LED light-emitting module with liquid metal heat dispersion heat sink

A liquid metal, light-emitting module technology, applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve problems such as the advent of high-power LED products, and achieve the effects of simple structure, low noise and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

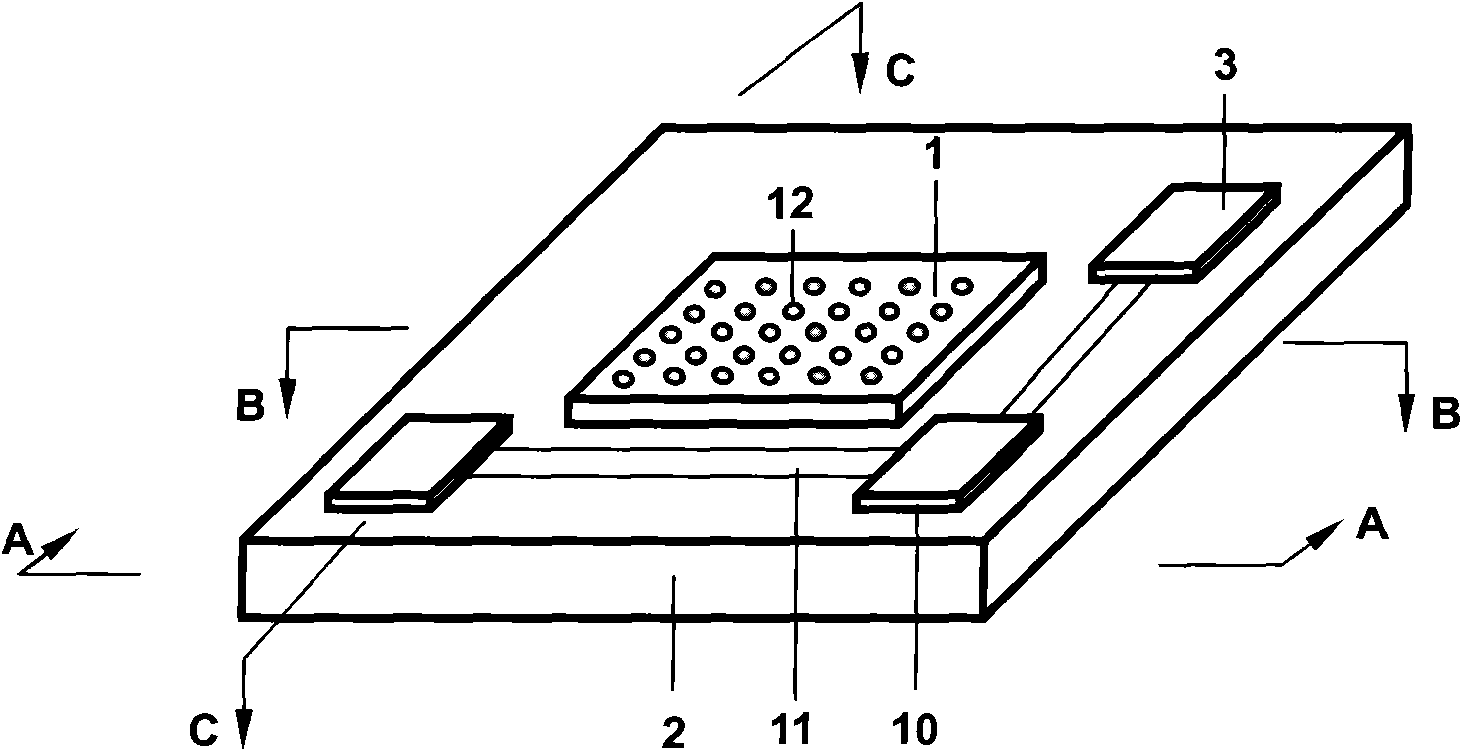

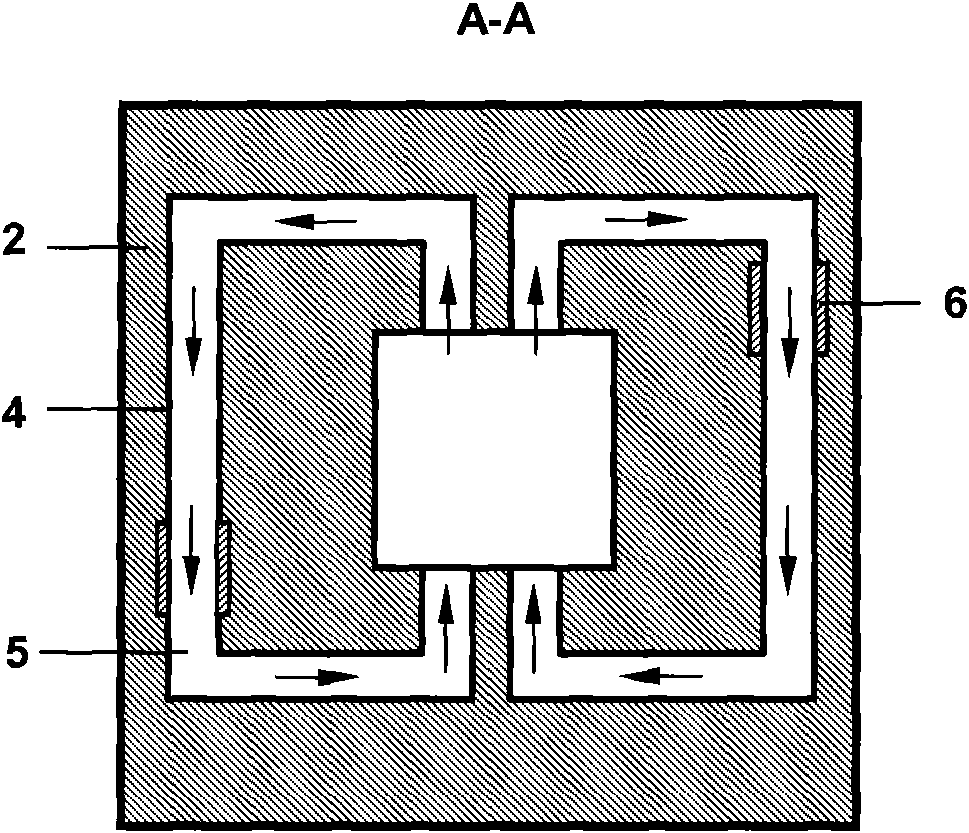

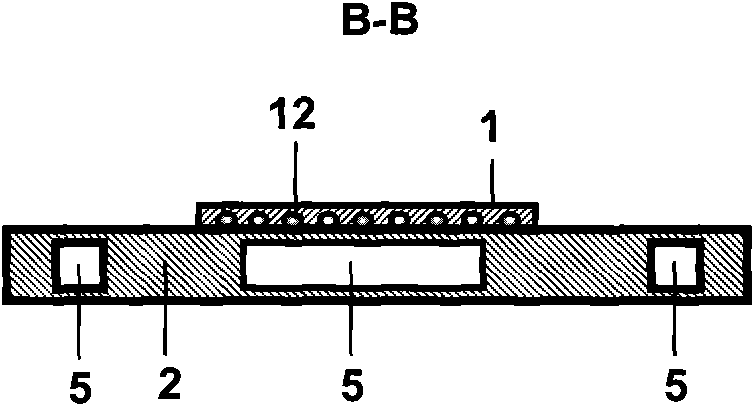

[0036] figure 1 It is a structural schematic diagram of the LED light-emitting module with liquid metal heat dissipation heat sink of the present invention, and it is also an embodiment of the present invention; Picture 1-1 for figure 1 A-A cross-sectional schematic diagram of ; Figure 1-2 for figure 1 B-B cross-sectional schematic diagram when the middle light-emitting module 1 and the heat sink flat plate 2 are manufactured separately; Figure 1-3 for figure 1 The C-C cross-sectional schematic diagram of ; Figure 1-4 for figure 1 The B-B cross-sectional schematic diagram of the middle light-emitting module 1 and the heat sink flat plate 2 when they are made into an integrated structure; it can be seen from the figure that the LED light-emitting module with liquid metal heat dissipation heat sink of the present invention includes:

[0037] An LED light-emitting module 1; the LED light-emitting module 1 can be directly processed from the market after purchasing basic ...

Embodiment 2

[0054] attached figure 2 , diagram 2-1 and Figure 2-2 It is a structural schematic diagram of another embodiment of the present invention. As can be seen from the figure, all structures of this embodiment are the same as those of Embodiment 1 except for the difference of adopting multiple parallel hollow runners 4, so in appearance figure 2 with the aforementioned figure 1 unanimous. At this time, the cross-section of the hollow flow channel 4 is circular, and the radius can be 10nm-1cm. At this time, the number of multi-strand hollow flow channels 4 at the place where the heat sink flat plate corresponds to the LED light-emitting module can be between 1 and 1000; The advantage is that, on the one hand, the amount of liquid metal fluid can be reduced and the cost of heat sink can be reduced; on the other hand, the flow of fluid in this hollow flow channel can achieve the maximum heat transport capacity.

[0055] In the present invention, the nano- and micron-scale holl...

Embodiment 3

[0057] attached image 3 It is a structural schematic diagram of yet another embodiment of the present invention. As can be seen from the figure, all structures of this embodiment are the same as those of Embodiment 1 except that the driving direction of the driving pump (electromagnetic pump) is changed. The drive can be used to drive the flow of the liquid metal fluid in different directions and structures, so as to complete the delivery of LED heat to different directions or locations. For example, in this embodiment, the liquid metal fluid mainly flows along a direction perpendicular to the LED light-emitting module; while in Embodiment 1 or 2, the liquid metal fluid mainly flows along a direction parallel to the LED light-emitting module. The reason why such a structure is adopted in this embodiment is mainly considering that in some occasions, when the size of the LED light-emitting module is limited in the lateral direction, the heat can be transported to the direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com