Patents

Literature

185results about How to "Increased hydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

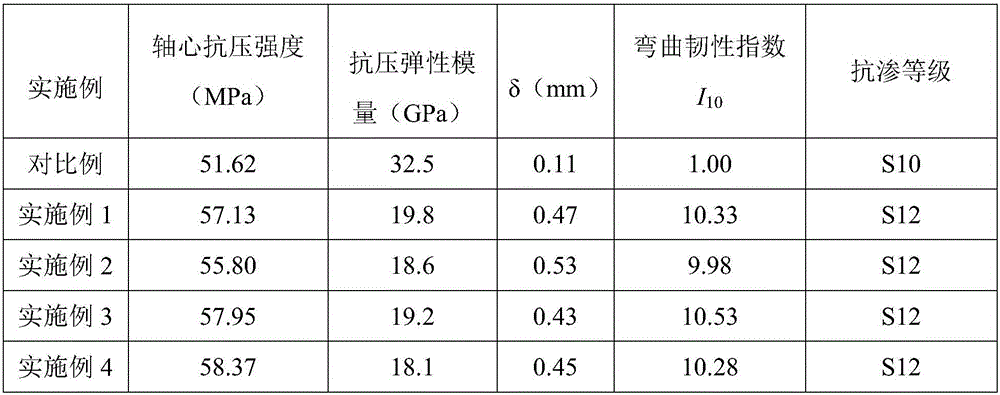

Cellulose fiber internal curing-based ultra-high-performance cement-based composite material and preparation method thereof

ActiveCN106396555AImprove early shrinkage deformationIncreased hydrationCement based compositesMaterials science

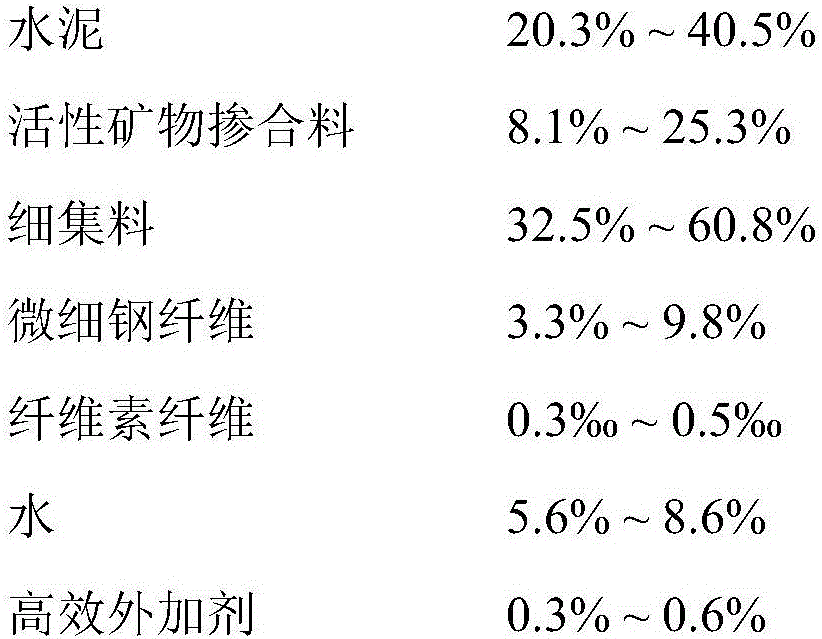

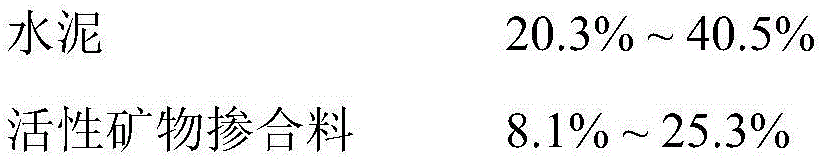

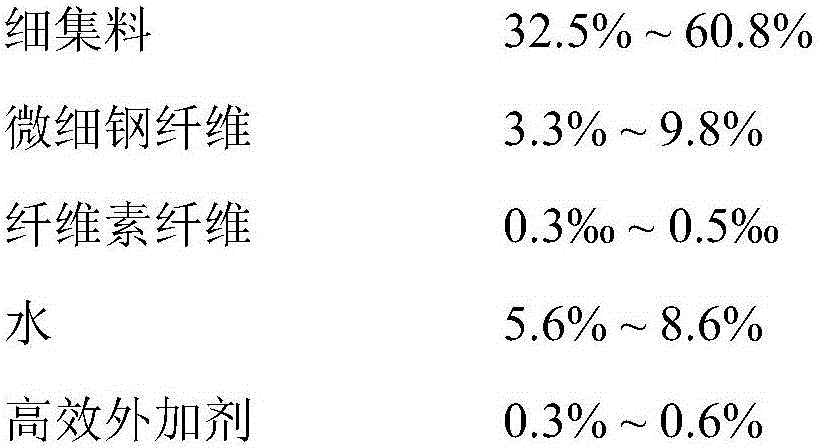

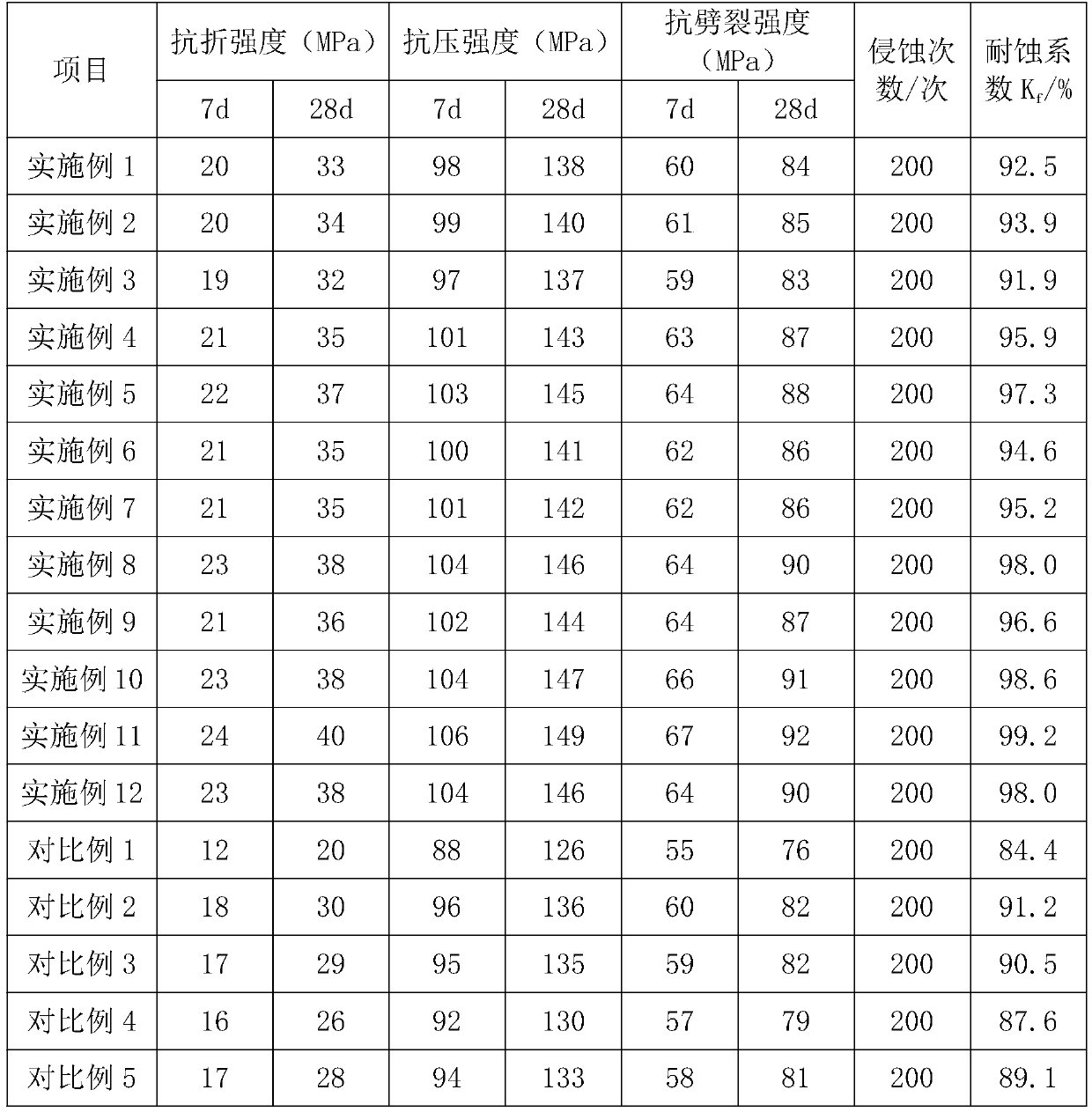

The invention discloses a cellulose fiber internal curing-based ultra-high-performance cement-based composite material and a preparation method thereof. The cellulose fiber internal curing-based ultra-high-performance cement-based composite material comprises the following components in weight percentage: 20.3-40.5% of cement, 8.1-25.3% of active mineral admixture, 32.5-60.8% of fine aggregate, 3.3-9.8% of micro-fine steel fibers, 0.03-0.05% of cellulose fibers, 5.6-8.6% of water and 0.3-0.6% of efficient admixture. According to the technical scheme of the ultra-high-performance cement-based composite material and the preparation method thereof, the advantages of good slurry workability, high breaking strength, low early hydration speed of cement-based materials, small early shrinkage and deformation amount, high overall hydration degree and the like are realized compared with the prior art. Meanwhile, the later compressive strength of cement-based materials is less affected by cellulose fibers. Therefore, the mechanical property and the durability during the later period are improved.

Owner:SOUTHEAST UNIV

Recycled concrete and preparation method thereof

InactiveCN111039624AReduce porosityCompact structureSolid waste managementEpoxyCompressive resistance

The invention relates to recycled concrete and a preparation method thereof, and belongs to the technical field of concrete. The recycled concrete comprises (by weight): 150-280 parts of cement, 90-130 parts of water, 800-950 parts of modified recycled coarse aggregate, 400-530 parts of fine aggregate, 40-85 parts of fly ash, 80-100 parts of mineral powder, 50-140 parts of zeolite powder, 30-60 parts of epoxy resin, 4-10 parts of a water reducing agent and 2-6 parts of an air entraining agent. The preparation method of the modified recycled coarse aggregate comprises the following steps: S1, crushing and screening waste concrete to obtain recycled coarse aggregate; S2, soaking the recycled coarse aggregate obtained in the step S1 in an acetic acid solution with the mass concentration of 2-7%, and airing; S3, stirring 80-110 parts of polyvinyl alcohol, 60-110 parts of silica fume, 40-80 parts of sodium silicate and 800-1,000 parts of water to obtain a modified liquid; and S4, soaking the recycled coarse aggregate obtained in the step S2 in the modified liquid obtained in the step S3, taking out the soaked recycled coarse aggregate, and baking the recycled coarse aggregate to obtainthe modified recycled coarse aggregate. The recycled concrete provided by the invention has a good compressive strength effect.

Owner:泸州临港思源混凝土有限公司

Concrete gel reducing agent

ActiveCN104119014ARefined particlesImprove initial flow propertiesThree-dimensional spaceUltimate tensile strength

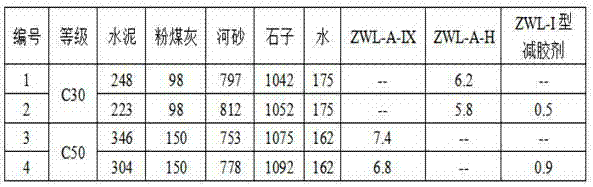

The invention relates to a concrete gel reducing agent which comprises the following formula components in percentage by weight: 1%-3% of phosphonic acid ramifications A, 2%-5% of hydroxy aromatic compounds B, 8%-13% of alkylamine C and the balance of water, wherein the total amount of the phosphonic acid ramifications A, the hydroxy aromatic compounds B and the alkylamine C is 15%. A part of organic substances contained in the concrete gel reducing agent used as a novel concrete additive have molecular structures with three-dimensional spaces and have higher micro dispersion property on cement. If the gel reducing agent is doped into concrete, cement particles are sufficiently refined under the condition that the usage amount of the cement is reduced, the initial flowing property of the concrete is improved, and the hydration degree of a cement mineral is enhanced by promoting the hydration of ferrite which is more difficult to hydrate, so that the early strength is enhanced, the later strength of the cement is effectively excited and the compactness of the concrete is enhanced.

Owner:浙江五龙新材股份有限公司

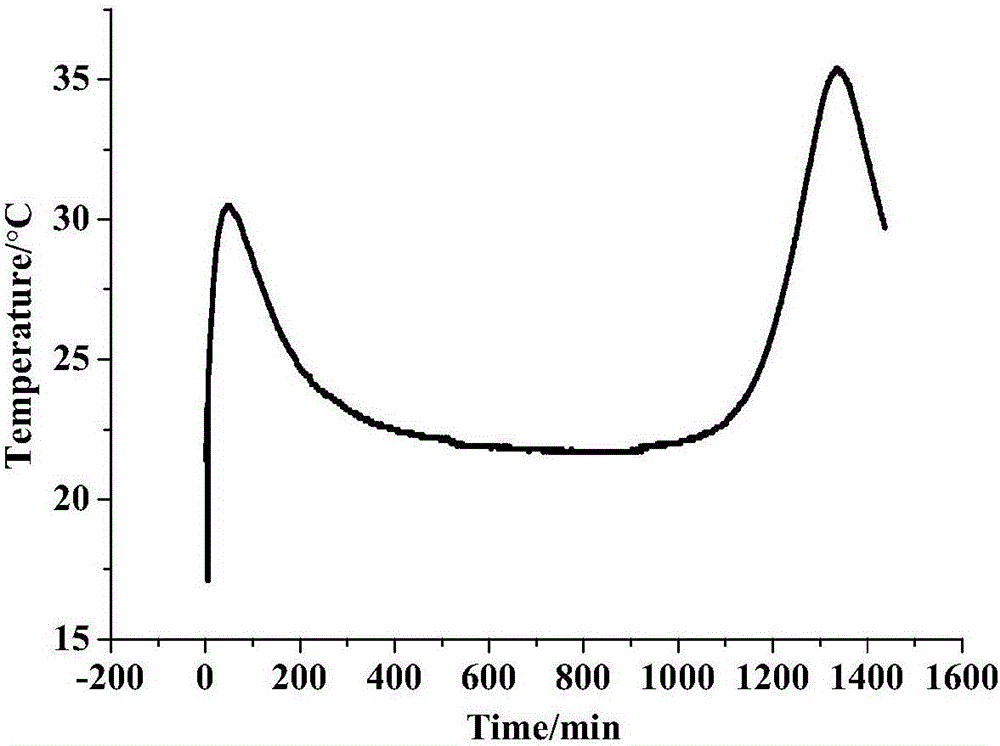

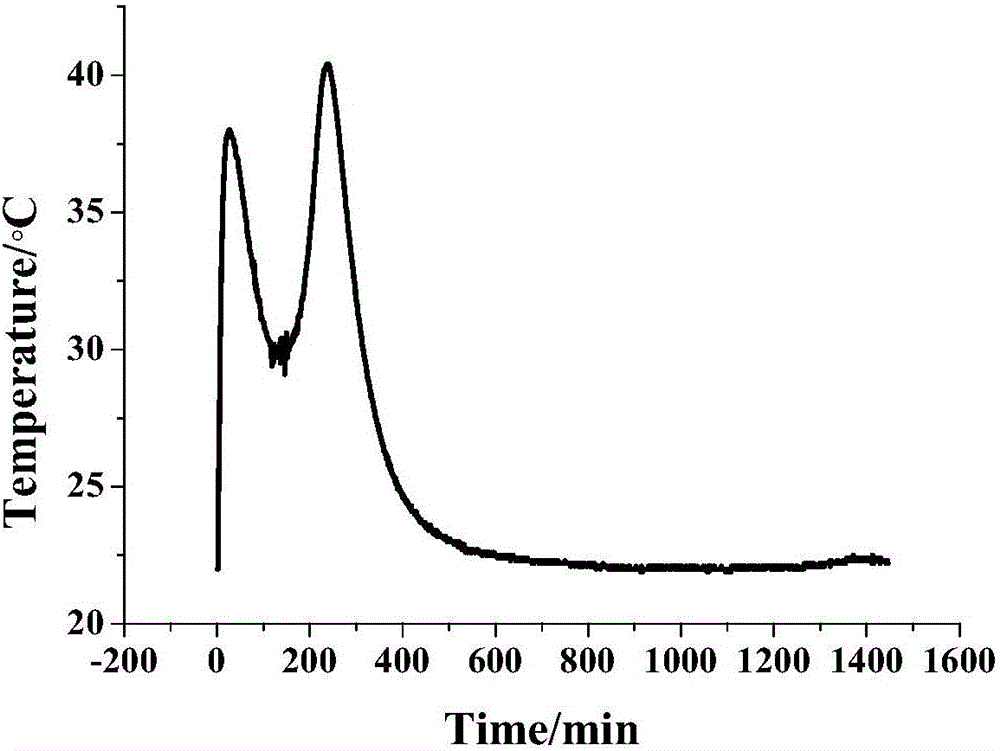

Polycarboxylate water reducer for ultra-compact concrete for nuclear power and preparation method of polycarboxylate water reducer

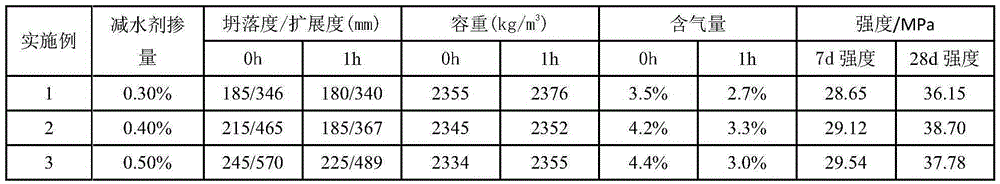

The invention relates to a polycarboxylate water reducer for ultra-compact concrete for nuclear power and a preparation method of the polycarboxylate water reducer. Every 100 parts of the water reducer comprises components in parts by weight as follows: 50-55 parts of a dispersing ether type polycarboxylate water reducer, 20-25 parts of a slump retaining ether type polycarboxylate water reducer, 3-5 parts of a retarder, 0.01-0.05 parts of a defoaming agent, 1-3 parts of a water retaining agent, 1-2 parts of a shrinkage reducing agent, 0.1-0.3 parts of a preservative and the balance of water. The components are uniformly mixed in parts by weight during preparation. Compared with the prior art, the water reducer has the advantages as follows: concrete workability and liquidity are improved, a temperature peak value and a shrinkage value of the concrete are reduced, the internal porosity of the concrete is reduced, the self-compacting performance and the durability of the concrete are improved and the like; besides, the preparation method is simple, raw material sources are wide, the cost is low, and the water reducer is environment-friendly and has the good application prospect.

Owner:TONGJI UNIV

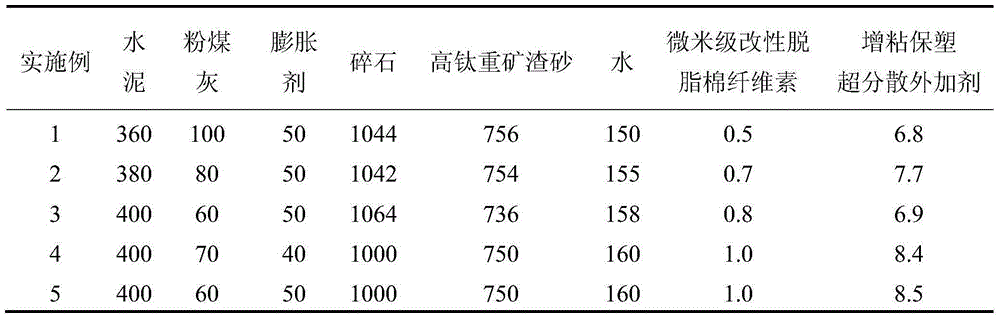

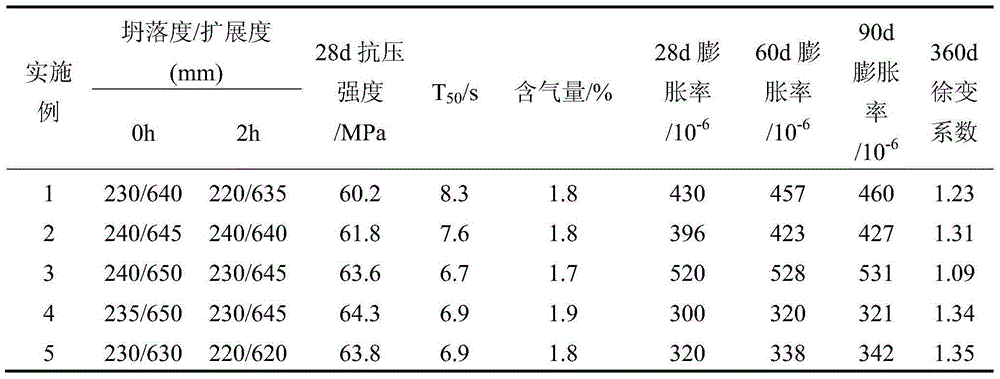

High titanium-bearing heavy slag C50 self-compacting weakly expansive concrete-filled steel tube and preparation method thereof

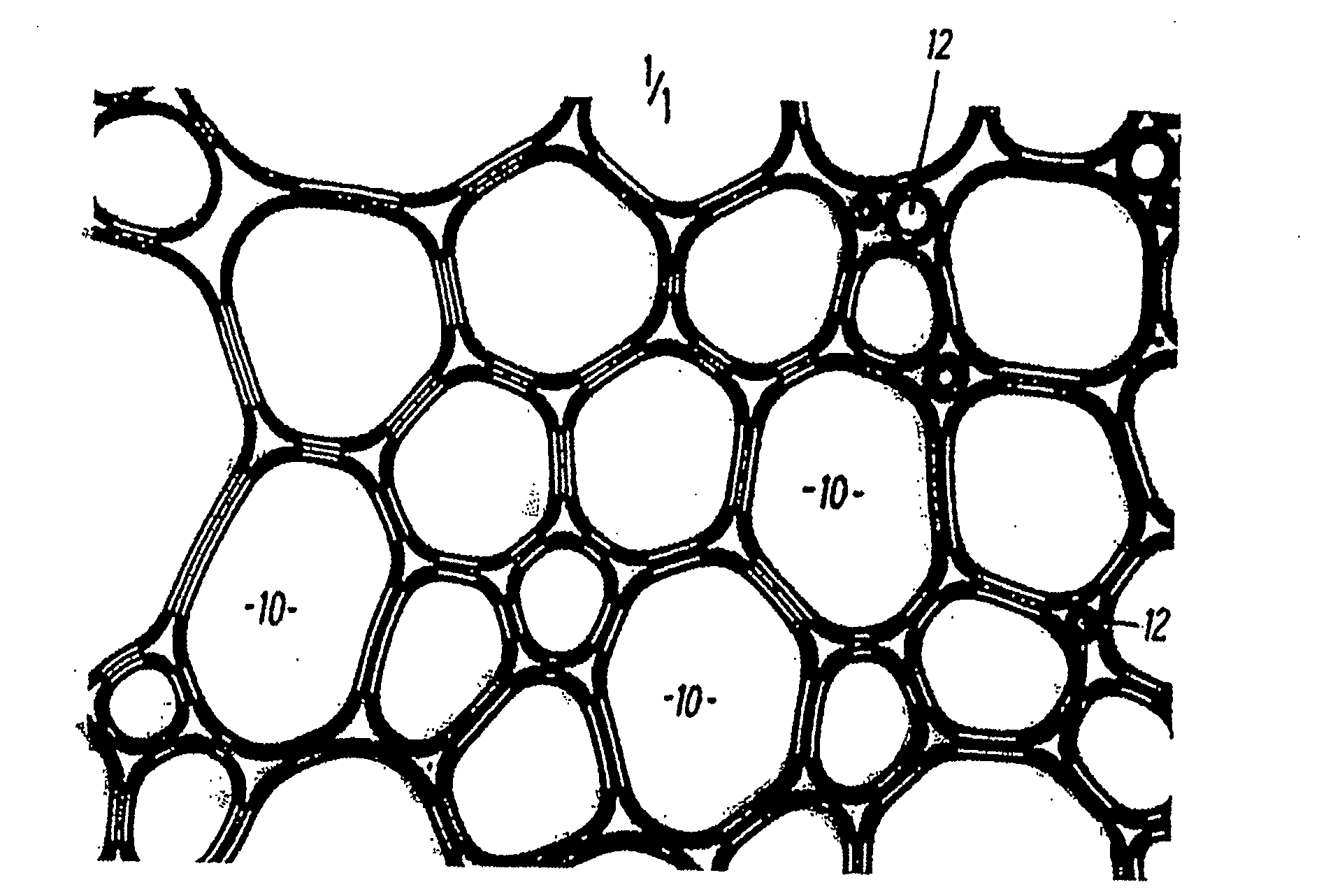

ActiveCN105060793AImprove cementing performanceFull hydration activitySolid waste managementCelluloseCompensation effect

The invention discloses a high titanium-bearing heavy slag C50 self-compacting weakly expansive concrete-filled steel tube, and belongs to the field of building materials. The concrete-filled steel tube is prepared from the following raw materials: cement, coal ash, composite expanding agent, macadam, high titanium-bearing heavy slag, a tackifying plasticity-maintaining super-dispersing additive, micron-sized modified absorbent cotton cellulose and water. The prepared concrete-filled steel tube has the characteristics of high flow state, low gas content, large strength extra coefficient and stable expansibility; the problem of poor working performance caused by application of high titanium-bearing heavy slag to concrete is solved; due to the water absorption and water releasing effect of the porous structure, the internal maintenance effect on the concrete-filled steel tube can be realized, the shrinkage compensation effect of the expanding agent on the concrete-filled steel tube is improved, the concrete-filled steel tube is weakly expansive to be suitable for jacking pouring of upper chord pipes and lower chord pipes of a concrete-filled steel tube arched bridge and a concrete-filled steel tube truss bridge, as well as high-casting pouring of a concrete-filled steel tube pier column. Therefore, the problem of disengaging caused by poor-density pouring of the concrete-filled steel tube is solved effectively.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

Cosmetic compositions comprising exopolysaccharides derived from microbial mats, and use thereof

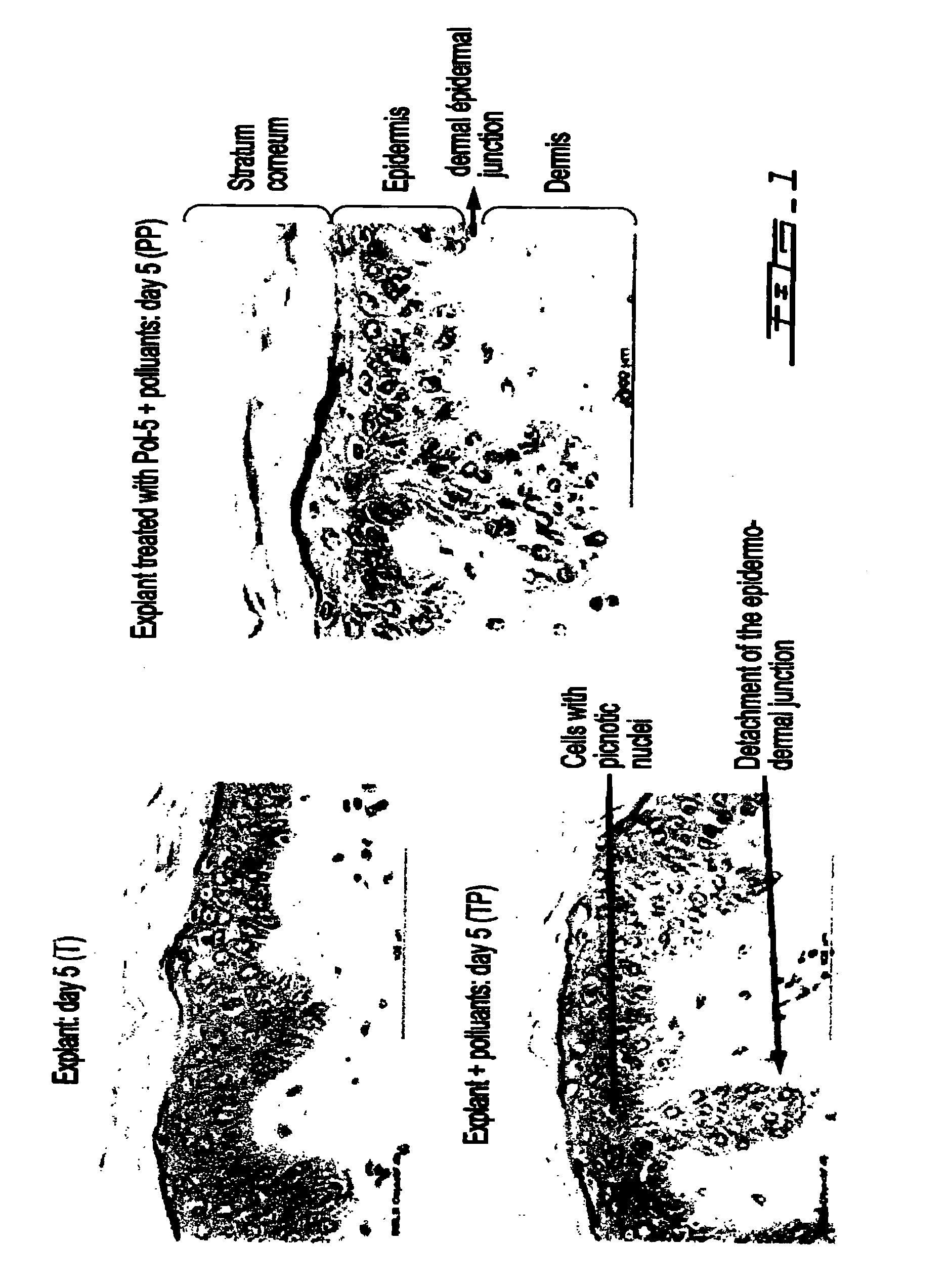

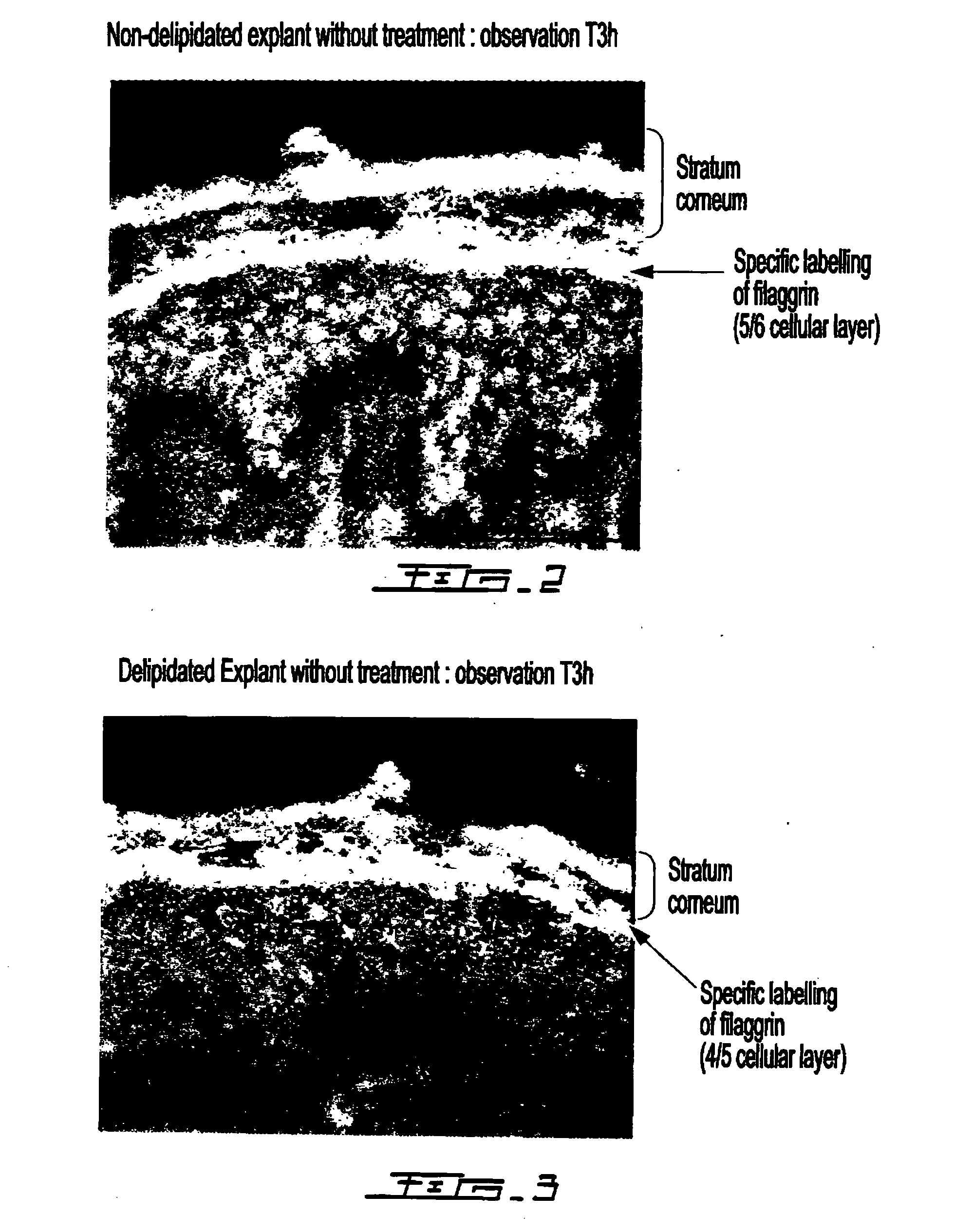

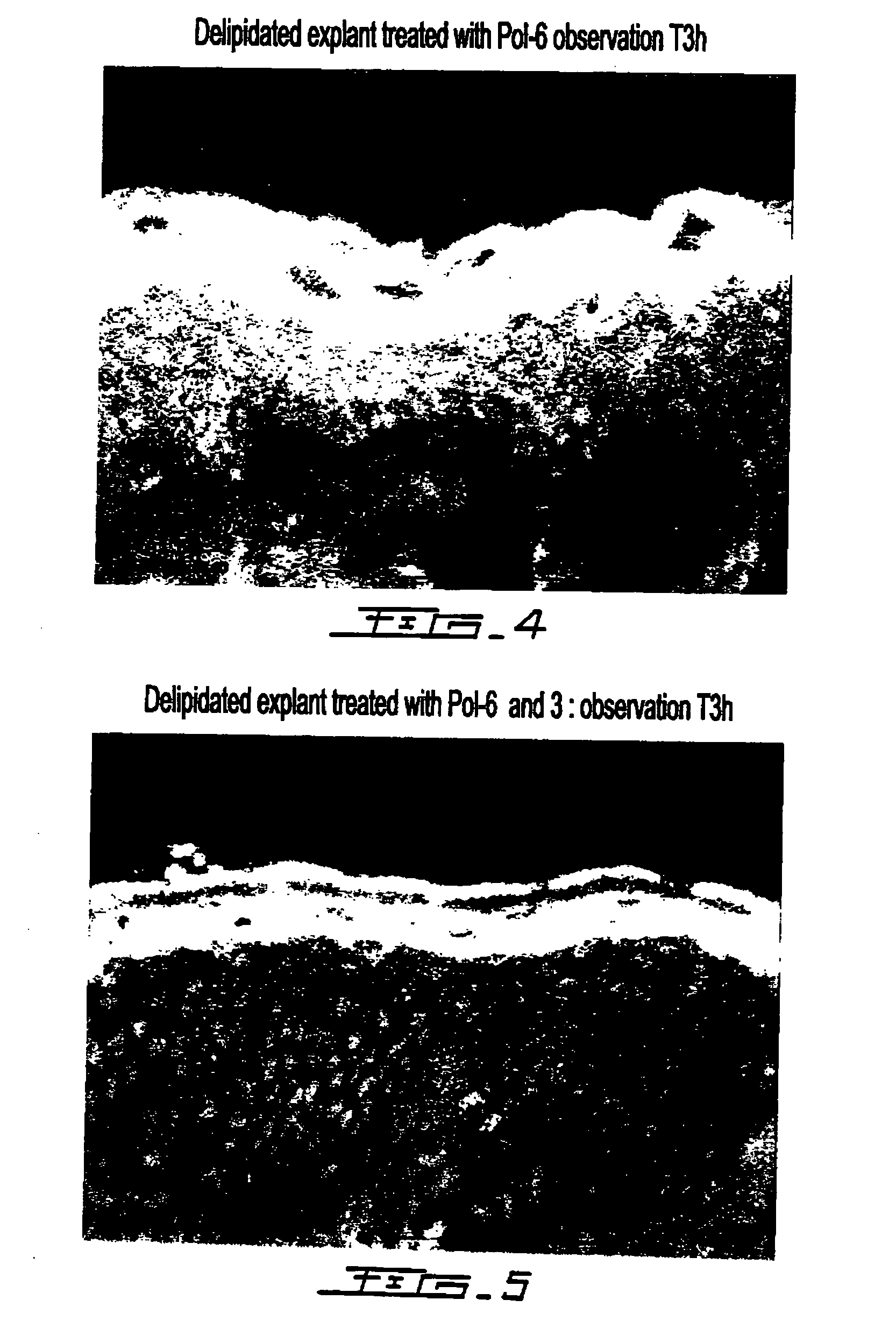

InactiveUS20110150795A1Increased hydrationReduce bacterial adhesionOrganic active ingredientsBiocideMicronesia-PolynesiaCellular metabolism

Disclosed herein is a skin care composition comprising at least one exopolysaccharide (EPS) originating from a microbial mat, wherein the EPS is in a concentration of about 0.001% w / w to about 1.5 w / w of the composition. Preferably, the EPS is derived from microorganism isolated from microbial mats found in French Polynesia. The composition is useful in reducing and preventing signs of skin aging and environmental damage by altering skin cell metabolism and improving hydration.

Owner:LUCAS MEYER COSMETICS CANADA

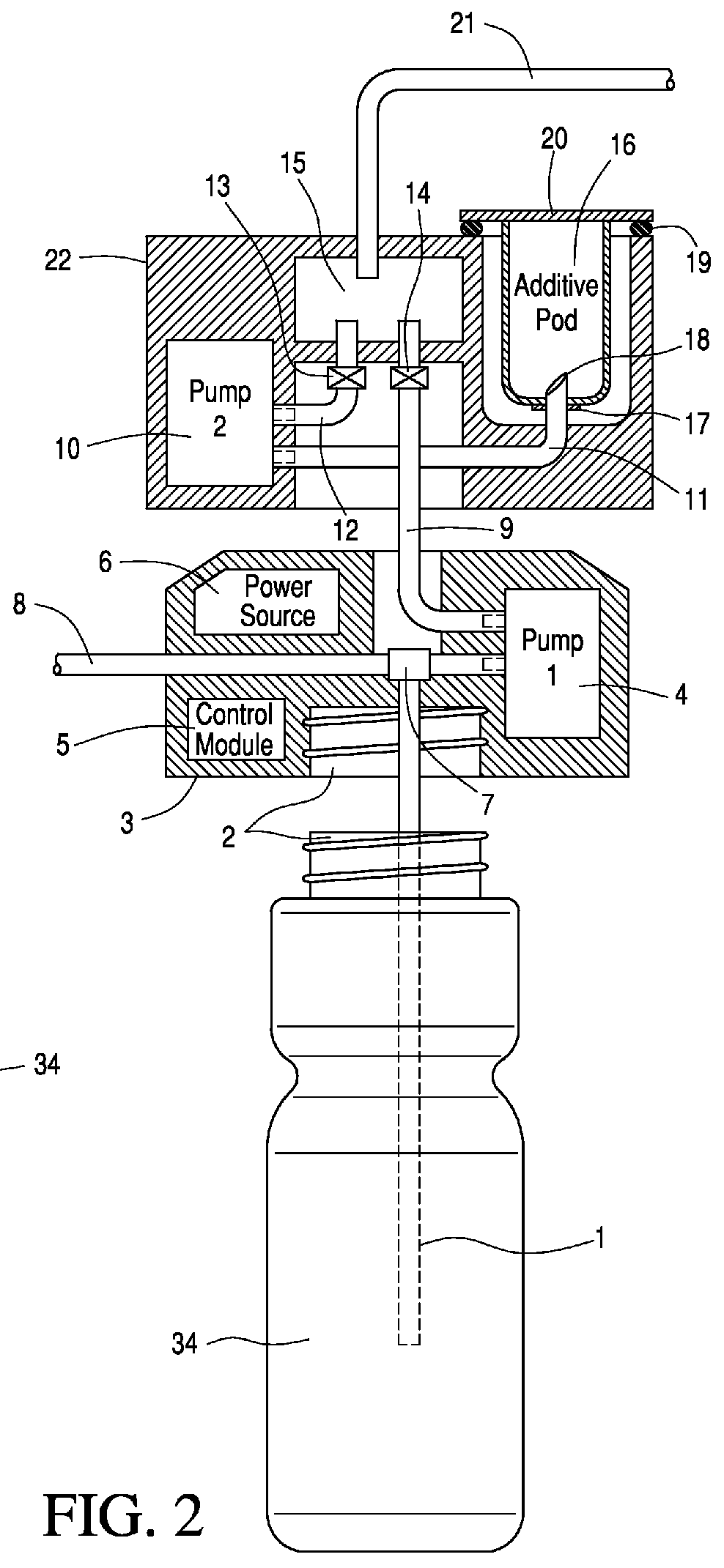

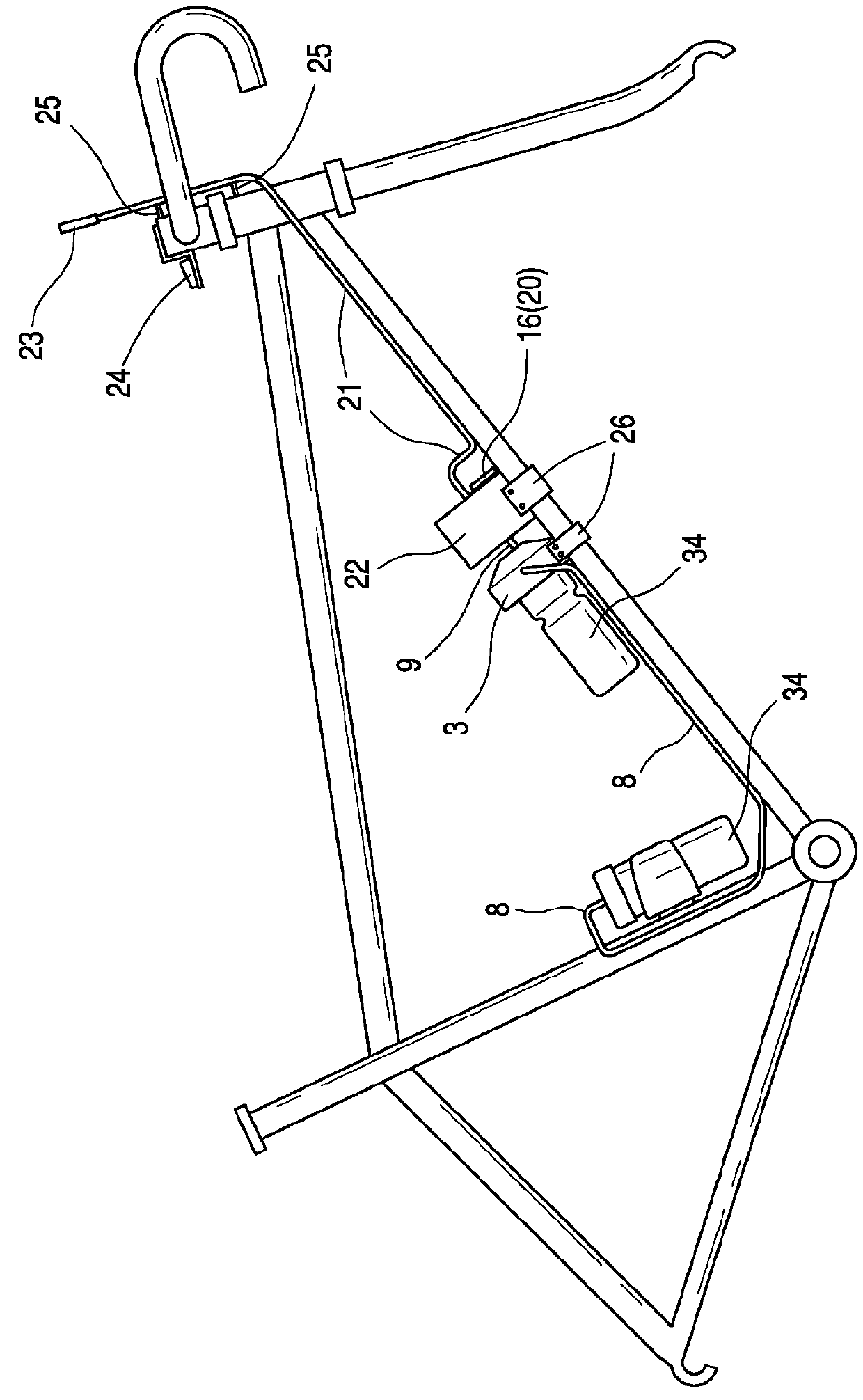

Motorized hydration system

ActiveUS9375742B1Easy to installIncreased hydrationTravelling sacksCycle equipmentsPower controlEngineering

The motorized hydration kit provides motorized unpressurized hydration to persons riding bicycles and / or persons using waist or back packs while driving, walking, running and hiking. A miniature light weight vane and / or peristaltic and / or diaphragm liquid pumps powered by a rechargeable direct current power source are built into a proprietary water bottle cap assembly that will replace most caps of water bottles type in the market. Same cap along with two tubing fittings will allow a simple and quick modification of most types of hydration bladders used in waist or back packs in the market. A programmable pump power control module will allow users to draw liquid and liquefied food additives from water bottles or water bladders and proprietary food additive capsules / containers on demand.

Owner:YOKED YEHUDA

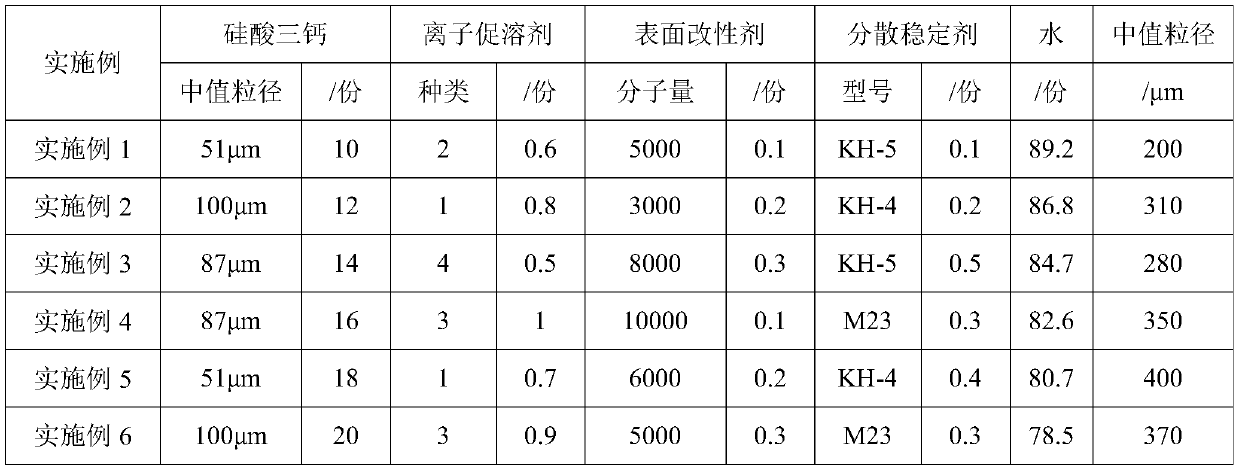

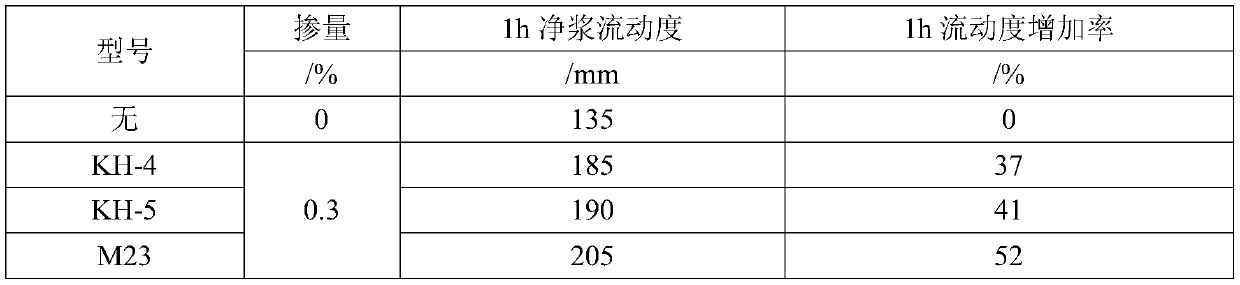

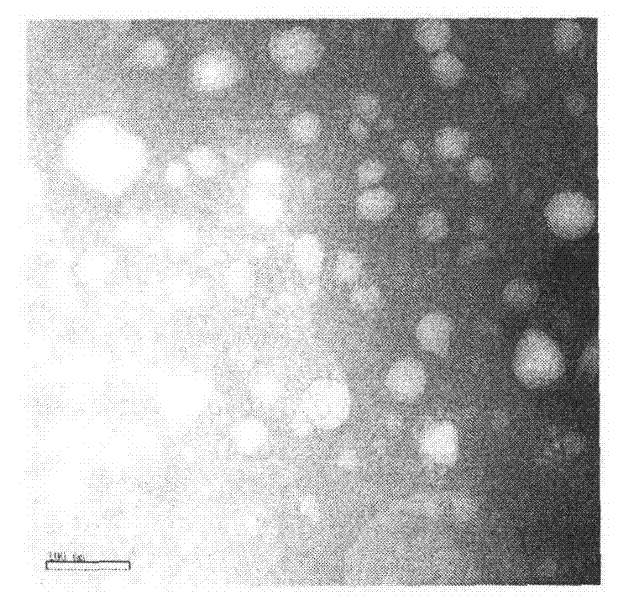

C-S-H gel nanocrystal nucleus early strength agent, preparation method and application thereof

ActiveCN110330257AAccelerated nucleation growthImprove pore structureIon acceleratorsNucleation growth

The invention provides a C-S-H gel nanocrystal nucleus early strength agent, a preparation method and application thereof. The C-S-H gel nanocrystal nucleus early strength agent is mainly prepared from the following components by weight through wet milling process: 10-20 parts of tricalcium silicate, 0.5-1 part of an ion promoter, 0.1-0.3 part of a surface modifier, 0.1-0.5 part of a dispersion stabilizer, and 78.5-89.2 parts of water. The C-S-H gel nanocrystal nucleus early strength agent provided by the invention utilizes the crystal nucleus induction effect of nano form C-S-H gel to accelerate the nucleation growth of hydration products at the early stage of hydration, and can achieve the early strength purpose from the two aspects of by improving the pore structure and inducing nucleation.

Owner:WUHAN UNIV OF TECH

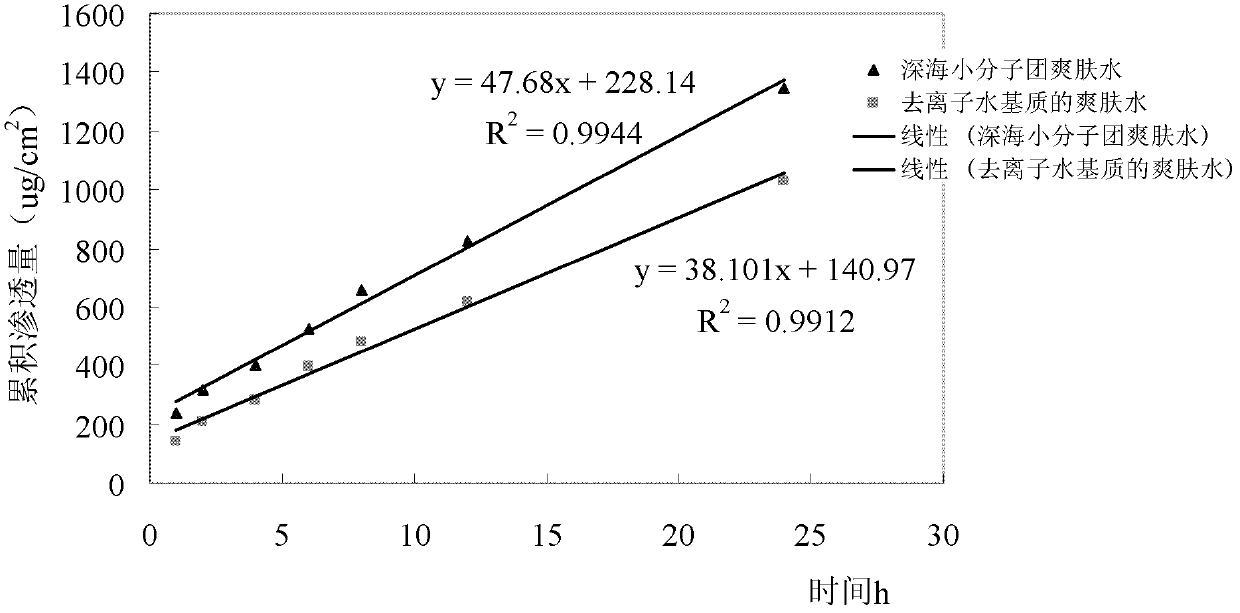

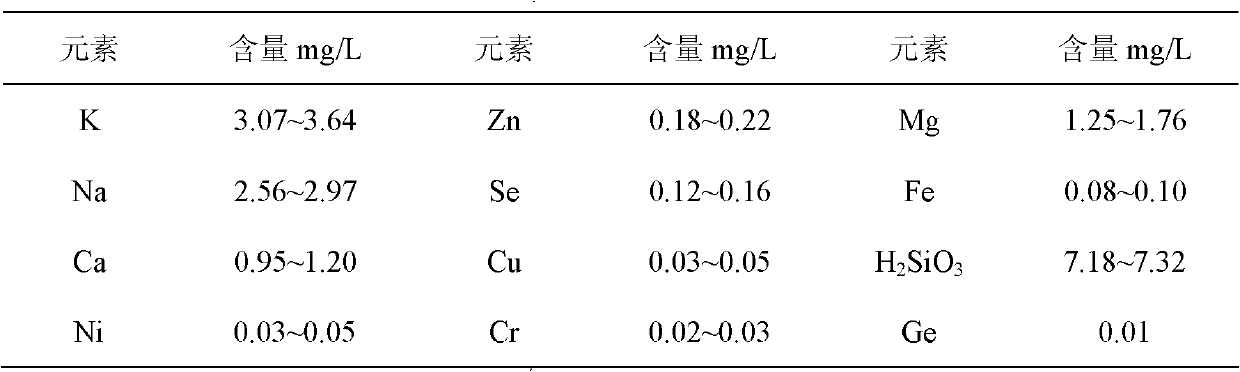

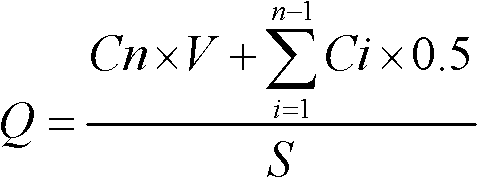

Mineral nutrient elements-enriched deep-sea small-molecular cluster water and preparation method and cosmetic applications thereof

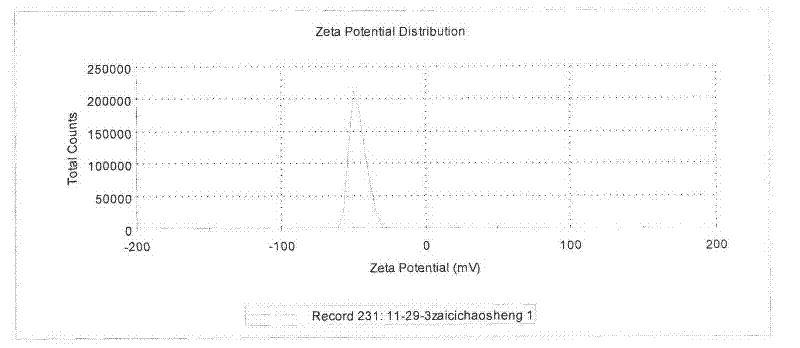

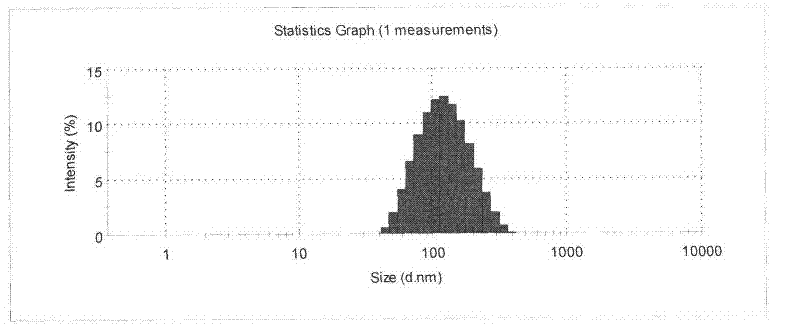

ActiveCN102600044AIncrease moisture contentIncreased hydrationCosmetic preparationsHair cosmeticsIonSeawater

The invention discloses a mineral nutrient elements-enriched deep-sea small-molecular cluster water and a preparation method and cosmetic applications of the deep-sea small-molecular cluster water. The preparation method of deep-sea small-molecular cluster water comprises the steps of adding 80-120g mineralizing and activating preparation material into per liter of desalinized seawater, and processing the mixture by impulse ultrasound for 20-40 min to obtain the deep-sea small-molecular cluster water, wherein the ultrasound time / interval time is 3 / 5-2 / 3, the ultrasonic power is 850-1000W / L and the ultrasonic temperature of 30-60 DEG C; the mineralizing and activating preparation materials contain 15-30% of medical stone, 40-60% of Tourmaline weak-base stone and 30-50% of far infrared stone based on a total mass fraction of 100%, or contain 50-70% of Tourmaline weak-base stone and 30-50% of far infrared stone based on a total mass fraction of 100%. The deep-sea small-molecular cluster water can replace water that is used in preparation of various cosmetics and water that is used in synthesis and preparation of various components, and the prepared cosmetics have various physicochemical properties significantly superior to the cosmetics prepared by deionized water; moreover, the cosmetics can effectively balance pH value of skin and hair, and quickly compensate active water to keep the skin moisturized for a long period.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI +1

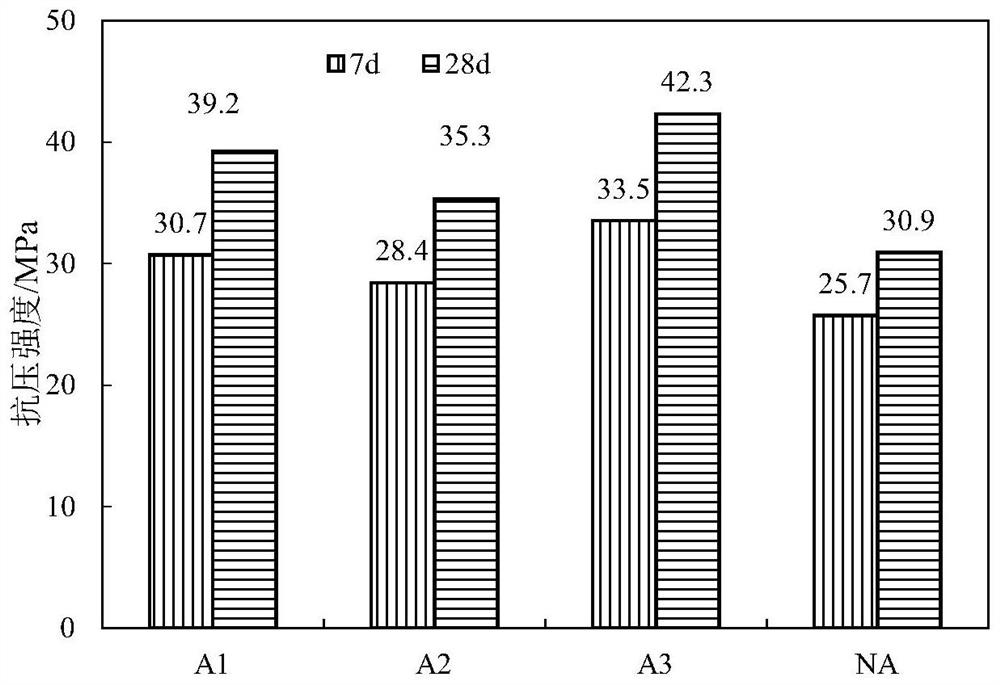

Steel fiber high-strength concrete and preparation method thereof

The invention relates to steel fiber high-strength concrete and a preparation method thereof, and belongs to the technical field of concrete, and relates to concrete. The steel fiber high-strength concrete is prepared from 125-170 parts of water, 400-480 parts of cement, 700-760 parts of fine aggregate, 800-900 parts of coarse aggregate, 80-105 parts of fly ash, 85-105 parts of mineral powder, 10-15 parts of silica fume, 5-7 parts of additive, 10-18 parts of organic fibers and 6-15 parts of modified steel fibers. The modification method of the modified steel fibers comprises the following steps: mixing a silane coupling agent, alcohol and deionized water to obtain a modification solution, immersing steel fibers into the modification liquid, performing stirring, and taking out and drying the steel fibers to obtain the modified steel fibers. The preparation method comprises the following steps: mixing an admixture with half of water to obtain a mixed solution; mixing the organic fibers,the modified steel fibers and half of the mixed solution to obtain a mixture; mixing cement, fly ash, mineral powder, silica fume and the mixture to obtain a primary mixture; mixing the fine aggregate, the rest mixed solution and the primary mixture to obtain a base material; and mixing the coarse aggregate, the balance of water and the base material to obtain the concrete. The method has the effects that the bonding strength of the steel fibers and the concrete is improved, and the compression resistance of the concrete is improved.

Owner:上海兆捷实业发展有限公司

Cleaning composition

InactiveUS20080261842A1Increased hydrationReduce lossCosmetic preparationsHair cosmeticsGlycerol ester of wood rosinSaturated aliphatic hydrocarbons

A post-foaming personal cleaning composition in the form of a gel for use in an aerosol container. This composition includes a base material of a surfactant in an amount not less than 7% by weight and a thickener that is a blend of at least one of glyceryl ester, and a glyceryl ester derivative with at least one of a betaine and a gum. The base material preferably has a viscosity greater than 9,500 cps. The composition also includes a foam forming material, above 9% by weight of the composition with at least a part of the foam forming material being maintained in suspension in the composition until after the composition is dispensed from the aerosol container. The foam forming material is preferably a saturated aliphatic hydrocarbon having from 4 to 5 carbons and the composition is in the form of a gel prior to inclusion of the foam forming material.

Owner:PZ CUSSONS INT

Tripterine nano structure lipid carrier and preparation method and application thereof

InactiveCN102225205AReduce systemic side effectsImprove bioavailabilityOrganic active ingredientsAntipyreticNano structuringTreatment effect

The invention relates to the field of Chinese medicine preparation, in particular to a method for preparing tripterine nano structure lipid carrier containing traditional Chinese medicine monomer and application of the tripterine nano structure lipid carrier in preparation of transdermal drugs used for treating psoriasis, rheumatoid arthritis, skin cancer and breast cancer. The tripterine nano structure lipid carrier is characterized by comprising the following components in parts by weight: 1 part of tripterine, 5-100 parts of mixed lipid, 0.5-10 parts of phospholipid, 0.1-15 parts of poloxamer-188 and 0.5-10 parts of vitamin E and tocopherol polyethylene glycol succinate, wherein the mixed lipid is composed of solid lipid monoglycerine and liquid lipid octylic acid / caprin according to the weight ratio of 1: 0.1-10: 1. Tripterine is prepared into the nano structure lipid carrier, the tripterine nano structure lipid carrier in a semi-solid or liquid preparation form is applied in a transdermal way, bioavailability of the tripterine can be improved, toxic response of tripterine can be reduced, and the nano structure lipid carrier provided by the invention has great clinical application value in the improvement of the treatment effect of tripterine.

Owner:JIANGSU PROVINCE INST OF TRADITIONAL CHINESE MEDICINE

Thermal insulation plaster bonding agent

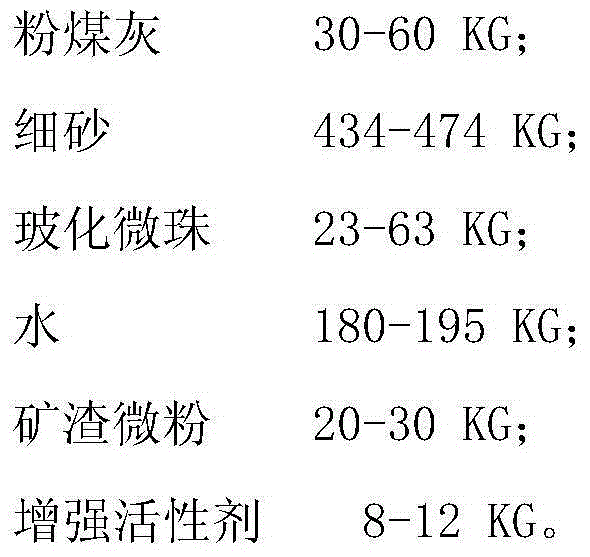

A novel multifunctional heat preserving and insulating plaster adhesive has the components with the following weight content: cement 20-40%, silicon-aluminium glass hollow sphere material 15-35%, grinded high-calcium flyash 15-35%, water reducing agent 0.5-1.2%, air-entrainer 0.005-0.05%, modifier 1-5%, fiber 0.1-5%, and water-loss reducer 0.5-2%. In the adhesive the cement is common silicate 42.5 grade cement; the silicon-aluminum glass hollow sphere material has specific surface area 400-15000m<2> / kg, the sphere grain diameter is 0.5 mu m-60 mu m, and the content of silicon oxide is above 50%; the grained high-calcium flyash is obtained by grinding the common high-calcium flyash with the polarization grinder for 30min, the CaO content is above 18% and the fineness degree is 4000-6000m<2> / kg; the water reducing agent is alkali lignin water reducing agent; the fiber is the combination of one or a plurality of fibers in modified polypropylene fiber, alkali-resistant glass fiber, nylon fiber, animal and vegetable fibers; the air-entrainer is the colophony pyrolytic polymer series air-entrainer; and the modifier is cellulose or the derivative of the cellulose. The adhesion promoter is sodium group or potassium-group alta-mud.

Owner:武汉科华高新材料发展有限公司

Painted smooth mirror surface color-holding lip glaze and preparation method thereof

ActiveCN110638691AHigh glossImprove durabilityCosmetic preparationsMake-upEngineeringFilm-forming agent

The invention provides painted smooth mirror surface color-holding lip glaze and a preparation method thereof. The painted smooth mirror surface color-holding lip glaze comprises the following components in percentage by weight of 20-80% of grease, 0.1-15% of oil-in-water emulsifying agents, 0.05-15% of coloring agents, 0.5-10% of oil-phase film forming agents, 0.5-20% of water-phase film formingagents and the balance water. The painted smooth mirror surface color-holding lip glaze is an oil-in-water type lip product, oil is an inner phase, and the water is a continuous outer phase, so that the problem of greasy feeling of ointment type products can be well solved. Besides, the oil-phase film forming agents and the grease mutually cooperate to generate synergistic effects, so that the glossiness, the persistence and the nourishing degree can be greatly increased.

Owner:广州那比昂生物科技有限公司

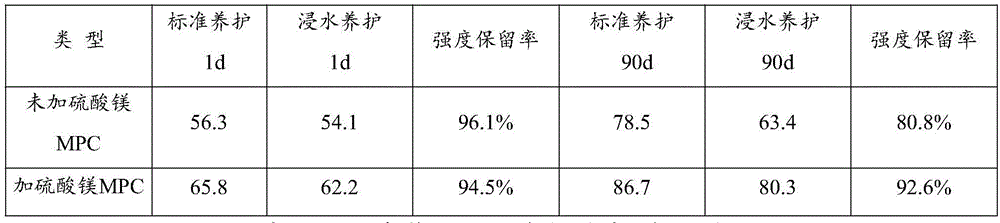

Method for improving water resistance of magnesium phosphate cement base

InactiveCN106587683AIncreased hydrationIncreased retention of strengthSolid waste managementMagnesium orthophosphateMagnesium phosphate

The invention relates to a method for improving water resistance of a magnesium phosphate cement base. The method comprises 1, mixing dead-burned magnesia powder as a basic component, monoammonium phosphate as an acidic component and a multielement compound retarder according to a mass ratio of 70 to 90: 15 to 35: 16 to 26 to obtain magnesium potassium phosphate cement base powder, and 2, mixing the magnesium potassium phosphate cement base powder and additives such as magnesium sulfate and water to obtain magnesium phosphate cement base slurry, wherein a mass ratio of magnesium potassium phosphate cement base powder, magnesium sulfate to water is 100: 1 to 2: 12 to 18. The method solves the technical problem that the existing magnesium phosphate cement base is condensed quickly, concentratedly releases hydration heat in the early period, and has a serious loss of early water curing strength.

Owner:CHINA UNIV OF MINING & TECH +2

Slag modifier and preparation method thereof

The invention discloses a slag modifier, which is obtained by complex formulation and mixing of an activator, a reinforcing agent, a grinding aid, a dispersant and water. The slag modifier comprises the following raw materials: 15-30% of the activator, 12-25% of the reinforcing agent, 25-38% of the grinding aid, 1-3% of the dispersant, and the balance of water; wherein the percentage is mass percentage. The high-molecular dispersant having good chemical stability is used, halogen ions capable of corroding the equipment are not contained, and the gelling activity, hydration speed and degree of the slag are excited. The modified grinding aid and the dispersant are added in a grinding assisted process of the slag so that the slag and mixed clinker are easily ground in a system. The elements which are harmful to cement equipment do not contained, the safety performance is good, spontaneous combustion is not generated, the slag modifier has the advantages of no toxicity, no corrosion and simple experiment operation, compared with common slag modifiers, the doping amount of the slag modifier is low, the raw materials have the advantages of low cost and easy acquisition, the slag modifier has high application prospect, and can be reused on real meaning.

Owner:南京成弘建新材料有限公司

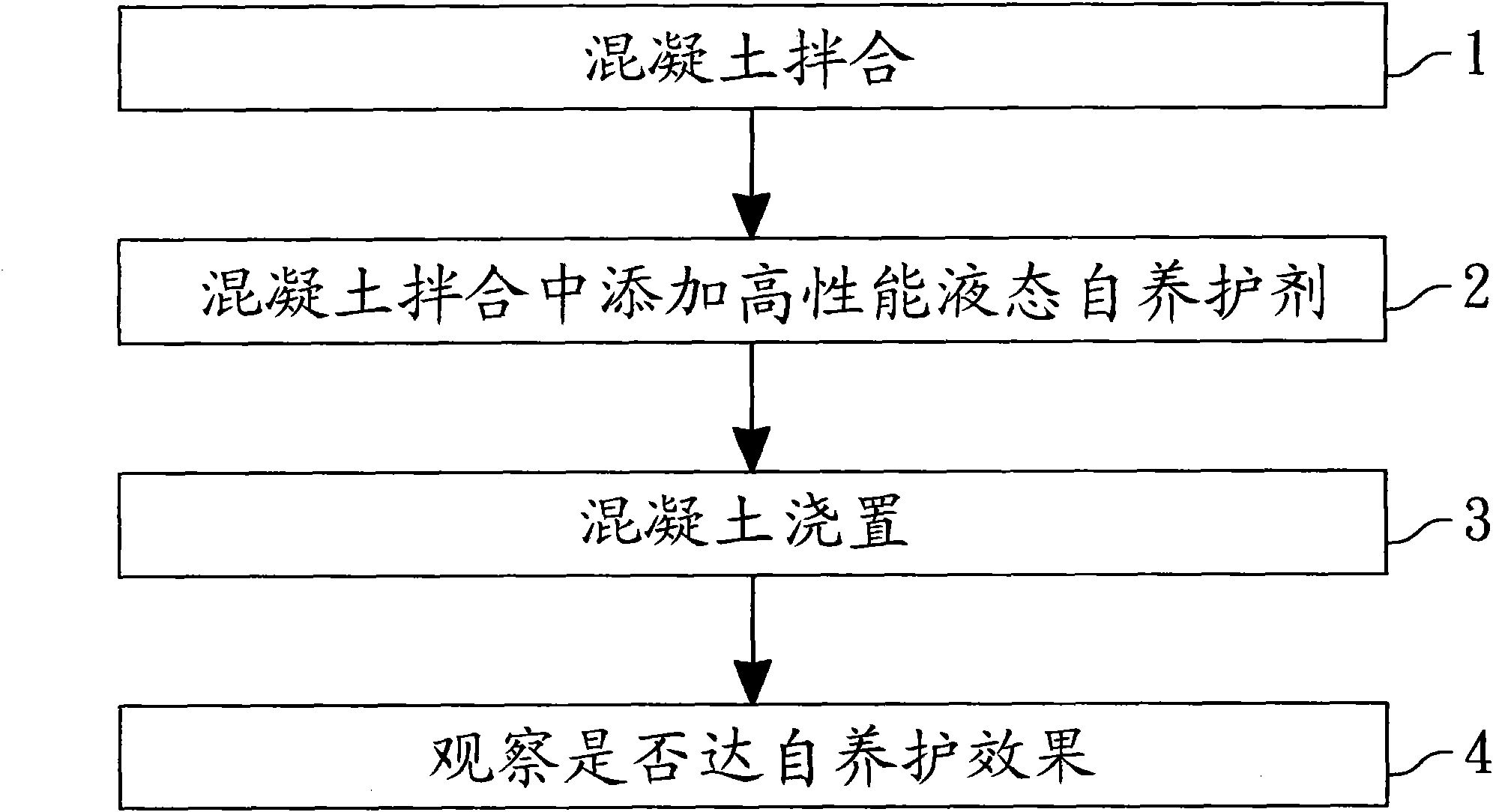

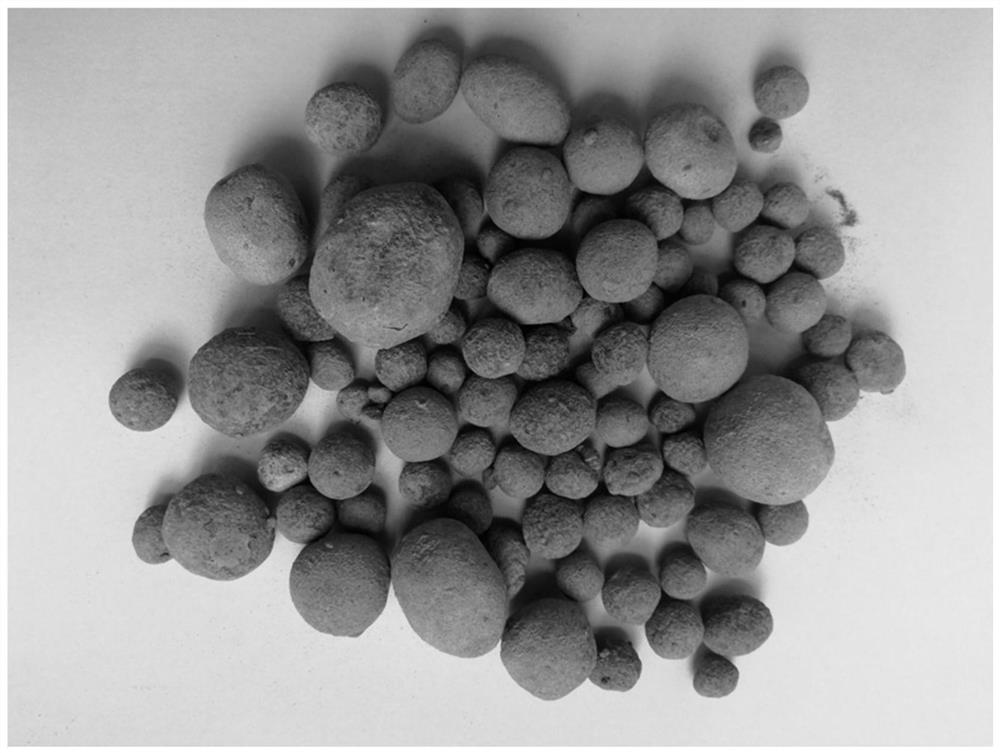

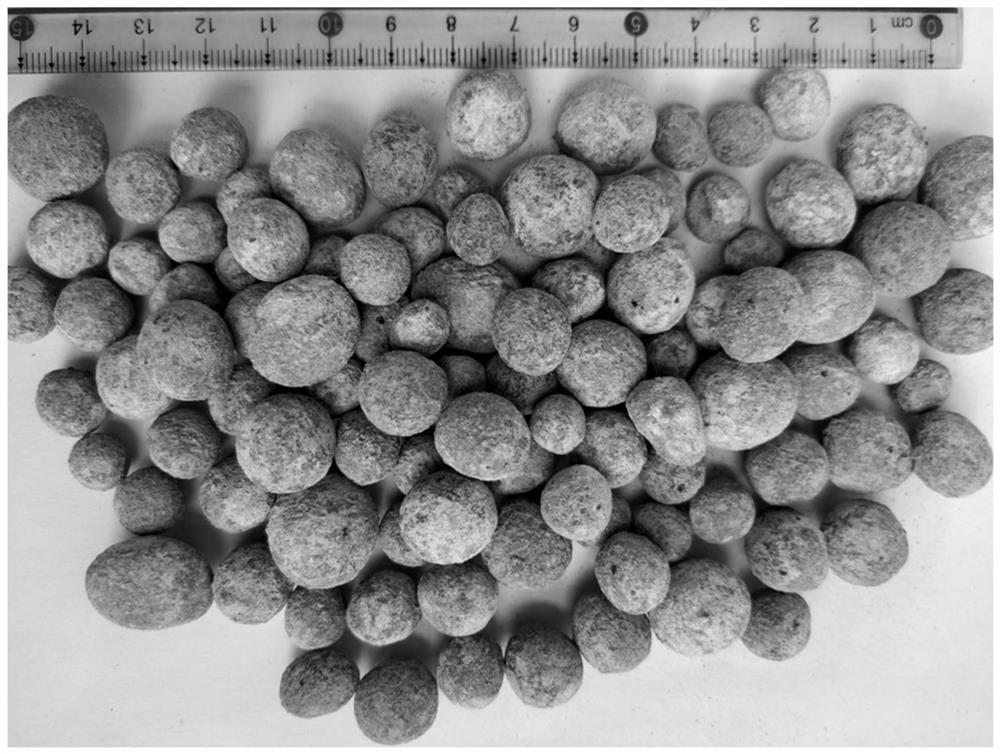

Preparation method of carbonized steel slag lightweight aggregate and concrete containing carbonized steel slag lightweight aggregate

The invention discloses a preparation method of carbonized steel slag lightweight aggregate and concrete containing the carbonized steel slag lightweight aggregate. The preparation method of the carbonized steel slag lightweight aggregate comprises the following steps: step 1, weighing 40-60 parts by mass of steel slag powder, 30-50 parts by mass of vitrified micro bubbles and 10-30 parts by massof quick lime, putting into a tray, and performing mixing to form uniform mixed powder; step 2, uniformly spraying water drops to the surface of the mixed powder according to a certain water-cement ratio, continuously shaking the oscillation tray, and mixing the powder with water to form small balls, so as to obtain steel slag lightweight aggregate; 3, placing the steel slag lightweight aggregatein a curing chamber with the temperature being 20 + / -1 DEG C and the relative humidity being 55 + / -5% to be cured for 48 h; and step 4, putting the cured steel slag lightweight aggregate into a carbonization box to be carbonized for 24 hours. The invention has the advantages of simple preparation process, light weight and high strength of aggregate, low cost, low-carbon and environment-friendly production and the like. When applied to concrete, the carbonized steel slag lightweight aggregate can provide internal curing, promote hydration of a cementing material and reduce shrinkage cracking ofthe concrete.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +1

Cement concrete for wet connection seam of system sequentially comprising simply-supported bridge and continuous bridge, and preparation method thereof

The present invention discloses a cement concrete for the wet connection seam of a system sequentially comprising simply-supported bridge and continuous bridge, and a preparation method thereof, wherein the cement concrete comprises cement, river sand, water, a polycarboxylic acid-based efficient water reducer, rice hull ash, apatite, sericite, sepiolite, a sodium polyacrylate high water absorption resin, talc powder, nanometer calcium carbonate, polyethylene fibers and polyester fibers, and with the synergistic effect among the mineral components such as the apatite, the sericite and the sepiolite and the two fibers, the toughening can be achieved, the impact resistance and the extension ability of the concrete can be improved, and the problems that the wet connection seam concrete is damaged and the bridge surface cracks can be effectively solved. According to the present invention, the cement concrete has advantages of high compressive strength, good toughness, impact resistance, permeation resistance, self-leveling, and the like.

Owner:CHANGAN UNIV

Modified material and treatment method of low-quality aggregate

The invention belongs to the technical field of building materials, and specifically relates to a modified material and treatment method of a low-quality aggregate. The modified material of the low-quality aggregate provided by the invention comprises the following components in percentage by mass: 46-50% of cement, 10-15% of a mineral admixture, 2-5% of an active powder, 0.2-0.6% of a water reducing agent, 0.001-0.004% of a viscosity adjusting agent, 0-3.2% of an expanding agent, 0-0.12% of an air entraining agent, and 0-0.0007% of a defoaming agent. The modified material provided by the invention can realize effective filling and coating modification of the low-quality aggregate through the cooperation between the components, and the adjustment of the use amount, and especially through the cooperation of the specific use amount of the cement, active powder and viscosity adjusting agent, the surface tension and viscosity of the modified material can be effectively adjusted, and a porepenetration amount and a shell coating thickness are coordinately optimized. The combined use of the inorganic and organic components promotes the secondary hydration / chemical bonding of a slurry layer, and improves the strength of an interface between the aggregate and the slurry layer. The cylindrical compress strength of the aggregate after modification treatment is increased by 40% or more, acrushing value is reduced by 30% or more, and a water absorption rate in 24 h is reduced by 15% or more.

Owner:CHINA BUILDING MATERIALS ACAD

Recycled aggregate water-permeable brick and production method thereof

ActiveCN110407533AHigh strengthIncrease added valueSolid waste managementCeramicwareBrickCompressive strength

The invention provides a recycled aggregate water-permeable brick and a production method thereof. The recycled aggregate water-permeable brick comprises a base layer, and the base layer comprises, byweight, 95-105 parts of recycled aggregates, 14-16 parts of cement, 14-16 parts of fly ash and 0.22-0.32 part of a water reducer. The production method comprises the following steps: uniformly mixingthe cement, the fly ash and the water reducer, adding water, performing stirring, and adding wetted aggregates; adding the obtained mixture into a mold, and carrying out vibration extrusion molding under 1.5-3 MPa for 15-30 s; and demolding the obtained water-permeable brick, standing the water-permeable brick for 2 h, transferring the water-permeable brick into an autoclave, and curing the water-permeable brick under 0.8-1 MPa at 173-185 DEG C for 6-10 h. The aggregates are recycled aggregates, the use amount of the cement is small, the water-permeable brick has a high compressive strength and a high water permeability, the molding process is quick and simple, and has a low cost, and the environmental pollution can be effectively reduced, so the recycled aggregate water-permeable brick is suitable for large-scale industrial production.

Owner:QINGDAO AGRI UNIV

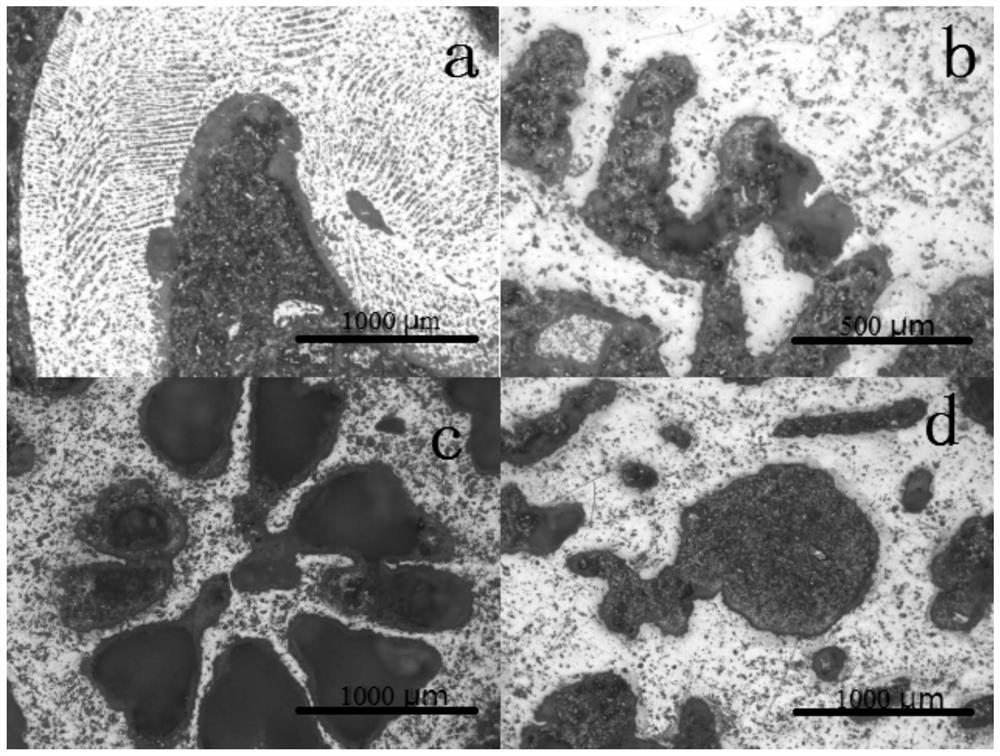

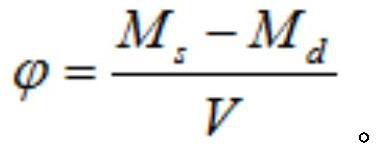

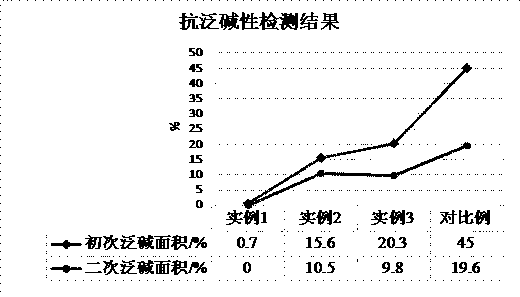

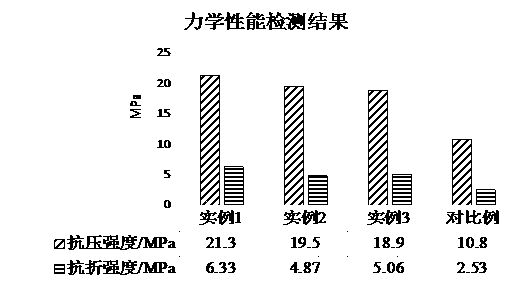

Method for preparing tile grout

The invention discloses a method for preparing tile grout, and belongs to the technical field of construction materials. The method comprises the following steps: mixing chitosan-polyvinyl alcohol hydrogel and saturated sodium carbonate solution, and filtering to obtain pre-treated hydrogel; stirring and mixing pretreated zeolite and degraded protease, and filtering to obtain modified zeolite; mixing graphite and oxidant, stirring to react, concentrating by rotary evaporation to obtain oxidized graphite; sequentially weighing the following components in parts by mass: 30-40 parts of cement, 50-60 parts of quartz sands, 2-6 parts of pigment, 8-12 parts of pretreated hydrogel, 12-15 parts of modified zeolite and 6-10 parts of oxidized graphite; and stirring and mixing the raw materials, adding water which is 0.6-0.8 times mass of the cement, continuously stirring, and discharging to obtain the tile grout. The tile grout has excellent mechanical performance, and the phenomenon of efflorescence can be reduced.

Owner:广东亿固壁安粘贴技术有限公司

Dry-mixed mortar prepared from industrial solid waste

The invention provides dry-mixed mortar prepared from industrial solid waste. The dry-mixed mortar is characterized by being prepared from materials in parts by weight as follows: 100 parts of cement, 300-400 parts of river sand, 50-100 parts of steel slag, 0-50 parts of iron mine tailings, 0-50 parts of glass powder, 1-2 parts of an interface reinforcing agent, 1-2 parts of an exciting agent, 0.1-0.5 parts of a water retaining agent, 1-2 parts of a water reducing agent and 0.1-0.3 parts of reinforcing fibers. According to the dry-mixed mortar, the industrial solid waste is fully utilized as aggregate to replace natural river sand, environmental protection is facilitated, resource recycling is realized, and meanwhile, performance such as the freezing resistance, the permeability resistance and the like of the dry-mixed mortar is improved through addition of the industrial solid waste.

Owner:四川震强建筑材料有限责任公司

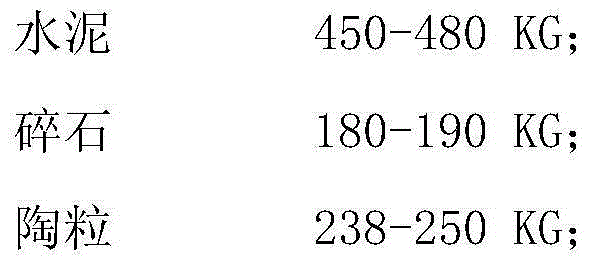

Light-weight high-intensity concrete and preparing method of light-weight high-intensity concrete

The invention provides light-weight high-intensity concrete. 1m<3> concrete consists of 450 to 480kg of cement, 180 to 190kg of gravel, 238 to 250kg of porcelain granules, 30 to 60kg of fly ash, 434 to 474kg of fine sand, 23 to 63kg of glazed hollow beads, 180 to 195kg of water, 20 to 30kg of slag powder and 8 to 12kg of enhancing activating agents. The invention also provides a preparing method of the light-weight high-intensity concrete. According to the method, firstly, each ingredient is weighed according to the weight percentage; then, the ingredients are sufficiently and uniformly stirred, and are contained into a mold to be maintained; the light-weight high-intensity concrete can be obtained. The light-weight high-intensity concrete and the preparing method have the advantages that the porcelain granules are used for replacing partial coarse aggregates; the glazed hollow beads are used for replacing partial fine aggregates; the fly ash, the slag powder and the like are used as mixing materials to prepare the light-weight high-intensity concrete; on the premise of meeting the concrete pressure-resistant intensity, the concrete achieves the goal of light weight.

Owner:SHANGHAI INST OF TECH

Lightweight high-strength gangue baking-free brick

The invention discloses a lightweight high-strength gangue baking-free brick, which is prepared from the following ingredients: gangue, basalt powder, electrolytic manganese residue, ceramic powder, glass powder, red mud, limestone, arsenic sandstone, water glass, a modifier, a cementing material, boron mud and a proper amount of water. The production technology of the baking-free brick is simple, and the cost is low. Through synergism of the materials, the prepared baking-free brick is endowed with high strength, low thermal conductivity and good crack resistance, is energy-saving and environment friendly, meets requirements of constructional engineering, and accords with environmental protection requirement. The baking-free brick has excellent high and low temperature resistance. Problems of general baking-free bricks, such as poor crack resistance and frost resistance, are solved. The application range of baking-free brick is greatly broadened.

Owner:安徽金丰新型建材有限公司

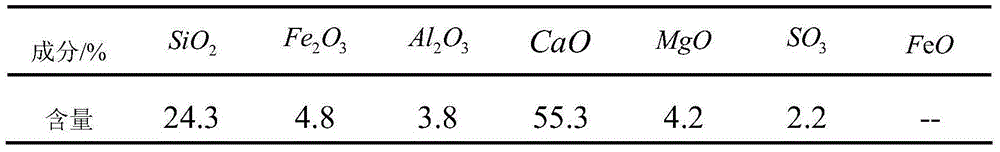

Self-curing concrete

The invention relates to self-curing concrete capable of preventing moisture from being excessively evapotranspired on the surface of concrete so as to solve the problem that the development of concrete does not meet the requirement due to incomplete cement hydration caused by curing failure in the prior art. A high-performance liquid self-curing agent is added into blended concrete, and the using amount of the high-performance liquid self-curing agent is 0.01 to 10 weight percent of powder in the concrete; and the high-performance liquid self-curing agent can absorb aqueous vapor in the air and release moisture to the concrete, so that after the concrete is poured, the concrete does not need extra moisture or any external curing to fulfill the self-curing aim.

Owner:赵文成

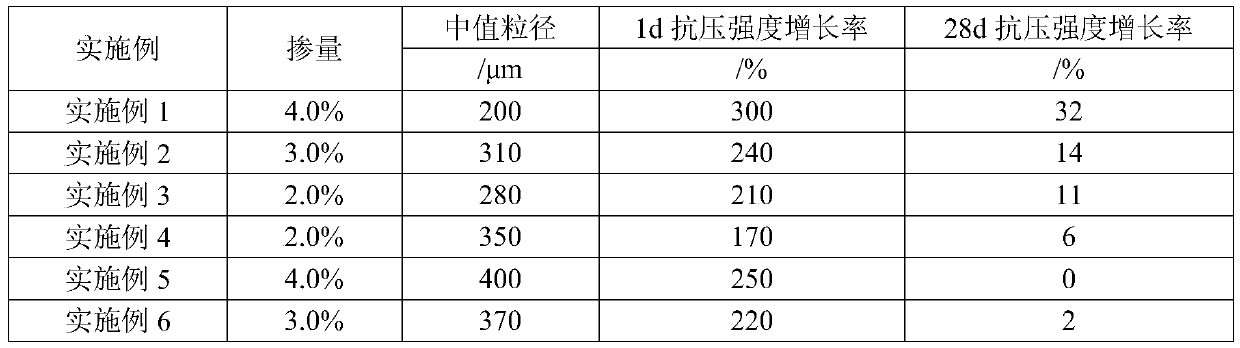

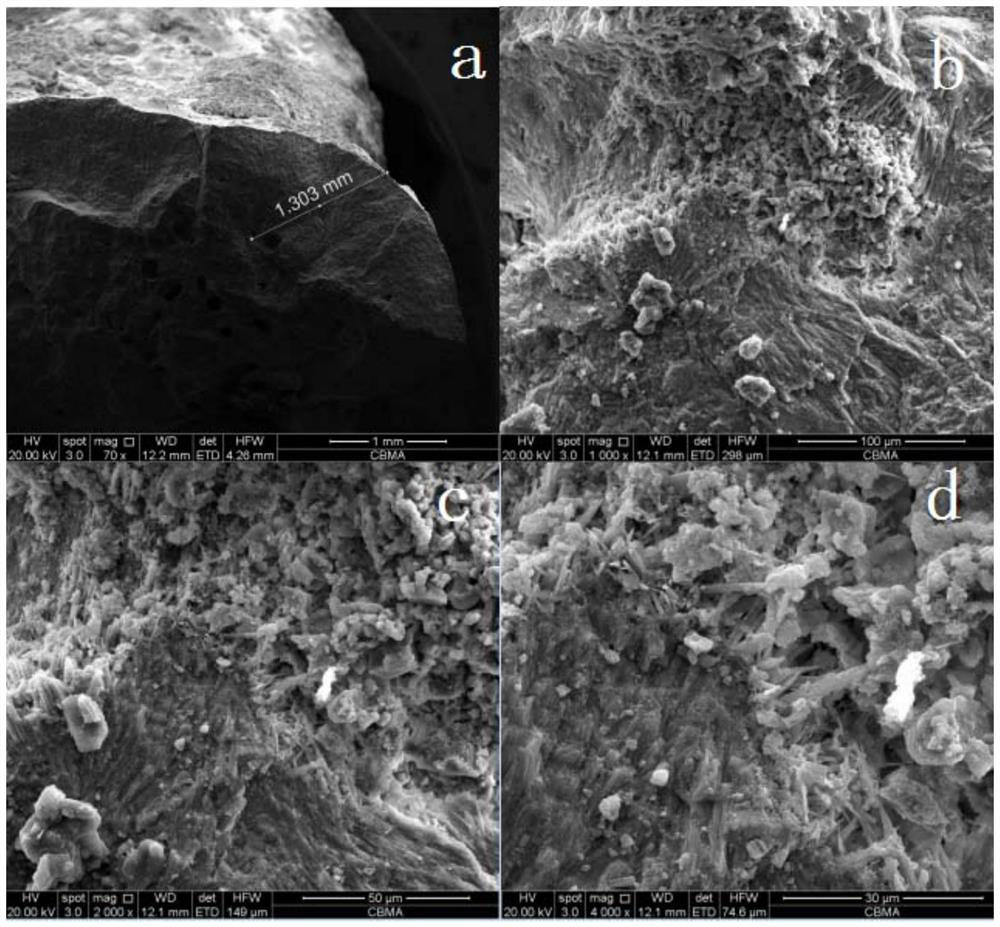

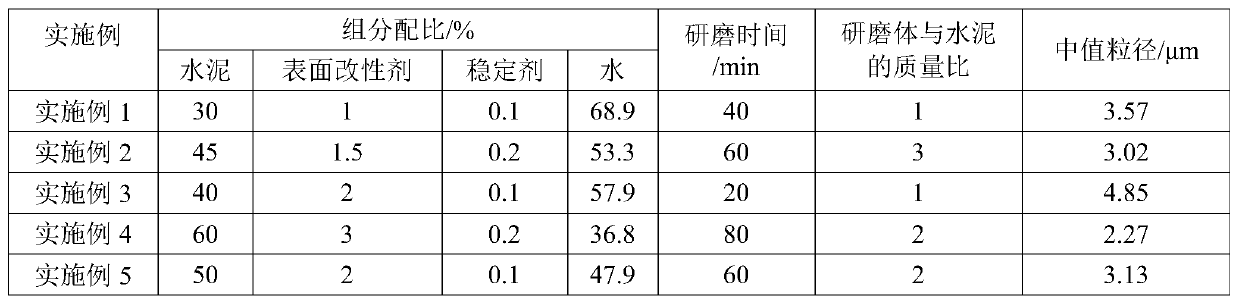

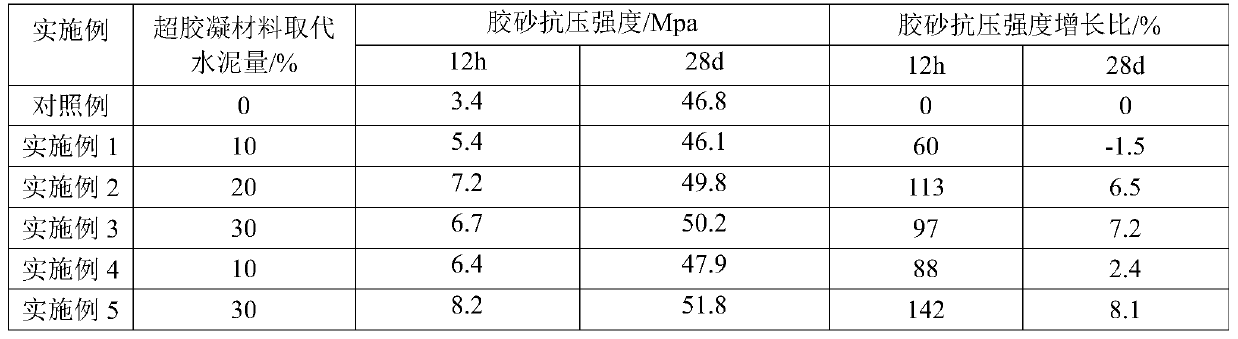

Super cementitious material based on wet grinding and preparation method and application thereof

The invention provides a super cementitious material based on wet grinding and a preparation method and application thereof. The super cementitious material based on wet grinding is made from, by mass, 28-60% of cement, 1-3% of a surfactant, 0.1-0.2% of a stabilizer and 37-70% of water through wet grinding. The super cementitious material based on wet grinding is mainly made from ordinary Portlandcement; the surfactant and the stabilizer are added during wet grinding, so that the super cementitious material having medium particle size of 2-5 mu m is acquired. As the whole system is in prehydrated state after wet grinding and the particle size is small, the super cementitious material herein has higher hydration degree and very high activity than raw cement; after the cement is partially replaced, early strength can be improved evidently. Grading can be optimized, and later strength can be improved to certain degree, wherein 12-hour strength increase ratio is up to 142%.

Owner:WUHAN UNIV OF TECH

Fat loss and slimming cream and preparation method

InactiveCN107441390AFast and efficient penetrationIncreased hydrationAntipyreticAerosol deliveryAdditive ingredientPeppermints

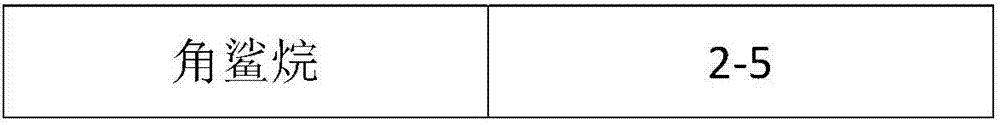

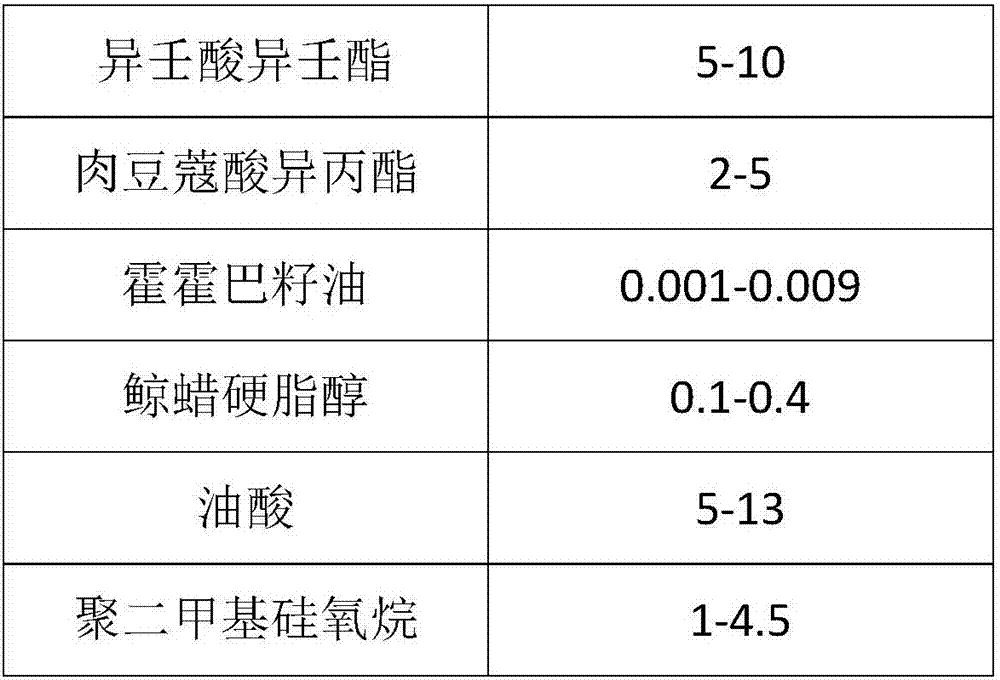

The invention discloses a cellulite-reducing and slimming cream and a preparation method thereof, comprising the following components and contents (parts by weight): cellulite-reducing active blend: 9.721-60.703, emulsifier: 8-17.5, oil: 15.101-37.909, Thickener: 0.11‑0.54, humectant: 13.5‑57.5, chelating agent: 0.1‑0.7, pH neutralizer: 0.5‑4, fragrance: 0.82‑4.08, preservative: 0.4‑2.25, deionized water: 40‑ 80. The anti-cellulite active blend comprises peppermint leaf extract, geranium geranium extract, golden chamomile extract, flavescens root extract, purslane extract, aloe barbadensis leaf extract, brazilian cocoa Fruit extract, coix seed extract, licorice extract, salvia miltiorrhiza extract, Sichuan Codonopsis pilosula extract, Osmanthus seaweed extract, oolong tea extract, astragalus root extract, chuanxiong root extract combination. Melt oil and emulsifier, add water, humectant and thickener to the mixture and emulsify, then add chelating agent, pH neutralizer, essence and preservative. It has a good fat-reducing and slimming effect.

Owner:广州中晟生物科技有限公司

Artificial steel slag aggregate and preparation method and application thereof

PendingCN112266193AGood performanceAchieve permanent storageSolid waste managementBall millSilicate Cement

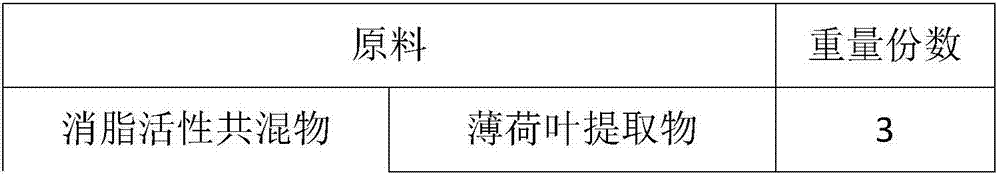

The invention discloses an artificial steel slag aggregate and a preparation method and application thereof. The preparation method comprises the following steps: step 1, grinding steelmaking tailingsby using a ball mill to obtain uniform steel slag powder; 2, weighing Portland cement, an admixture fine powder and steel slag powder, and conducting uniform mixing to obtain an aggregate raw material; 3, preparing an additive aqueous solution; 4, putting the aggregate raw material into a ball forming mill, and uniformly spraying the additive aqueous solution prepared in the step 3 to form balls,so as to obtain spherical artificial steel slag aggregate; step 5, putting the pelletized aggregate into a closed environment or a natural environment for pre-curing; and step 6, putting the pre-cured aggregate into a carbonization device for carbonization treatment to finally prepare the artificial steel slag aggregate. The artificial steel slag aggregate prepared by the method can achieve the goals of safety and high strength, the crushing index of the aggregate can reach 9.26% and reach the I-grade aggregate use standard, the production process is simple, the solid waste is recycled, the carbon dioxide is absorbed and cured, and the artificial steel slag aggregate is free of burning, low-carbon and environment-friendly.

Owner:NANJING UNIV OF TECH

Magnesian concrete damage self-repairing additive and preparation method thereof

The invention relates to the field of building material additives. A magnesian concrete damage self-repairing additive comprises the following components in parts by weight: 30 to 60 parts of magnesium oxide, 15 to 40 parts of quartz powder, 10 to 20 parts of kaoline, 2 to 6 parts of sodium silicate, 2 to 10 parts of sodium hexametaphosphate and 5 to 10 parts of gypsum. The concrete damage self-repairing additive based on a light calcinesia magnesia expanding agent has rapid and excellent self-repairing effect on cracks and internal damage caused by various reasons while improving the mechanical property and the crack resistance of the concrete.

Owner:GUANGDONG YUESHENG SPECIAL BUILDING MATERIALS

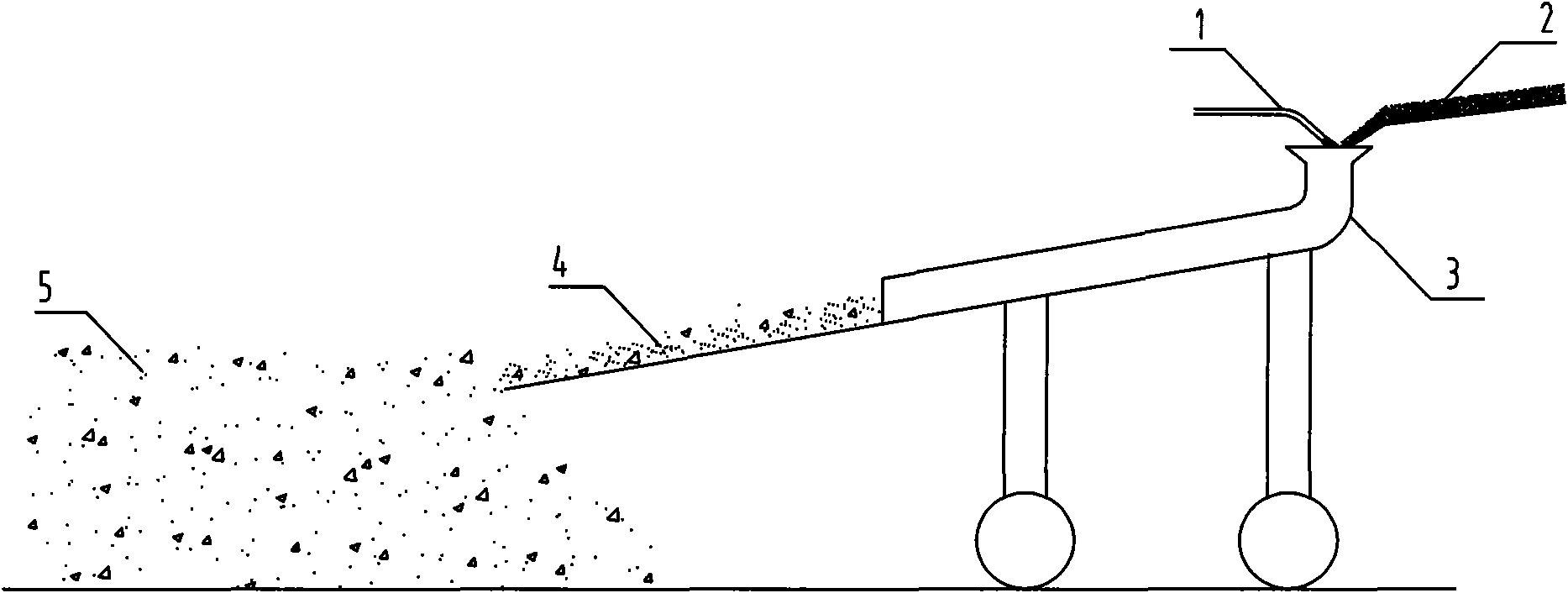

Construction method of gunite concrete

InactiveCN101624826AIncrease mechanical bite forceGuaranteed uniformityFoundation engineeringBuilding material handlingMechanical indexIncomplete mixing

The invention discloses a construction method of gunite concrete, comprising the following steps: adopting normal pure cement paste consisting of water and cement or mixed cement paste consisting of water and cement mixed with fly ash, which is provided by a high-speed stirring slurrying device; respectively injecting dynamic gravel mixed material of a free falling body or respectively injecting dynamic sand and aggregate of the free falling body via a slurry transmission device; injecting cement paste and dynamic gravel mixed material or dynamic sand and aggregate to cause that the mixture enters a mixed conveyor entrance in an imperfect-mixing state; after stirred into even mixed material, directly sending the mixed material into a cabin via the gravity of the mixed material or sending the mixed material into a cabin via a mixed material sending device for vibrating and pouring into concrete. The invention combines concrete mixing, transporting and pouring technology into a whole, directly pours in site to continuously perform concrete construction, which simplifies concrete construction technology; the invention has few in-site construction devices, convenient operation, quick pouring, low cost and short construction period, effectively strengthens various mechanical indexes of concrete and obviously improves construction efficiency.

Owner:沈阳乾玉水利有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com