Water-absorbent resin and preparation method thereof

A technology of resin and water absorption, applied in the field of preparation of superabsorbent resin polymer gel, can solve the problems of poor liquid permeability, high content of acrylic acid monomer, and unsatisfactory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

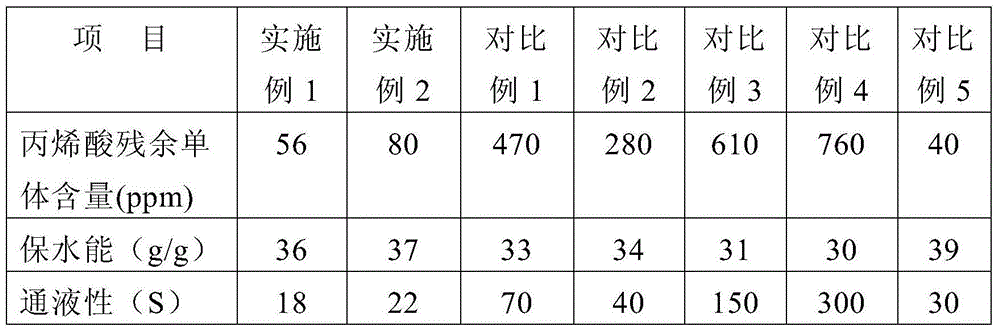

Examples

preparation example Construction

[0019] The preparation method of the water-absorbing resin of the present invention has the following steps:

[0020] (I) Add crosslinking agent and polymerization initiator to the alkaline aqueous solution of acrylic monomer

[0021] The acrylic monomer of the present invention is not particularly limited, and can be any acrylic monomer known in the art. Non-limiting examples thereof include, for example, acrylic monomer, methacrylic monomer, acrylic C 1-6 Alkyl ester monomers (such as methyl acrylate, ethyl acrylate, n-propyl acrylate, isopropyl acrylate, etc., preferably acrylic acid C 1-3 Alkyl ester monomer), methacrylic acid C 1-6 Alkyl ester monomers (such as methyl methacrylate, ethyl methacrylate, n-propyl methacrylate, isopropyl methacrylate, etc., preferably C methacrylate 1-3 Alkyl ester monomer), or a mixture of two or more of the above monomers.

[0022] The concentration of the acrylic monomer aqueous solution is not particularly limited, and may be any conventional con...

Embodiment 1

[0073] At 1m 3 Add 283kg of sodium hydroxide aqueous solution (32wt%) and 351kg of deionized water to the reaction kettle, turn on the stirring of the reaction kettle, slowly add 225kg acrylic acid dropwise, keep the temperature of the reaction kettle at 20-30°C, add 0.45 kg cross-linking agent polyethylene glycol diacrylate and 0.55 kg cross-linking agent polyethylene glycol glycidyl ether, then add 0.25 kg initiator ammonium persulfate, continue to stir, fill the reactor with nitrogen for 15 minutes, add 0.25 kg Sodium bisulfite, keep the reactor stirred for 5 minutes, keep the temperature of the reactor at 20-30°C, and continuously enter the above-mentioned materials at a flow rate of 34.5kg / hr on a continuous conveyor belt with a length of 6000mm and a width of 500mm for polymerization.

[0074] 1) Aggregation induction segment

[0075] The uniformly mixed polymerization reaction material passes through the microwave generator at the entrance of the polymerization reactor throu...

Embodiment 2

[0086] The preparation of the gel is the same as in Example 1. The difference is that the thickness of the prepared gel is about 30mm by increasing the feed amount of the polymer material, and the prepared gel is broken, dried, pulverized, and surface crosslinked to obtain The performance of the product is: acrylic acid residue is 80ppm, water retention capacity is 37g / g, liquid permeability is 22s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com