Bacterium resisting type high water absorption resin and preparation method thereof

A super absorbent resin, soluble technology, applied in the field of functional polymer materials, can solve the problems affecting the balance of SAP performance, adverse effects of SAP application performance, inability to effectively inhibit bacterial growth, etc., to improve wettability, improve Liquid absorption speed and liquid flow performance, and the effect of improving the rate of salt water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

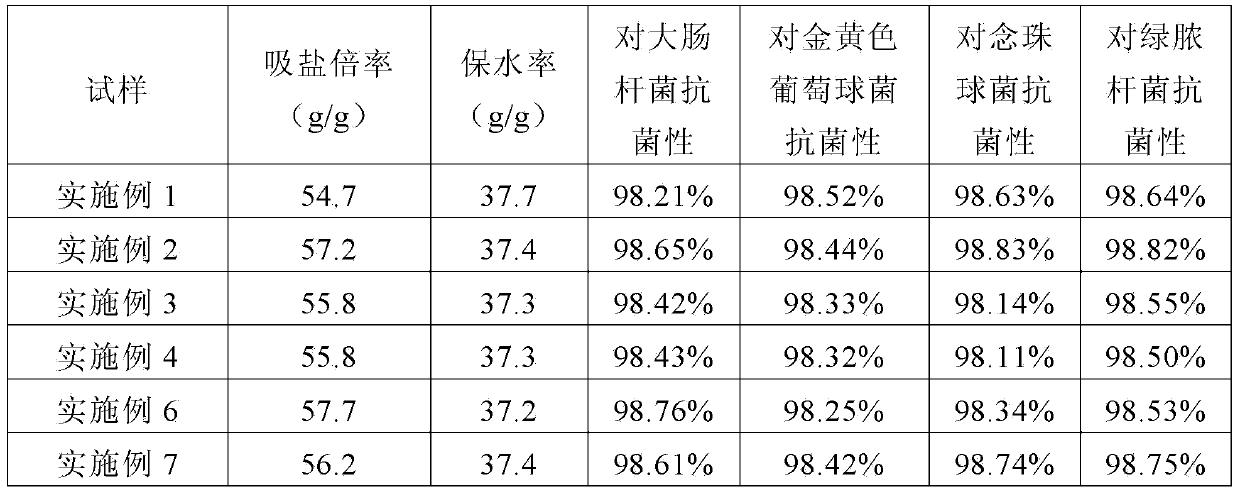

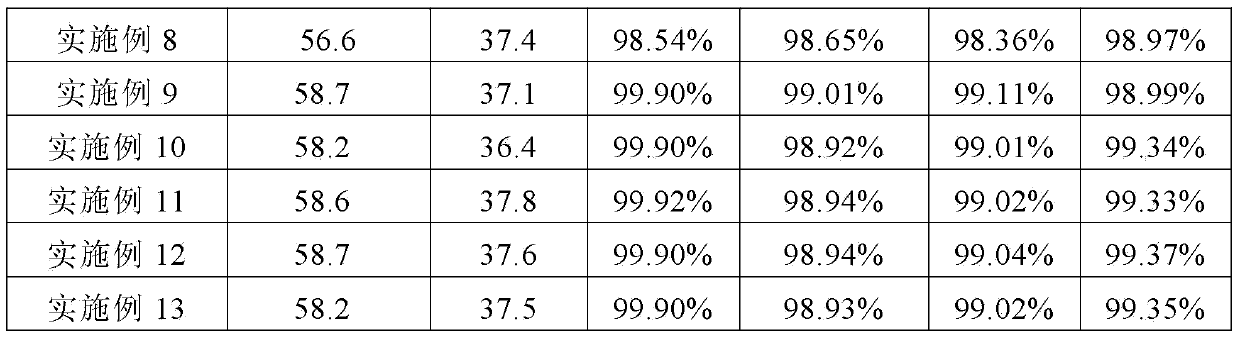

Examples

Embodiment 1

[0042] Add 500g of acrylic acid and 180g of deionized water into a 2000mL four-necked flask with a stirrer, which is equipped with a dropping funnel and a thermometer. Under the condition of external cooling and temperature control lower than 50°C, 600 g of aqueous sodium hydroxide solution with a mass concentration of 32% was added dropwise to the flask with a dropping funnel. After neutralization, add 25g of 2wt% N,N'-bisacrylamide and 1wt% cetyltrimethylammonium chloride solution, mix well, pour the neutralization solution into a 2000mL beaker, and then pass nitrogen gas for 30 Minutes, then heated to 55°C, and quickly added polymerization initiators successively under stirring, that is, 15g each of 10wt% ammonium persulfate solution and 10wt% sodium bisulfite solution, and the reaction was completed after 10min to obtain a polymer, which was kept for half an hour Then take it out. Spray into the granulation aid solution, use a small meat grinder to granulate the obtained ...

Embodiment 2

[0044] Add 500g of acrylic acid and 180g of deionized water into a 2000mL four-necked flask with a stirrer, which is equipped with a dropping funnel and a thermometer. Under the condition of external cooling and temperature control lower than 50°C, 600 g of aqueous sodium hydroxide solution with a mass concentration of 32% was added dropwise to the flask with a dropping funnel. After neutralization, add 2wt% N, N'-bisacrylamide and 0.5wt% octyldimethylallyl ammonium bromide and 0.5wt% dodecyldimethylammonium bromide mixed solution 25g, after mixing evenly, pour the neutralization solution into a 2000mL beaker, then pass nitrogen gas for 30 minutes, then heat to 55°C, and add the polymerization initiator rapidly in turn, that is, 10wt% ammonium persulfate solution and 10wt% 15g of each sodium bisulfite solution, the reaction was completed after 10 minutes to obtain a polymer, which was taken out after half an hour of heat preservation. Spray into the granulation aid solution, ...

Embodiment 3

[0046] Add 500g of acrylic acid and 180g of deionized water into a 2000mL four-necked flask with a stirrer, which is equipped with a dropping funnel and a thermometer. Under the condition of external cooling and temperature control lower than 50°C, 600 g of aqueous sodium hydroxide solution with a mass concentration of 32% was added dropwise to the flask with a dropping funnel. After neutralization, add 50g of 2wt% N,N'-bisacrylamide solution, mix evenly, pour the neutralization solution into a 2000mL beaker, then pass nitrogen gas for 30 minutes, then heat to 55°C, and rapidly Add a polymerization initiator, that is, 15 g each of 10 wt % ammonium persulfate solution and 10 wt % sodium bisulfite solution, and the reaction is completed after 10 min to obtain a polymer, which is taken out after half an hour of heat preservation. Spray 25g of dodecylbenzyltrimethylammonium chloride solution of granulation aid and 1wt%, the colloid obtained is granulated with a small meat grinder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com