Battery electrode, preparation method of battery electrode and battery

A battery electrode and battery technology, which is applied in the direction of battery electrodes, non-aqueous electrolyte battery electrodes, electrode carriers/collectors, etc., can solve the problems that heat cannot be transferred from the inside to the environment in time, and the battery has poor high-temperature performance, so as to reduce heat generation, Uniform dispersion and lower internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

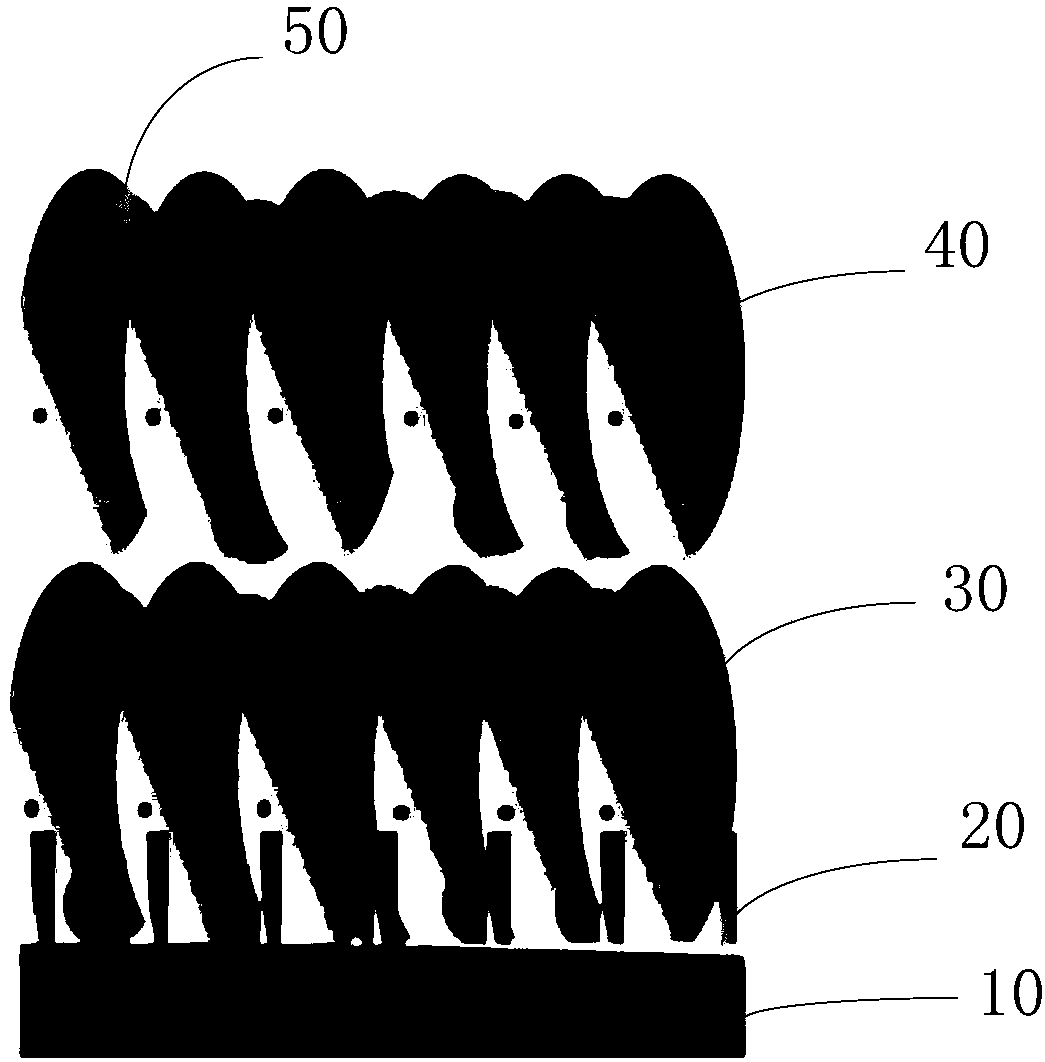

[0060] Correspondingly, an embodiment of the present invention also provides a method for preparing a battery electrode, comprising the following steps:

[0061] (1) A current collector is provided, and a thermally conductive modified layer is prepared on the current collector by a physical coating method, a chemical vapor deposition method, an evaporation deposition method or a sputtering method;

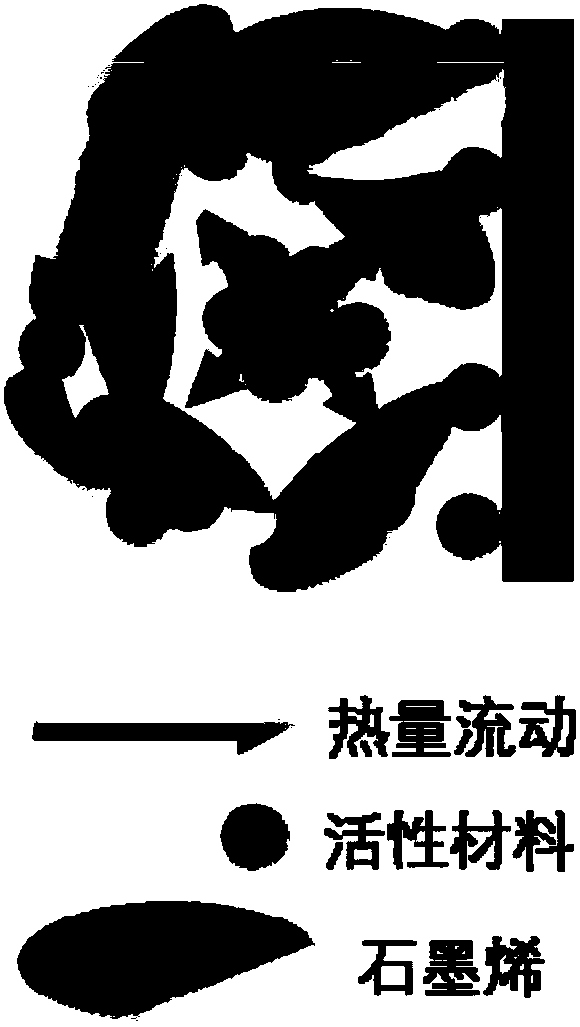

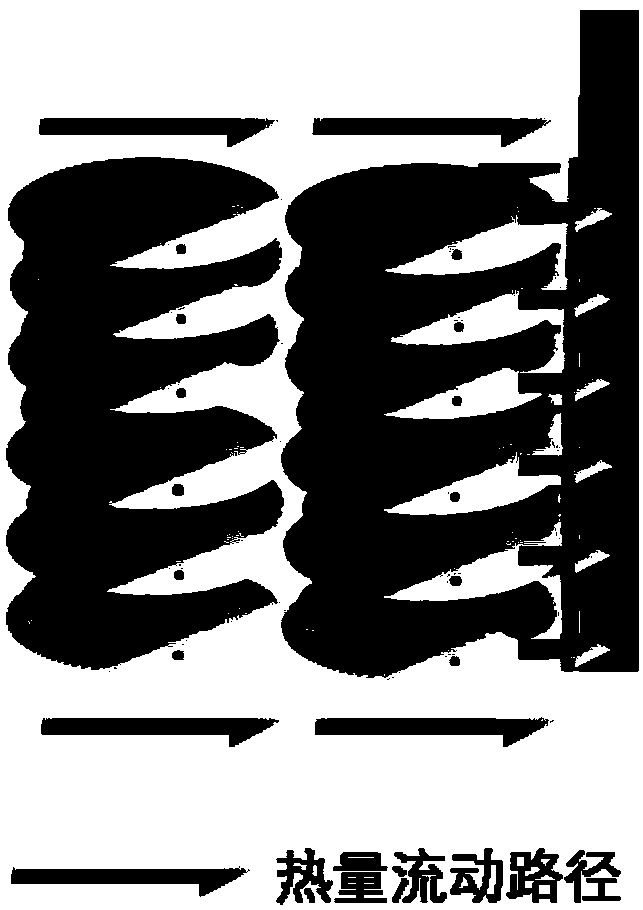

[0062] (2) Take graphene with a sheet-like structure, and prepare graphene surface-modified with magnetically responsive nano-dots by microwave synthesis, hydrothermal method, magnetron sputtering method, evaporation deposition method or chemical vapor deposition method;

[0063] (3) Mix the graphene whose surface is modified with magnetically responsive nano-dots with electrode active materials and binders to obtain a slurry, and apply the slurry evenly on the thermally conductive modification layer under the action of an external magnetic field surface, and dried under the action...

Embodiment 1

[0087] A method for preparing a battery electrode, comprising the following steps:

[0088] (1) Construction of copper current collector with graphene coating on the surface: soak copper foil (99.9% purity) in 1mol / L hydrochloric acid solution for 10 minutes to remove surface impurities, rinse and dry repeatedly with clean water, then place copper foil in N 2 In a protective atmosphere, the temperature was raised to 600° C. within 30 minutes, and 5% (oxygen accounted for the volume fraction of the entire incoming gas flow) trace oxygen was introduced for 1 hour to perform micro-oxidation treatment to form a three-dimensional current collector with CuO nanowire arrays grown on the surface. Then adjust the atmosphere to H 2 / Ar, heat up to 700°C, and introduce 3% methane / Ar mixed gas (3% is the volume fraction of methane in the total gas), cool down to room temperature naturally after reacting for 1h, and obtain a copper current collector with a graphene coating on the surface,...

Embodiment 2

[0095] A method for preparing a battery electrode, comprising the following steps:

[0096] (1) Construction of aluminum-magnesium alloy current collector with graphene coating on the surface: soak the aluminum-magnesium alloy current collector in 0.1mol / L hydrochloric acid solution for 5 minutes to remove impurities on the surface of the current collector, rinse and dry repeatedly with clean water. Then place the aluminum-magnesium alloy current collector in H 2 In the / Ar mixed atmosphere, the temperature was raised from room temperature to 450 °C at a rate of 10 °C / min, and the temperature was kept constant for 1 hour to remove impurity salts that may remain in the current collector. Then the temperature was raised to 700°C at 3°C / min, and 3% acetonitrile / Ar mixed gas was introduced, and the temperature was naturally cooled to room temperature after 1 hour of reaction to obtain an aluminum-magnesium alloy current collector with a graphene coating on the surface;

[0097] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness dimension | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com