Patents

Literature

58results about How to "Less residual monomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Interpolymer latex of polystyrene and acrylic ester in hud polymerization type, and preparation method

This invention relates to a core-shell polystyrene-acrylate copolymer emulsion, which comprises: emulsifiers 0.2-1.5 wt.%, monomers 45-55 wt.%, initiator 0.1-0.3 wt.%,, pH regulator 0.1-0.2 wt.%, and deionized water as balance. The emulsifiers are two or three of anionic emulsifier, nonionic emulsifier and functional allyloxy hydroxypropyl sulfonate emulsifier. The monomers are soft monomer, hard monomer and functional silane monomer containing epoxy groups and oxy groups. The solid content of the emulsion is 48-52%, the glass transition temperature of the core is 25-35 deg.C, and the glass transition temperature of the shell is (-5)-5 deg.C. The emulsion has such advantages as high wet adhesivness of the coating film and high washing resistance of the coating film.

Owner:CHANGZHOU GUANGHUI CHEM +1

Thermal expansibility microsphere and method for reducing residual monomers therein

The invention provides a thermal expansibility microsphere and a method for reducing residual monomers therein. The method comprises a re-initiation step of supplementing an initiating agent of the residual monomers in a process of preparing the thermal expansibility microsphere by using a suspension polymerization method, wherein the initiating agent of the residual monomers is an oxidation reduction initiator system. The preparation method of the thermal expansibility microsphere, provided by the invention comprises the following steps: preparation of a water phase, preparation of an oil phase, suspension polymerization and residual monomer reduction. The technical scheme provided by the invention realizes quick reduction of the residual monomers under a low-temperature condition, is simple in production process, low in consumption and short in processing time, and simultaneously can efficiently reduce the content of the residual monomers in the thermal expansibility microsphere and a suspension reaction medium. The thermal expansibility microsphere prepared by using the method contains a little number of residual monomers and is small in pollution.

Owner:NANOSPHERE SHANGHAI

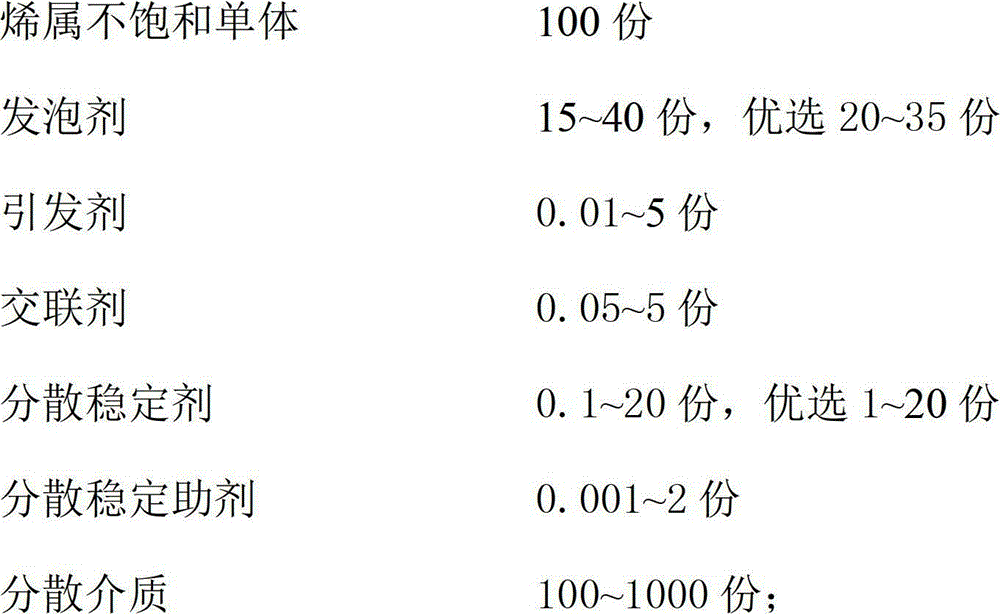

Preparation method of amphoteric polyacrylamide dispersion liquid

The invention discloses a preparation method of amphoteric polyacrylamide dispersion liquid. The preparation method comprises the following steps: putting a main functional monomer into a mixed system comprising an amphoteric dispersion stabilizer, a chelating agent, a pH regulator and inorganic salt deionized water solution; initiating a reaction by virtue of an initiating agent; and preparing the amphoteric polyacrylamide dispersion liquid by virtue of a dispersion polymerization method. The dispersion liquid prepared by adopting a novel amphoteric polymer dispersion stabilizer has the characteristics of good stability, high molecular weight, high dissolution rate and the like, and a synthetic process of the dispersion liquid is environment-friendly and pollution-free and is low in energy consumption, and the product is nontoxic and noncorrosive, cannot generate secondary pollution and accords with the development direction of green and environment-friendly chemical assistants. The amphoteric polyacrylamide dispersion liquid has an application prospect in the fields of water treatment, papermaking, printing and dyeing, oil fields, mining, daily chemicals and the like.

Owner:JIANGSU FEYMER TECH

Acrylate copolymer emulsion, and aqueous industrial anticorrosive paint adopting acrylate copolymer emulsion as film forming substance

ActiveCN105859936AReduce the temperatureGuaranteed compactnessAnti-corrosive paintsCross-linkSodium bisulfate

The invention discloses an acrylate copolymer emulsion, and belongs to the technical field of aqueous coatings. The acrylate copolymer emulsion comprises, by weight, 450-550 parts of deionized water, 1-2 parts of an anionic surfactant, 5-8 parts of a reactive emulsifier, 3-15 parts of hydroxypropyl acrylate, 50-160 parts of methyl methacrylate, 20-75 parts of butyl acrylate, 200-410 parts of styrene, 5-10 parts of methacrylic acid, 3-10 parts of an adhesion function monomer, 2-9 parts of a cross-linking monomer, 3-10 parts of a cross-linking agent, 0.1-3 parts of an antifoaming agent, 0.8-2 parts of an initiator, 3-5 parts of ammonia water, 0.8-2 parts of an antiseptic, 0.1-1 part of tert-butyl hydroperoxide and 0.1-0.8 parts of sodium bisulfate. The invention also discloses an aqueous industrial anticorrosive coating adopting the acrylate copolymer emulsion as a film forming substance. The coating has the advantages of high adhesion to a substrate, high water resistance and high salt spray resistance.

Owner:HENGSHUI XINGUANG CHEM

Pure-acrylic emulsion with low VOC and preparation method thereof

The invention discloses a pure-acrylic emulsion with low VOC and a preparation method thereof. The pure-acrylic emulsion is mainly used for preparing indoor paint and the formulation thereof comprises: 20-25% of methyl methacrylate, 10-15% of butyl acrylate, 7-10% of ethyl hexyl acrylate, 0.5-1% of crylic acid, 1-5% of emulsifier, 0.3-0.5% of persulfate, 0.2-0.3 of oxidant, 0.15-0.25% of reducing agent and 53% of water. The preparation method comprises the following steps: selecting monomers with similar reactivity ratio to carry out emulsion polymerization, and then adopting a redox system to carry out after-treatment on the emulsion so as to further reduce the content of residual monomers. According to measurement, the VOC content of the polymerization emulsion is less than or equal to 30(g / L) and far below the national regulation.

Owner:上海巴德富实业有限公司

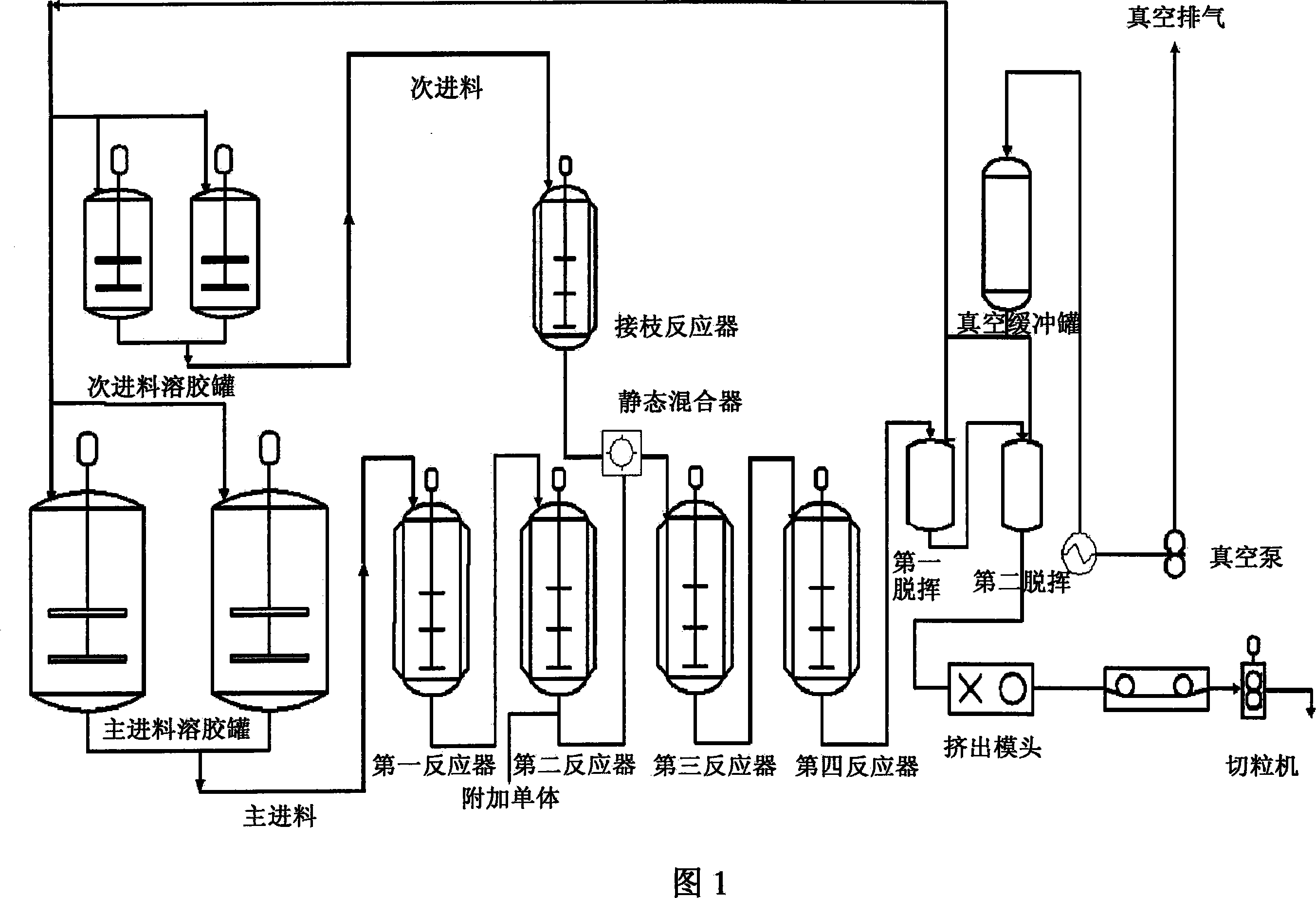

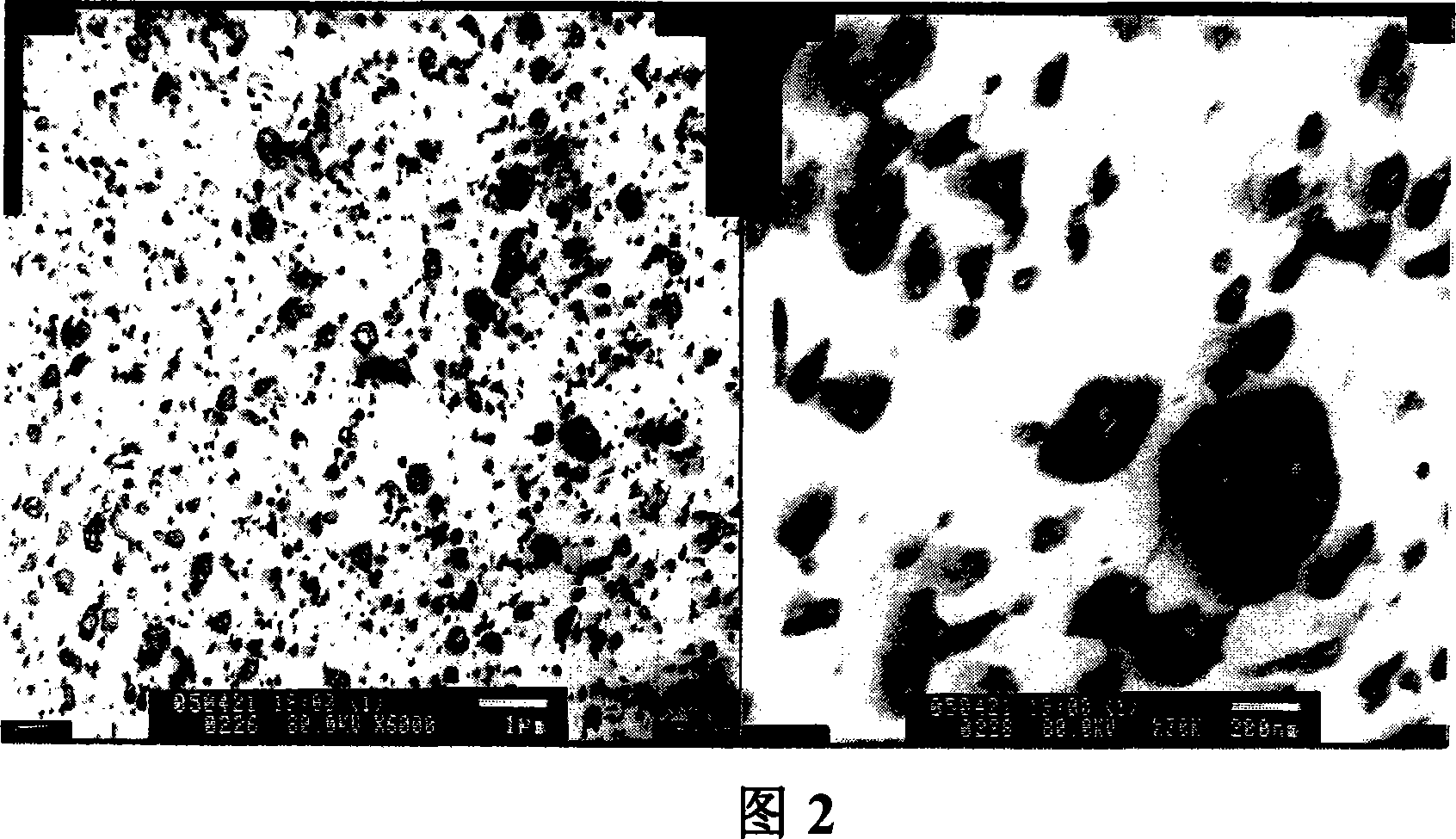

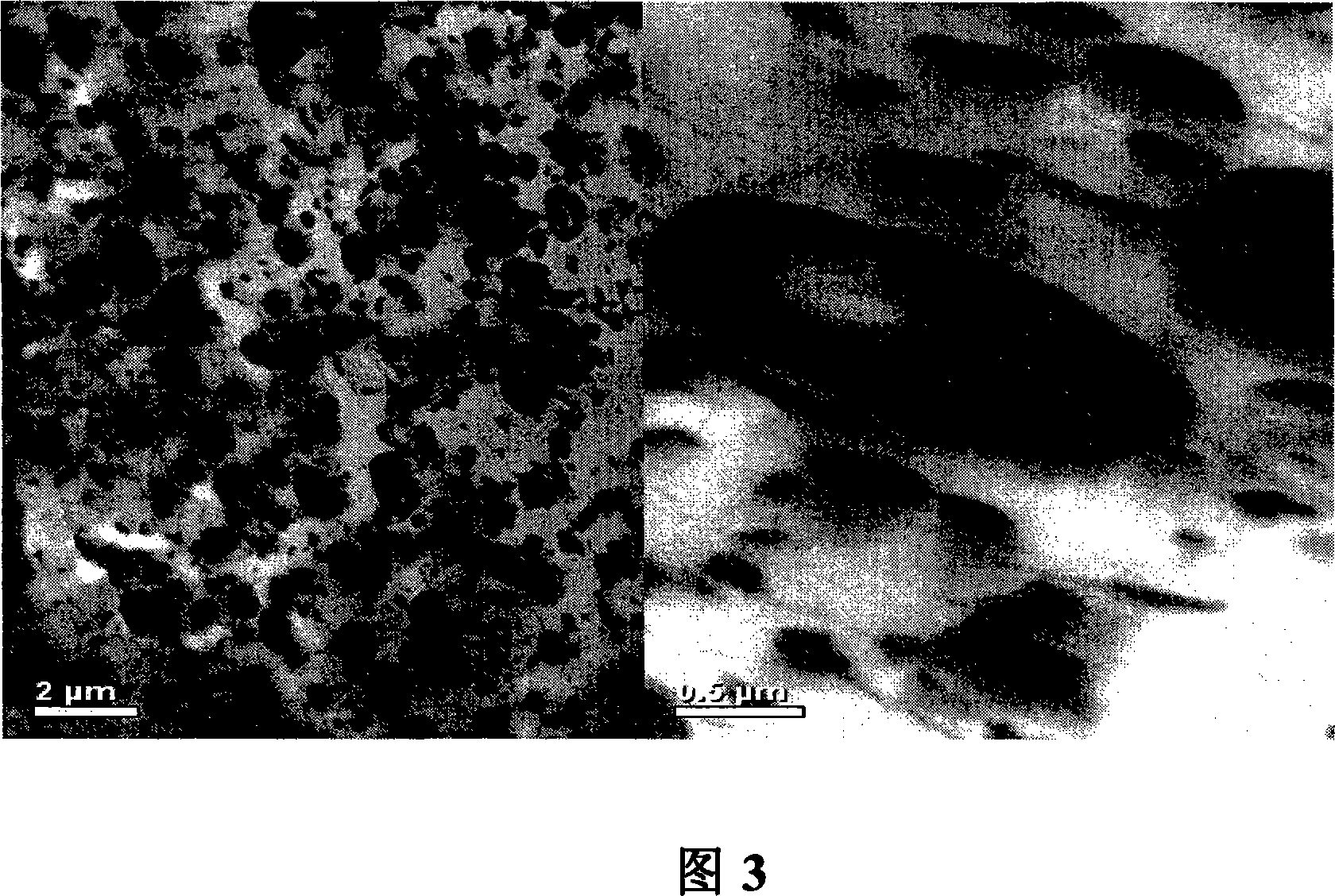

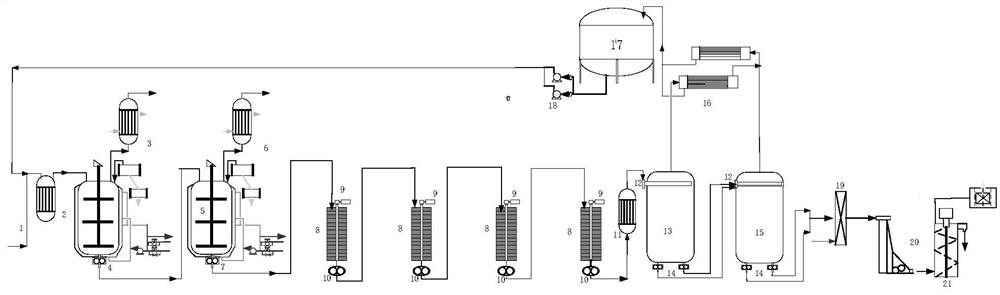

Method of preparing heat-resistant ABS polymer by continuous noumenon method

The invention discloses a making method of heat-proof ABS polymer through continuous bulk method, which comprises the following steps: inputting main material; inputting secondary material; grafting main material to transform phase; grafting the secondary material to transform phase; blending main material and secondary material; obtaining the product with swelling index at 9-15, rubber content at 14-16% and grain size at 1-2um; fitting for heat-proof modification and accessory manufacturing in the automobile domain.

Owner:中国中化股份有限公司 +1

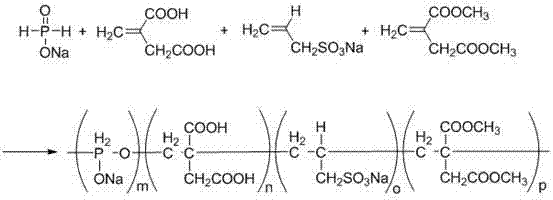

Polynary itaconic acid copolymer as high efficiency anti-sludging agent and preparing method

InactiveCN1511793ASimple production processLess residual monomer in the productScale removal and water softeningItaconic acidAqueous solution

The present invention features that the polynary copolymer is prepared with itaconic acid, sulfonate and acrylate and through water phase polymeriztion in the presence of initiator system. Relates to itaconic acid, the amount of sulfonate is 0-50 wt%, the acrylate 5-200 wt% and the initiator 0-30 wt%. The preparation process includes mixing itaconic acid and sulfonate to prepare water solution, and adding initiator solution and acrylate homogeneously for copolymerization reaction at 30-100 deg.c. The prepared polynary copolymer solution may be used as anti-sludging agent, scale remover, dispersant, detergent aid, etc. The production process is simple and has no 'three-waste' exhaust.

Owner:ZIBO MINING GRP

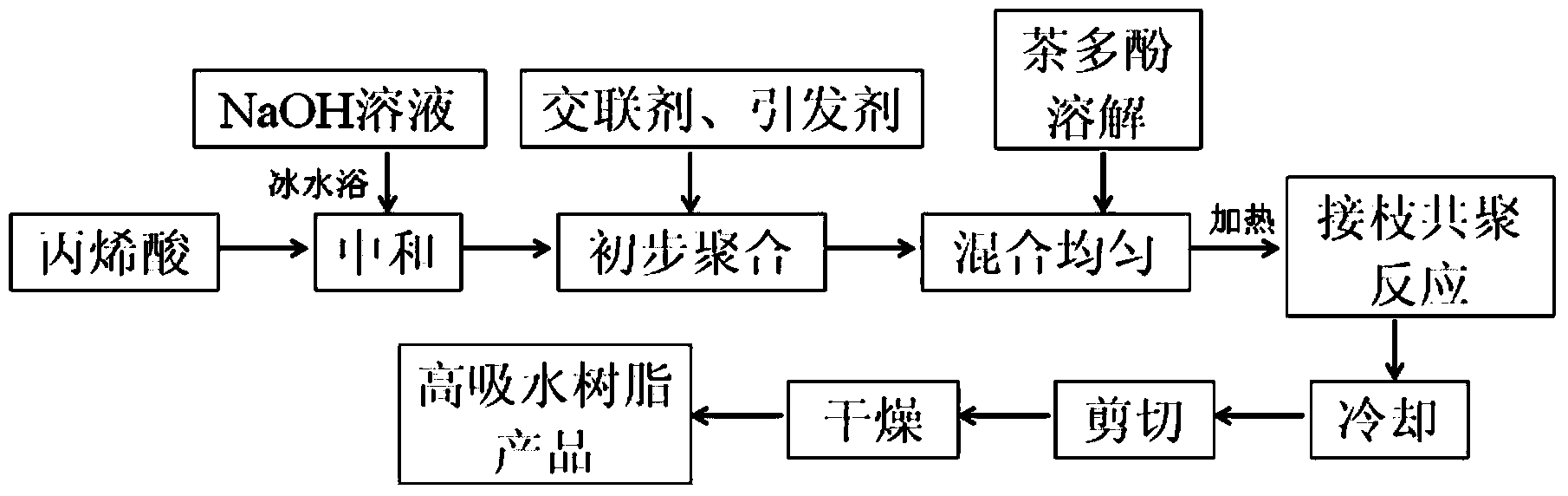

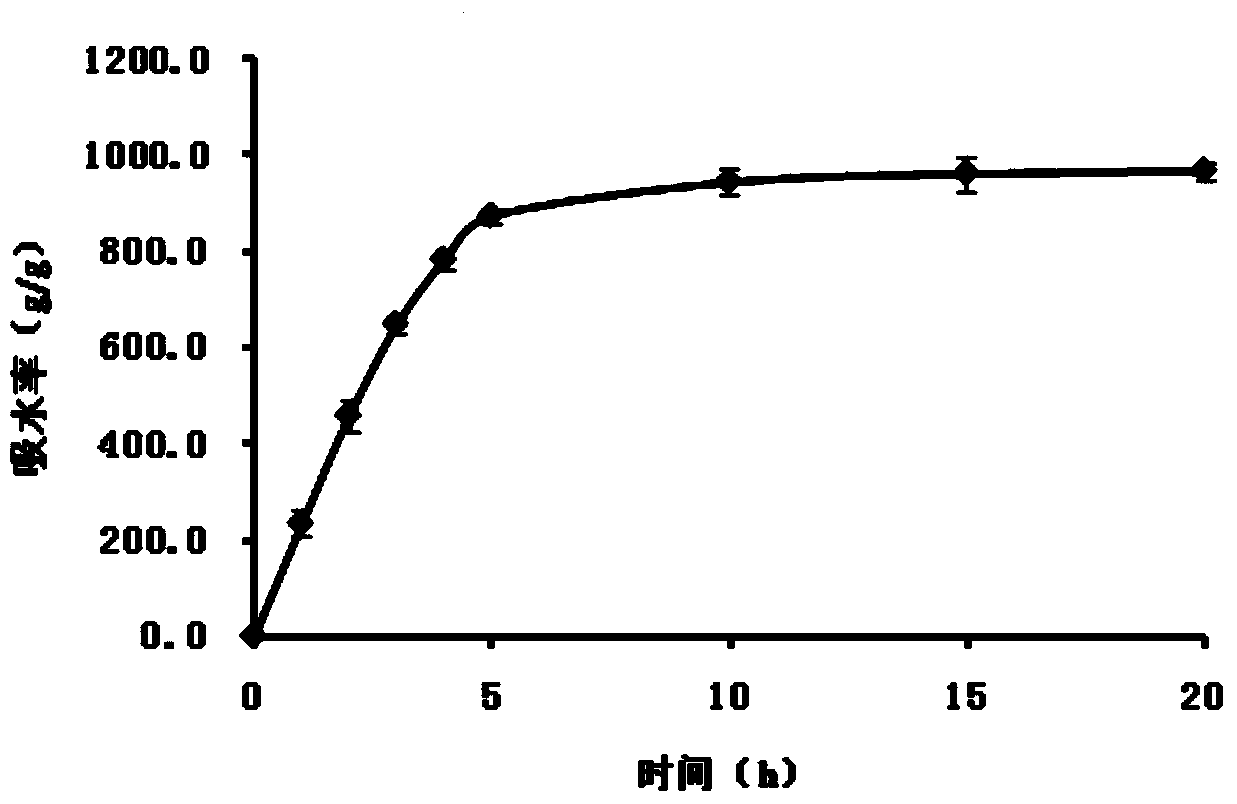

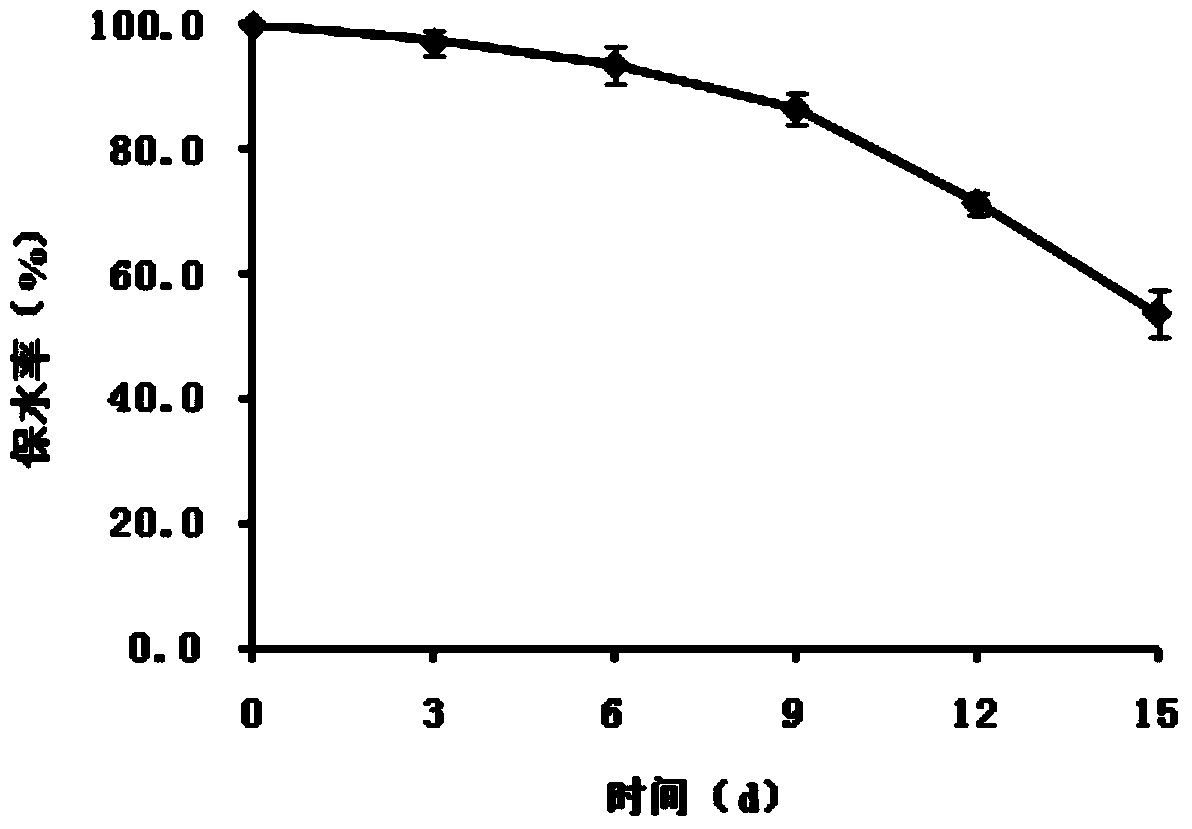

Tea polyphenol-acrylic acid series super absorbent resin and preparation method thereof

The invention discloses a tea polyphenol-acrylic acid series super absorbent resin. Acrylic acid is neutralized with a NaOH solution firstly; then N,N'-methylene bisacrylamide is taken as a cross-linking agent, potassium persulfate is taken as an initiator, and the mixture has a polymerization reaction with tea polyphenols in water; and gel obtained after the reaction is cooled, cut and dried, so that the tea polyphenol-acrylic acid series super absorbent resin is formed. The tea polyphenol-acrylic acid series super absorbent resin is a brownish yellow particle, has few residual monomers and no visible impurities, has sufficient gel strength, and has excellent water absorption, water retention and antibacterial properties; the water absorption rate can reach more than 950 times; and the tea polyphenol-acrylic acid series super absorbent resin is applicable to hygiene care supplies such as baby diapers, women's sanitary towels and the like. A preparation method of the tea polyphenol-acrylic acid series super absorbent resin is simple, raw material resources are extensive, the production cost is low, the production efficiency is high, and the resin has remarkable advantages.

Owner:HUAZHONG AGRI UNIV

Acrylate tile back glue emulsion and preparation method thereof

InactiveCN106590477AImprove stabilityHigh monomer conversion rateEster polymer adhesivesFunctional monomerWeather resistance

The invention relates to an acrylate tile back glue emulsion and a preparation method thereof. The preparation method comprises preparation of a base material liquid A, preparation of a monomer solution B, preparation of an initiator solution C, preparation of a later added initiator solution D, pre-emulsification semi-continuous dropwise addtion, and later treatment processes. The emulsion comprises, by weight, 100 to 500 parts of an alkyl acrylate monomer, 20 to 100 parts of an alkyl methacrylate monomer, 0.1 to 10 parts of alkyl carboxylic acid, 1 to 10 parts of a functional monomer, 0.1 to 10 parts of vinyltrioxysilane, 1 to 30 parts of an emulsifier, 0.1 to 5 parts of an initiator, 0.1 to 5 parts of a buffering agent, and 100 to 150 parts of deionized water. The preparation method has the advantages of simple processes, low cost and safety. The emulsion has characteristics of good gloss, good water resistance, good weather resistance, high peel strength, high adhesion and instant-coating and instant-pasting of a single component.

Owner:佛山市顺德区巴德富实业有限公司

Water-based flexographic printing ink for cigarette tipping paper printing and preparation method thereof

ActiveCN106928771AImprove antibacterial propertiesTroubleshoot MigrationInksFreeze thawingDispersion stability

The invention discloses a water-based flexographic printing ink for cigarette tipping paper printing and a preparation method thereof. The water-based flexographic printing ink is composed of a modified acrylic emulsion, pigment and filler, a wetting dispersant, a transfer printing agent, a defoaming agent, deionized water, and a cosolvent. The modified acrylic emulsion is a novel acrylic emulsion formed by copolymerization of an imported high quality emulsifier, acrylate and special functional monomers, and has the advantages of fantastic calcium ion stability, dilution stability, mechanical stability and freeze-thaw stability, and small pollution to the environment. The water-based flexographic printing ink for tipping paper printing provided by the invention is non-toxic and tasteless, has quick drying speed and good dispersion stability, the printing product is free of deformation and edge curling, and has bright color and excellent antibacterial properties. The printing product has few residual monomer and low odor, is green and environment-friendly, the printing ink can be used cooperatively with a flexographic press, the printing speed can reach 250-300m / min, and the machine speed is doubled than the traditional intagliotipping paper printing press, thus greatly improving the production efficiency, and saving the production cost.

Owner:JIANGSU TANGCAI PRINTING INK SCI TECH CO LTD

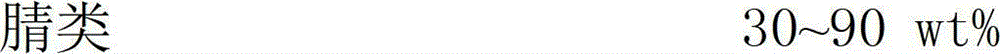

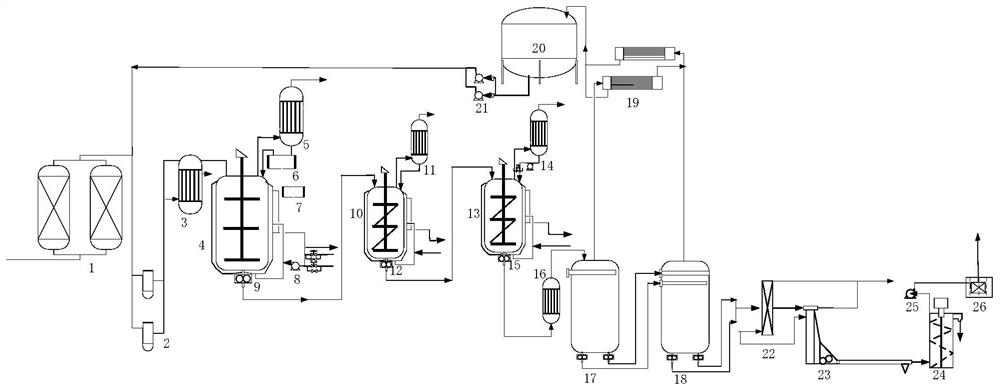

Method for preparing polyacrylonitrile spinning solution

ActiveCN103145915AHigh solid contentLess residual monomerFibre chemical featuresSpinning solutions preparationPolymer scienceItaconic acid

The invention belongs to the field of organic polymers and particularly relates to a method for preparing polyacrylonitrile spinning solution. The method comprises the following steps of: mixing the dimethyl sulfoxide solution of acrylonitrile, itaconic acid and methyl acrylate which serve as comonomers with the dimethyl sulfoxide solution of azo-bis-iso-heptonitrile, wherein the concentrations of the comonomers are12-20%, the concentration of the azo-bis-iso-heptonitrile is 0.1-1%, and the molar ratio of the acrylonitrile, the itaconic acid and the methyl acrylate is (96-99):(0.5-3):(0.5-3); carrying out polymerization reaction at the temperature of 50-80 DEG C; controlling the temperature at 60-80 DEG C 5-10 hours later; continuing to stir and extracting a polymer solution in a polymerizing kettle in vacuum until the vacuum degree in the polymerizing kettle is -80kPa; increasing the vacuum degree in the polymerizing kettle to -98kPa after extracting for 1 hour; continuing to extract; feeding the polymer solution extracted in vacuum into a defoaming kettle; continuously defoaming under the condition of -80kPa and 60-80 DEG C; and carrying out tertiary filtering on a defoamed polymer. The method is simple in process and high in controllability, and the content of solid in the prepared spinning solution is large, and the content of residual monomers is low.

Owner:WEIHAI TUOZHAN FIBER

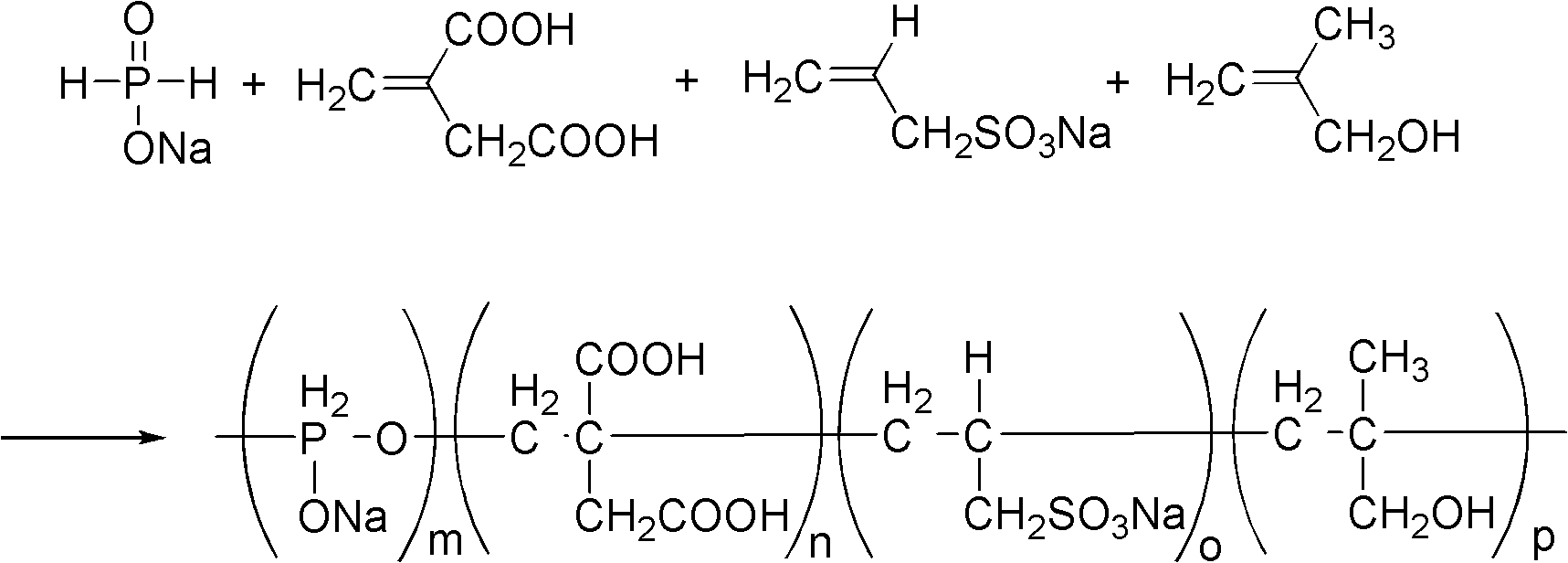

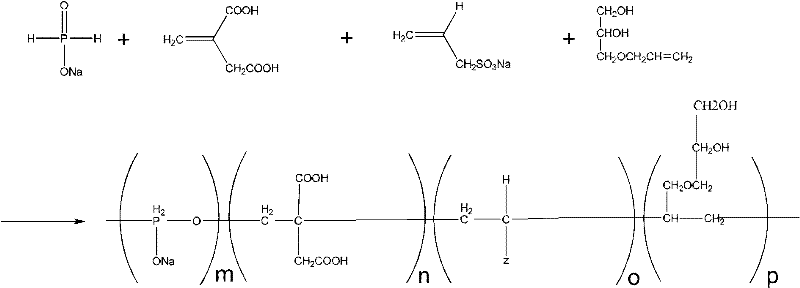

Propenol itaconic acid sulfonate multipolymer scale inhibiting agent and preparation method thereof

InactiveCN101786733ASimple production processLess residual monomerScale removal and water softeningSludgePhosphate

The invention relates to a polynary scale and corrosion inhibiting agent and a preparation method thereof, in particular to a propenol itaconic acid sulfonate multipolymer scale inhibitin agent and a preparation method thereof. The scale inhibiting agent is characterized by being prepared from propenol, itaconic acid and sulfonate through aqueous polymerization under an initiating agent system, wherein by taking the mass of the itaconic acid as a reference, the addition of the sulfonate is 10-50 percent, the addition of the propenyl is 5-20 percent, the addition of the initiating agent is 5-30 percent, and the addition of sodium hypophosphite is 5-30 percent. In the invention, the itaconic acid is used as a raw material and is subjected to the aqueous polymerization with the propenyl and the sulfonate, and the invention has simple production process, fewer product residual monomers and no three waste exhausts. A polymer prepared by using the method has high-efficiency inhibiting effect on the formation and the adhesion of scale layers of carbonates, sulfates, phosphates, silicates, and the like in a cooling water system and good dispersant effect on iron oxide, sludge, and the like.

Owner:山东省特种设备检验研究院淄博分院

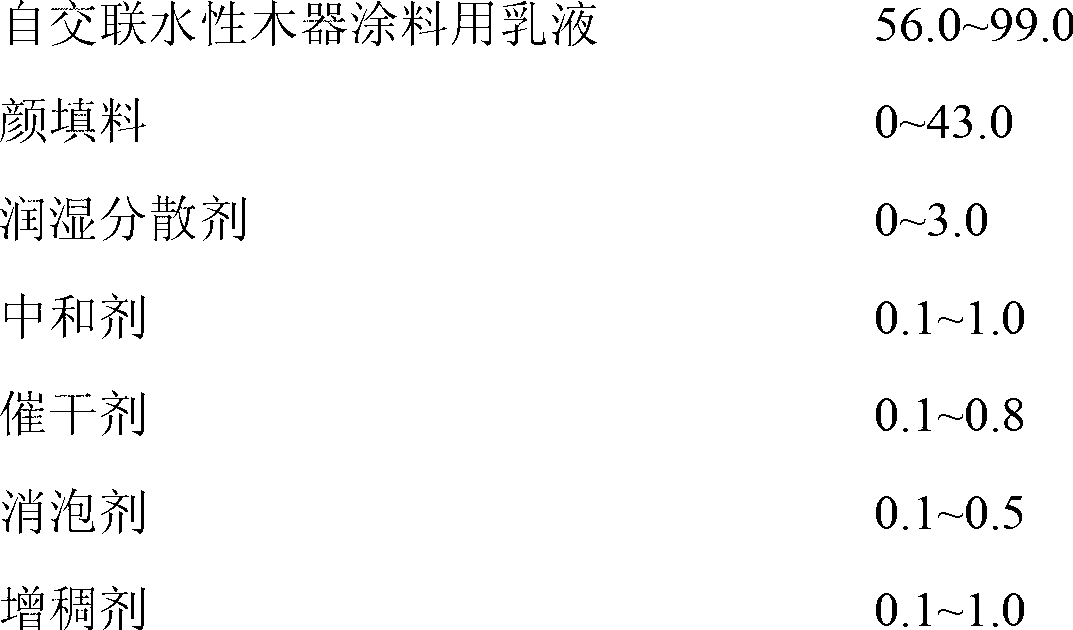

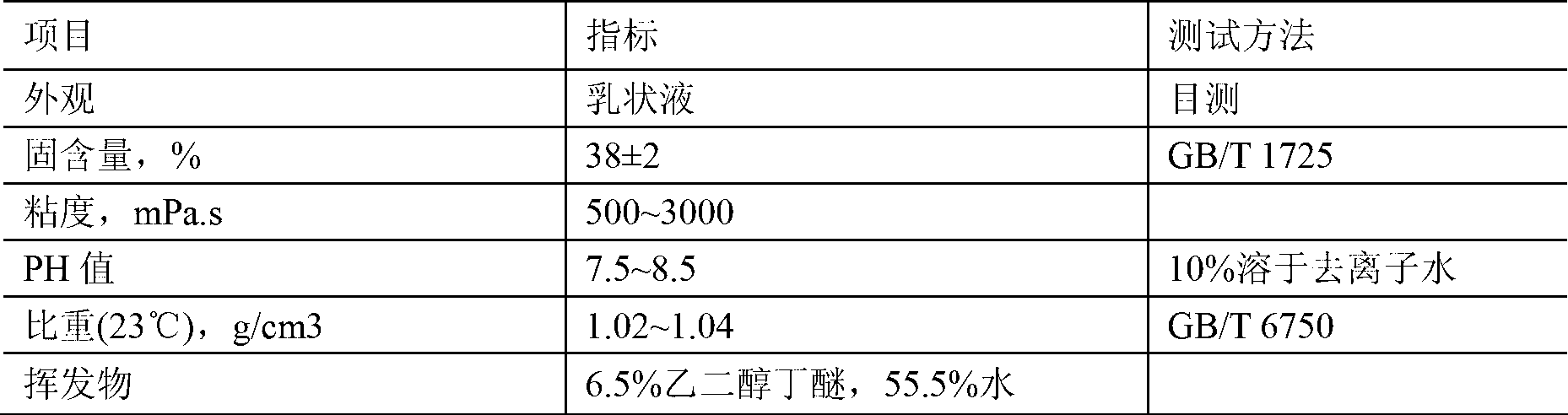

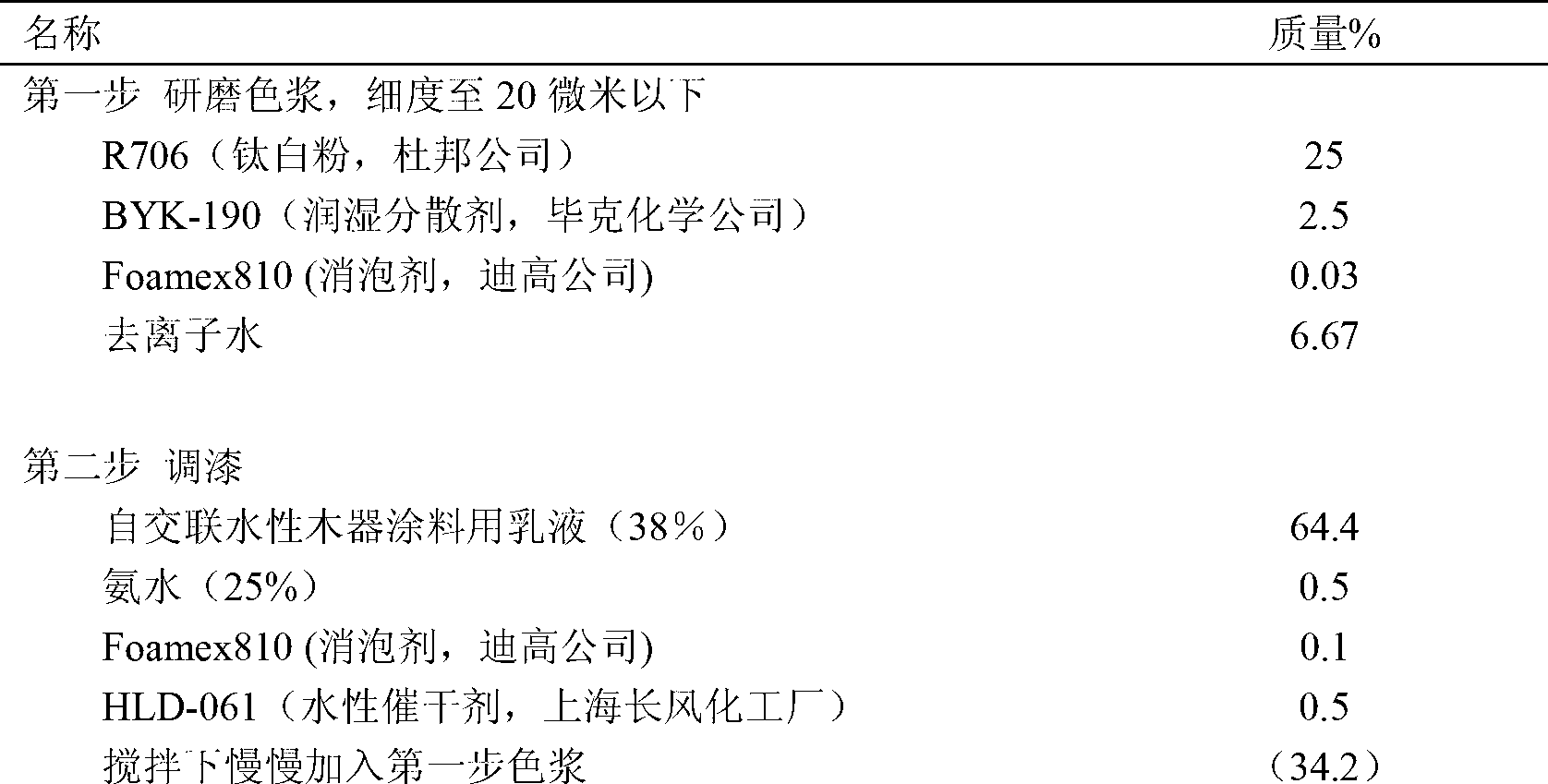

Method for preparing emulsion for self-crosslinked waterborne wood coating

The invention discloses a method for preparing emulsion for a self-crosslinked waterborne wood coating. The emulsion comprises a component A and a component B. The method is characterized in that the preparation process comprises the following steps of a, for the component A, preparing acrylic resin with a high acid value containing air dry vegetable oil fatty acid composition, wherein the acid value is 180-240mgKOH / g; b, for the component B, preparing the acrylic resin with a high hydroxyl value, wherein the hydroxyl value is 120-260mgKOH / g; c, carrying out esterification reaction between the acrylic resin (component A) with the high acid value and the acrylic resin (component B) with the high hydroxyl value, neutralizing with ammonia (or amine) and diluting with water after the acid value is qualified, so as to obtain the emulsion C for the self-crosslinked waterborne wood coating. The emulsion can be used for preparing the self-crosslinked waterborne wood coating. The paint is low in VOC (volatile organic compound) content, accords with the environmental protection requirement, belongs to the environment friendly type, and can be widely applied to furniture coating and house decoration.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Thermal expansibility microsphere and method for reducing residual monomers therein

The invention provides a thermal expansibility microsphere and a method for reducing residual monomers therein. The method comprises a re-initiation step of supplementing an initiating agent of the residual monomers in a process of preparing the thermal expansibility microsphere by using a suspension polymerization method, wherein the initiating agent of the residual monomers is an oxidation reduction initiator system. The preparation method of the thermal expansibility microsphere, provided by the invention comprises the following steps: preparation of a water phase, preparation of an oil phase, suspension polymerization and residual monomer reduction. The technical scheme provided by the invention realizes quick reduction of the residual monomers under a low-temperature condition, is simple in production process, low in consumption and short in processing time, and simultaneously can efficiently reduce the content of the residual monomers in the thermal expansibility microsphere and a suspension reaction medium. The thermal expansibility microsphere prepared by using the method contains a little number of residual monomers and is small in pollution.

Owner:NANOSPHERE SHANGHAI

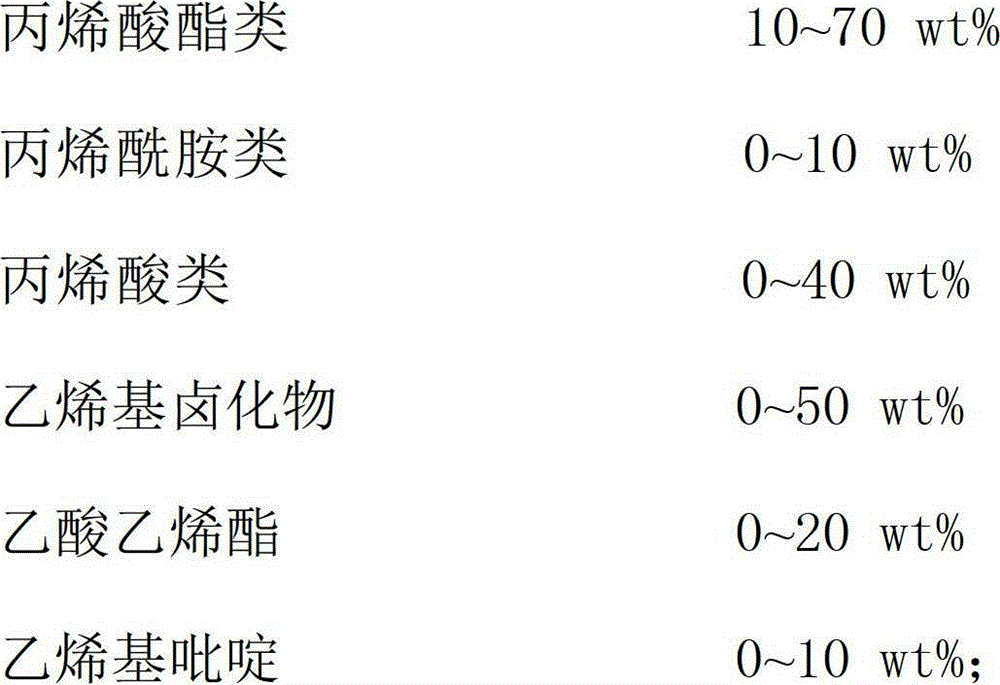

Water-absorbent resin and preparation method thereof

The invention discloses a water-absorbent resin and a preparation method, the method comprises the following steps: 1)adding a cross-linking agent and a polymerization initiator in an acrylic acid monomer alkaline aqueous solution; 2)applying microwave to initiate a polymerization; 3)performing polymerization for 3-10 minutes at 100-140 DEG C, increasing the temperature of 10-30 DEG C and slaking for 10-20 minutes to obtain a polymer gel; 4)sprinkling water vapor on the surface of the polymer gel to obtain the water-absorbent gel, by metering weight of the polymerization material, wherein the water vapor amount is 1-3weight%; and 5)using microwave for irradiate the water-absorbent gel under temperature which is lower than water boiling temperature.

Owner:SHANGHAI HUAYI NEW MATERIAL

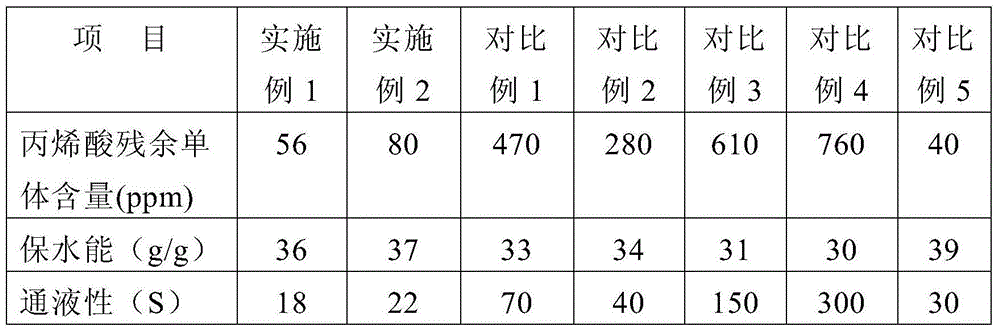

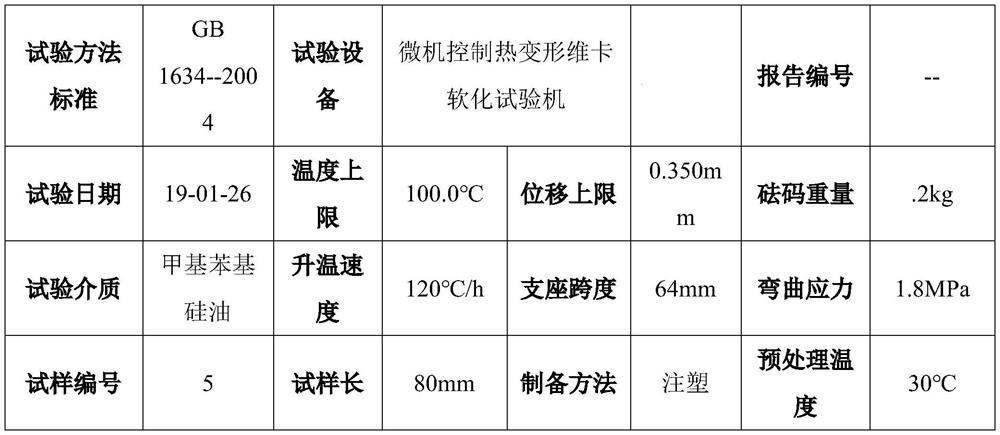

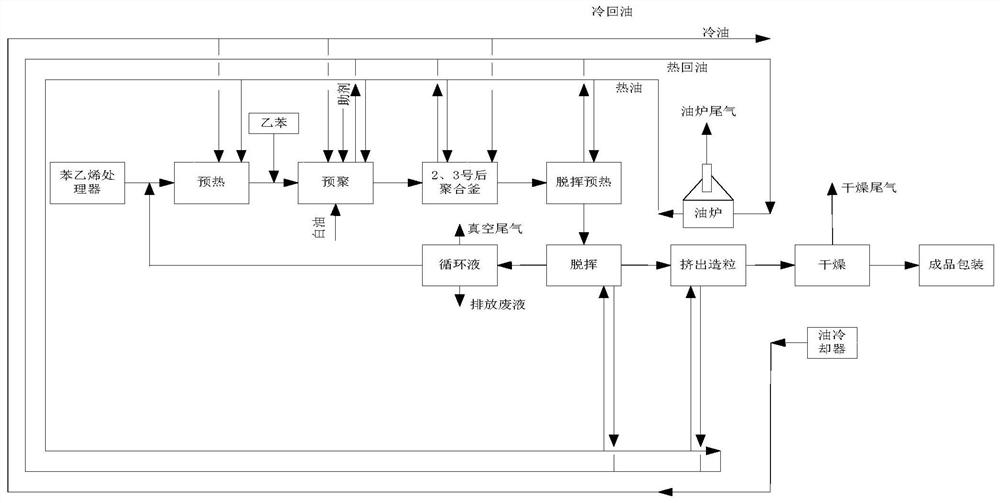

Impact polystyrene with capacity scale of 50,000 tons or above as well as equipment and production process of impact polystyrene

PendingCN112661910AImprove impact resistanceHigh tensile strengthChemical industryChemical/physical/physico-chemical stationary reactorsPolystyreneStearic acid

The invention discloses impact polystyrene with the capacity scale of 50,000 tons or above as well as equipment and a production process of the impact polystyrene. More than 90% of the components of the rubber modified polystyrene product are represented by the formula, n is the polymerization degree, the range of n is 600-7000, and n is different along with different types of products; in addition to the main components, the rubber composition also contains 3-10% of butadiene rubber for modification, 0-7% of white oil, 0-1% of an additive of stearate, and a small amount of an organic residue such as a monomer (the total amount is 800 ppm or less). The modified polystyrene has good impact strength, the vicat softening point is 92-106 DEG C, the tensile strength of the modified polystyrene is 22-45 MPa at normal temperature, and the modified polystyrene is a thermoplastic material with good toughness. No process waste water is generated in the production process, all the raw materials are recycled, a small amount of generated process waste gas reaches the standard and is discharged after being subjected to condensation and adsorption treatment of special equipment, and the good environment-friendly, energy-saving and consumption-reducing effects can be achieved.

Owner:江苏可立特工程设计研究有限公司

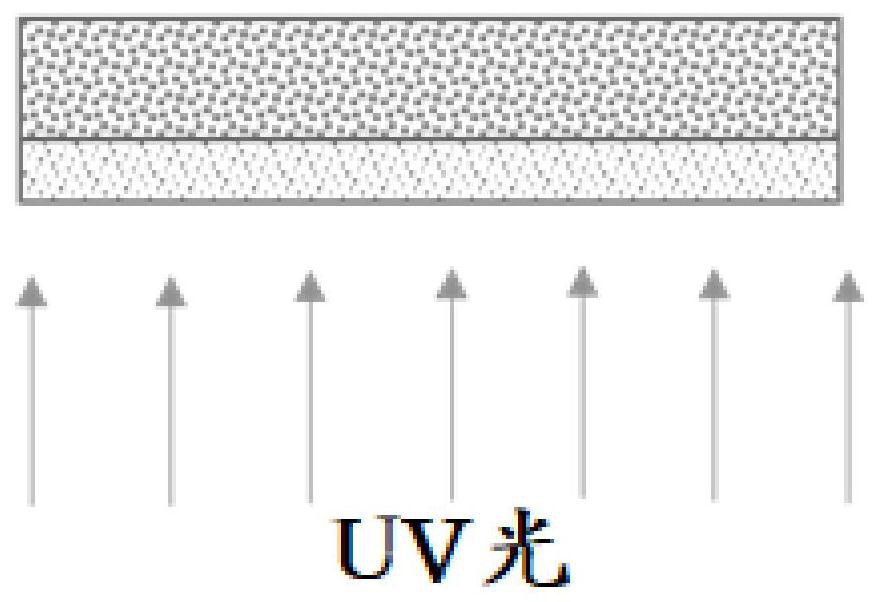

Method for producing low-residue monoacrylamide polymer

The invention discloses a method for producing a low-residue monoacrylamide polymer. The method comprises the following steps: preparing a polymerization solution containing acrylamide, an ionic monomer, an auxiliary material, a solvent, a pH value regulator and an initiator; placing the polymerization solution on a polymerization belt which is protected by a gas and is continuously conveyed; carrying out low temperature-to-high temperature stepped initiation on the polymerization solution placed on the polymerization belt by using a composite initiator, wherein the composite initiator comprises a low-temperature photoinitiator and a medium-high-temperature polyazo initiator; and performing microwave radiation when the temperature in the reaction reaches the highest temperature or the temperature of a rubber block is reduced to achieve heat insulation of the rubber block. The photo-initiation and polyazo stepped initiation system and microwave radiation heat insulation are adopted, sothe synthesized product has the advantages of low residual monomer, low crosslinking degree, good solubility, simple process and easiness in industrial production.

Owner:JIANGSU FEYMER TECH

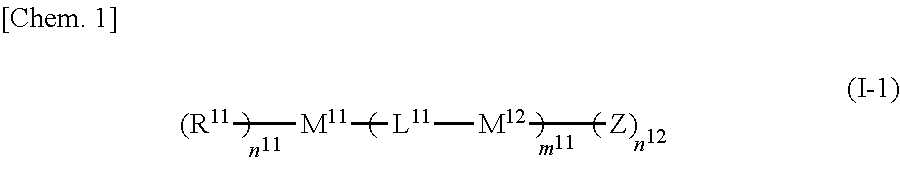

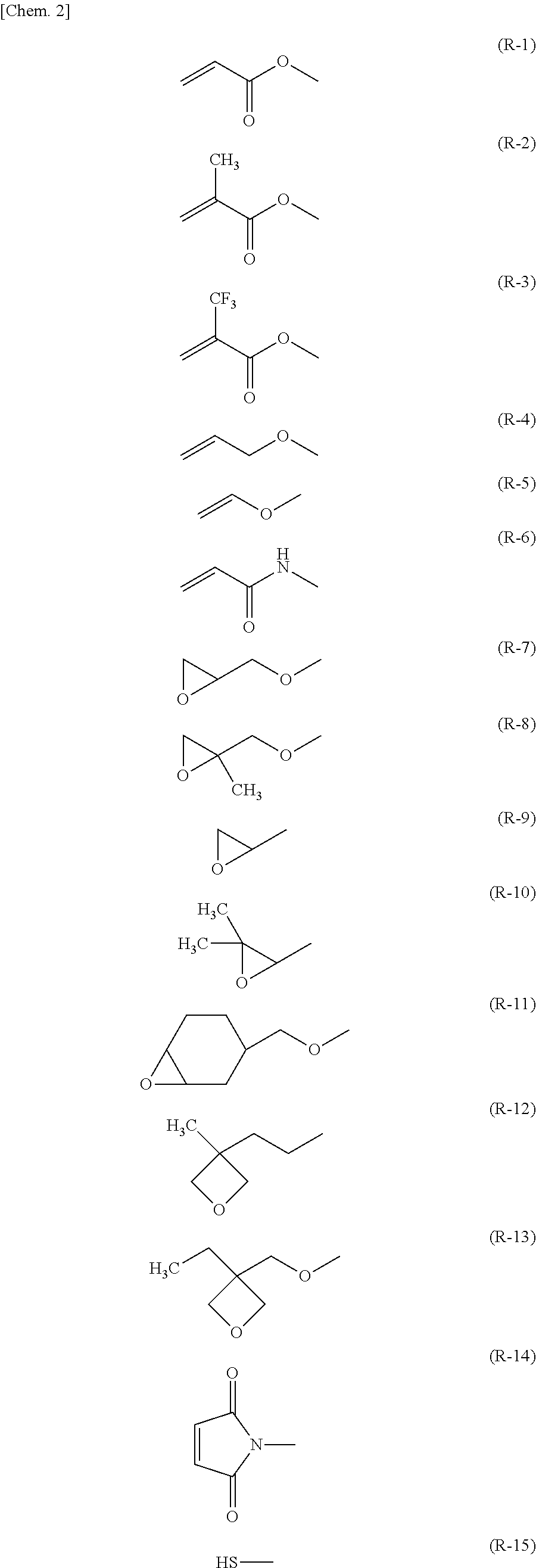

Nematic liquid crystal composition and liquid crystal display element using the same

ActiveUS10323186B2Low rotational viscosityLarge elastic modulusLiquid crystal compositionsThin material handlingLiquid-crystal displayRefractive index

There is provided a liquid crystal composition that exhibits a sufficiently low viscosity (η), a sufficiently low rotational viscosity (γ1), and a large elastic modulus (K33) without decreasing the refractive index anisotropy (Δn) and the nematic phase-isotropic liquid phase transition temperature (Tni) and without increasing the solid phase-nematic phase transition temperature (Tcn). The liquid crystal display element that uses this liquid crystal composition satisfactorily obtains a pretilt angle and has a high voltage holding ratio (VHR) and high-speed response. Thus, a liquid crystal display element that has no or less alignment defects and display defects such as image sticking, and has high display quality and high response speed is obtained.

Owner:DIC CORPORATION

Method of preparing polyacrylate super absorbent resin at high temperature

The invention discloses a method of preparing polyacrylate super absorbent resin at a high temperature. The method comprises the following steps: adding a sodium hydroxide solution (50%) into an acrylic acid solution with a certain concentration to carry out neutralization reactions so as to obtain a neutral solution; when the temperature of the neutral solution is 50-90 DEG C, adding a crosslinking agent and other auxiliary agents into the neutral solution according to a certain ratio, carrying out reactions to obtain gel, wherein the final temperature of gelling reactions can reach 100-160 DEG C; grinding and extruding gel, drying, grinding, sieving, and finally carrying out secondary surface crosslinking to prepare the polyacrylate super absorbent resin. The heat of neutralization reactions is utilized, a crosslinking agent is added at a high temperature to carry out reactions, the energy consumption for cooling is reduced, and continuous production is guaranteed. Because the primary temperature of polymerization is high, the highest temperature of gelling reactions is high, a large amount of water is removed through evaporation, drying is promoted; the reaction time is short, the production efficiency is largely improved, the steps of nitrogen introducing and oxygen removing are not needed, and the production cost is reduced therefore.

Owner:JIANGSU SAILBOAT PETROCHEMICAL CO LTD

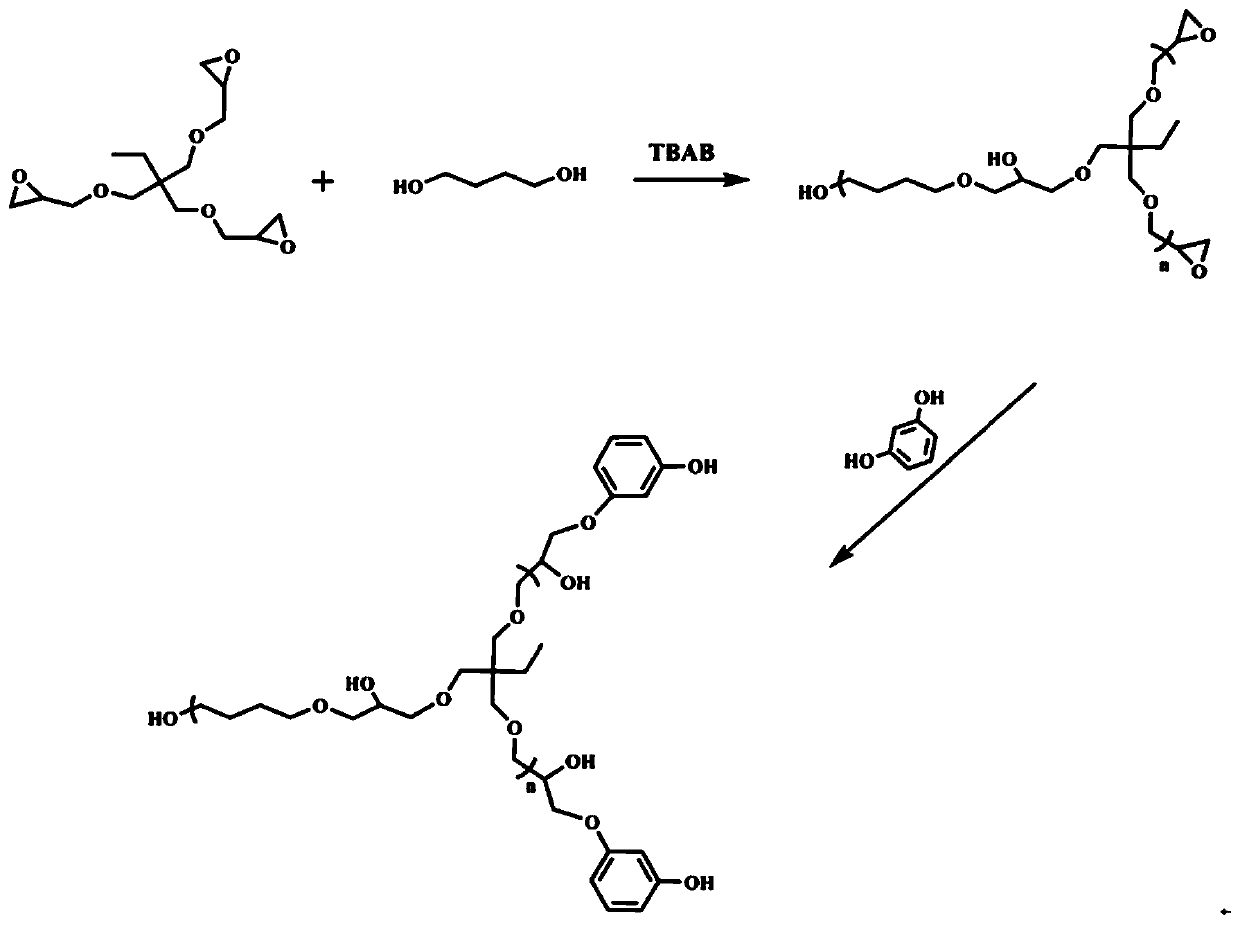

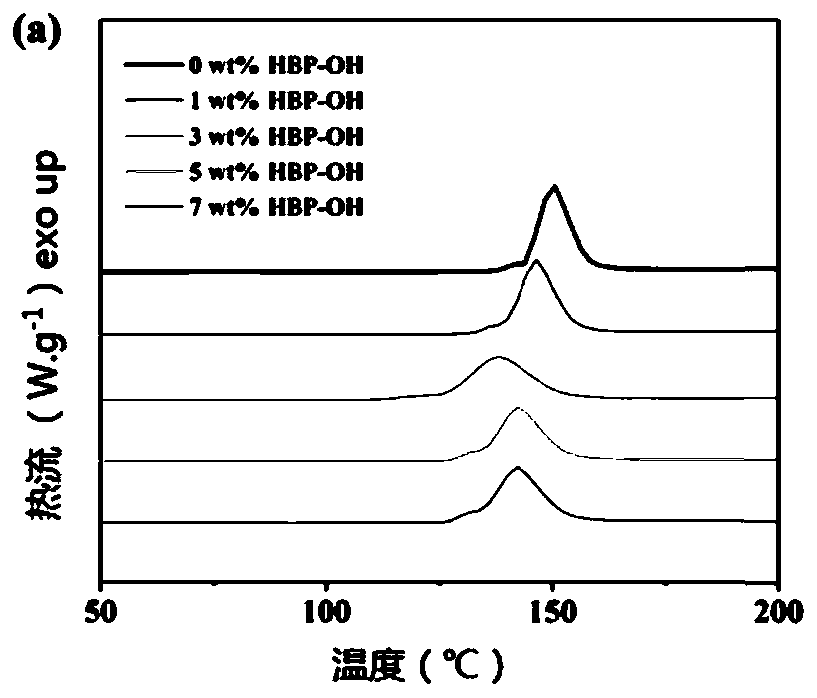

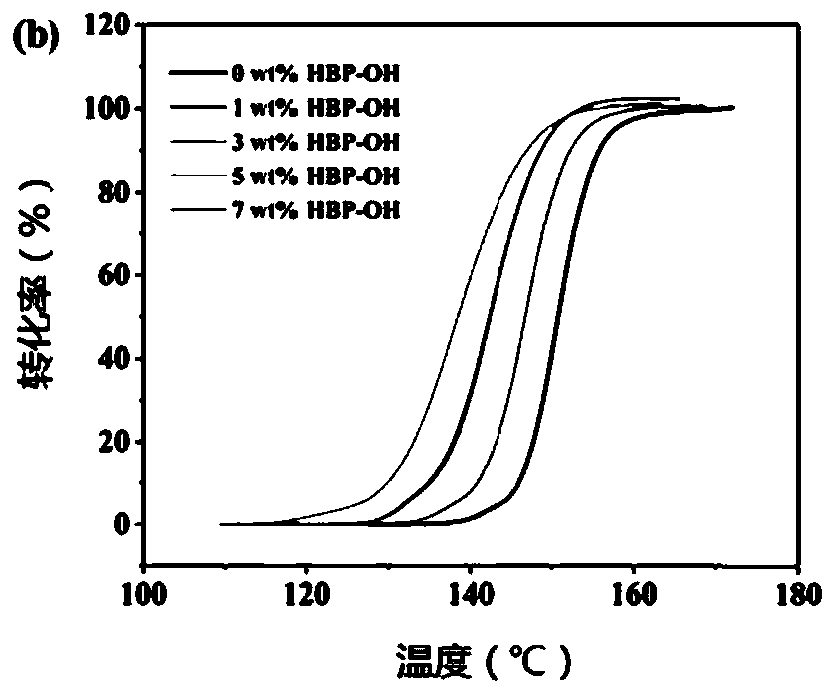

Polyhydroxy hyperbranched polymer, preparation method of polymer and application of polymer in dental composite resin

ActiveCN110527109AEasy accessThe synthesis process is simpleImpression capsDentistry preparationsEpoxyPolymer science

The invention belongs to the field of polymer materials, and relates to a polyhydroxy hyperbranched polymer, a preparation method of the polymer and an application of the polymer in dental composite resin. The polyhydroxy hyperbranched polymer has a structure represented by a formula I shown in the specification. The polyhydroxy hyperbranched polymer provided by the invention is simple to obtain and simple to use, and can improve the bending strength of the dental epoxy resin and reduce the curing shrinkage rate of the dental epoxy resin.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY +1

Dimethyl itaconate sulfonate multi-copolymer scale inhibitor and preparation method thereof

InactiveCN101955266BSimple production processLess residual monomerScale removal and water softeningChemical industrySludge

The invention relates to a dimethyl itaconate sulfonate multi-copolymer scale inhibitor and a preparation method thereof, which belong to the technical field of chemical industry. The scale inhibitor is prepared by performing aqueous polymerization on dimethyl itaconate, itaconic acid and sulfonate under an initiator system. Based on the mass of the itaconic acid, the adding amount of the sulfonate is between 10 and 50 percent, the adding amount of the dimethyl itaconate is between 5 and 100 percent, the initiator content is between 5 and 30 percent and sodium hypophosphite is between 5 and 30 percent. The itaconic acid serving as a raw material undergoes aqueous solution free radical polymerization with the dimethyl itaconate and the sulfonate in the presence of the initiator, so that production process is simple, the product has a small quantity of residual monomers and three wastes are not discharged. The polymer prepared by the method has efficient inhibitory action on the formation and attachment of fouling layers such as carbonate, sulphate, phosphate, silicate and the like in a cooling water system and plays a good role in dispersing iron oxide, sludge and the like.

Owner:山东省特种设备检验研究院淄博分院

Coating thickener

The invention discloses a coating thickener which is prepared from the following raw materials in parts by weight: 25-35 parts of acrylic acid, 15-25 parts of hydroxyethyl cellulose, 10-20 parts of stearic acid, 2-7 parts of sodium dodecyl benzene sulfonate, 0.2-4 parts of an initiator and 80-100 parts of solvent oil. The coating thickener disclosed by the invention is remarkable in thickening effect, can be combined with various coatings, is few in residual monomer and has a self-thickening property, and the thickener is convenient in color base preparation, good in stability, free of crust on the surface and good in compatibility with coatings and has good stability.

Owner:徐饶春

A kind of preparation method of amphoteric polyacrylamide dispersion liquid

The invention discloses a preparation method of amphoteric polyacrylamide dispersion liquid. The preparation method comprises the following steps: putting a main functional monomer into a mixed system comprising an amphoteric dispersion stabilizer, a chelating agent, a pH regulator and inorganic salt deionized water solution; initiating a reaction by virtue of an initiating agent; and preparing the amphoteric polyacrylamide dispersion liquid by virtue of a dispersion polymerization method. The dispersion liquid prepared by adopting a novel amphoteric polymer dispersion stabilizer has the characteristics of good stability, high molecular weight, high dissolution rate and the like, and a synthetic process of the dispersion liquid is environment-friendly and pollution-free and is low in energy consumption, and the product is nontoxic and noncorrosive, cannot generate secondary pollution and accords with the development direction of green and environment-friendly chemical assistants. The amphoteric polyacrylamide dispersion liquid has an application prospect in the fields of water treatment, papermaking, printing and dyeing, oil fields, mining, daily chemicals and the like.

Owner:JIANGSU FEYMER TECH

Low-viscosity high-speed cigarette adhesive and preparation method thereof

The invention provides a low-viscosity high-speed cigarette adhesive prepared from seed emulsion, a vinyl acetate monomer, an oxidant, an initiator, a capturing agent, an alcohol compound, a pH regulator and water, wherein the seed emulsion is one or combination of more of vinyl acetate-ethylene emulsion, vinyl acetate-acrylate emulsion, a vinyl acetate homopolymerized emulsion, the seed emulsionhaving solid content of 40.0-65.0% and viscosity of 500-5000 mPa*s. In the invention, firstly, the protective colloid in the emulsion is broken to reduce the viscosity, and then the stable emulsion system is reconstructed through polymerization, and the generation quantity of new emulsion particles is controlled, thus producing the emulsion. The viscosity of the emulsion can be lowered to 200 mPa*s, which not only satisfies the cigarette lap adhesion at the machine speed of 14,000-16,000 / min but also can be used for adhesion of common materials, such as paper processing, coating decoration, nonwoven clothes, carpets, etc. The adhesive is simple in preparation method and is suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +2

Ether-based itaconic acid sulfonate type multi-copolymer scale inhibitor and method for preparing same

InactiveCN101786731BSimple production processLess residual monomerScale removal and water softeningSulfonateSodium Hypophosphite Monohydrate

The invention relates to a multiple scale-resisting corrosion inhibitor, in particular to an ether-based itaconic acid sulfonate type multi-copolymer scale inhibitor and a method for preparing the same. The scale inhibitor is characterized by being prepared by the aqueous polymerization of alpha-allyl glyceroether, itaconic acid and sulfonate in an initiator system; and based on the mass of the itaconic acid, the additive amount of the sulfonate is 10 to 50 percent, the additive amount of the alpha-allyl glyceroether is 5 to 20 percent, the initiator content is 5 to 30 percent, and the additive amount of sodium hypophosphite is 5 to 30 percent. In the method, the itaconic acid serving as the raw material undergoes aqueous polymerization with the alpha-allyl glyceroether and the sulfonate,the production process is simple, residual monomers of the product is little, and three-wastes are not emitted; and the polymer prepared by the method can efficiently inhibit formation and adhesion of the scale layer such as carbonate, sulfate, phosphate and silicate, and better disperse iron oxide, sludge and the like.

Owner:山东省特种设备检验研究院淄博分院

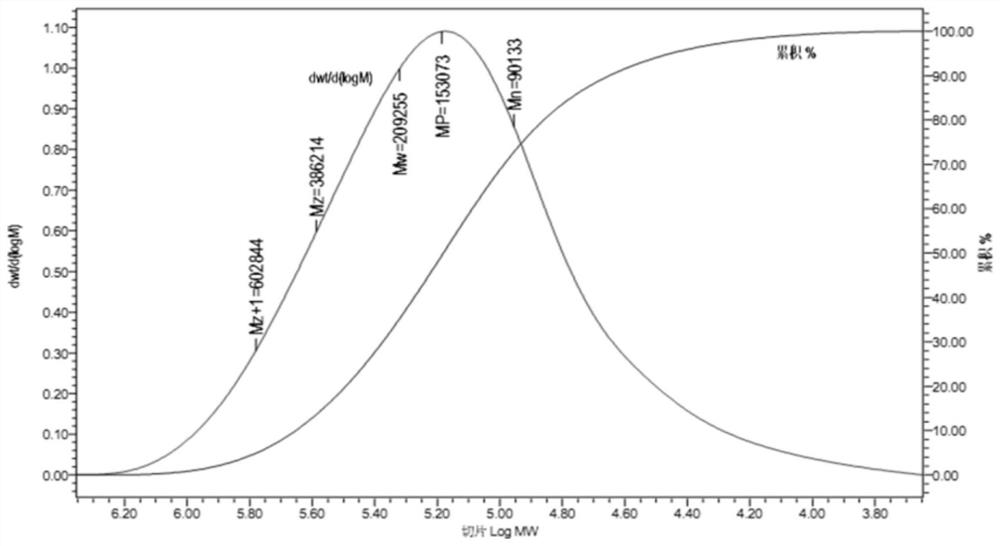

Transparent polystyrene with capacity scale of 50,000 tons or above as well as production equipment and process of transparent polystyrene

PendingCN112724296AMolecular weight easyEasy distributed controlPolystyreneStructural Macromolecules

The invention discloses transparent polystyrene with the capacity scale of 50,000 tons or above as well as production equipment and process of the transparent polystyrene. The main component of the obtained transparent polystyrene product is as follows: n is the degree of polymerization, and the range of the n is 600-7000, and the n is different along with different types of products. The transparent polystyrene has good transparency, the Vicat softening point is 85-106 DEG C, the tensile strength of the transparent polystyrene is 40-55 Mpa at normal temperature, and the transparent polystyrene is a thermoplastic material. The molecular structure contains a small amount of macromolecules with a special structure, and a considerable amount of hydrocarbon micromolecules are contained in gaps of the macromolecules, so that certain slippage can be generated among the macromolecules, and the material has good transparency and mechanical properties compared with products obtained by other process production methods. The process waste water is basically not generated in the production process, all the raw materials are recycled, a small amount of generated process waste gas reaches the standard and is discharged after being condensed and adsorbed by special equipment, and good environment-friendly, energy-saving and consumption-reducing effects can be achieved.

Owner:江苏可立特工程设计研究有限公司

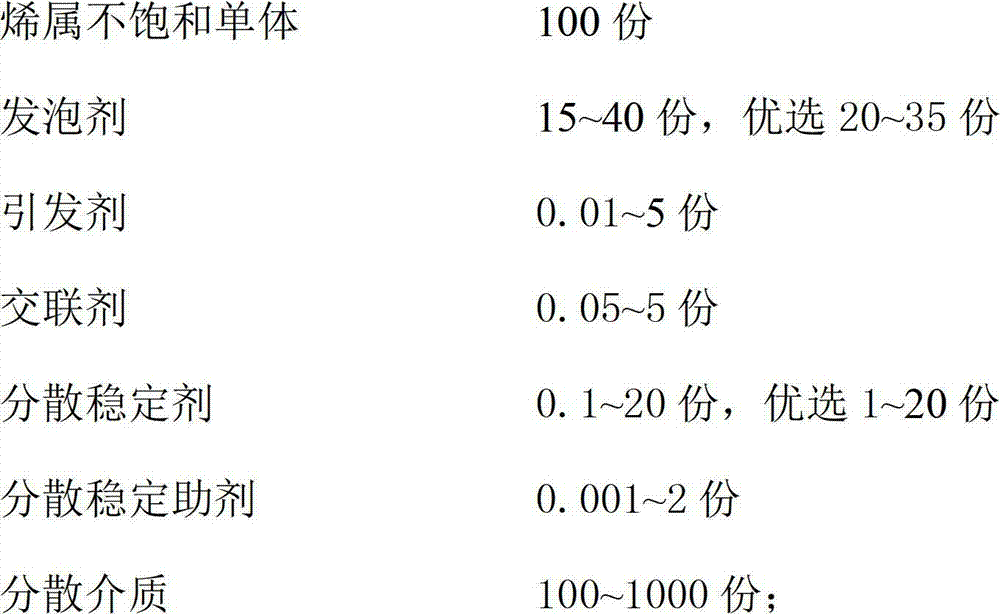

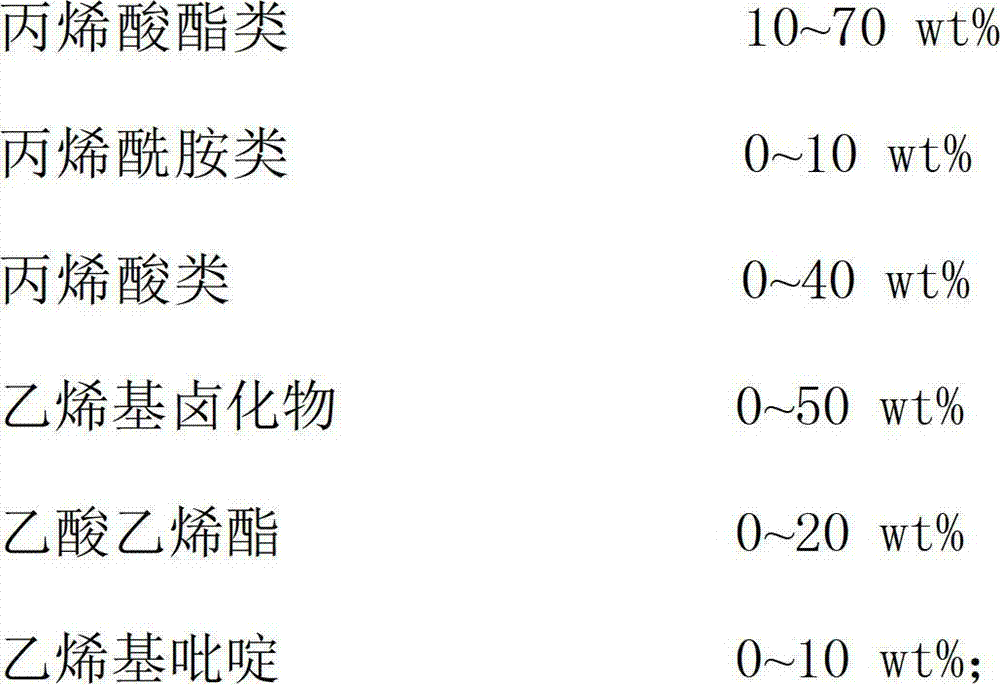

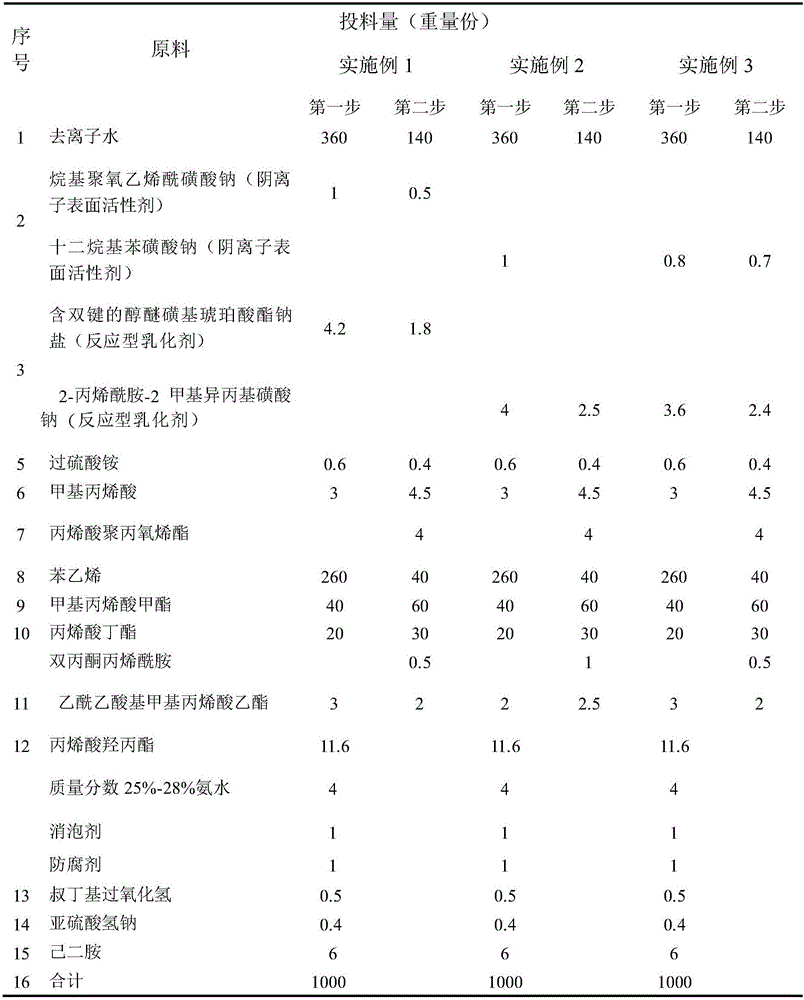

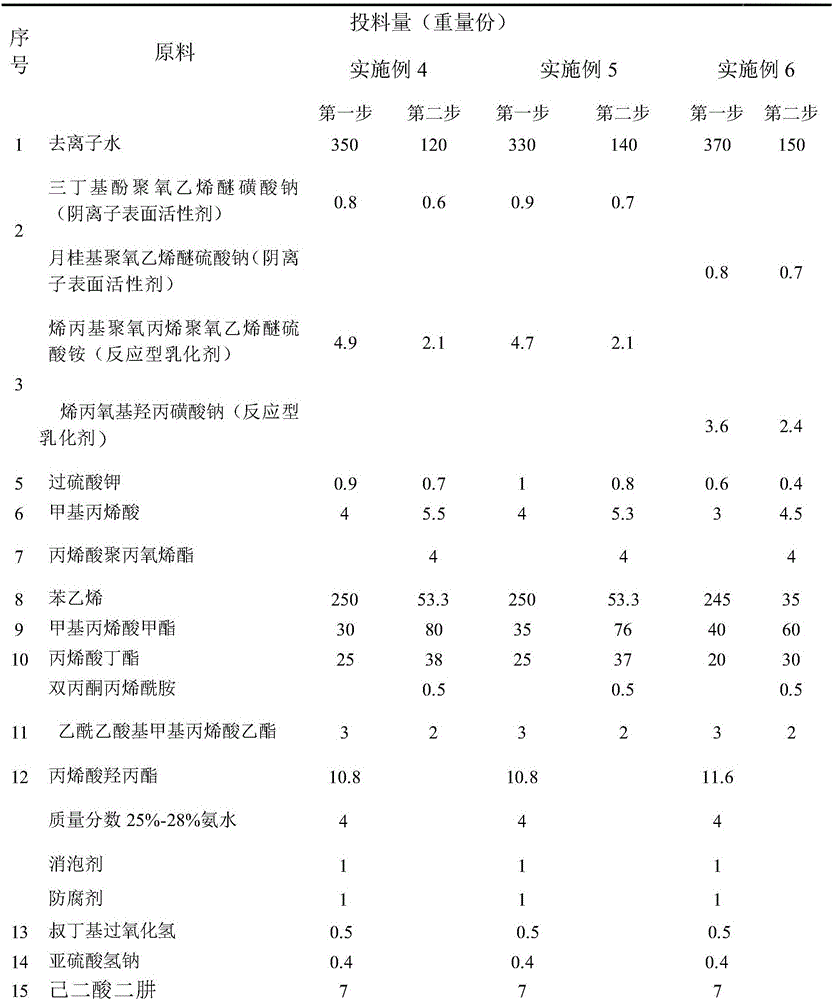

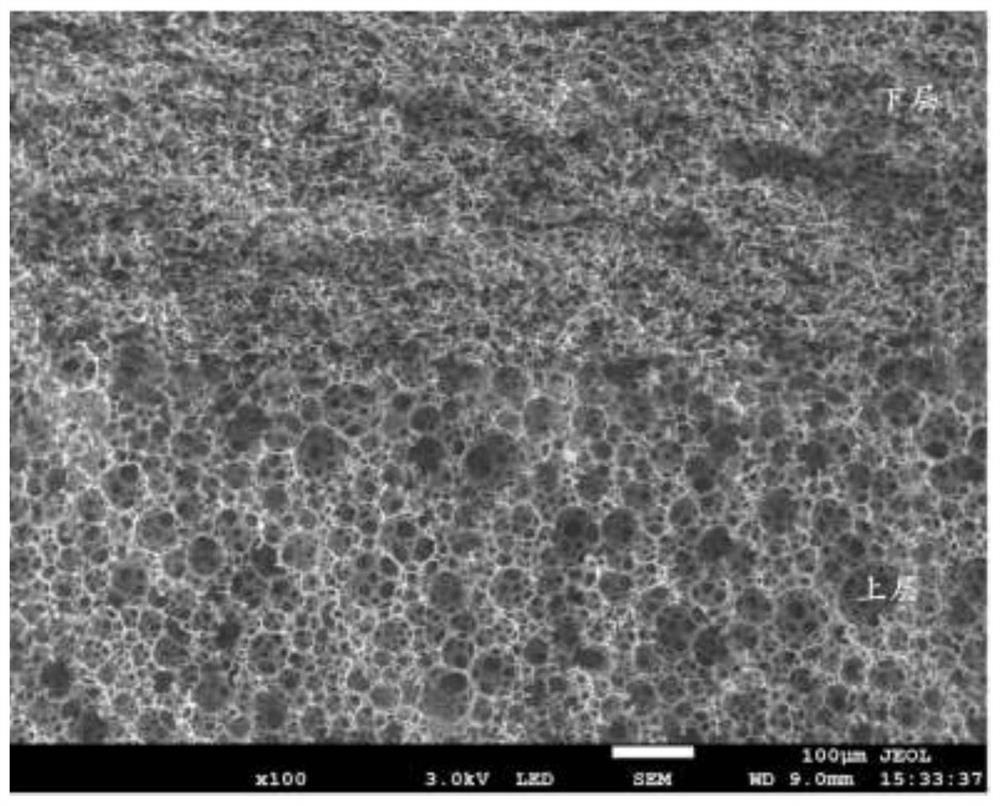

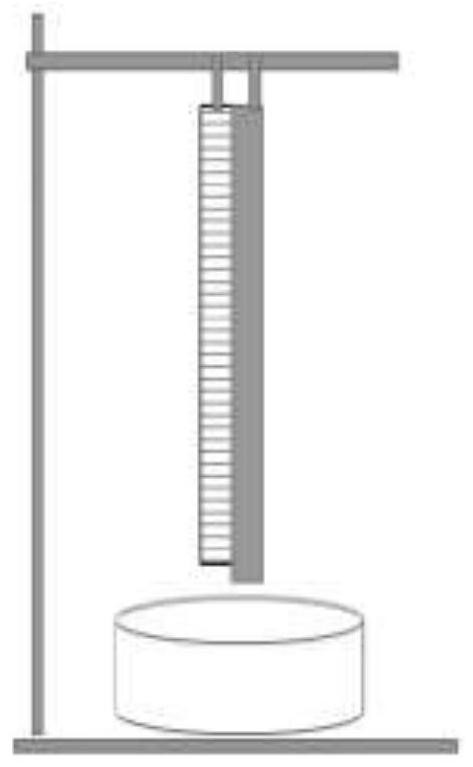

Method for rapidly preparing double-layer structure foam with low residual monomer content, foam material and application thereof

The invention relates to a method for preparing double-layer structure foam with low residual monomer content through rapid curing, a foam material and application thereof. The prepared double-layer structure foam can be used for disposable hygiene products; upper-layer foam holes are large and play a role in rapidly absorbing and guiding fluid to other absorption areas; and lower-layer foam holes are small in size and large in specific surface area and has very high wicking capacity and fluid storage capacity. The prepared hygiene product has very good liquid treatment performance, low reverse osmosis, low odor and good softness, is better in fitness to the body compared with a traditional sanitary product, and is comfortable to use.

Owner:WANHUA CHEM GRP

Thermal insulation type high-weather-resistance low-carbon 5D granite coating and preparation method thereof

InactiveCN111849291ALow VOCSmall smellAntifouling/underwater paintsPaints with biocidesIsooctyl acrylatePhenolic content in tea

The invention discloses a thermal insulation type high-weather-resistance low-carbon 5D granite coating prepared from the following components in parts by weight: 20-30 parts of methyl methacrylate, 10-20 parts of butyl acrylate, 10-20 parts of 2-ethylhexyl acrylate, 1-3 parts of acrylic acid, 2-6 parts of an emulsifier, 1-2 parts of persulfate, 0.3-0.5 part of an oxidizing agent, 0.2-0.3 part ofa reducing agent, 53 parts of water, 10-20 parts of glass beads, 20-30 parts of silicon dioxide, 0.5-1 part of tea polyphenol, 15-20 parts of montmorillonite, 1-3 parts of kaolin deionized water, 1-8parts of a coalescing agent and 5-7 parts of a dispersing agent. Treatment is carried out through a redox system; further residual monomers are reduced, the 5D granite coating has the advantages of low VOC, low odor, environment friendliness and suitability for market popularization; a prepared emulsion adhesive has strong water resistance, acid resistance, alkali resistance and stain resistance,and the added silicon dioxide has good acid and alkali resistance, small silicon dioxide expansion coefficient, high hardness and good acid and alkali weather resistance, and can provide protection for vitrified micro bubbles.

Owner:泉州市美尔奇装饰材料有限公司

Preparation method of carboxylic acrylonitrile butadiene rubber latex containing vinyl chloride structure

The present invention provides a kind of preparation method of the carboxyl nitrile latex of vinyl chloride structure, comprises the following steps: (1) the synthesis of latex, add deionized water, electrolyte, pH buffering agent, mercaptan, emulsifier, Acrylonitrile, unsaturated carboxylic acid, unsaturated carboxylic acid ester, initiator, nitrogen filling and vacuuming, repeated three times, adding butadiene and vinyl chloride; (2) latex degassing and aftertreatment, the present invention adopts multiple chemical copolymerization reaction to form a four- or five-polymer copolymer containing vinyl chloride structural units; by adding an oil-soluble initiator in the later stage of the polymerization reaction, the polymerization reaction is more complete and the residual monomer is less; the introduction of vinyl chloride into the polymer chain Monomer, the wear resistance, tensile strength and chemical resistance of its products have been significantly improved.

Owner:安庆华兰科技有限公司

Prefabricated part water washing surface coating agent

InactiveCN111360985AEasy to prepareLow costCeramic shaping apparatusComposite materialResidual monomer

The invention relates to the technical field of prefabricated part water washing surface coating agents, and discloses a prefabricated part water washing surface coating agent. The prefabricated partwater washing surface coating agent is characterized in that the mass ratio of water to glucose to a thickening agent is 1.7-2.3 to 0.7-1.3 to 0.02-0.08. When a prefabricated part is made, the coatingagent coats a formwork in advance for form erecting and pouring, after the strength of the concrete meets the hoisting requirement, form removal is performed, then a high pressure water gun is used for flushing to flush away concrete mortar on a contact surface of the coating agent, then stone aggregate is exposed outside to be conveniently combined with cast-in-place concrete, through the arrangement of components of the coating agent, the viscosity of the coating agent can be improved, meanwhile, the application performance of the coating agent also can be improved, the preparation processis simple, the cost is low, the effect is good, the proper viscosity can be conveniently adjusted, the thickening agent is arranged, so that residual monomers of the prefabricated part water washing surface coating agent are few, self-thickening property is achieved, the thickening agent color paste modulation is convenient, the stability is good, crusts are not formed on the surface, and the compatibility with a coating is good.

Owner:YUANJIAN INDZED HOUSING INTEGRATED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com