Super cementitious material based on wet grinding and preparation method and application thereof

A technology of cementitious materials and wet grinding process, which is applied in the field of cementitious materials, can solve the problems of low effective utilization rate and high energy consumption of cement, and achieve the effect of improving early strength, high hydration degree and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0024] The present invention will be described in detail below in conjunction with examples.

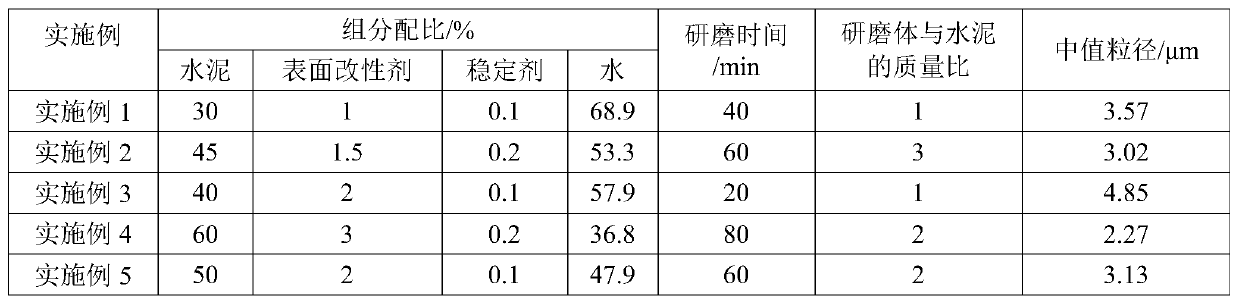

[0025] Table 1 is the proportion of each component in the supergelled material based on the wet milling process of Examples 1 to 5 of the present invention and the fineness and wet milling parameters of the supergelled material based on the wet milled process in each embodiment, Wherein, the cement in the supercementitious material based on the wet grinding process of embodiments 1 to 5 is P.O 42.5 grade, and the median particle size of the cement is 15.1 μm; the stabilizer is a temperature wheel with a mass concentration of 0.1%. glue.

[0026] Table 1

[0027]

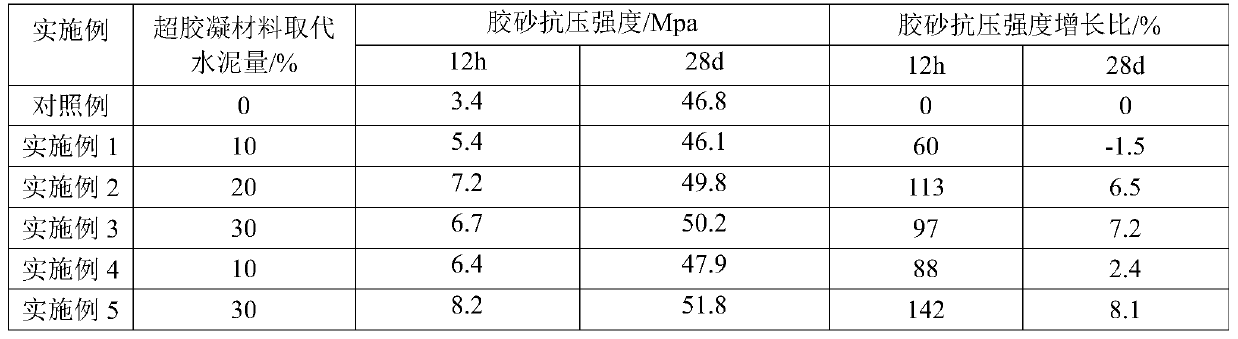

[0028] Table 2 shows the ratio of each component in the surface modifier in Examples 1 to 5 of the present invention. Wherein, the consumption of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com