Liquid filter substrate

A liquid filter and substrate technology, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of rising filtration pressure, unstable water permeability, unable to maintain porous structure, etc., to achieve stable liquid permeability , The effect of excellent liquid permeability and excellent capture performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

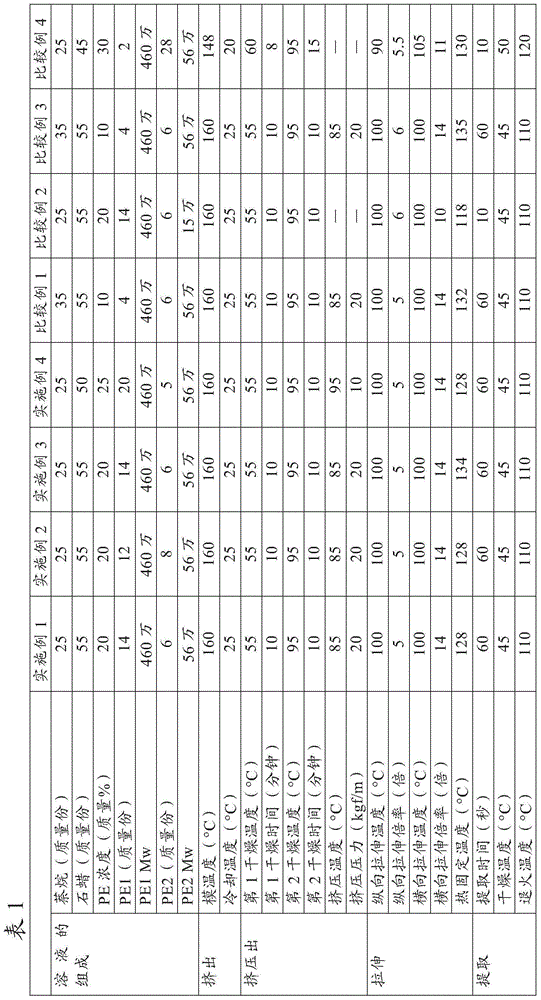

[0116] A polyethylene composition obtained by mixing 14 parts by mass of ultrahigh molecular weight polyethylene (PE1) having a mass average molecular weight of 4.6 million and 6 parts by mass of high density polyethylene (PE2) having a mass average molecular weight of 560,000 was used. A polyethylene solution was prepared by mixing with a previously prepared mixed solvent of 55 parts by mass of liquid paraffin and 25 parts by mass of decalin (decalin) so that the concentration of the total amount of polyethylene resin would be 20% by mass.

[0117] The polyethylene solution was extruded from a die in a sheet form at a temperature of 160° C., and while cooling the extrudate in a water bath at 25° C., a water flow was set on the surface of the water bath, thereby A gel-like sheet (base tape) was prepared while the mixed solvent discharged from the gelled sheet in the water bath and suspended on the water surface did not reattach to the sheet. The base tape was dried at 55°C for...

Embodiment 2

[0122] In Example 1, polyethylene obtained by mixing 12 parts by mass of ultra-high molecular weight polyethylene (PE1) with a mass average molecular weight of 4.6 million and 8 parts by mass of high density polyethylene (PE2) with a mass average molecular weight of 560,000 was used. Except for the composition, a polyolefin microporous membrane was obtained in the same manner as in Example 1.

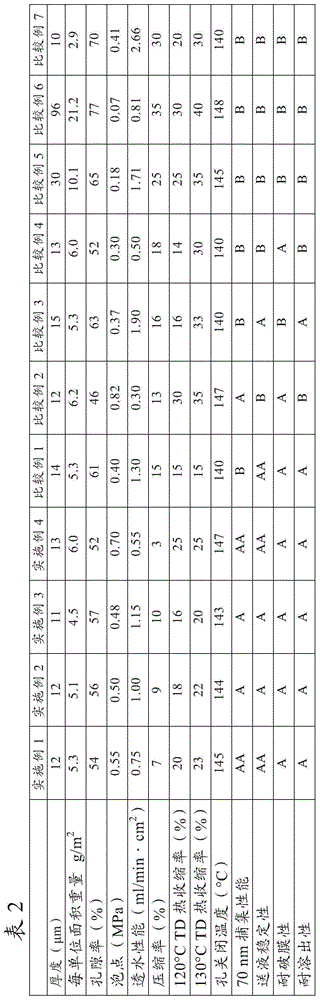

[0123] The obtained polyolefin microporous membrane has excellent trapping performance (the trapping rate of polystyrene particles with a particle diameter of 30nm is more than 80%), and has excellent water permeability and liquid delivery stability (the rate of change of water permeability 15% or less).

Embodiment 3

[0125] In Example 1, the polyolefin microporous membrane was obtained in the same manner as in Example 1 except that the heat treatment (heat setting) temperature after biaxial stretching was set to 134°C.

[0126] The obtained polyolefin microporous membrane has excellent trapping performance (the trapping rate of polystyrene particles with a particle diameter of 30nm is more than 80%), and has excellent water permeability and liquid delivery stability (the rate of change of water permeability 15% or less).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com