Foaming agent for hydrophobic foam concrete and preparation method of foaming agent

A foamed concrete and foaming agent technology, applied in the field of building materials, can solve the problems of low strength of foamed concrete, high continuous porosity of products, serious slump settlement, etc., and achieve good foam stability, improve hydration degree, and reduce water absorption. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

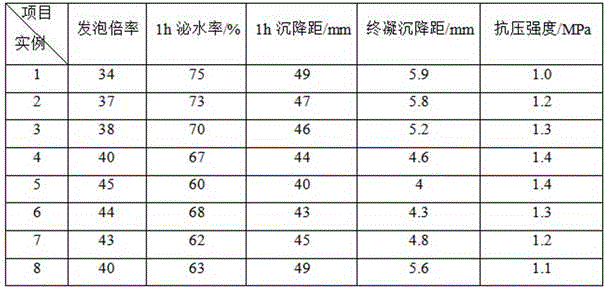

Examples

Embodiment 1

[0033] A foaming agent for hydrophobic foam concrete, comprising the following raw materials in parts by weight: foaming agent fatty alcohol polyoxyethylene ether sodium sulfate AES 200kg, foam stabilizer coconut oil fatty acid diethanolamide 6501 20 kg, thickening Agent hydroxypropyl methylcellulose 1kg, enhancer magnesium chloride 210kg, diluent n-butanol 15kg, preservative 1.5kg and water 420kg.

[0034] The preparation method of foaming agent for above-mentioned hydrophobic foam concrete comprises the following steps:

[0035] (1) Add 1 / 3 of the total water into the reaction kettle first, then add foaming agent, heat to 30°C, stir evenly to form foaming liquid;

[0036] (2) Heat the remaining water to 40°C to obtain warm water, and dissolve the enhancer in warm water;

[0037] (3) Add a foam stabilizer to the reactor in step (1), and stir evenly;

[0038] (4) Add 50% diluent to the inside of the reaction kettle in step (3) for pre-diluted, then add the enhancer treated i...

Embodiment 2

[0042] A foaming agent for hydrophobic foam concrete, comprising the following raw materials in parts by weight: foaming agent sodium lauryl sulfate K12 210 kg, foam stabilizer coconut oil fatty acid diethanolamide 6501 23 kg, thickener poly Vinyl alcohol 1.5 kg, enhancer sodium chloride 250 kg, diluent ethanol 16 kg, preservative 1.8 kg and water 430 kg.

[0043] The preparation method of foaming agent for above-mentioned hydrophobic foam concrete comprises the following steps:

[0044] (1) First add 1 / 2 of the total water into the reaction kettle, then add foaming agent, heat to 40°C, stir evenly, and form a foaming liquid;

[0045] (2) Heat the remaining water to 30°C to obtain warm water, and dissolve the enhancer in warm water;

[0046] (3) Add a foam stabilizer to the reactor in step (1), and stir evenly;

[0047](4) Add 40% diluent to the inside of the reaction kettle in step (3) for pre-diluted, then add the enhancer treated in step (2), stir evenly, and finally add ...

Embodiment 3

[0051] A foaming agent for hydrophobic foam concrete, comprising the following raw materials in parts by weight: foaming agent fatty alcohol polyoxyethylene ether sodium sulfate AES 180kg, tea saponin 25kg, foam stabilizer coconut oil fatty acid diethanolamide 6501 20.5 kg, thickener latex powder 1.5 kg, reinforcing agent calcium chloride 300 kg, diluent sec-butanol 20 kg, preservative 2kg and water 450kg.

[0052] The preparation method of foaming agent for above-mentioned hydrophobic foam concrete comprises the following steps:

[0053] (1) Add 1 / 3 of the total water into the reaction kettle first, then add foaming agent, heat to 30°C, stir evenly to form foaming liquid;

[0054] (2) Heat the remaining water to 40°C to obtain warm water, and dissolve the enhancer in warm water;

[0055] (3) Add a foam stabilizer to the reactor in step (1), and stir evenly;

[0056] (4) Add 50% diluent to the inside of the reaction kettle in step (3) for pre-diluted, then add the enhancer t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com