Coating thickener

A paint thickener and raw material technology, applied in the field of paint thickeners, can solve problems such as poor stability, achieve good stability, less residual monomers, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

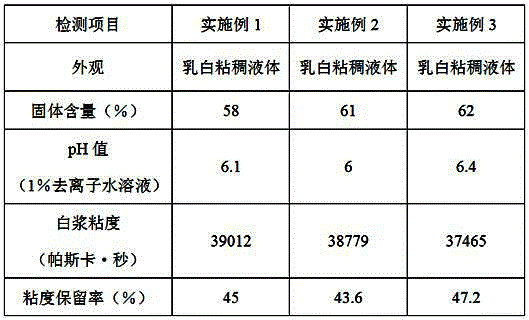

Examples

Embodiment 1

[0014] The paint thickener of this embodiment is prepared from the following raw materials in parts by weight: 25 parts of acrylic acid, 20 parts of hydroxyethyl cellulose, 10 parts of stearic acid, 2 parts of sodium dodecylbenzenesulfonate, cumene 0.2 parts of hydrogen peroxide, 80 parts of No. 150 mineral spirits.

[0015] The preparation method of the paint thickener in this example is as follows: Weigh the above-mentioned raw materials in parts by weight, add hydroxyethyl cellulose, stearic acid and acrylic acid to No. 150 solvent oil, stir evenly, and then add lauryl Sodium benzenesulfonate and cumene hydroperoxide, stirred for 2 hours, left to stand until the mixed solution is fully mixed to obtain a paint thickener.

Embodiment 2

[0017] The paint thickener of this embodiment is prepared from the following raw materials in parts by weight: 30 parts of acrylic acid, 15 parts of hydroxyethyl cellulose, 15 parts of stearic acid, 5 parts of sodium dodecylbenzenesulfonate, cumene 2 parts of hydrogen peroxide, 90 parts of No. 150 solvent naphtha.

[0018] The preparation method of the paint thickener in this example is as follows: Weigh the above-mentioned raw materials in parts by weight, add hydroxyethyl cellulose, stearic acid and acrylic acid to No. 150 solvent oil, stir evenly, and then add lauryl Sodium benzenesulfonate and cumene hydroperoxide were stirred for 3 hours, and left to stand until the mixed solution was fully mixed to obtain a paint thickener.

Embodiment 3

[0020] The paint thickener in this example is prepared from the following raw materials in parts by weight: 35 parts of acrylic acid, 25 parts of hydroxyethyl cellulose, 20 parts of stearic acid, 7 parts of sodium dodecylbenzenesulfonate, tert-butyl 4 parts of hydrogen peroxide, 100 parts of No. 100 solvent naphtha.

[0021] The preparation method of the paint thickener in this example is as follows: Weigh the above-mentioned raw materials in parts by weight respectively, add hydroxyethyl cellulose, stearic acid and acrylic acid to No. 100 solvent oil, stir evenly, and then add lauryl Sodium benzenesulfonate and tert-butyl hydroperoxide were stirred for 2.5 hours, and left to stand until the mixed solution was fully mixed to obtain a paint thickener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com