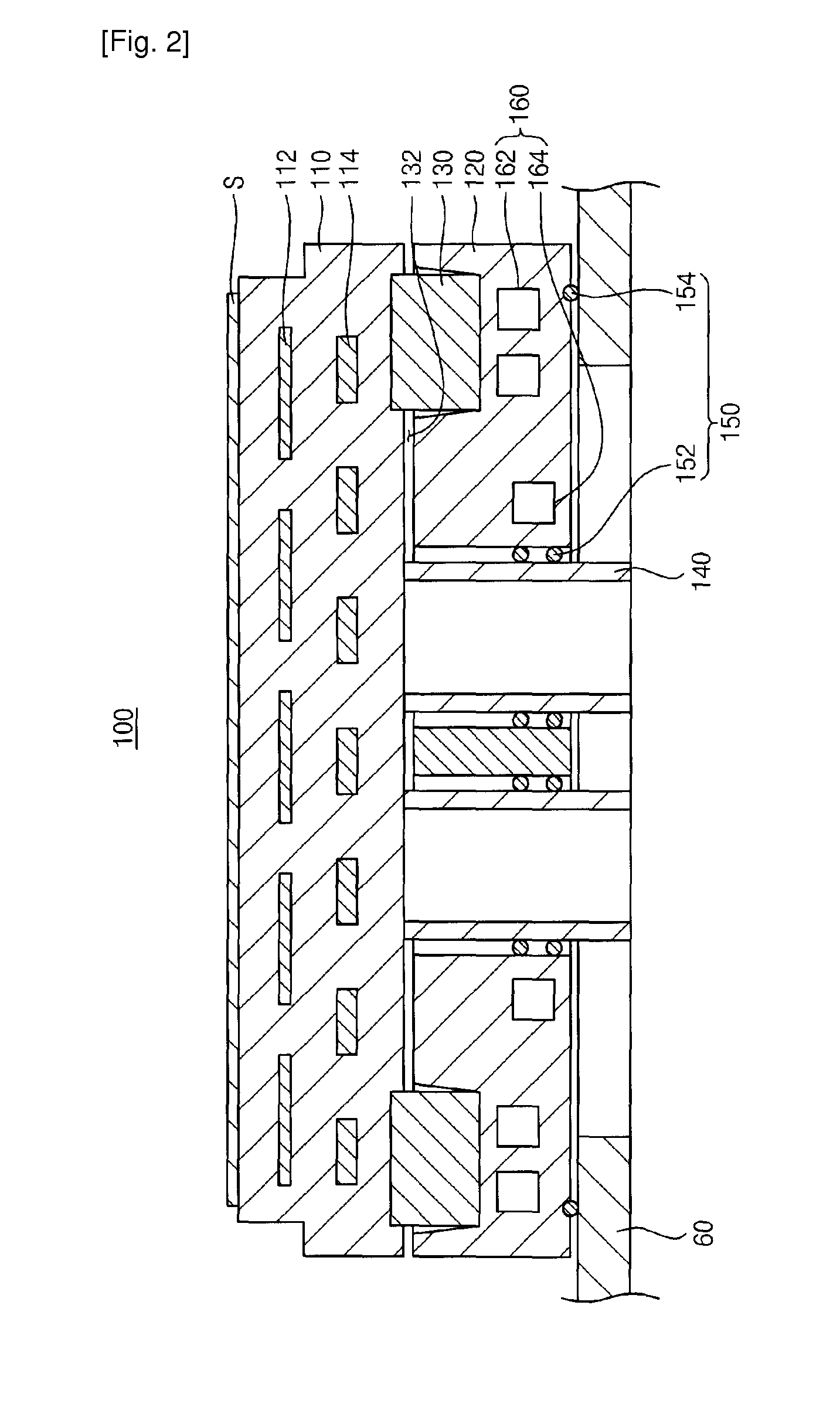

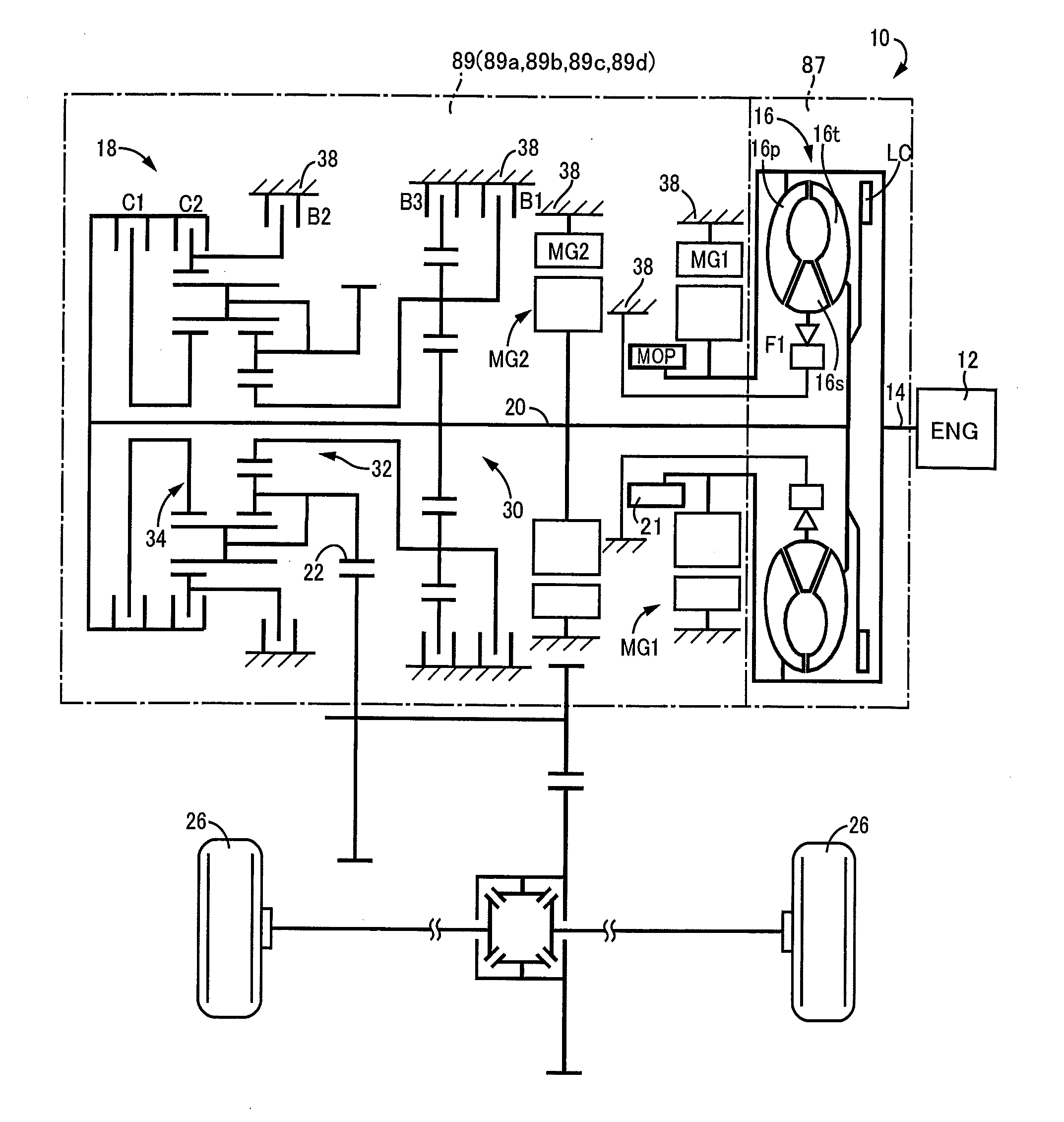

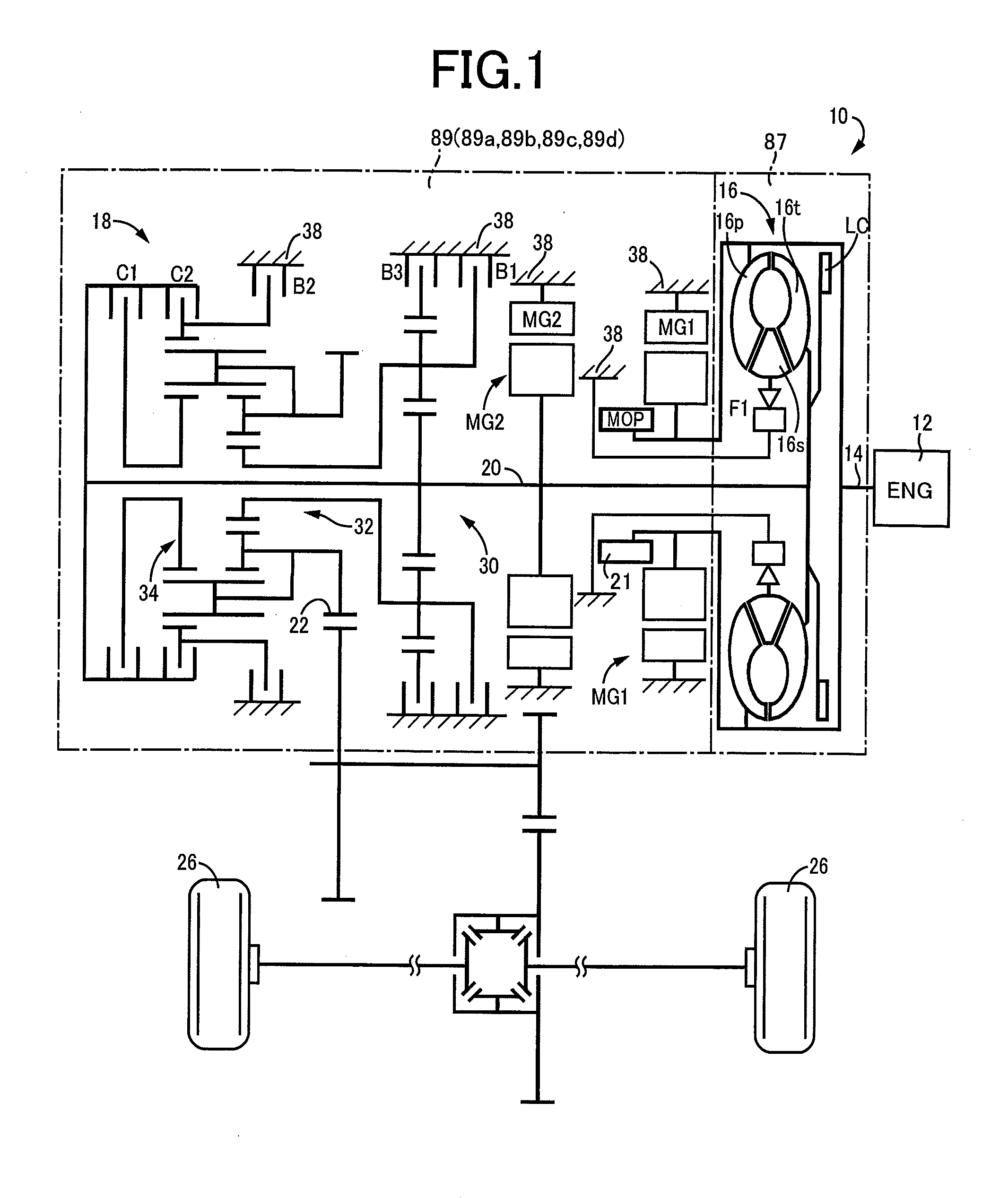

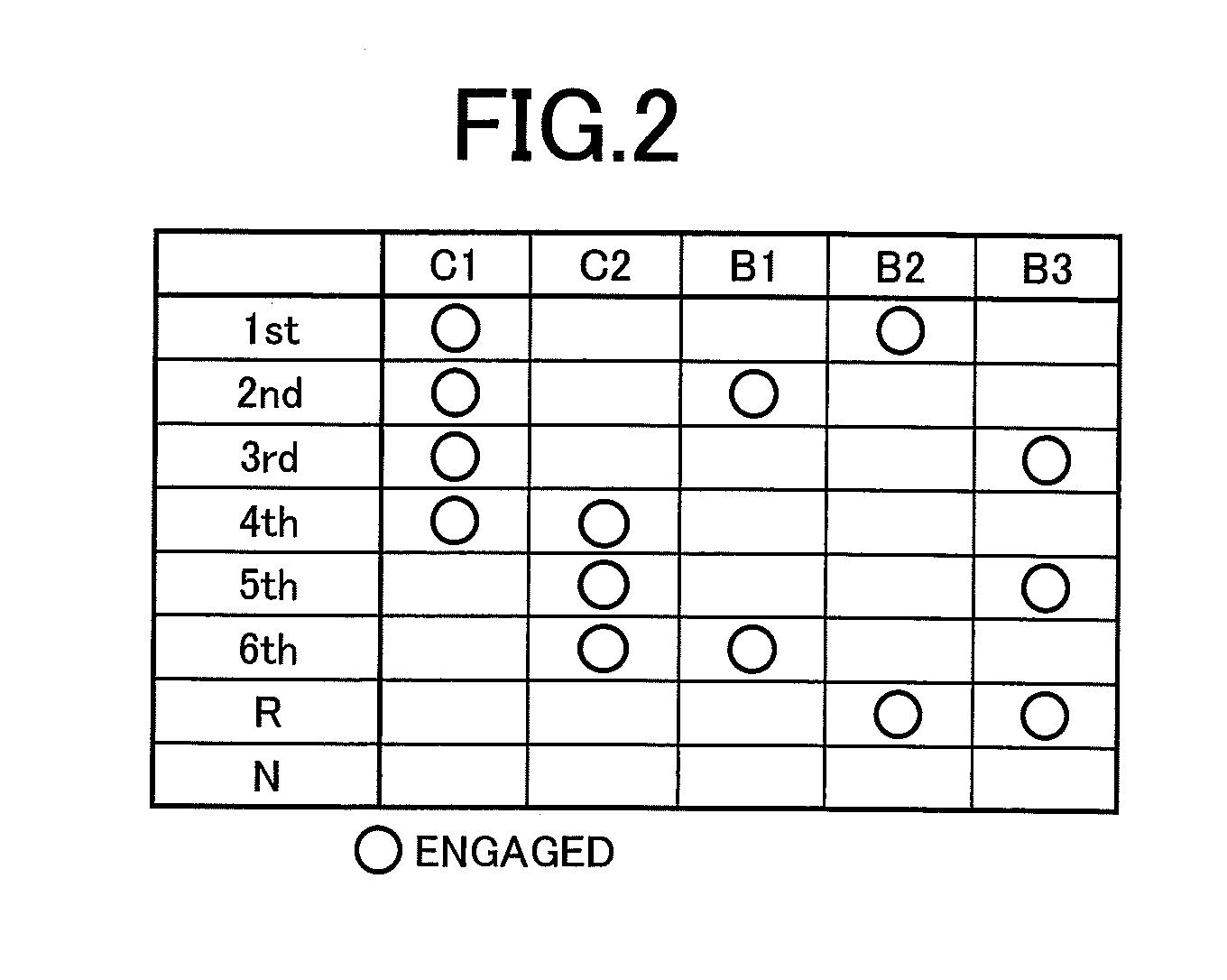

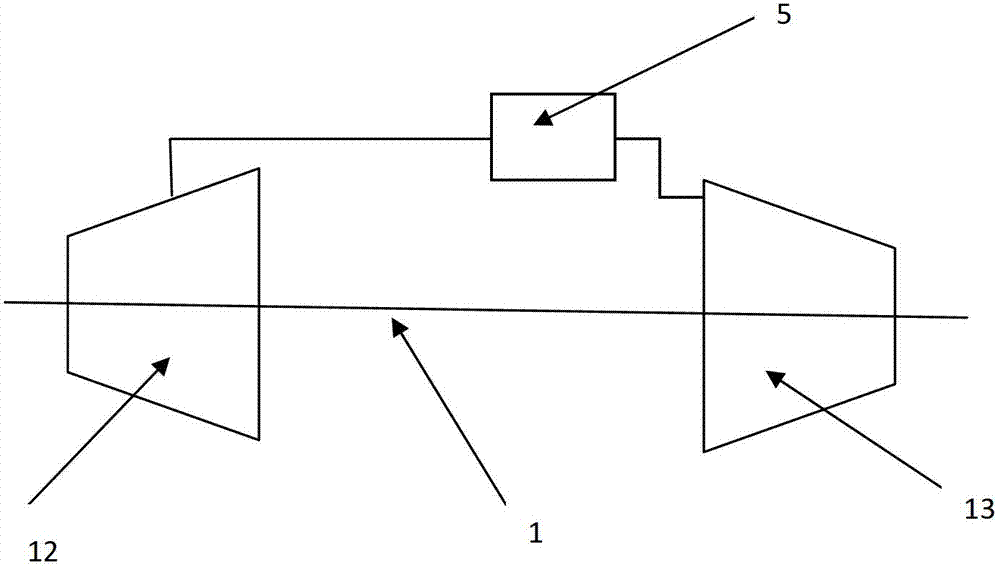

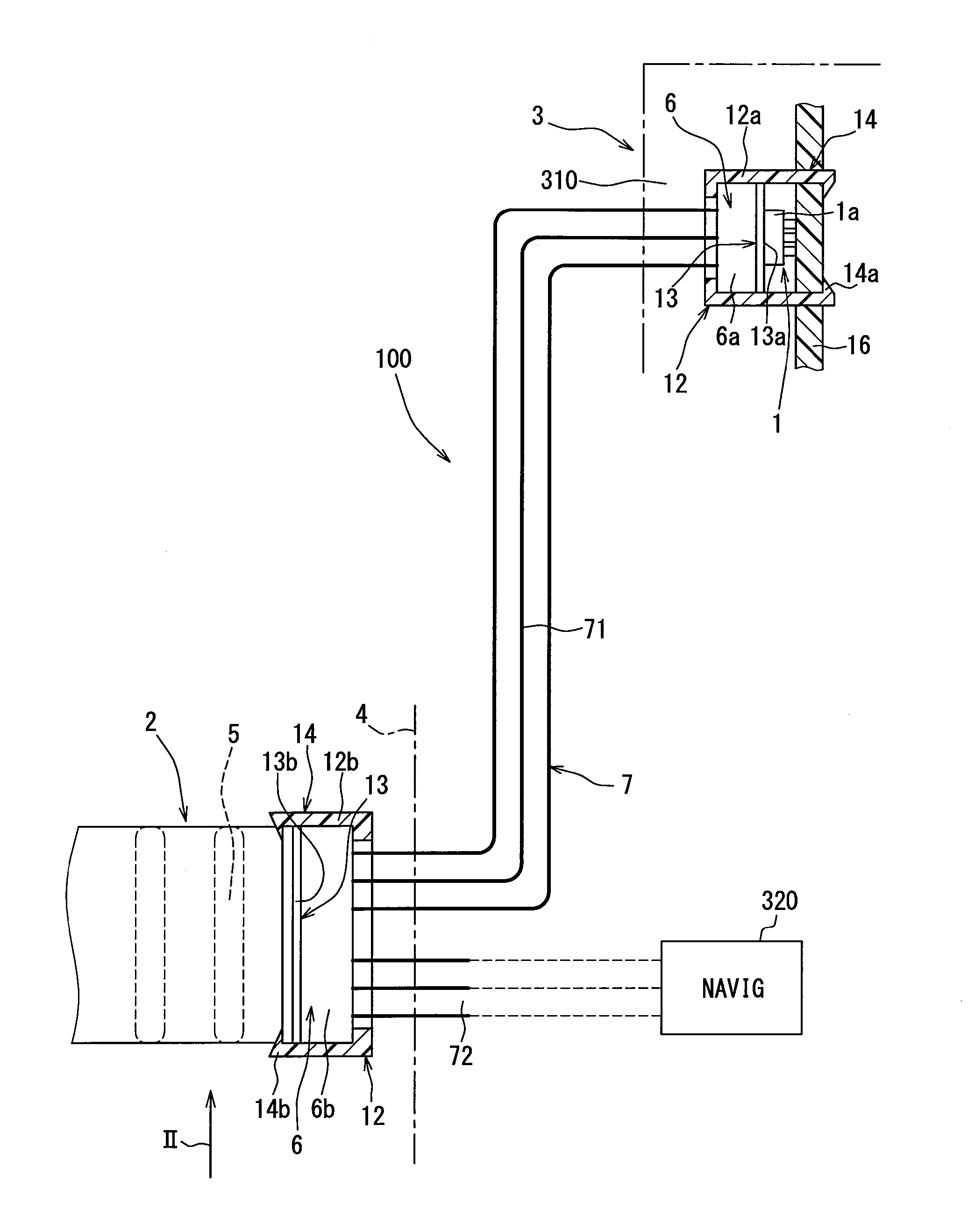

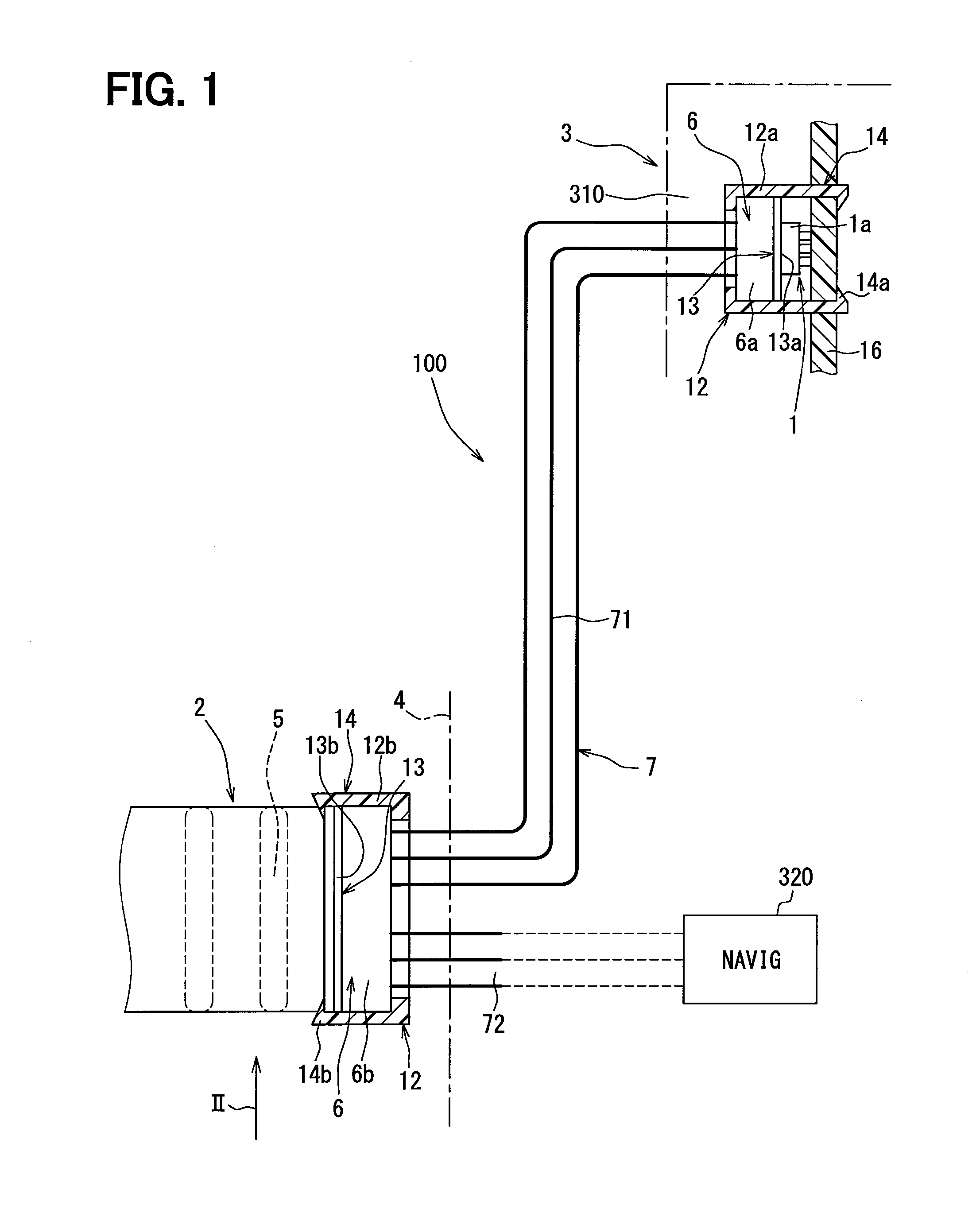

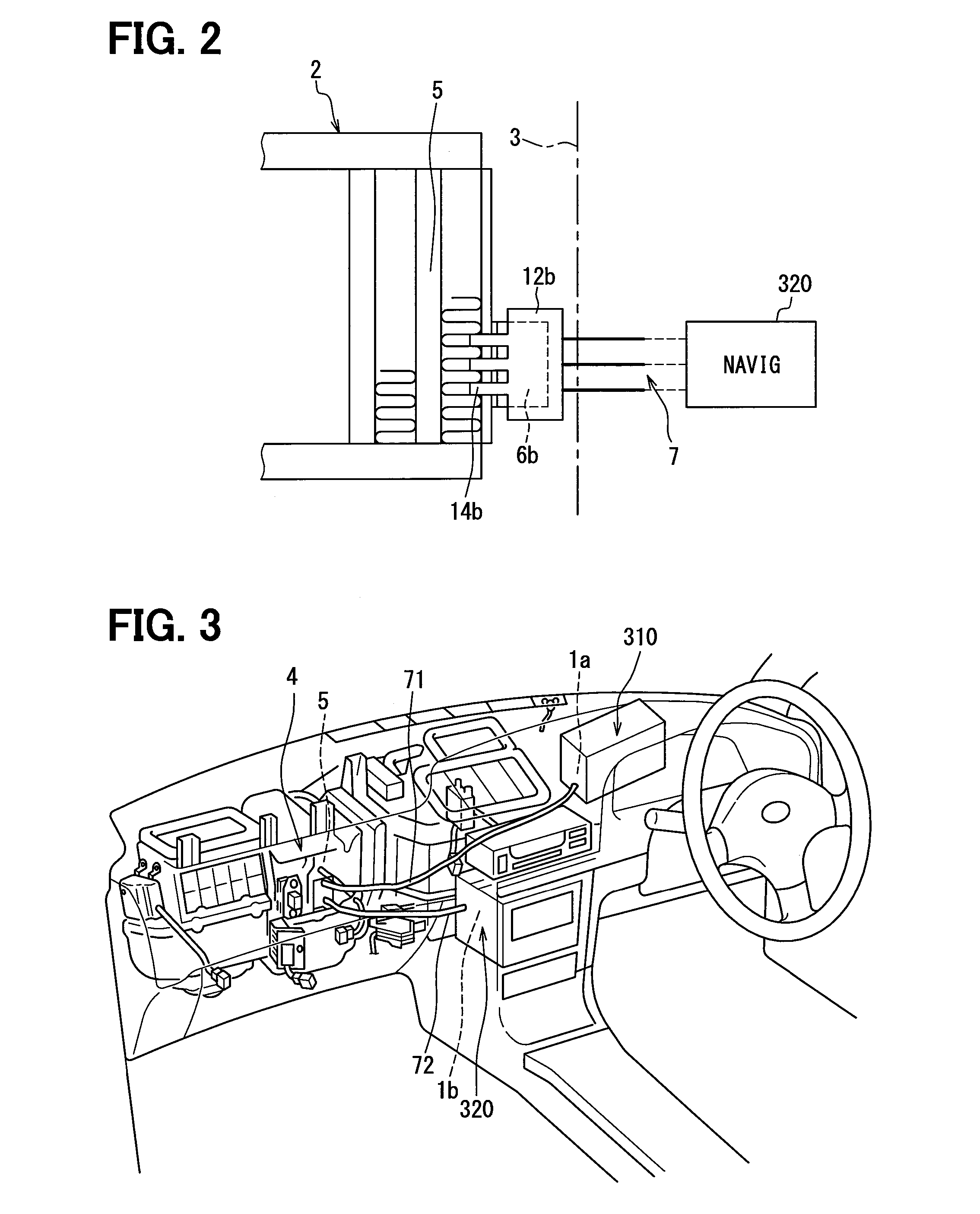

Vehicle drive device

ActiveUS20150239332A1Improve electrical performanceImprove cooling effectHybrid vehiclesReciprocating combination enginesImpellerDrive wheel

A vehicle drive device includes: a torque converter having an input-side rotating member to which power from a prime mover is input and an output-side rotating member outputting power to drive wheels; an electric motor coupled to the input-side rotating member; a transmission coupled to the output-side rotating member of the torque converter; and a case member housing the torque converter, the electric motor, and the transmission, the case member having an air chamber and an oil chamber, the prime mover and the electric motor being disposed at positions with the torque converter interposed therebetween in an axial direction, the torque converter being housed in the air chamber, the electric motor being housed in the oil chamber the vehicle drive device further comprising a second electric motor coupled to the output-side rotating member of the torque converter, the second electric motor being disposed between the electric motor and the transmission in the axial direction in the oil chamber, an oil pressure generating device being disposed between the electric motor and the second electric motor in the axial direction in the oil chamber, and a drive gear of the oil pressure generating device being coupled to the input-side rotating member of the torque converter via a first shaft disposed in parallel with an axis on an inner circumferential side of the electric motor, a second shaft parallel to the axis being disposed on an inner circumferential side of the first shaft, a stator impeller of the torque converter being coupled via a one-way clutch and the second shaft to a cover member that is a non-rotating member of the oil pressure generating device, and the second shaft and the cover member being coupled, and an oil passage for supplying an operating oil to the torque converter being made up of a gap formed between an inner circumferential surface of the first shaft and an outer circumferential surface of the second shaft.

Owner:TOYOTA JIDOSHA KK

LED light-emitting module with liquid metal heat dispersion heat sink

ActiveCN101771127AHighly integratedPromote environmental protectionSolid-state devicesSemiconductor devicesHeat sinkElectricity

The invention relates to a light-emitting module with a liquid metal heat dispersion heat sink, comprising a heat sink flat sheet, an LED light-emitting module arranged on the heat sink flat sheet and at least one driving pump, wherein at least one hollow flow passage is arranged in the heat sink flat sheet, and liquid metal fluid flows in the hollow flow passage; the LED light-emitting module isformed by integrating 1-5000 light-emitting chips; the driving pump consists of a pair of electrode plates respectively installed on a wall surface opposite to each hollow flow passage and a pair of permanent magnet sheets respectively and horizontally arranged on the upper surface and the lower surface of the heat sink flat sheet opposite to each hollow flow passage; the large planes of the pairof electrode plates are perpendicular to the large planes of the pair of permanent magnet sheets; and electrode leads of the pair of electrode plates are led out through pinholes in the wall surface of the hollow flow passage and are electrically connected with an external delay switch module. The electromagnetic pump drives the liquid metals in the hollow flow passage to flow so that LED heat can be transferred to the periphery of the heat sink to be discharged and dissipated. The LED light-emitting module has the advantages of high reliability, no need of maintenance, low noise, energy saving, environmental protection, and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

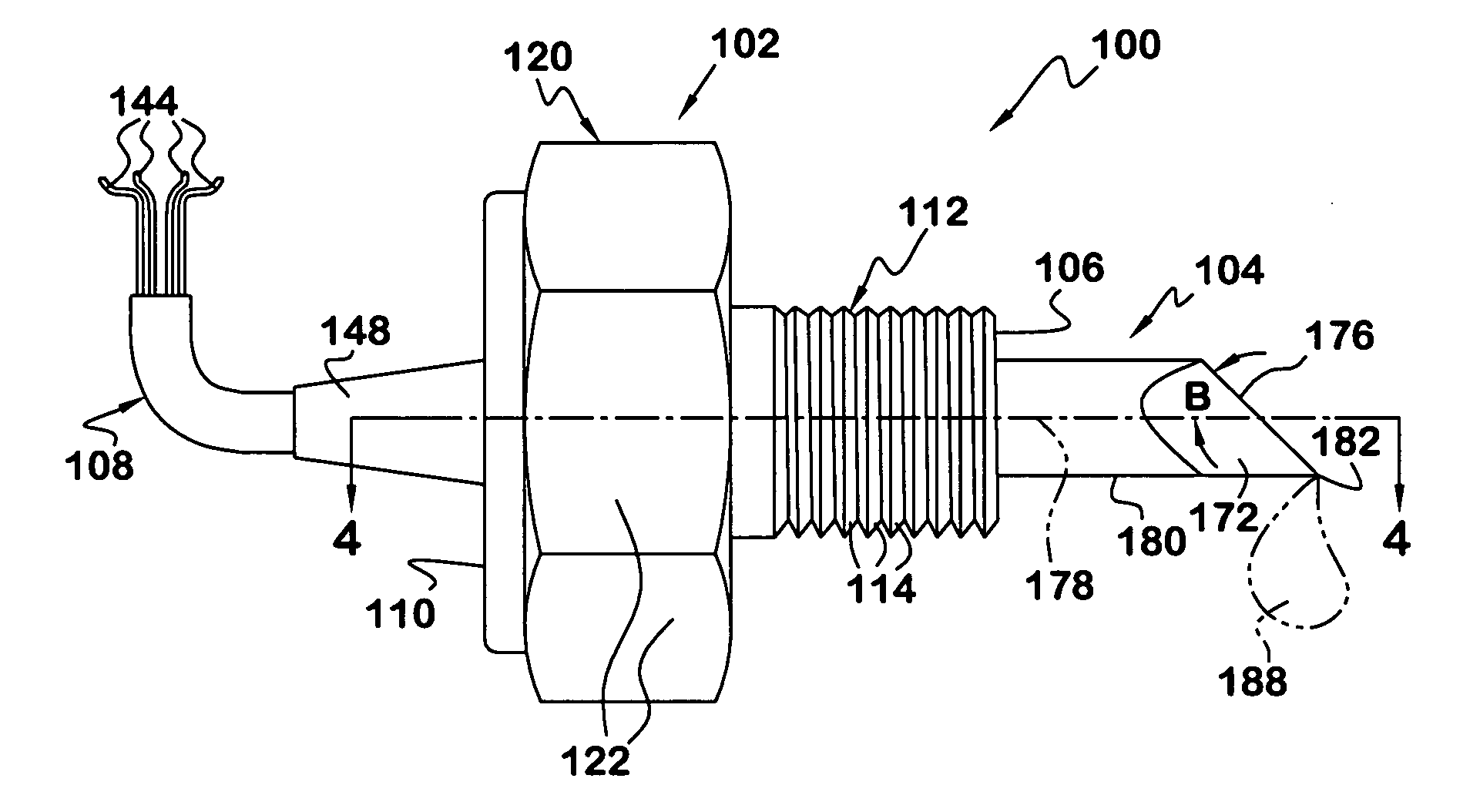

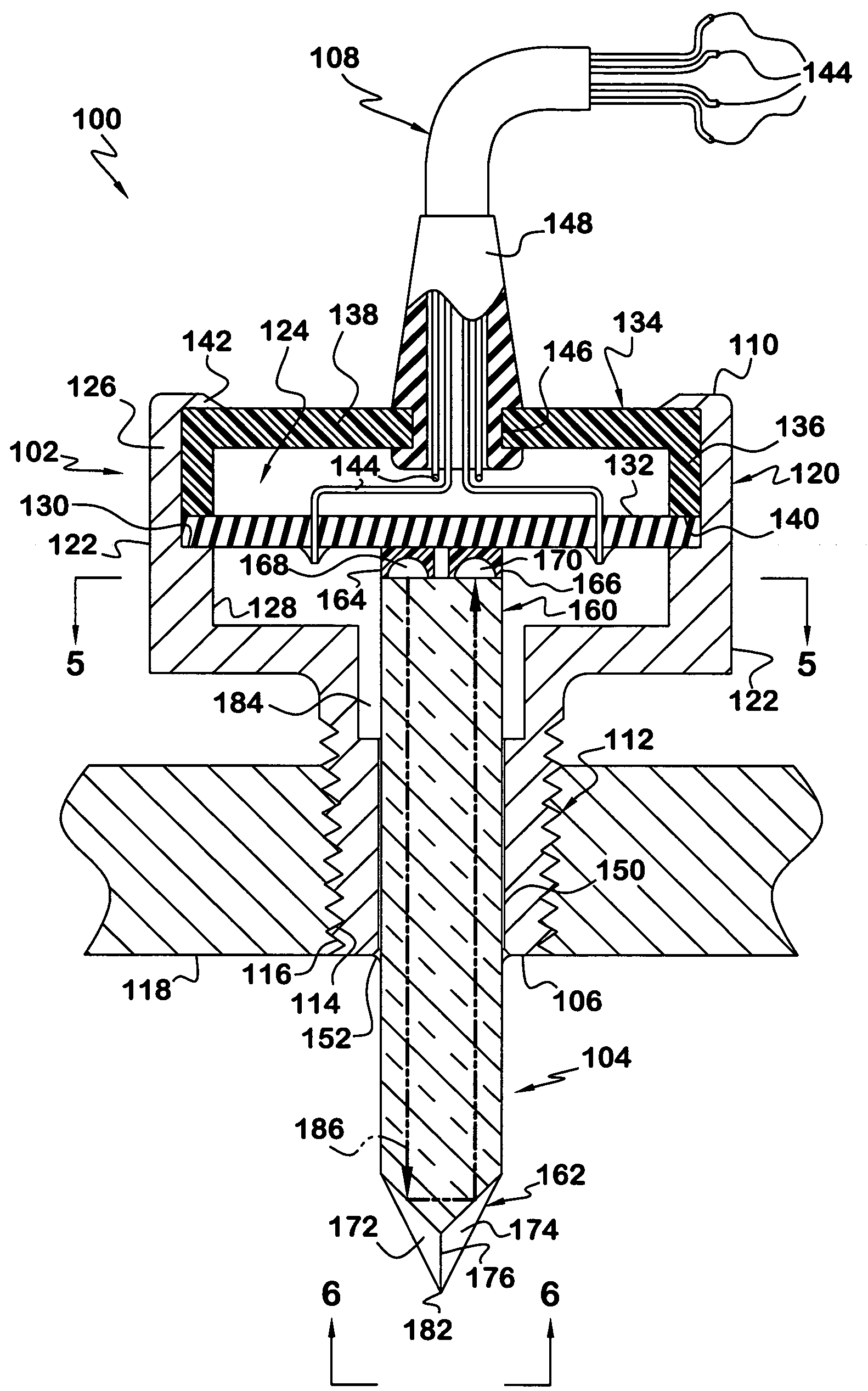

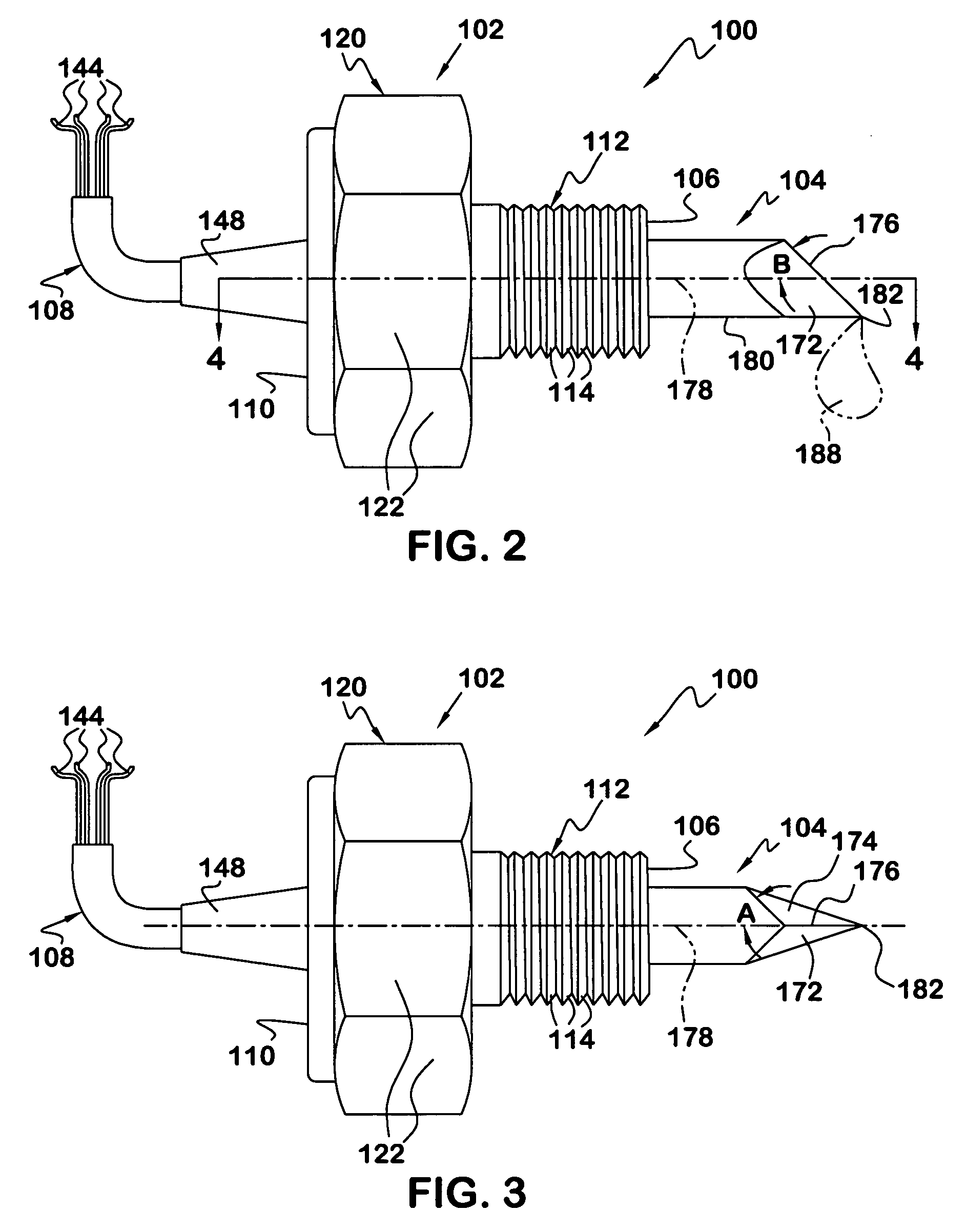

Optical transducer for detecting liquid level

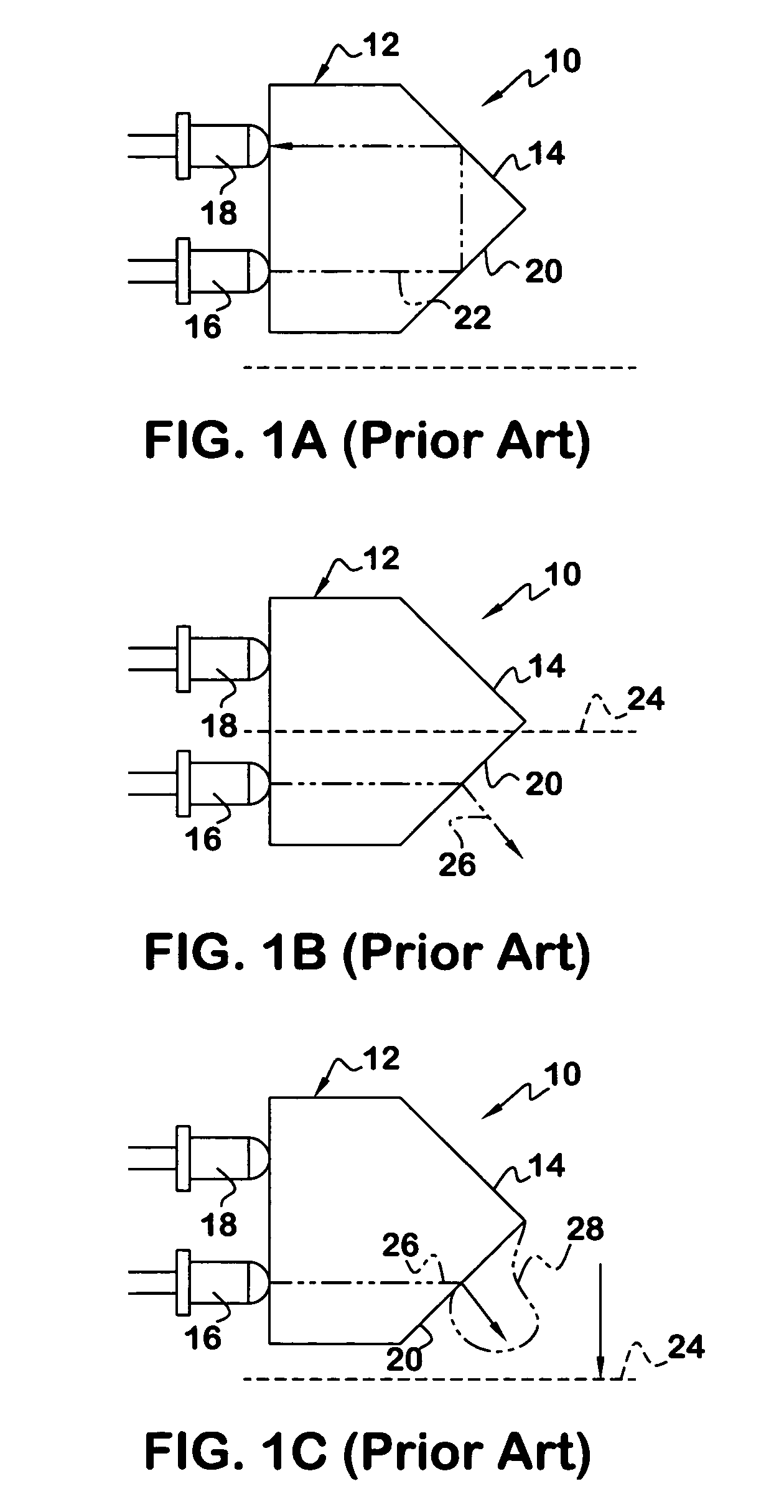

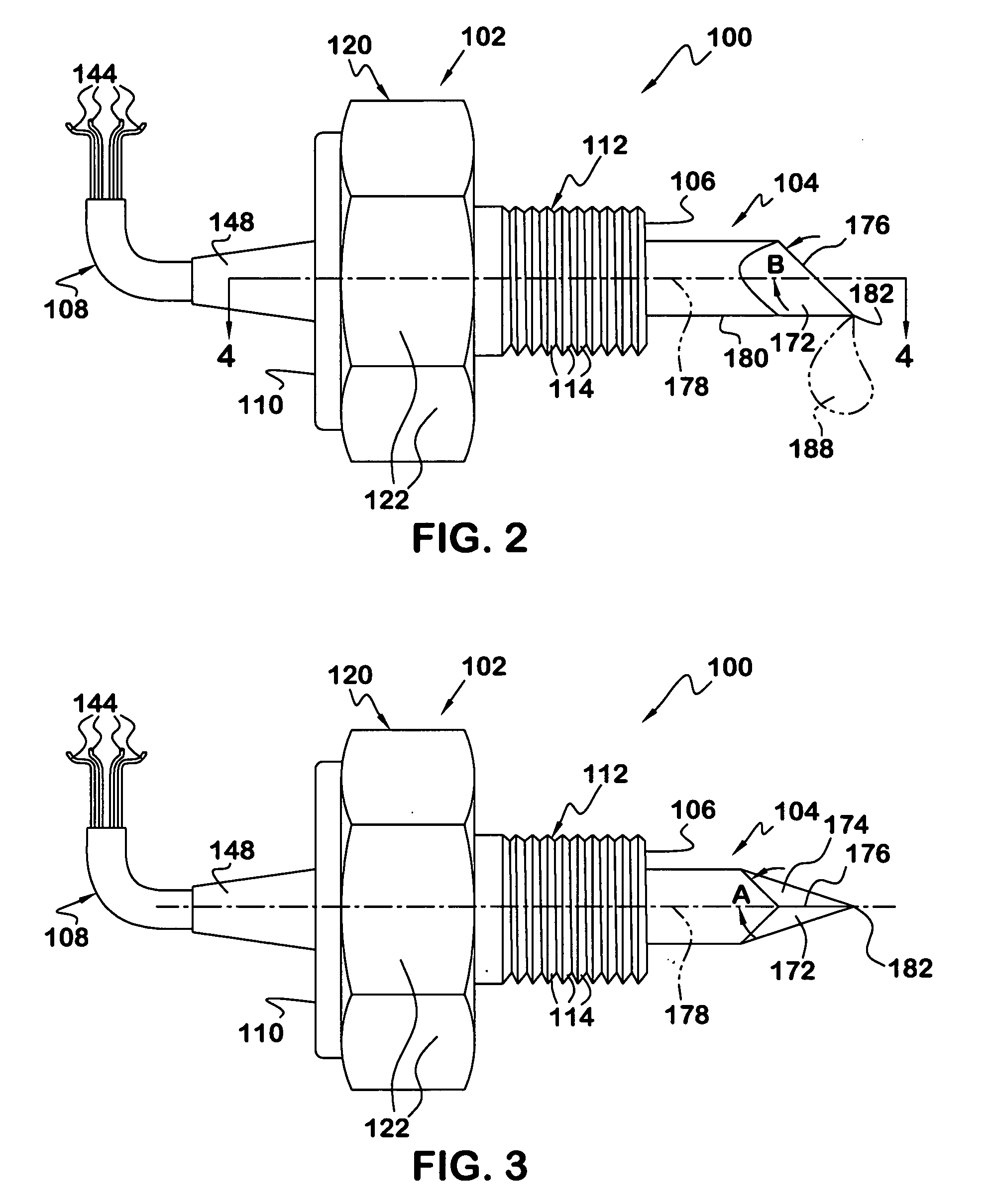

InactiveUS20050236591A1Heat transferMinimize heat transferRadiation pyrometryInvestigating moving fluids/granular solidsAcute angleEngineering

An optical transducer for determining the presence or absence of liquid or the like in a reservoir includes a housing with a hollow interior and an optical probe that extends through the housing. The optical probe has a central axis, a proximal end positioned in the hollow interior and a distal end positioned outside of the housing. The distal end has first and second measurement surfaces that intersect at a transverse edge. The transverse edge extends at an acute angle with respect to the central axis. A light source is arranged for projecting radiant energy into the optical probe toward the distal end. A photosensor is arranged for detecting radiant energy reflected from the distal end to thereby detect the presence and absence of liquid on the optical probe.

Owner:OPTI SENSOR SYST

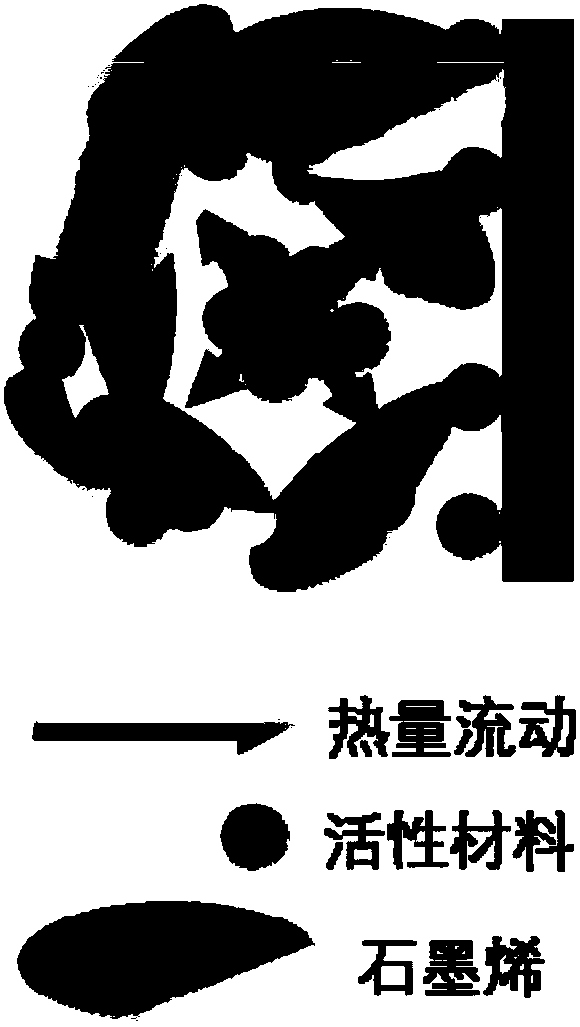

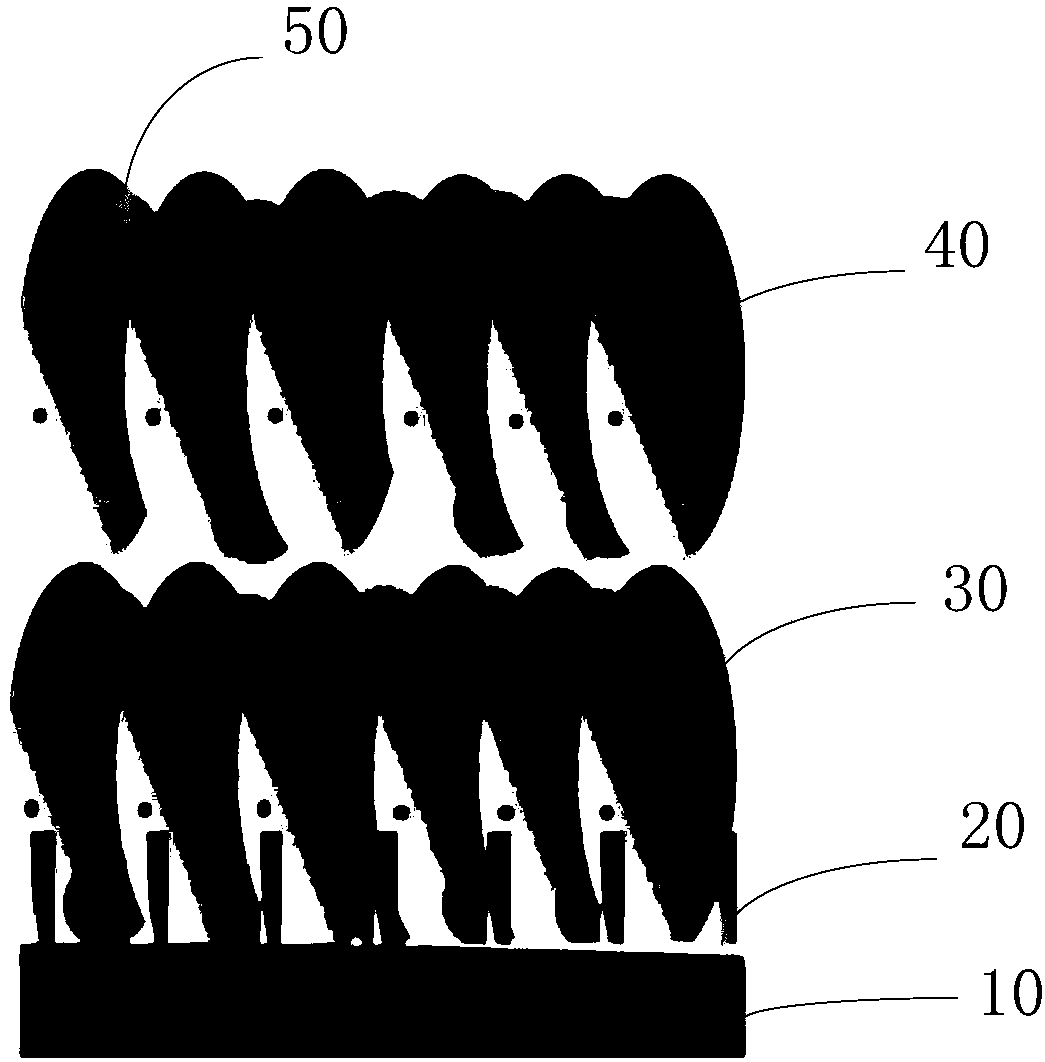

Battery electrode, preparation method of battery electrode and battery

ActiveCN108630945AImprove high temperature performanceReduce feverElectrode carriers/collectorsSecondary cellsNanodotElectrical battery

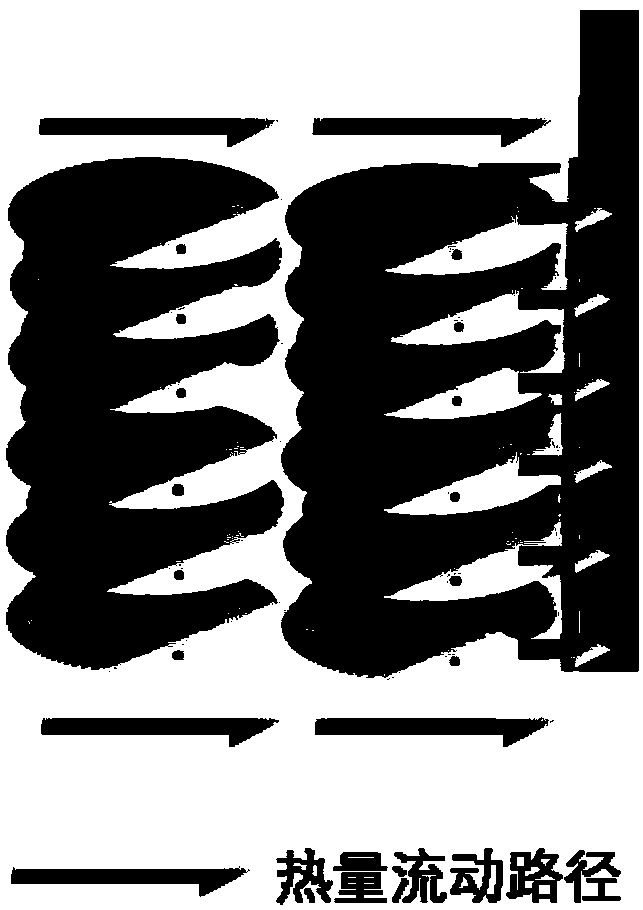

The embodiment of the invention provides a battery electrode. The battery electrode comprises a current collector and an electrode material layer, wherein the electrode material layer is arranged on the current collector; the electrode material layer comprises an electrode active material and sheet-structure graphene; the surface of the graphene is modified with magnetic response nanodots; in thegraphene, more than 50% mass ratio of the graphene is arranged in the orientation with an angle of 45-90 degrees with the surface of the electrode material layer arranged on the current collector so as to form a heat conduction path with the specific orientation. According to the battery electrode, a battery cell material of the battery electrode is provided with the fast heat conduction path withthe specific orientation, so that heat in a battery cell can be effectively transferred outwards to the current collector and then is transferred to the peripheral environment from the current collector, and therefore the problem that in the prior art, the high-temperature performance of a battery is poor due to the fact that the heat generated in a single battery cell cannot be transferred fromthe interior to the environment in time can be solved. The embodiment of the invention further provides a preparation method for the battery electrode and a battery comprising the battery electrode.

Owner:HUAWEI TECH CO LTD

Plastic intercooler

InactiveUS20080173436A1Heat transferEnhanced heat transferInternal combustion piston enginesHeat exchanger casingsPhysicsIntercooler

An intercooler comprises a plurality of plastic cooling tubes extending between a first end plate and a second end plate and a baffle arranged in the intercooler and extending at least partially between the first end plate and the second end plate. The baffle comprises a plurality of first openings for receiving a respective plastic cooling tube, the baffle further comprising a plurality of second openings arranged between the first openings. The second openings permit air to flow through the intercooler whilst creating turbulence in the air flow which increase the thermal transfer between the air and the tubes increasing the efficiency of the intercooler.

Owner:MAHLE INT GMBH

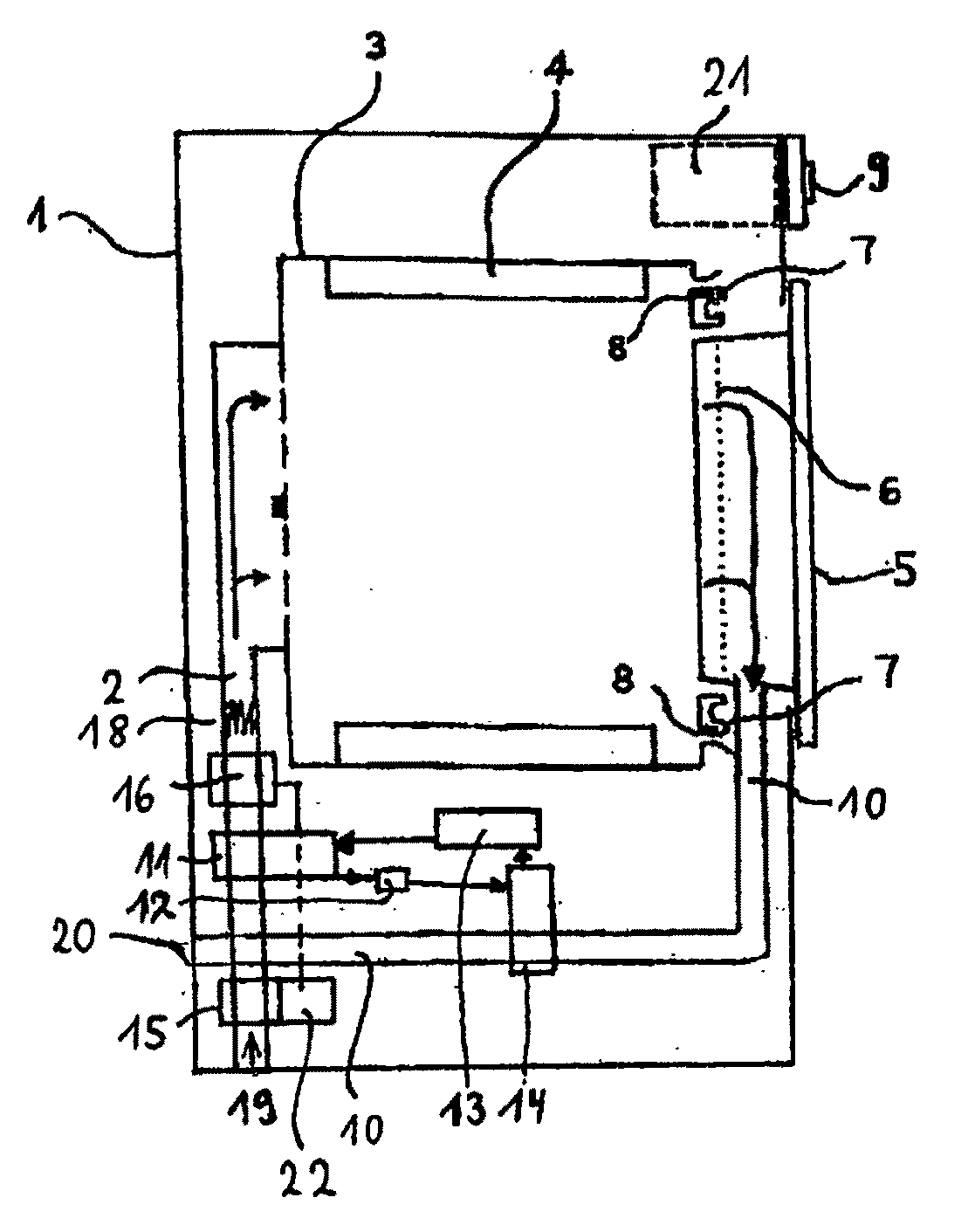

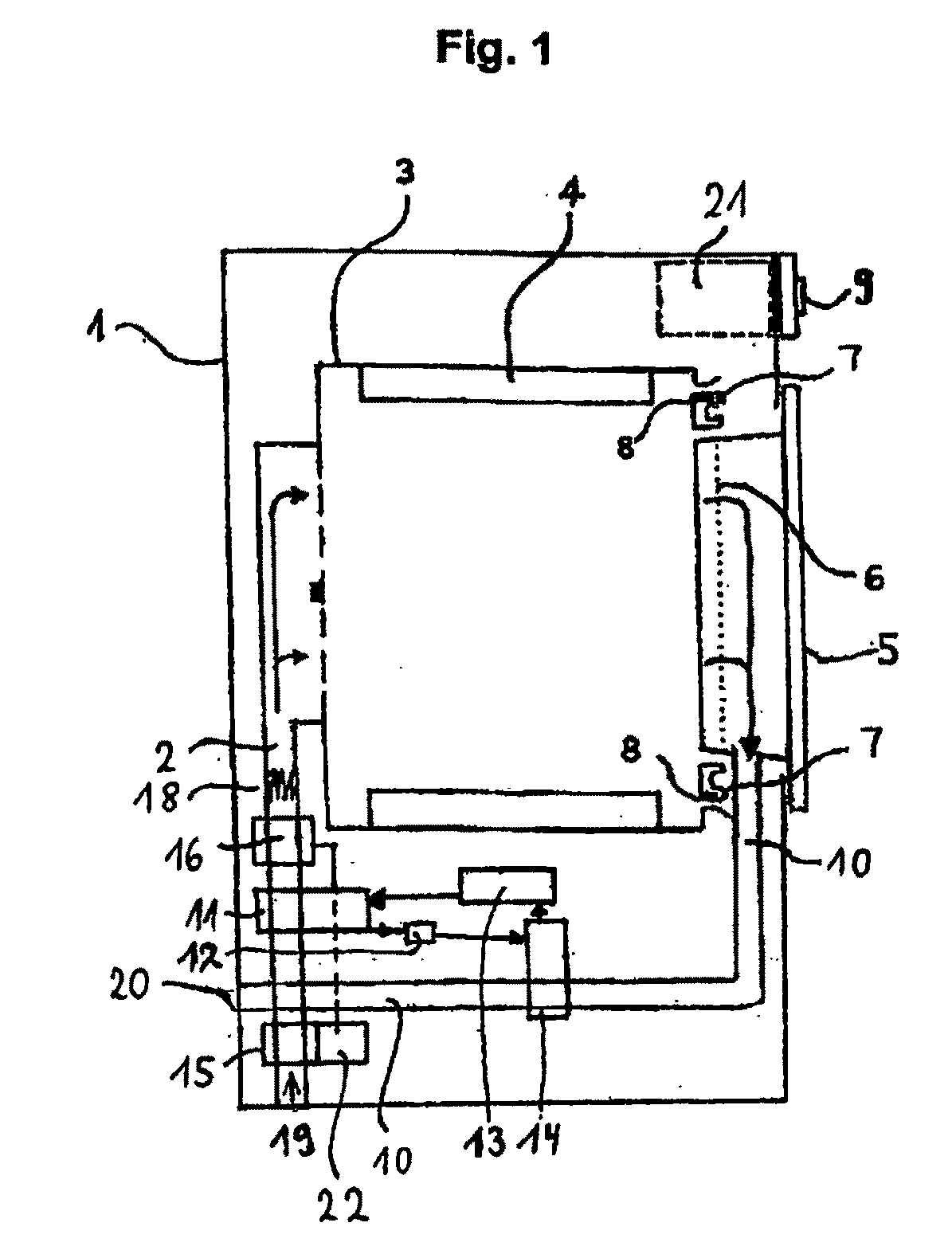

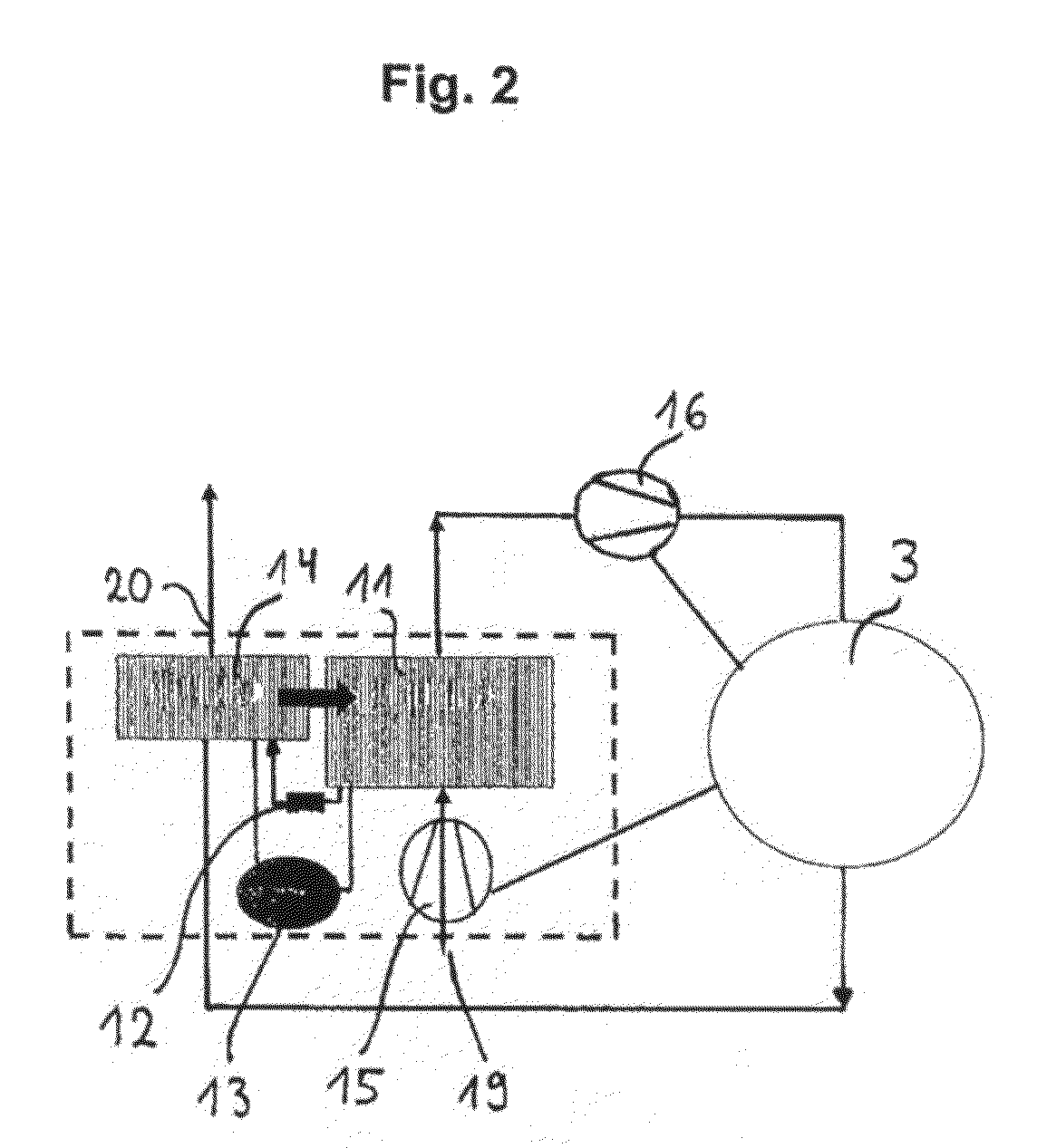

Exhaust air dryer with a heat pump and a first fan

InactiveUS20090139107A1Heating fastEasy to operateDrying machines with non-progressive movementsTextiles and paperPulp and paper industryAir dryer

The invention relates to an exhaust air dryer with a drying compartment for objects to be dried, a supply air duct upstream of the drying compartment, a first fan for the supply of process air from a supply air inlet to the drying compartment and to an exhaust air outlet, an exhaust air duct between the drying compartment and the exhaust air outlet and a heat pump, with a heat sink in the exhaust air duct and a heat source in the supply air duct, characterized in that the first fan in the supply air duct is arranged between the supply air inlet and the heat source and a second fan in the supply air duct is arranged between the heat source and the drying compartment.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

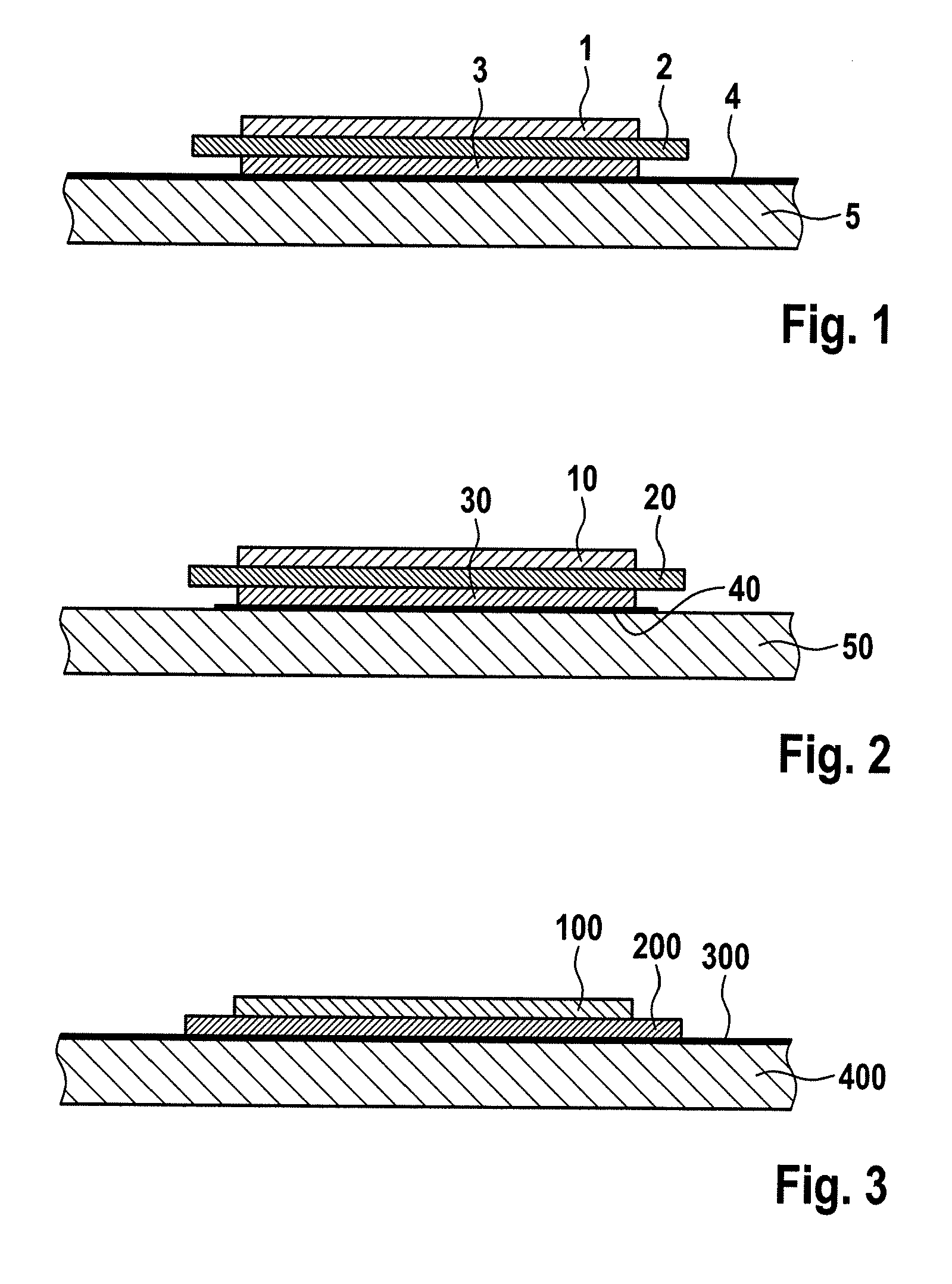

Method of Joining Metal-Ceramic Substrates to Metal Bodies

ActiveUS20120305281A1Good profile of propertyStrong and stable bondingSemiconductor/solid-state device detailsSolid-state devicesMetal alloyComputer module

A method of joining a metal-ceramic substrate having metallization on at least one side to a metal body by using metal alloy is disclosed. The metal body has a thickness of less than 1.0 mm and the metal alloy contains aluminium and has a liquidus temperature of greater than 450° C. The resulting metal-ceramic module provides a strong bond between the metal body and the ceramic substrate. The resulting module is useful as a circuit carrier in electronic appliances, with the metal body preferably functioning as cooling body.

Owner:IXYS SEMICON

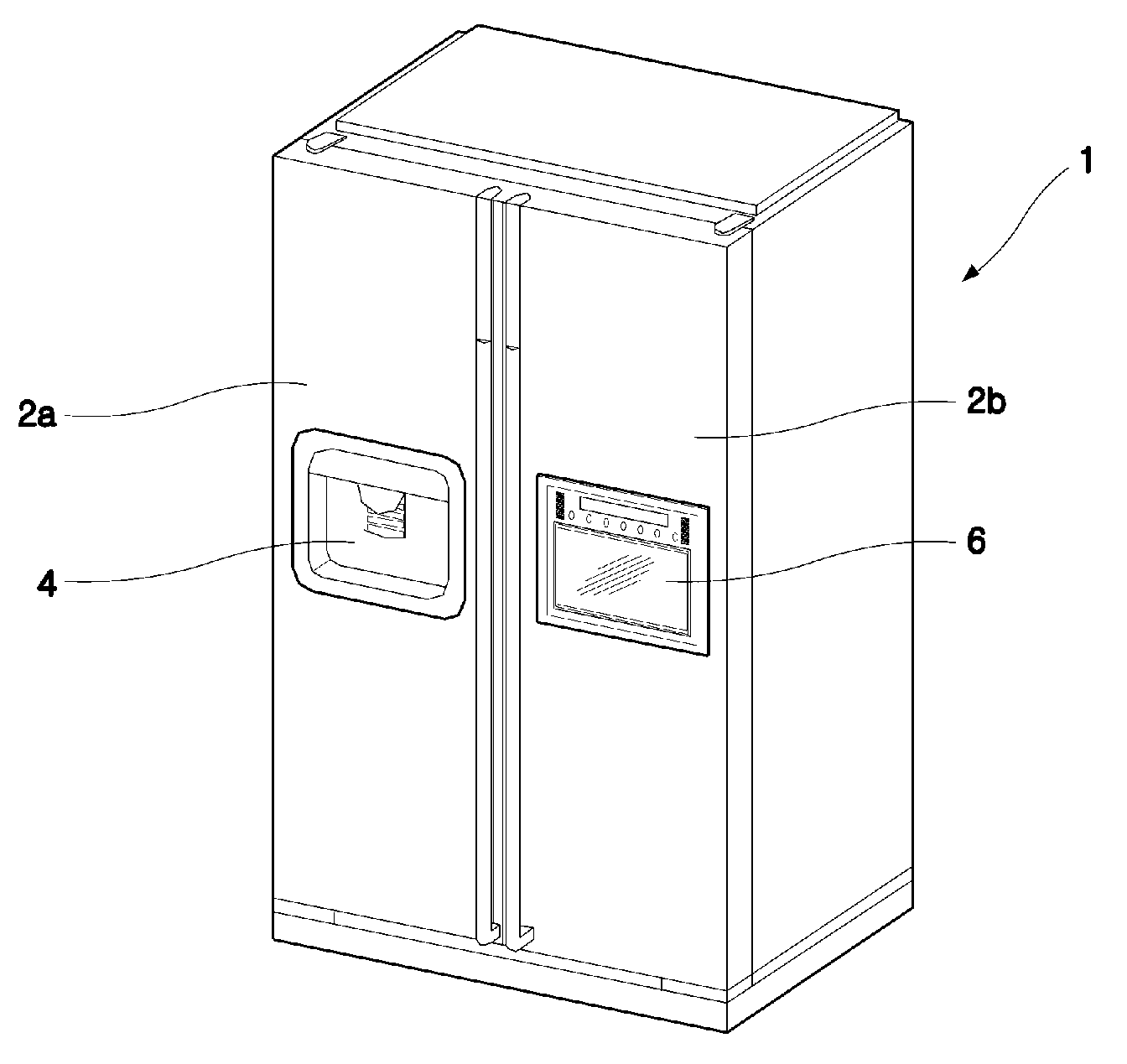

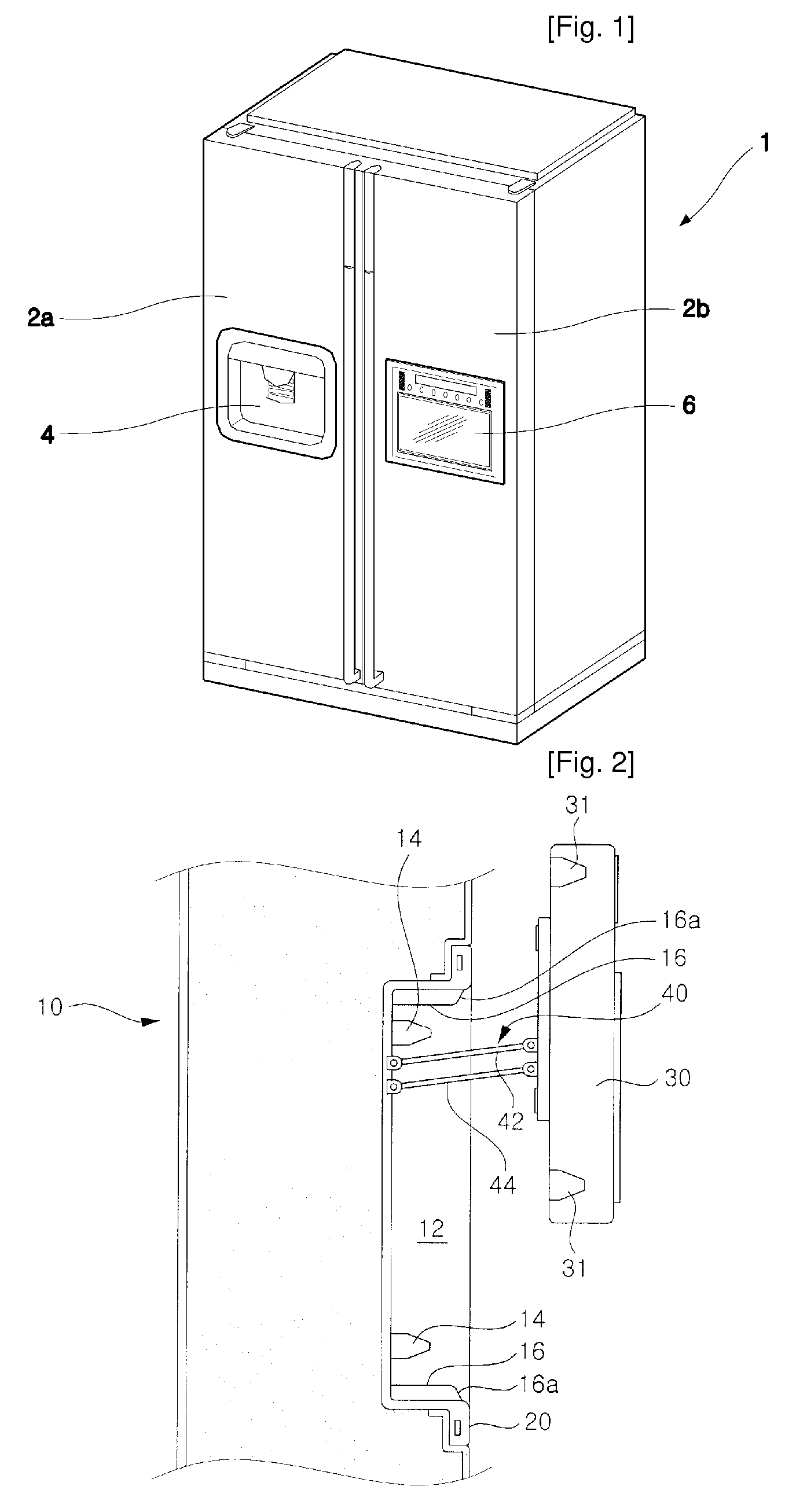

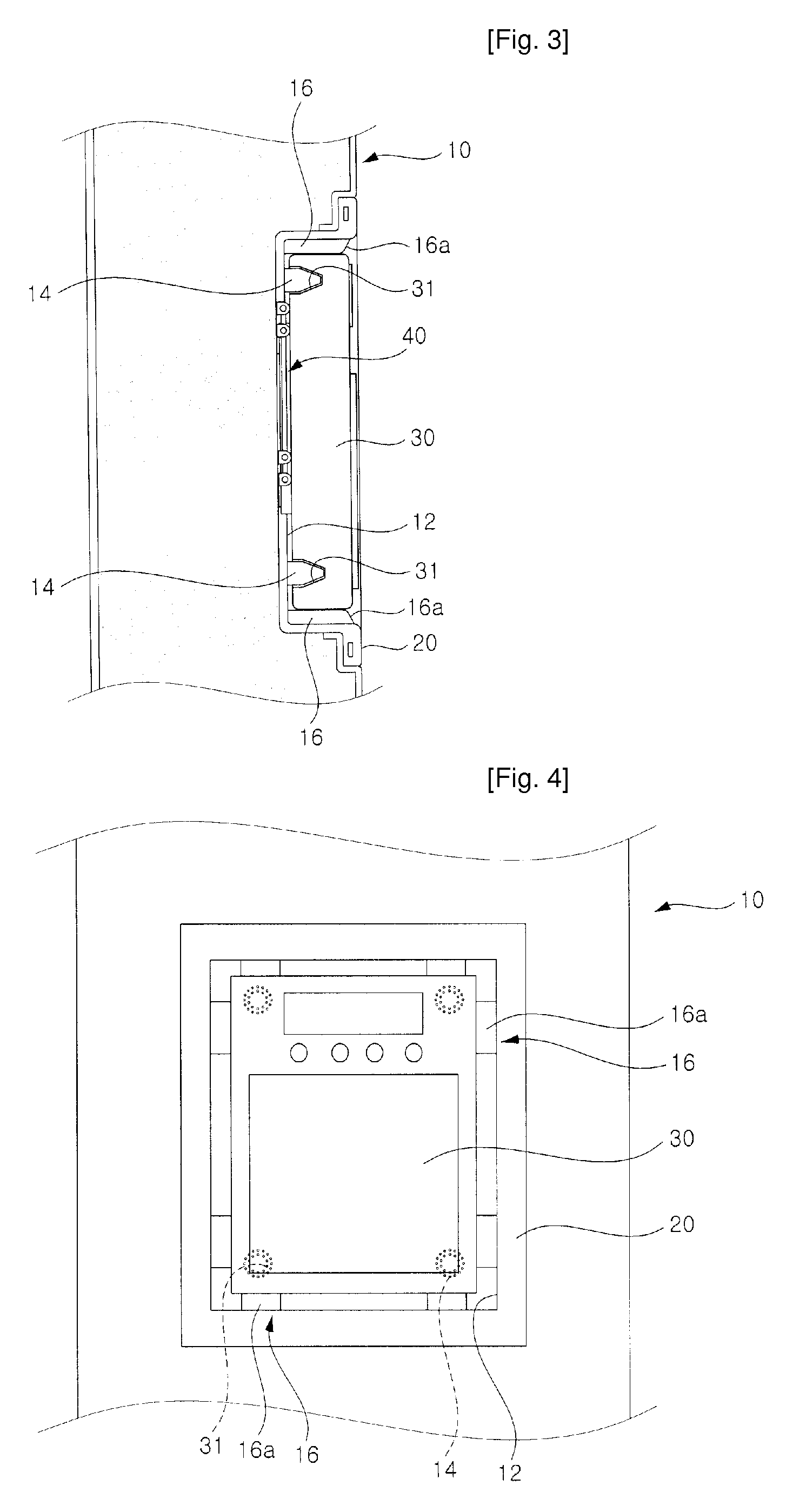

Display Unit Installing Structure for Refrigerator

InactiveUS20070290588A1Field of visionHeat transferLighting and heating apparatusDoors/windowsRefrigerated temperatureElectrical and Electronics engineering

The present invention relates to a display unit installing structure for a refrigerator. The present invention comprises an accommodating unit which is formed by depressing a portion on a front surface of a door and in which a display unit for displaying a variety of information thereon and inputting operating signals are retractably installed; a link mechanism for guiding accommodation and withdrawal of the display unit and tiltably supporting the display unit withdrawn from the accommodating unit at a predetermined angle; and a locking means for preventing the display unit from being inadvertently escaping from the accommodating unit. According to the present invention, there is an advantage in that the display unit can be retractably installed on the front surface of the refrigerator door.

Owner:LG ELECTRONICS INC

Air cooled heat exchanger with enhanced heat transfer coefficient fins

ActiveUS7743821B2Heat transferMinimum pressure lossStationary tubular conduit assembliesHeat transfer modificationEnhanced heat transferEngineering

Owner:NUOVO PIGNONE TECH SRL

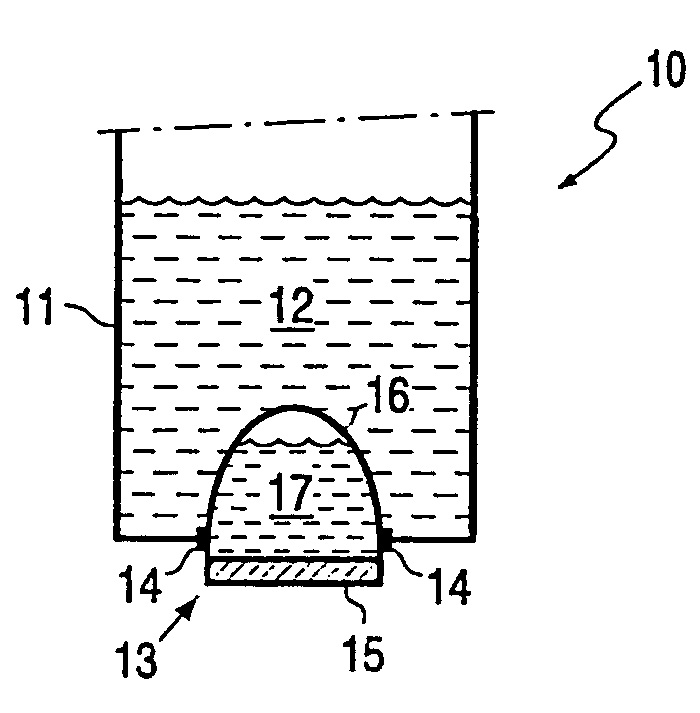

Device for heating liquids and assembly for use in such a device

InactiveUS7187855B2Enhances vapour bubble formationGood thermal contactImmersion heating arrangementsWater heatersElectrical equipmentHeating element

The invention relates to a device for heating liquids, comprising: a first liquid container for liquid for heating, and a heating element connected to the first liquid container. The invention also relates to an assembly for use in such a device. Such a heating device can be applied in diverse electrical appliances for heating liquids.

Owner:FERRO TECHNIEK HLDG

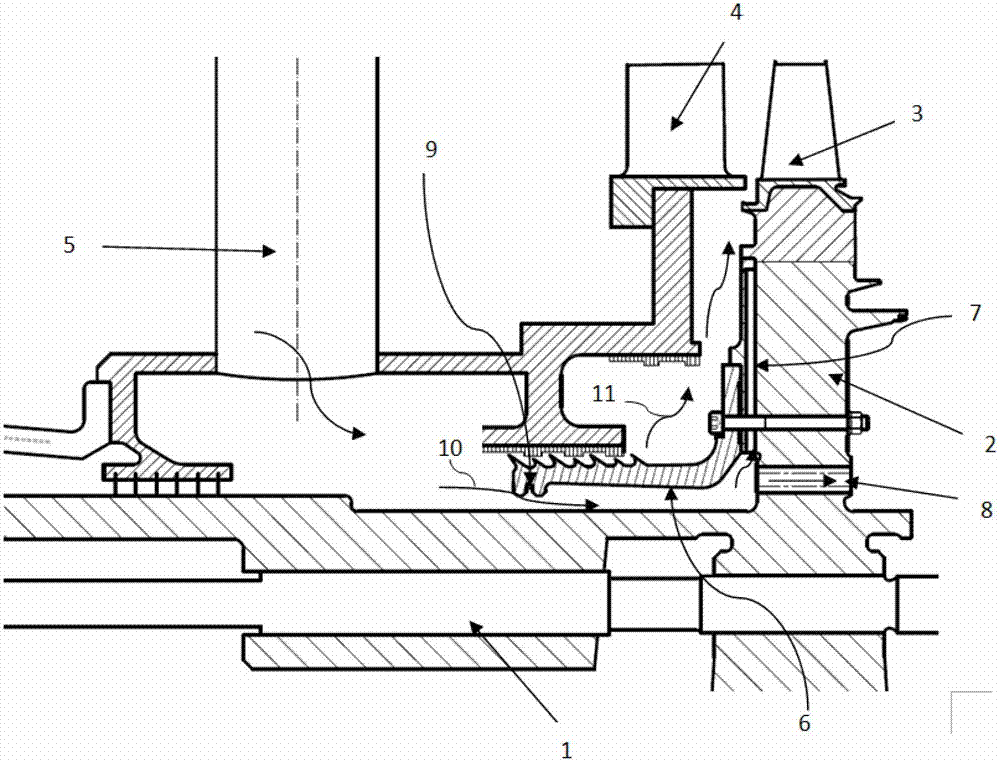

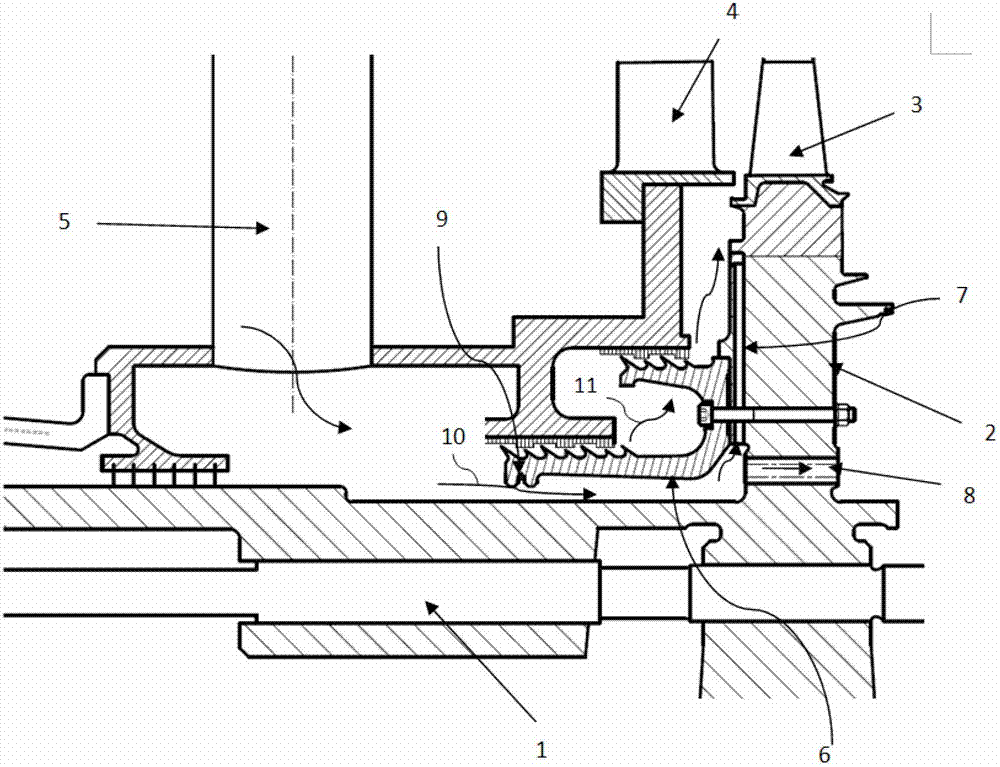

Method for cooling turbine disc and moving blade of combustion gas turbine

InactiveCN103206270AImprove cooling effectReduce thermal stressBlade accessoriesMachines/enginesRotary pumpCombustion

The invention relates to a method for cooling a turbine disc and a moving blade of a combustion gas turbine. High-temperature high-pressure air pumped out by an air compressor is divided into two air flows by a sealing structure after being cooled by an intercooler, wherein the two air flows are a cooling air flow and a sealing air flow; the cooling air flow is used for cooling a one-stage turbine moving blade and a one-stage turbine disc respectively, the other sealing air flow enters a channel between the one-stage turbine moving blade and a one-stage static blade to prevent gas from flowing backwards. According to the method, the one-stage turbine disc and the moving blade can be effectively cooled and the sealing effect of the front end of the one-stage turbine disc is achieved; besides, a radial channel in the one-stage turbine disc can achieve a rotary pump effect and a heat-exchange function of the cooling air, so that the cooling method can cool the one-stage turbine disc while performing pressurization and temperature rise on the cooling gas, the cooling air flow rate needed by the one-stage turbine disc and the one-stage turbine moving blade can be ensured, and the thermal stress of the one-stage turbine moving blade is reduced.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

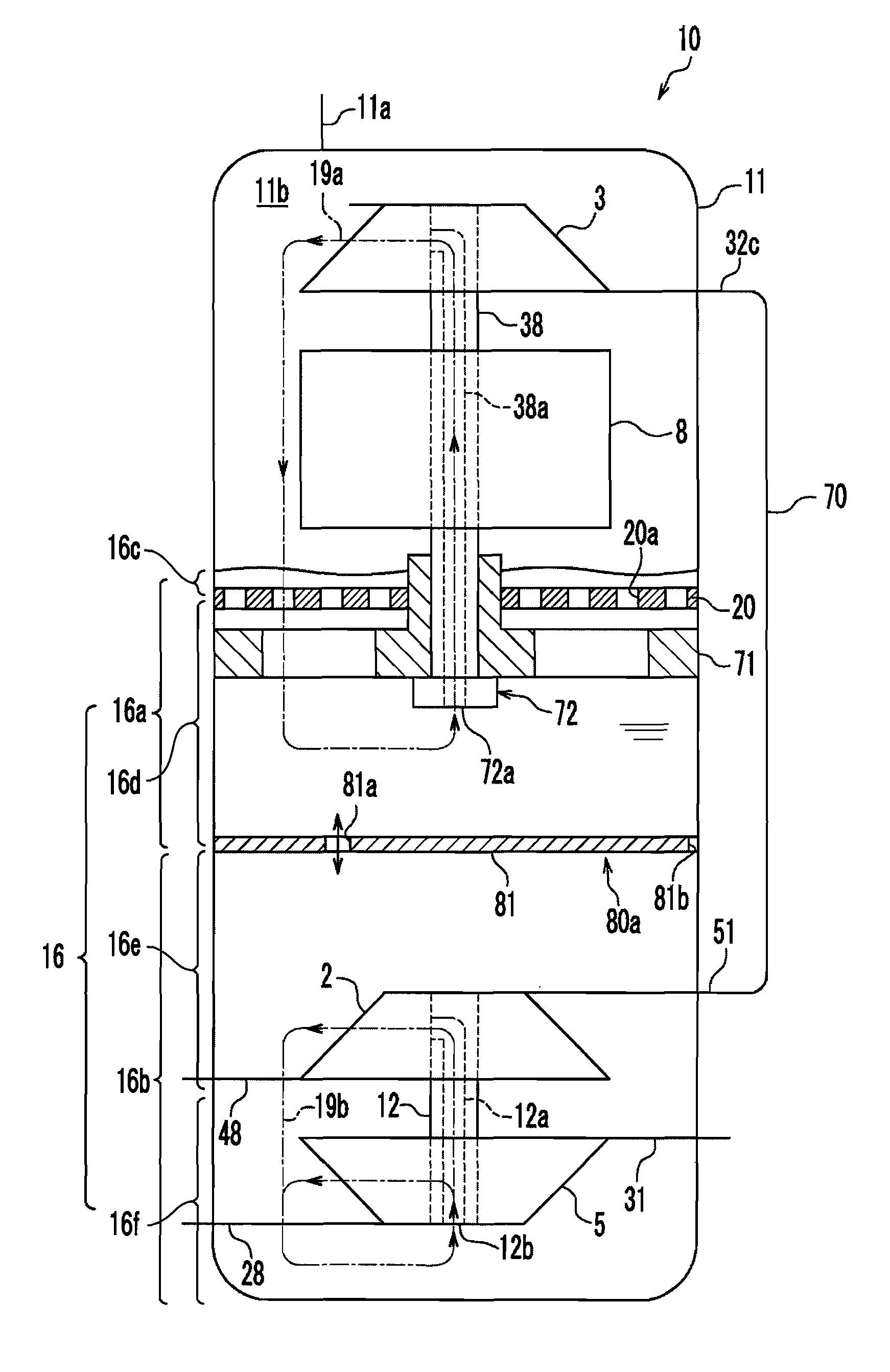

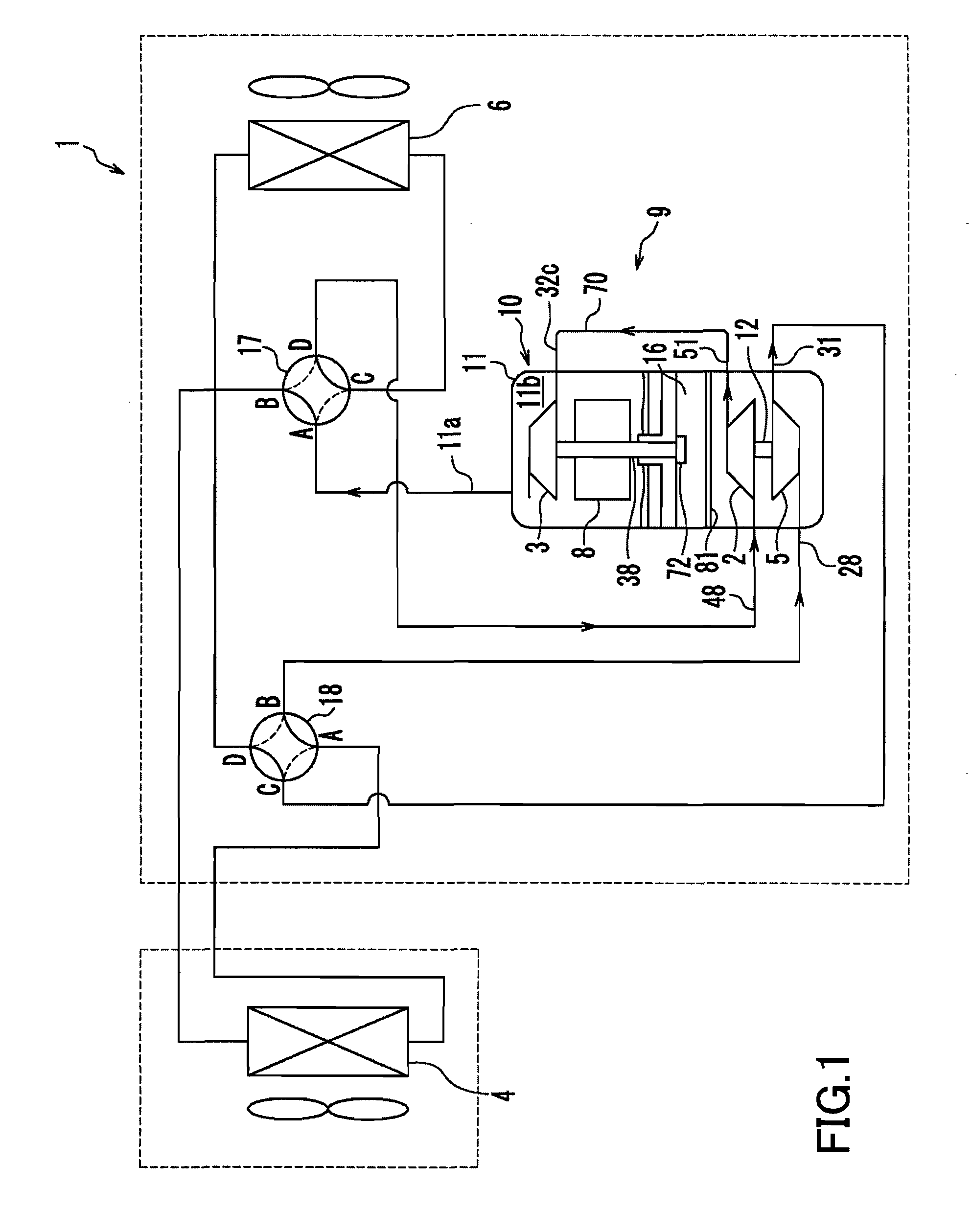

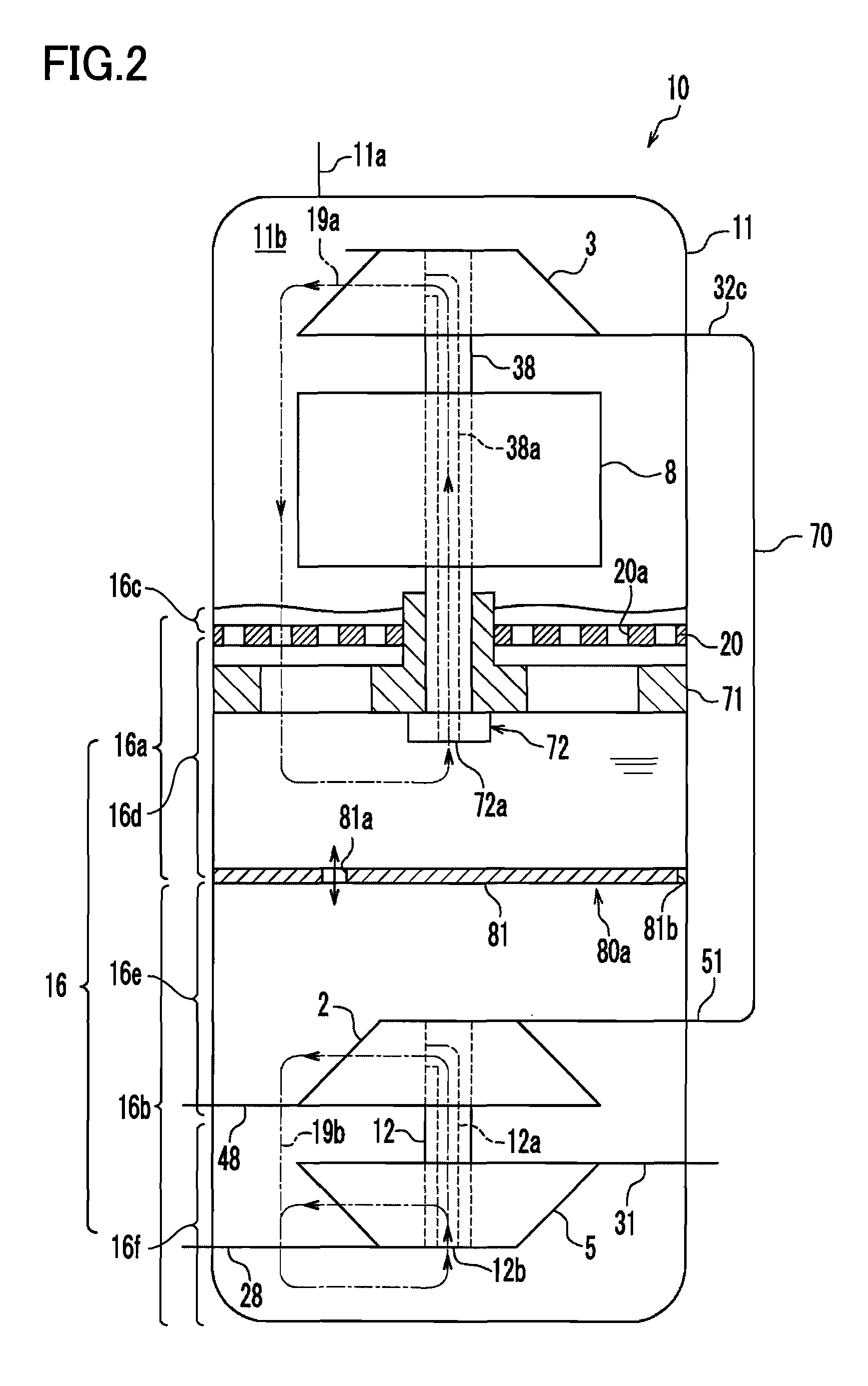

Fluid machine and refrigeration cycle apparatus having the same

InactiveUS20100132398A1Prevent heat transferHeat transferRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsWorking fluidEngineering

A fluid machine (10) includes: a closed casing (11) having an oil reservoir (16) in its bottom portion; a main compression mechanism (3) supplied with oil contained in an upper portion (16a) of the oil reservoir; a rotation motor (8); a main compression mechanism side shaft (38) for coupling the main compression mechanism (3) and the rotation motor (8); a mechanical power recovery mechanism (5) disposed below the upper portion (16a) and recovering mechanical power from a working fluid; a sub-compression mechanism (2) disposed below the upper portion (16a); a mechanical power recovery shaft (16) for coupling the mechanical power recovery mechanism (5) and the sub-compression mechanism (2); and a heat-insulating structure (80) located between the upper portion (16a) and the mechanical power recovery mechanism (5) and restricting flow of oil between the upper portion (16a) of the oil reservoir (16) and a lower portion (16b) of the oil reservoir in which the mechanical power recovery mechanism (5) is provided.

Owner:PANASONIC CORP

Heat exchanger and heat exchanging system

InactiveUS8826970B2Heat transferEfficient heat transferStationary conduit assembliesRefrigeration componentsPlate heat exchangerMechanical engineering

Owner:SHARP KK

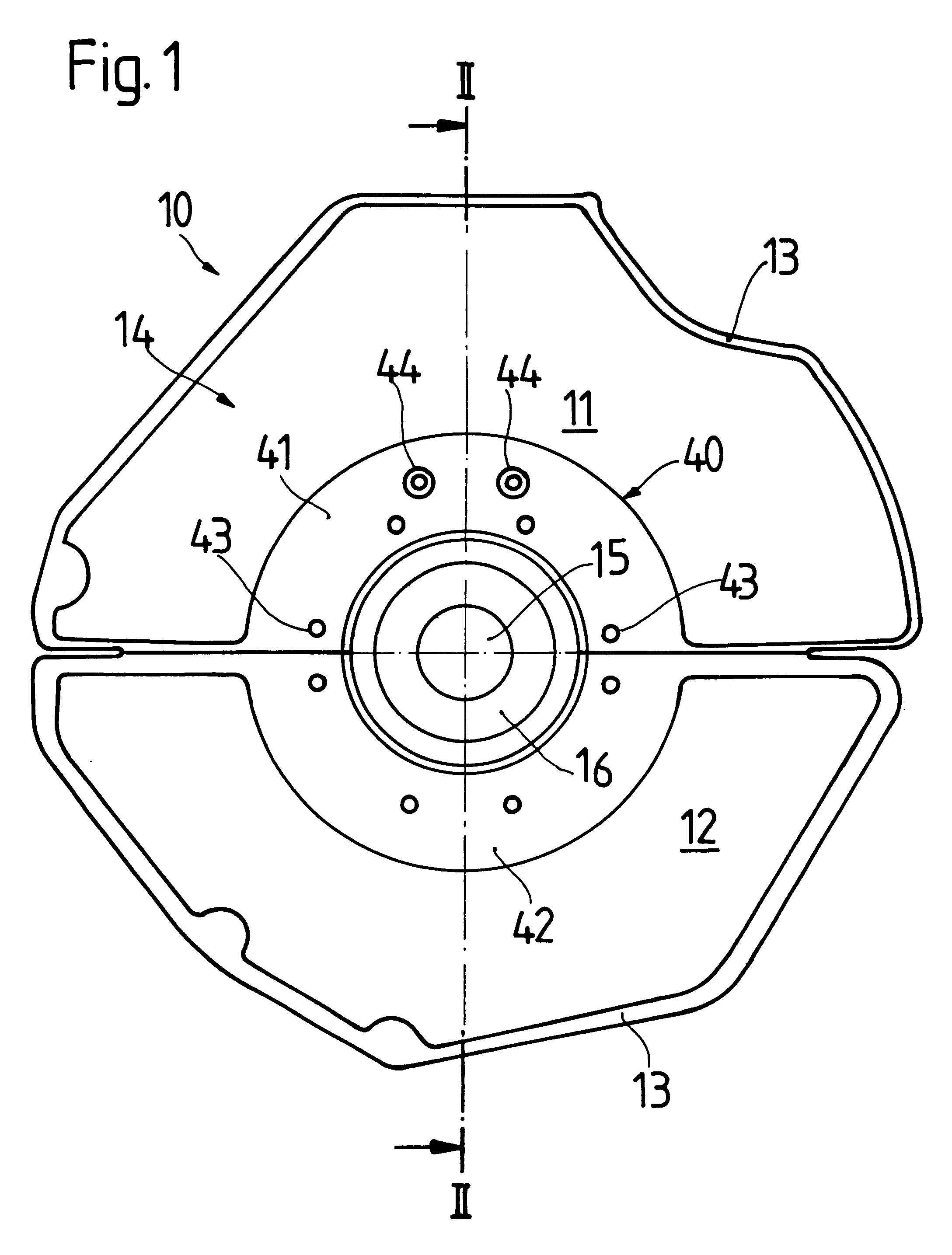

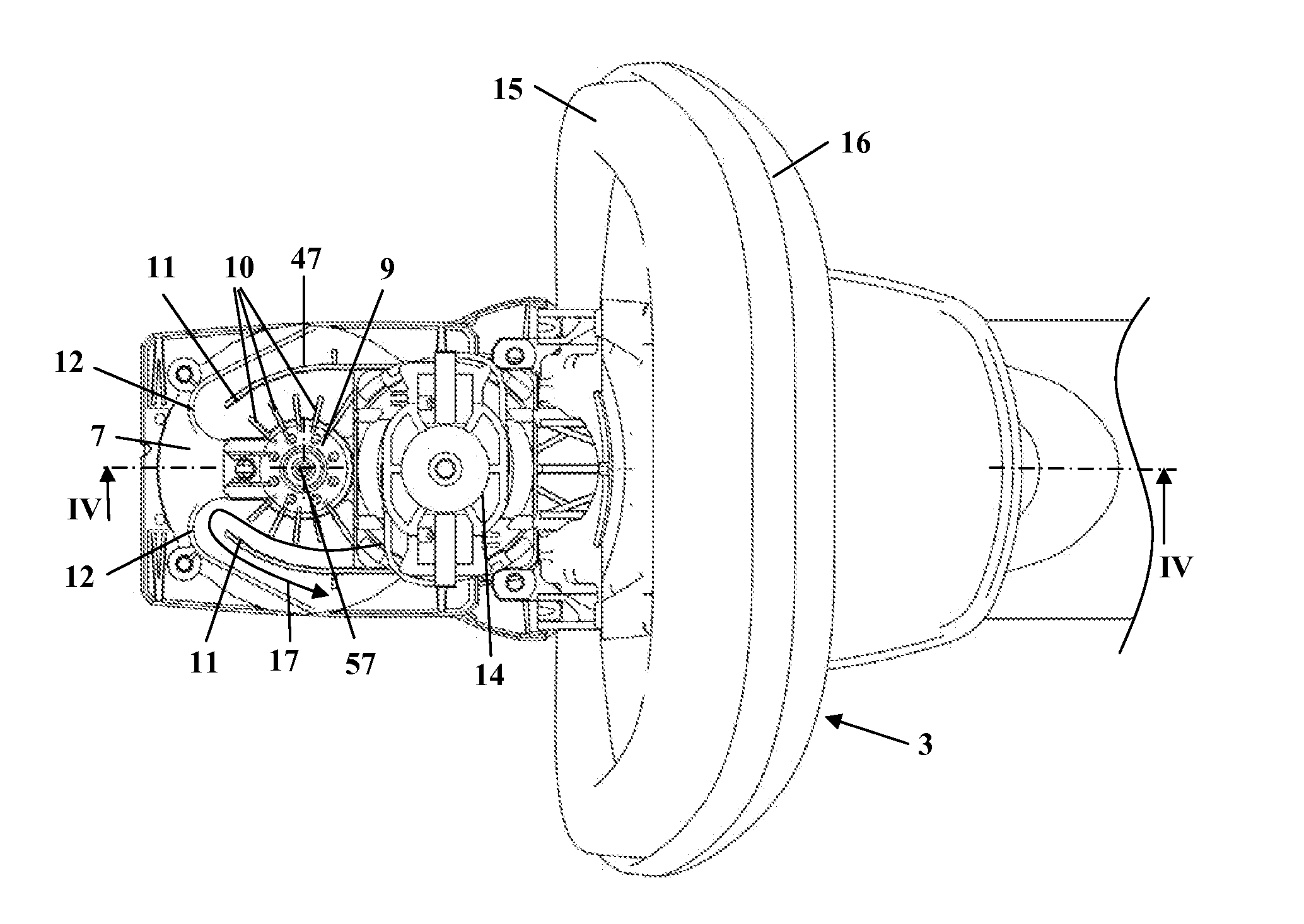

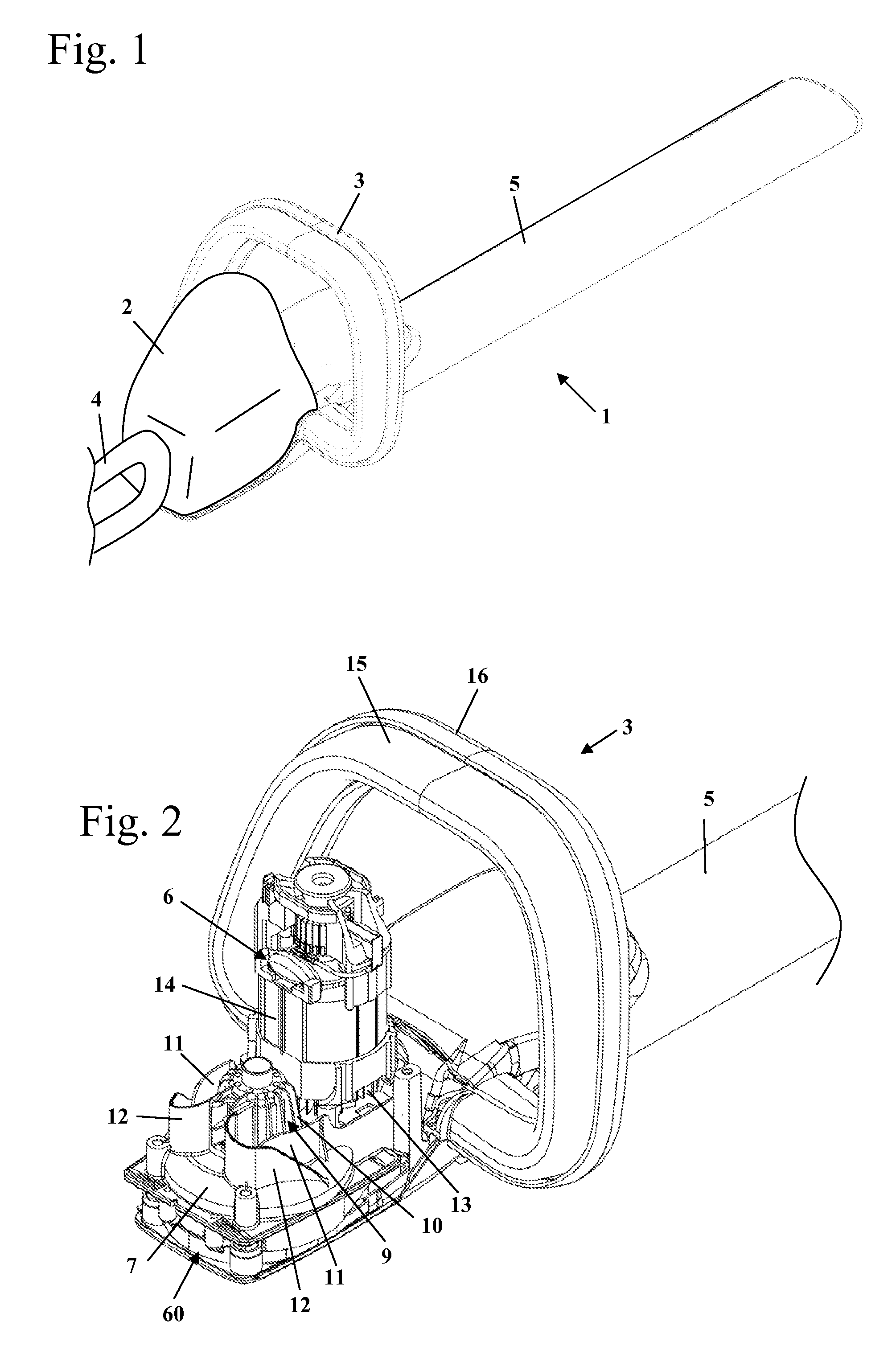

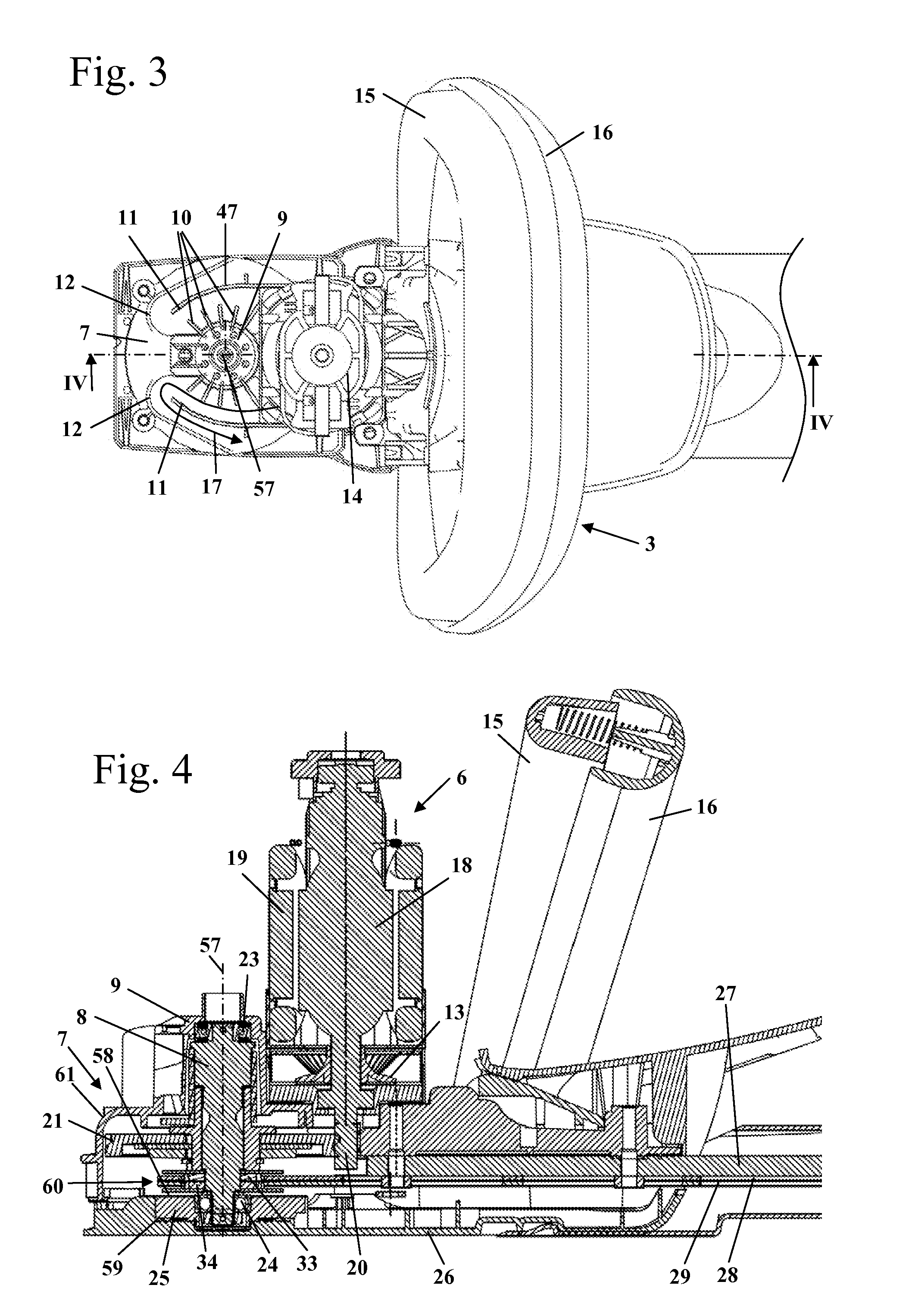

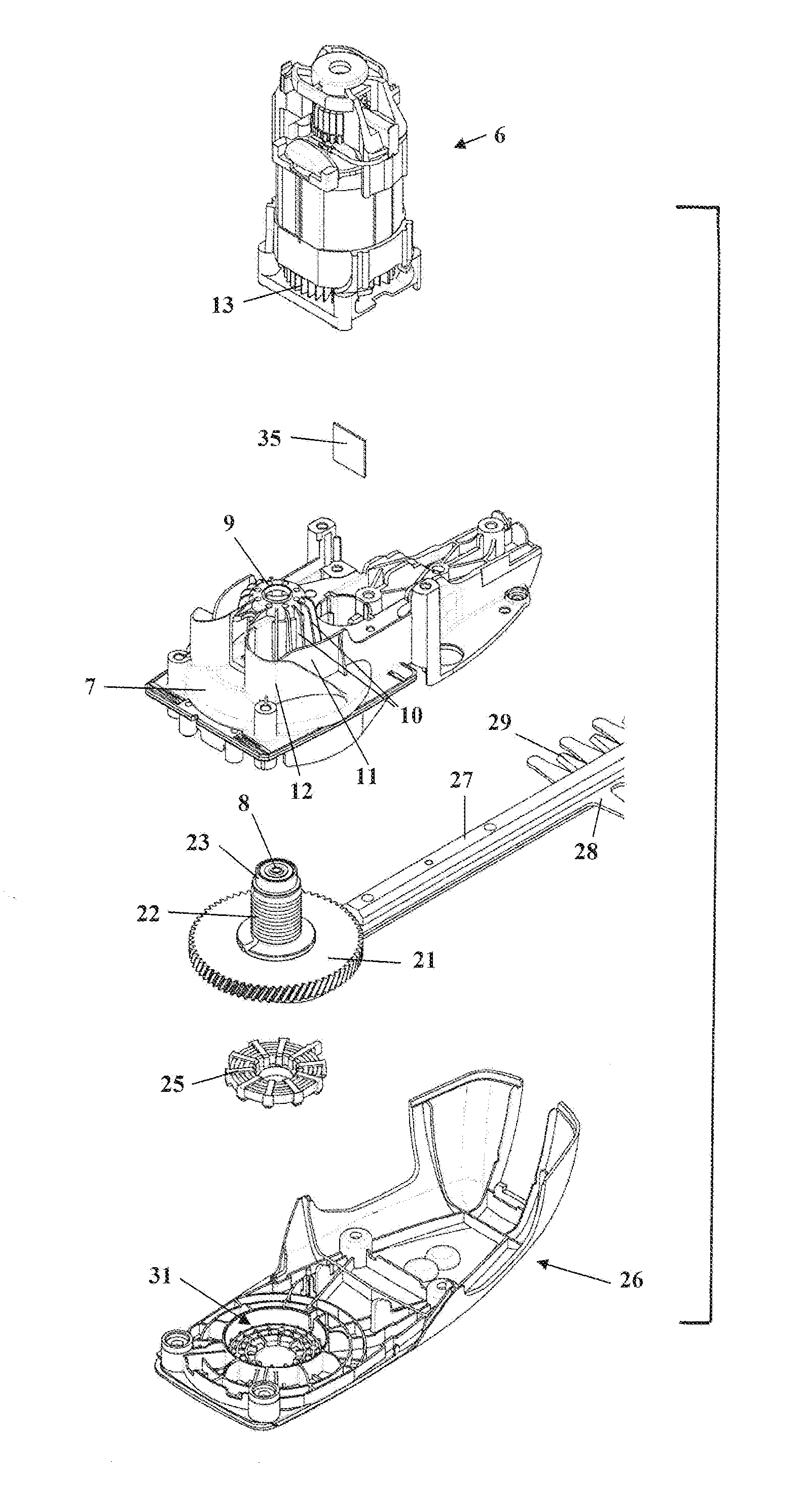

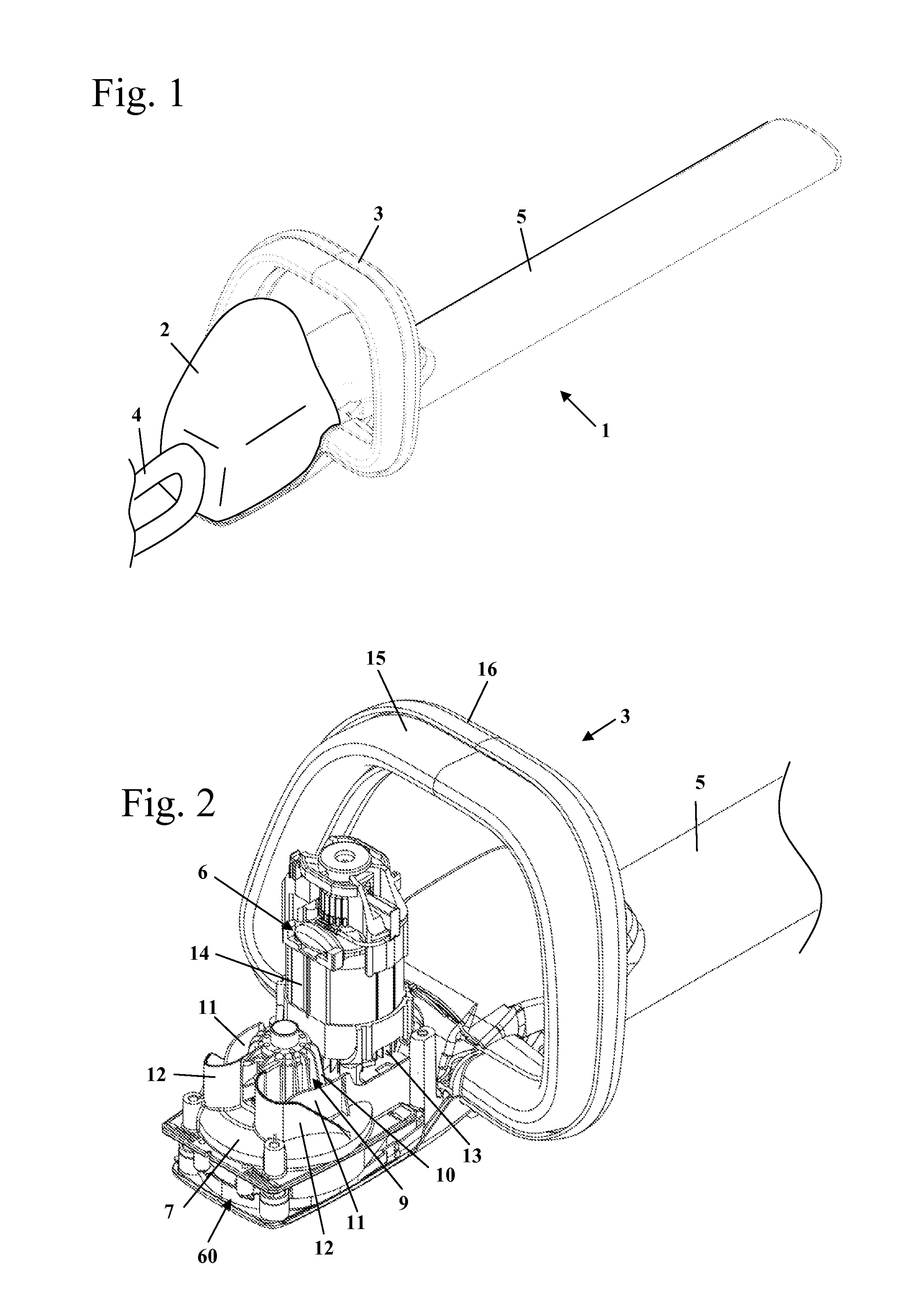

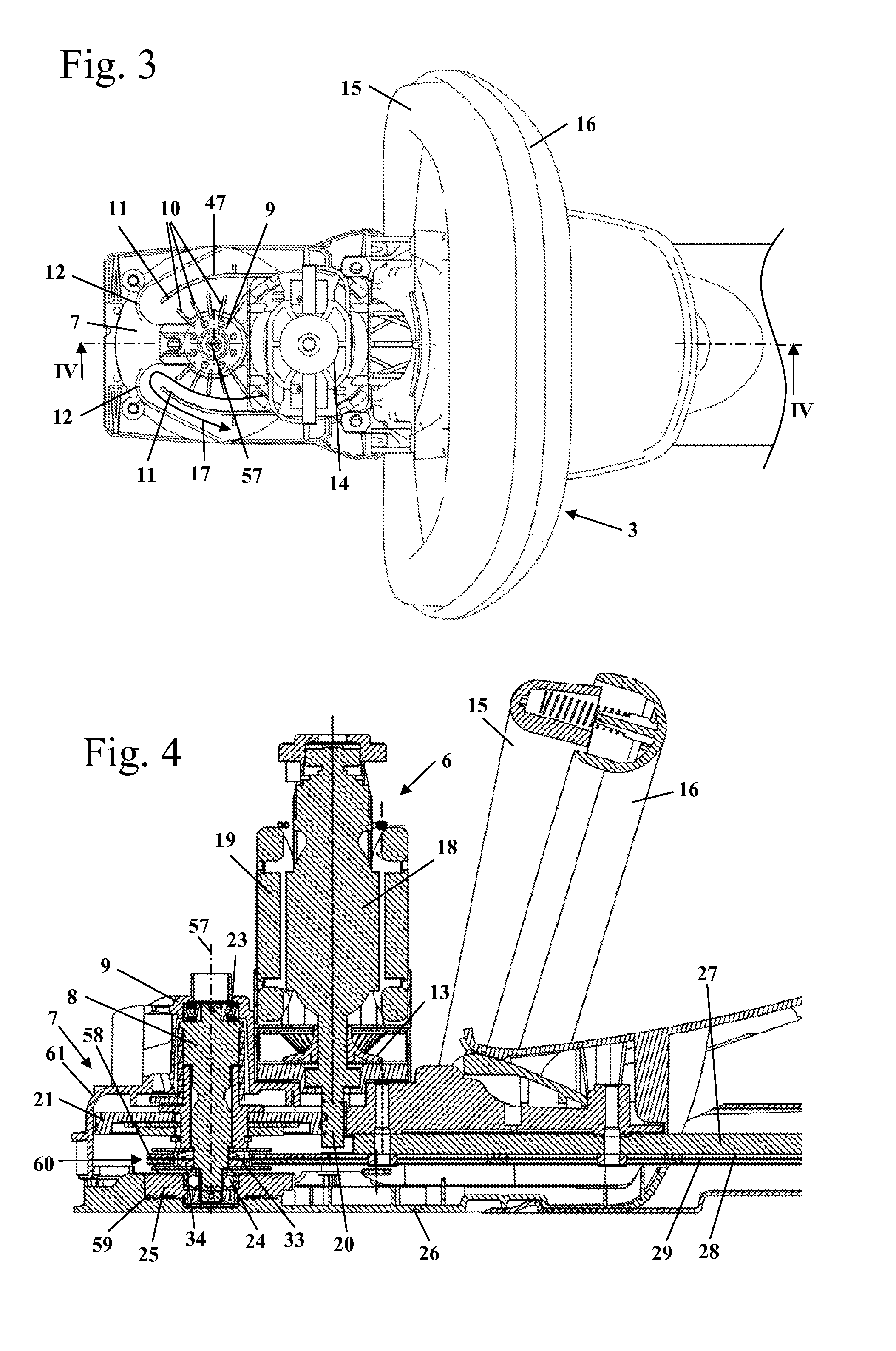

Hand-held power tool

ActiveUS9220201B2Simple configurationEasy to useDrilling rodsConstructionsPlastic materialsDrive shaft

A hand-held power tool has a power tool housing made at least partially of plastic material. A drive motor is arranged in the power tool housing and a drive shaft driven connected to the drive motor is provided. A tool member is connected to the drive shaft and driven by the drive motor through the drive shaft. A first bearing rotatably supports the drive shaft relative to the power tool housing. An intermediate element supports the first bearing relative to the power tool housing. The intermediate element is arranged in a receptacle of the power tool housing and is supported on a support surface relative to the bottom of the receptacle. The support surface is less than approximately 50% of an imaginary circular ring surface defined between an outer circumference of the first bearing and the circumcircle of the receptacle.

Owner:ANDREAS STIHL AG & CO KG

Industrial secondary refrigerant

The invention relates to an industrial secondary refrigerant. The industrial secondary refrigerant is composed of, by weight, 80 to 99% of glycol alkyl ether or propylene glycol alkyl ether compounds, 0.1 to 5% of a corrosion scale inhibitor and 0.9 to 10% function-adjusting liquid. According to the invention, the secondary refrigerant is added with the environment-friendly corrosion scale inhibitor which is harmless to the environment and human body, and the corrosion scale inhibitor can adsorb on metal surface and forms a physical adsorption protective film, so dissolved oxygen is blocked from diffusion to the metal surface; meanwhile, a compact passivation antirust film is generated through oxidation reduction reaction of the corrosion scale inhibitor with the metal surface, so metal oxidation is inhibited; moreover, the industrial secondary refrigerant provided by the invention also selects and uses the glycol alkyl ether or propylene glycol alkyl ether compounds with low viscosity, so effects of cold carrying and heat exchanging are guaranteed. The industrial secondary refrigerant in the invention is suitable for being used as the secondary refrigerant applied in industry under minus 80 to 200 DEG C, and an indirect heat transfer system in chemical industrial production and medicinal synthesis process. The secondary refrigerant is non-toxic and harmless, has excellent and safe heat transfer property and good fluidity at low temperature, does not precipitate and scale, and has the characteristics of environmental protection, cold carrying, heat transfer, corrosion inhibition, bacterial inhibition, low viscosity, corrosion resistance, etc.

Owner:CHAOYANG GUANGDA CHEM

Optical transducer for detecting liquid level

InactiveUS7259383B2Heat transferMinimize heat transferRadiation pyrometryInvestigating moving fluids/granular solidsAcute angleEngineering

Owner:OPTI SENSOR SYST

Heat transfer device

ActiveUS20170001492A1Efficient transferImprove heat transfer performanceAir-treating devicesSemiconductor/solid-state device detailsFiberCarbon fibers

A heat transfer device couples a heat generation member with a heat radiation member, and transfers heat from the heat generation member to the heat radiation member. The heat transfer device includes a composite member and a heat conductor. The composite member includes multiple carbon nanotubes and multiple carbon fibers which are mixed into a base material and complexed together, and the respective carbon fibers are crosslinked with each other by the carbon nanotubes. The heat conductor has one flexible end embedded in the composite member. The embedded one end is crosslinked with the carbon fibers in the composite member through the carbon nanotubes.

Owner:DENSO CORP

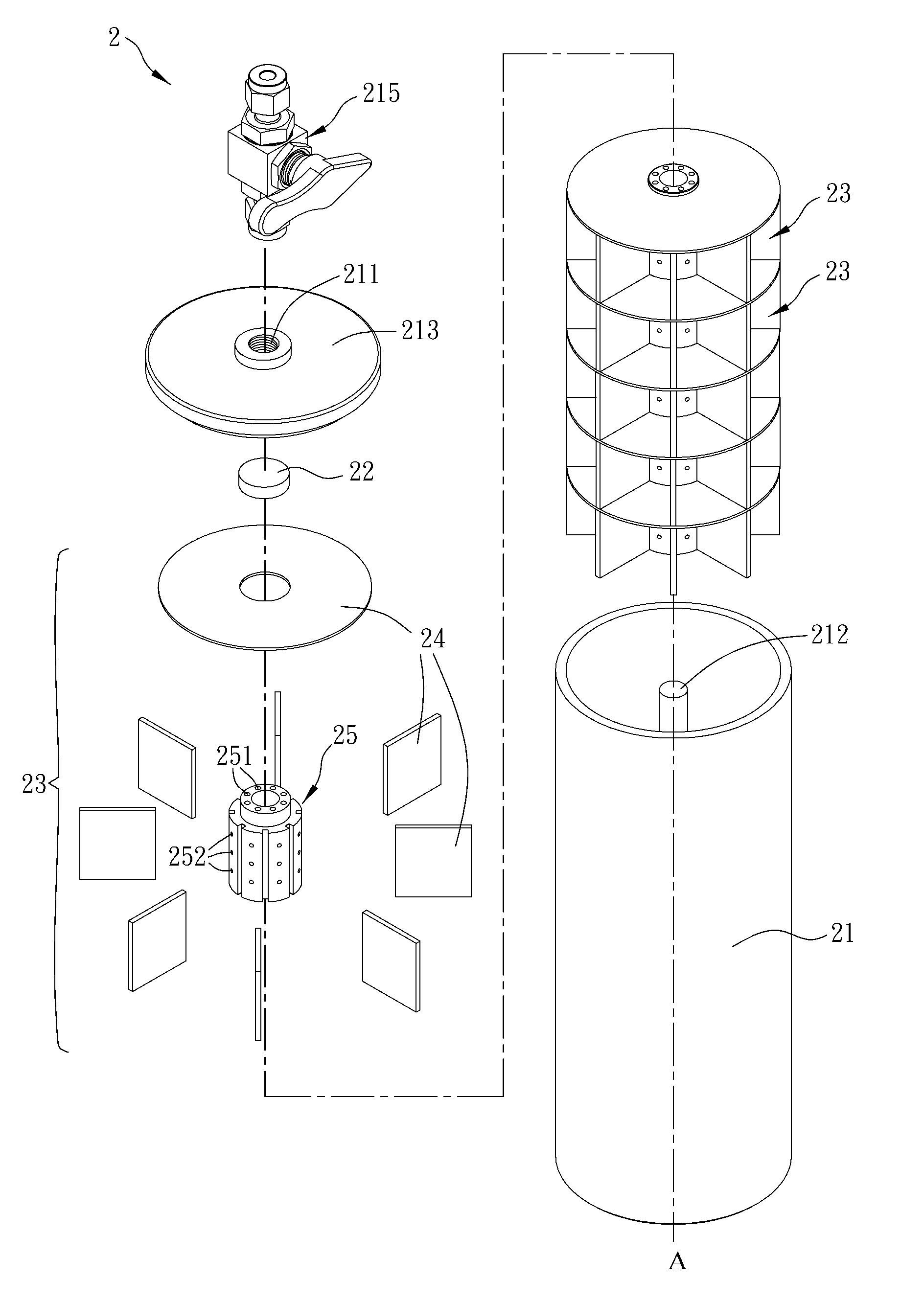

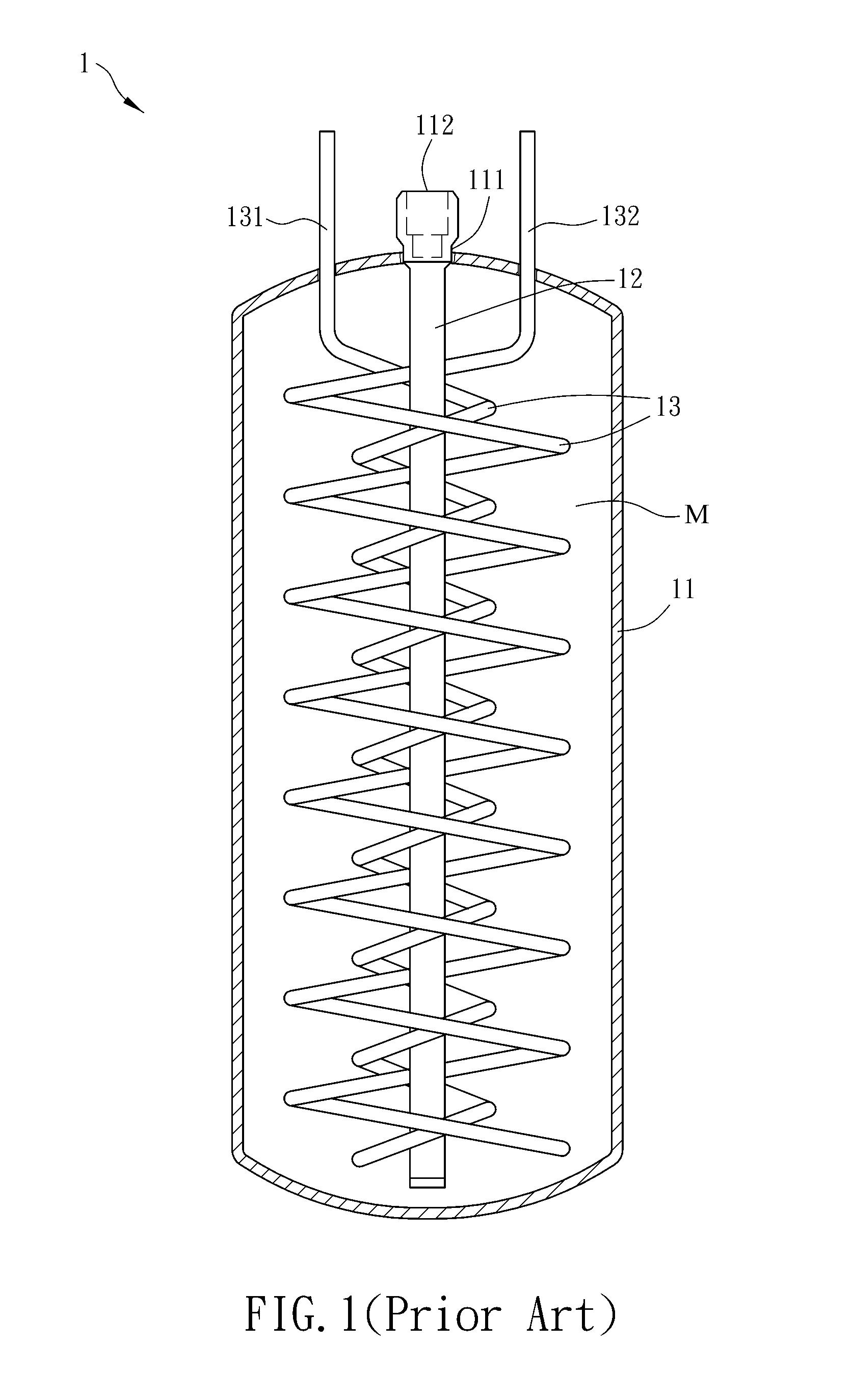

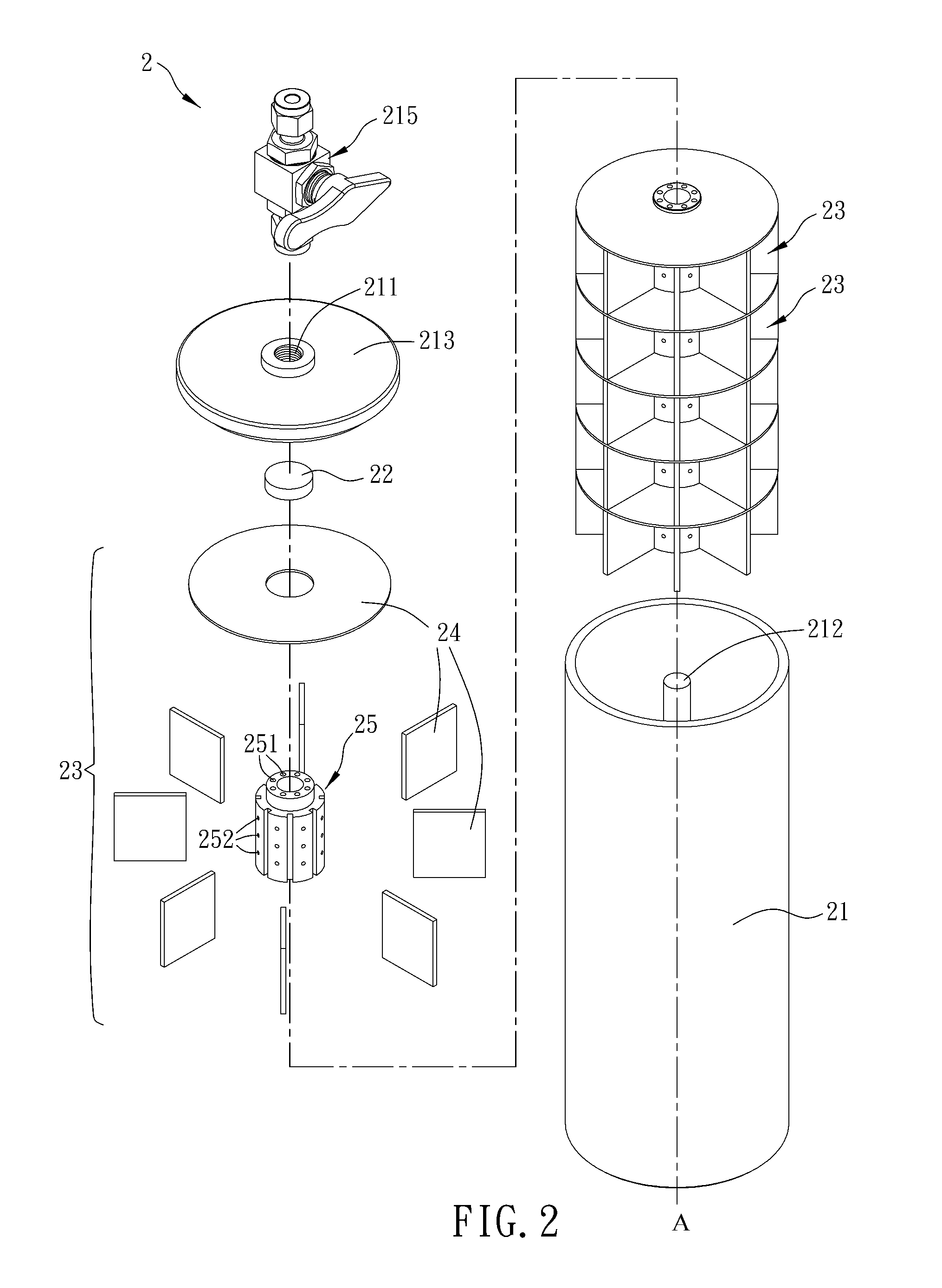

Hydrogen storage apparatus

InactiveUS20120211376A1Material be accumulate be easeEase phenomenonFixed capacity gas holdersLiquid materialEngineeringMechanical engineering

A hydrogen storage apparatus includes a canister, a first filter element and at least one hydrogen storage unit. The canister has an opening and a rod. The first filter element is disposed in the opening. The hydrogen storage unit is accommodated in the canister. The hydrogen storage unit includes a compartment structure and a hydrogen channel element. The compartment structure divides a space inside the canister, and the hydrogen channel element is pierced by the rod and connected with the compartment structure. The hydrogen channel element includes a plurality of axial channels and a plurality of radial channels. The axial channels are connected with the opening and the radial channels. The radial channels are connected with the space inside the canister.

Owner:NAT CENT UNIV

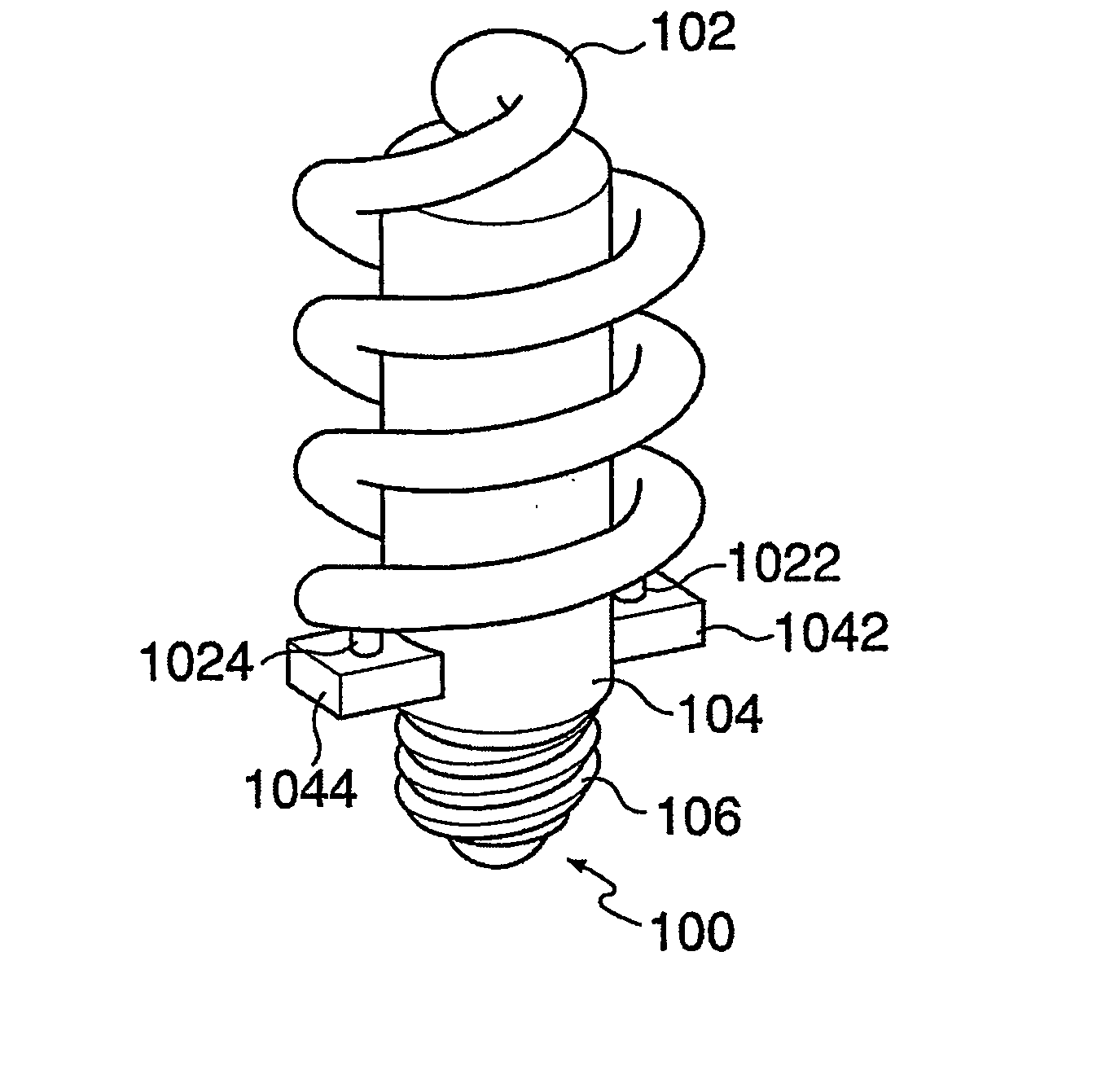

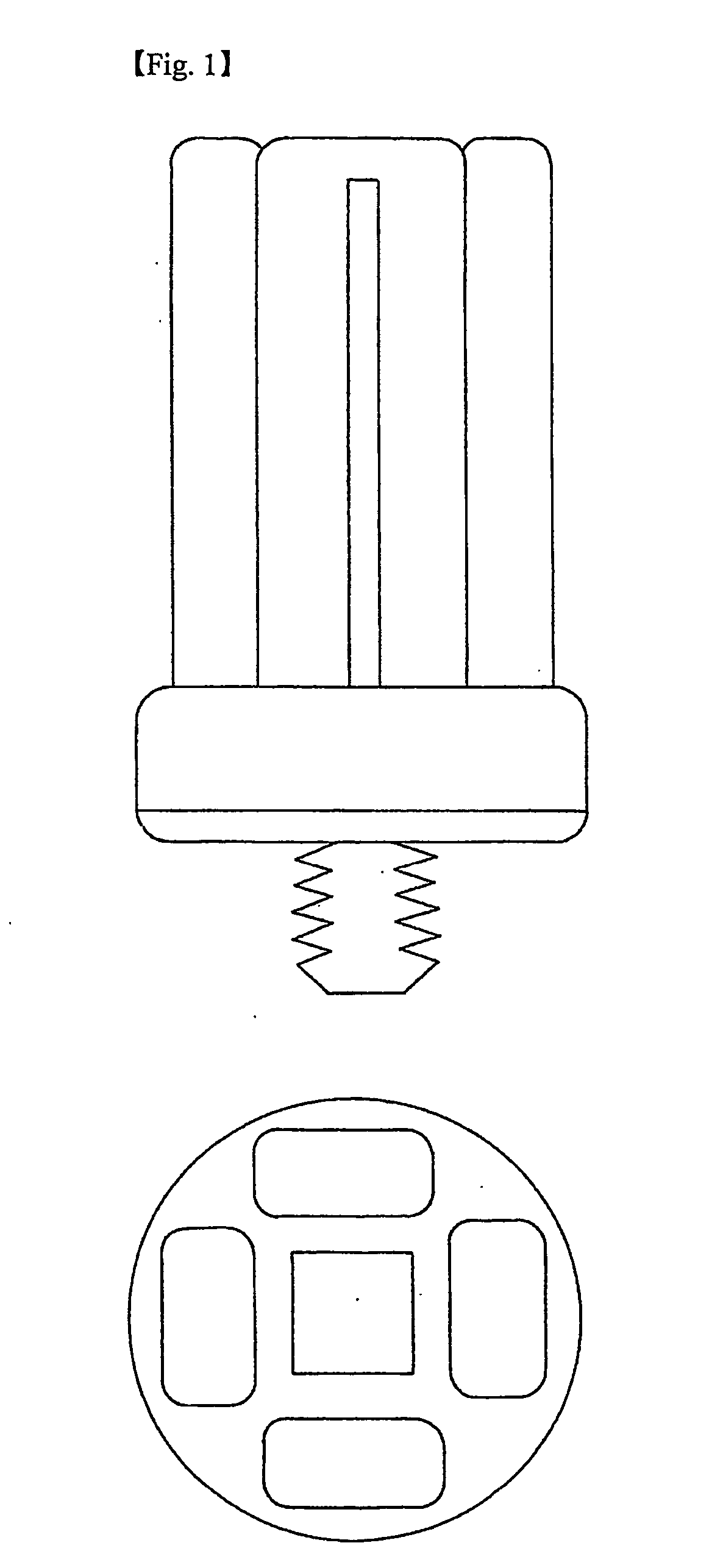

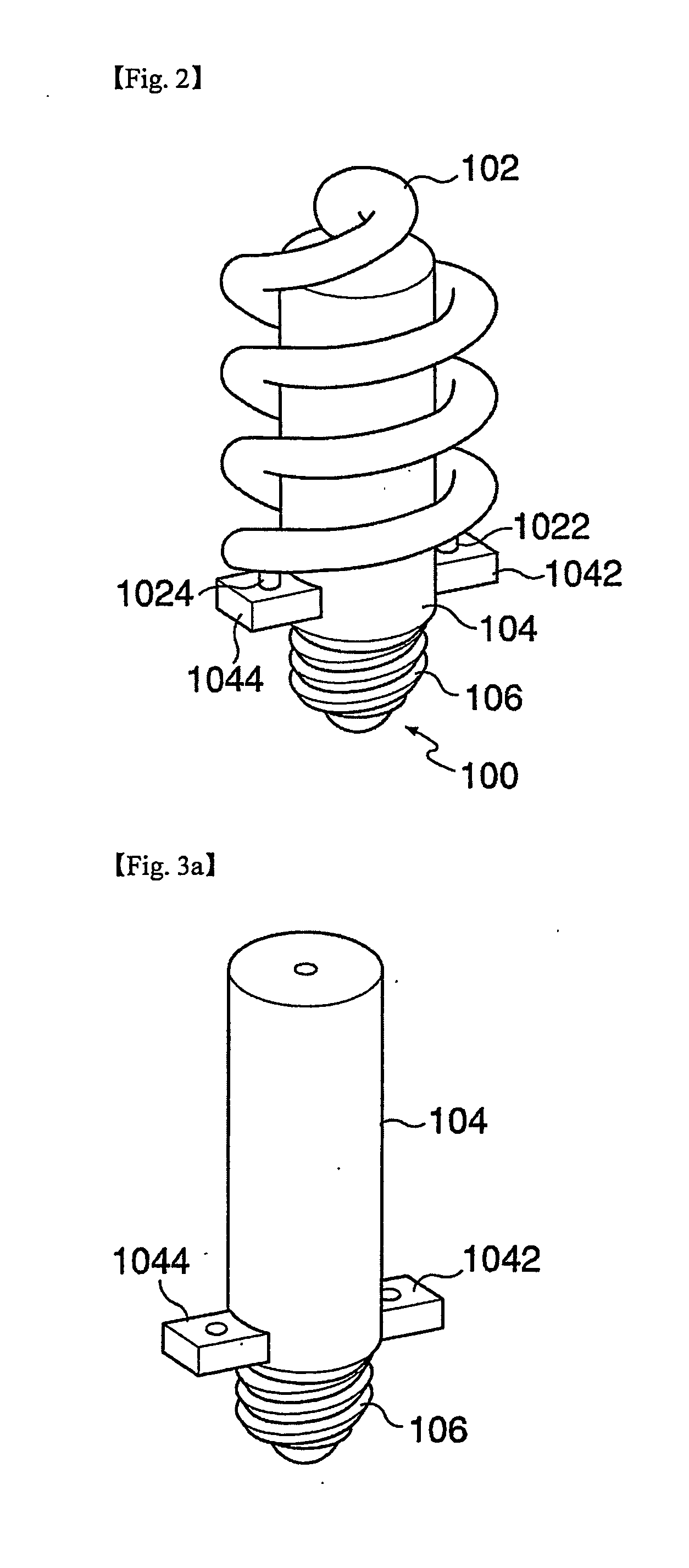

Compact-type discharge lamp

InactiveUS20060244359A1Heat transferMinimize heat transferDischarge tube luminescnet screensLamp detailsElectrical ballastEngineering

Owner:KANG SEONG JIN

Hand-Held Power Tool

ActiveUS20120234572A1Lowering support surfaceImprove cooling effectDrilling rodsConstructionsPlastic materialsDrive shaft

A hand-held power tool has a power tool housing made at least partially of plastic material. A drive motor is arranged in the power tool housing and a drive shaft driven connected to the drive motor is provided. A tool member is connected to the drive shaft and driven by the drive motor through the drive shaft. A first bearing rotatably supports the drive shaft relative to the power tool housing. An intermediate element supports the first bearing relative to the power tool housing. The intermediate element is arranged in a receptacle of the power tool housing and is supported on a support surface relative to the bottom of the receptacle. The support surface is less than approximately 50% of an imaginary circular ring surface defined between an outer circumference of the first bearing and the circumcircle of the receptacle.

Owner:ANDREAS STIHL AG & CO KG

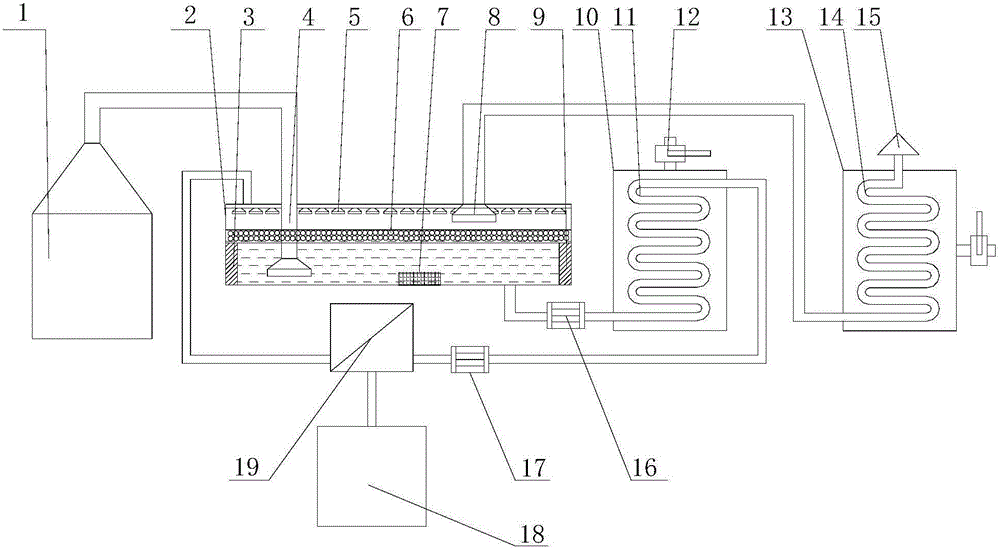

Boiler flue gas purifying and heat exchanging device and application method thereof

InactiveCN105749709AFully recycleReduce lossesCombination devicesGas treatmentActivated carbonFlue gas

The invention relates to a boiler flue gas purifying and heat exchanging device. The boiler flue gas purifying and heat exchanging device comprises a boiler, a flue gas purifying chamber, a first heat exchanger, a second heat exchanger and a reverse osmosis membrane set, wherein the boiler is communicated with a flue inlet in the flue gas purifying chamber through a flue gas pipeline, a flue gas outlet in the flue gas purifying chamber is communicated with the second heat exchanger, a liquid outlet in the flue gas purifying chamber is communicated with the first heat exchanger, the first heat exchanger is communicated with the reverse osmosis membrane set, and the reverse osmosis membrane set is communicated with a liquid inlet in the flue gas purifying chamber; the flue gas purifying chamber comprises a casing, a flue inlet pipe, a DC power supply, a negative electrode, a positive electrode, an activated carbon layer and a flue exhausting pipe; circulation liquid is stored in the casing; a coil pipe is arranged on the first heat exchanger, a heat exchanging flue pipe is arranged on the second heat exchanger, and an outlet in the heat exchanging flue pipe is communicated with a chimney. According to the boiler flue gas purifying and heat exchanging device disclosed by the invention, when flue gas is purified through the flue gas purifying chamber, the circulation liquid in the flue gas purifying chamber directly performs heat exchange with the flue gas; the circulation liquid is in direct contact with the flue gas, so that the heat exchanging efficiency is high, and the heat loss is low.

Owner:JIANGSU JINYUAN TENGFENG HEAT EXCHANGE EQUIP CO LTD

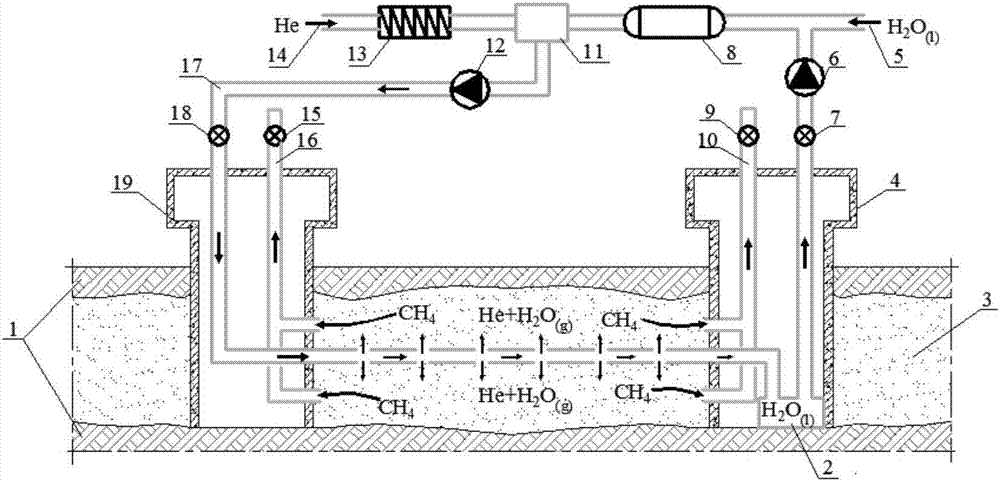

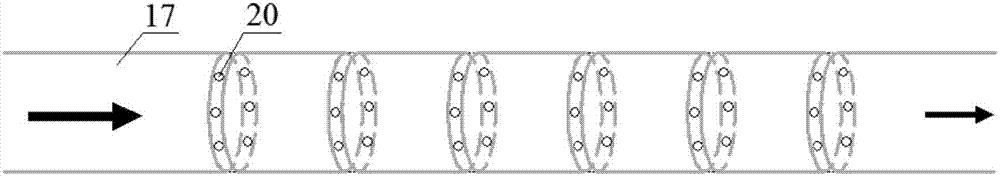

Thermal exploiting system and method for coalbed methane

InactiveCN107387045AImprove thermal conductivityIncrease desorption rateFluid removalFree energiesGas heater

The invention provides a thermal exploiting system and method for coalbed methane. The thermal exploiting system for the coalbed methane comprises a set of gas injecting system and a set of gas exploiting system; the gas injecting system comprises a gas heater, a booster pump, a high-temperature steam generator, a gas mixing box, two valves, a water storage tank, a water pumping pump and a ventilating pipeline; and the gas exploiting system comprises two gas exploiting pipelines and two valves. High temperature mixed gas is injected through the gas injecting system, heat is transferred to a coalbed, so that the temperature of the coalbed is increased to 50-80 DEG C, free energy of coalbed methane is improved and acting force between molecules is destroyed, the gas absorbed in a coalbed gap and on the surface of coal is desorbed, and the coalbed methane is obtained.

Owner:SUZHOU UNIV

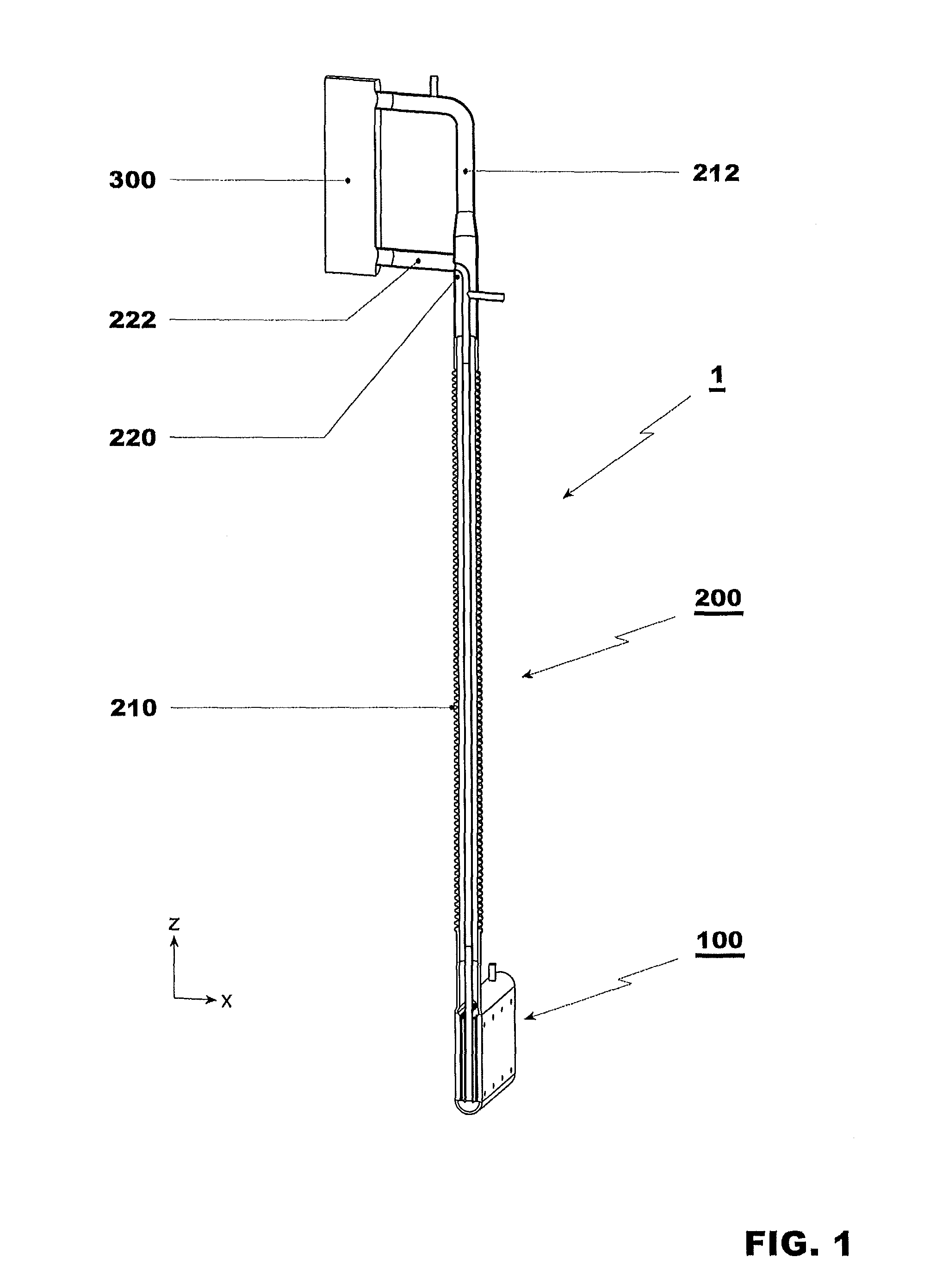

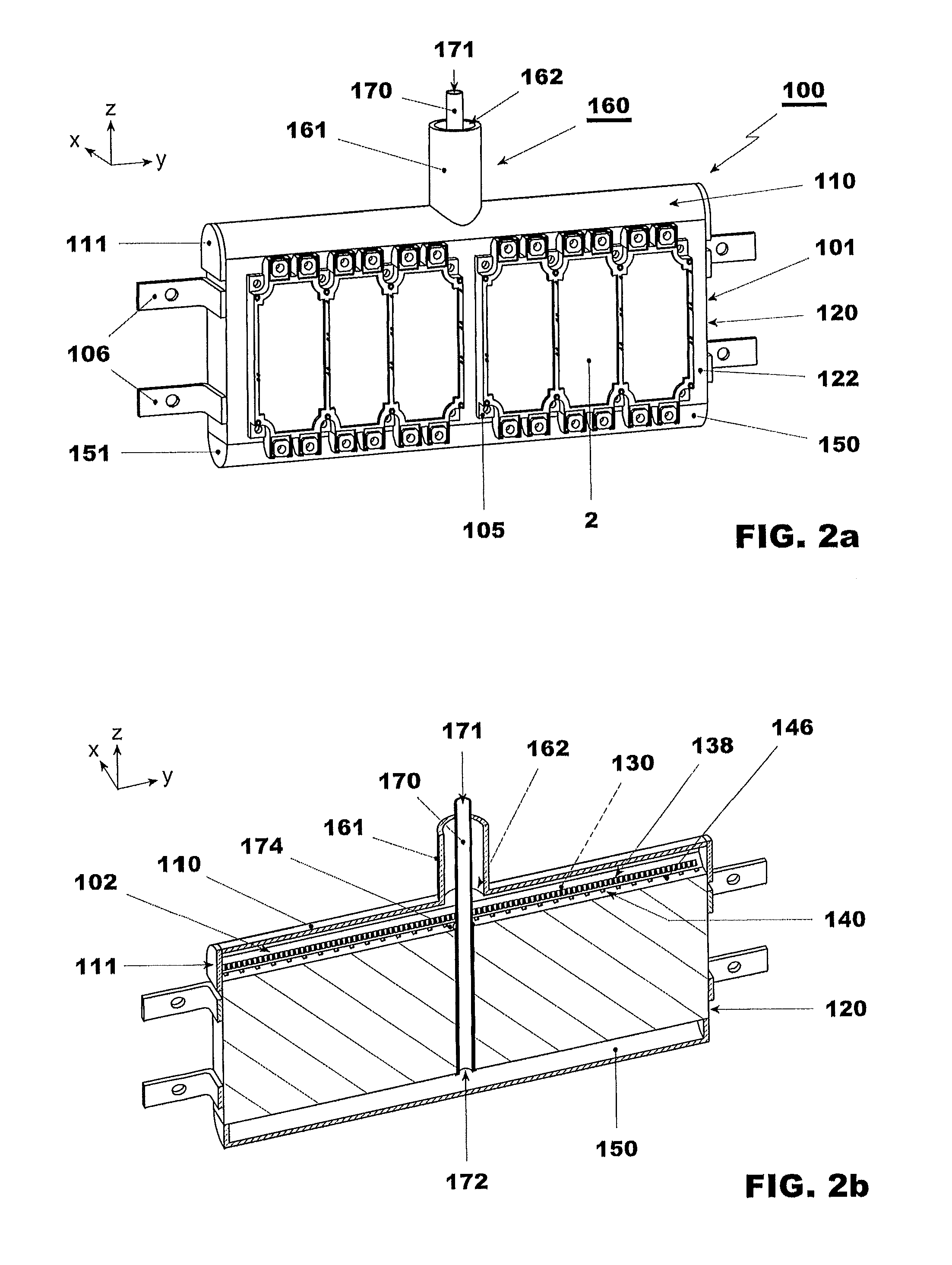

Evaporator and cooling circuit

ActiveUS8763681B2Heat transferPromote fluid circulationSolid-state devicesIndirect heat exchangersEvaporationReturn channel

An evaporator for a cooling circuit is provided, for cooling at least one heat emitting device by evaporation of a cooling fluid. The evaporator includes a top collector, a bottom collector, and an evaporator body. The evaporator body includes at least one thermoconducting wall that is thermally connectable to the at least one heat emitting device, a plurality of evaporation channels, and a plurality of return channels.

Owner:ABB (SCHWEIZ) AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com