Artificial steel slag aggregate and preparation method and application thereof

A technology of aggregate and steel slag, which is applied in the field of artificial steel slag aggregate and its preparation, can solve the problems that the steel slag utilization rate is less than 20%, it is not conducive to environmental protection and resource conservation, and the industrial utilization of steel slag is difficult, so as to improve the carbonization efficiency and reduce the weight , the effect of enhancing the strength of the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

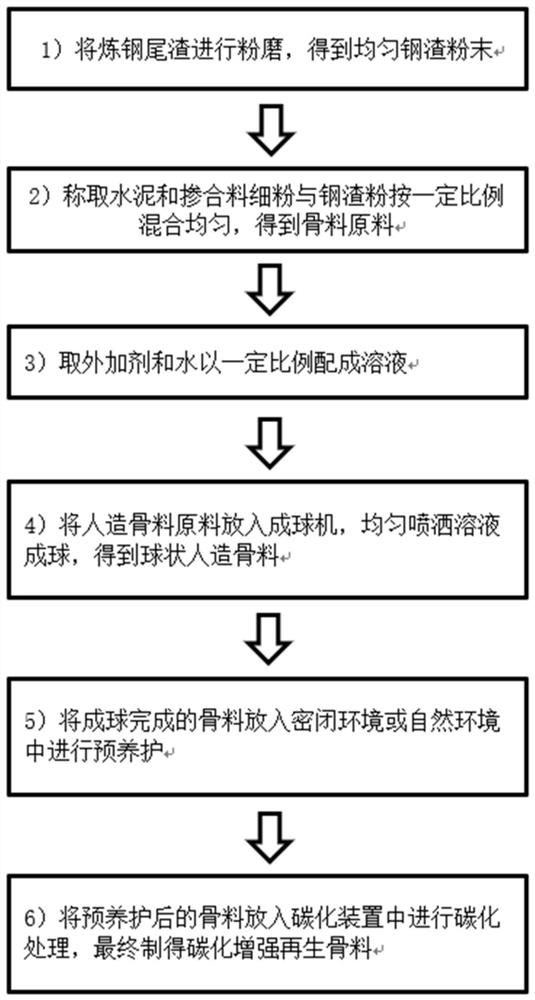

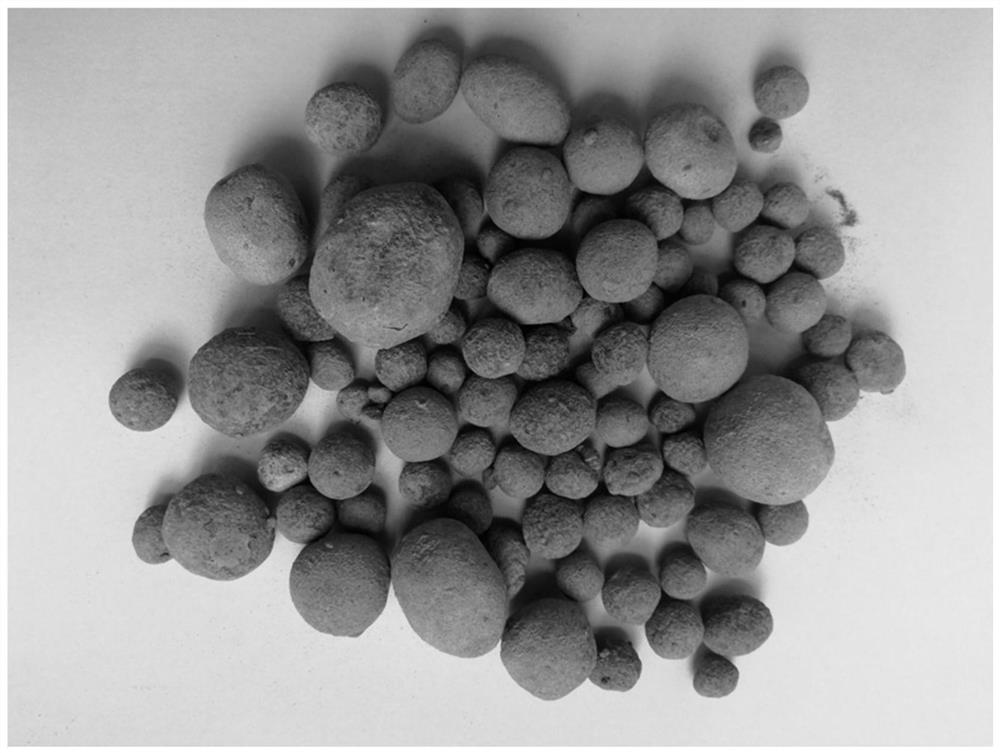

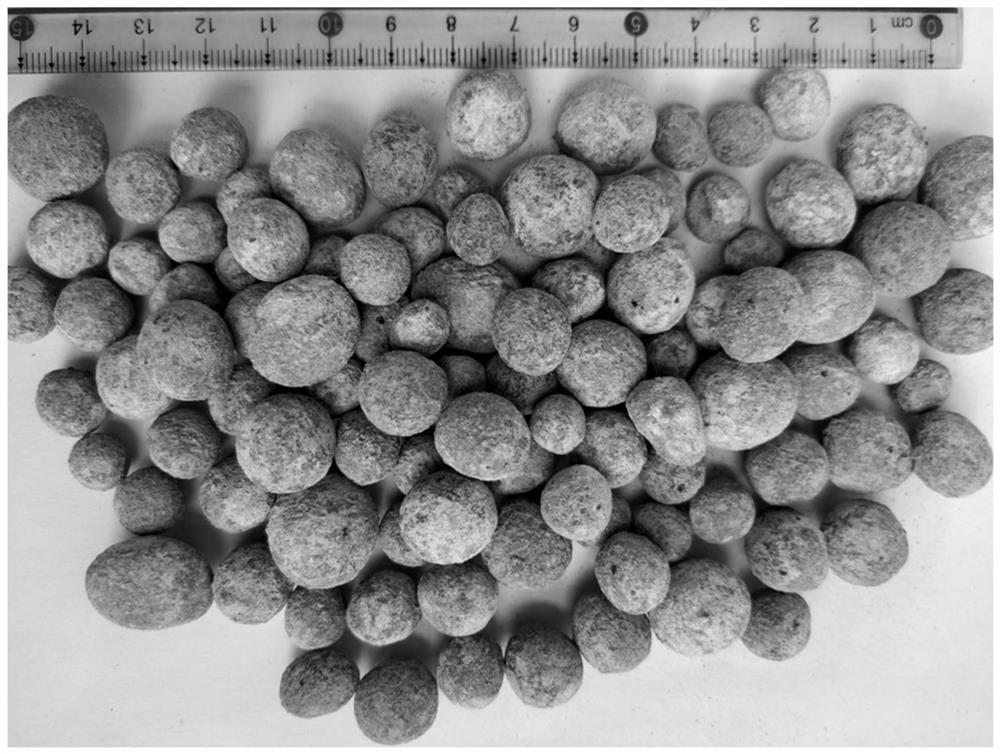

[0030] A kind of artificial steel slag recycled aggregate reinforced by additive, see figure 1 , the method comprises the following steps: crushing the steelmaking tailings, putting the obtained crushed steelmaking tailings into a mill, and grinding the steelmaking tailings into a specific surface area of 250m 2 / g of steel slag powder, weigh 80 parts by mass of steel slag powder, 5 parts by mass of Portland cement and 15 parts by mass of fly ash and mix them. A single-component admixture aqueous solution with a mass ratio of 0.146wt.% of EDTA was prepared. Use a granulator to add an aqueous solution of admixture to the mixture with a mass water-cement ratio of 0.18 to form balls to obtain spherical artificial steel slag aggregates of 9-31.5mm in appearance. figure 2 ; Then pre-cure the spherical steel slag aggregate obtained above for 4 days under the conditions of relative humidity of 50% and temperature of 20°C. After the curing is completed, put the spherical steel s...

Embodiment 2

[0033] An artificial steel slag regenerated aggregate reinforced by additives, said method comprising the following steps: crushing steelmaking tailings, putting the obtained crushed steelmaking tailings into a mill, and grinding them into a specific surface area of 250m 2 / g of steel slag powder, weigh 80 parts by mass of steel slag powder, 5 parts by mass of Portland cement and 15 parts by mass of brick fine powder and mix them. A single-component admixture aqueous solution with a mass ratio of 0.292wt.% of EDTA was prepared. Utilize the granulator to add admixture aqueous solution to the mixture with a mass water-cement ratio of 0.18 to form balls to obtain spherical artificial steel slag aggregates of 9-31.5mm; Spherical steel slag aggregate pre-curing 3d. After the curing is completed, put the spherical steel slag aggregate with carbonized pre-structure into the carbonization kettle, introduce carbon dioxide with a concentration of 99.9vol.%, and carbonize under the pre...

Embodiment 3

[0035] An artificial steel slag regenerated aggregate reinforced by additives, said method comprising the following steps: crushing steelmaking tailings, putting the obtained crushed steelmaking tailings into a mill, and grinding them into a specific surface area of 250m 2 / g of steel slag powder, weigh 70 parts by mass of steel slag powder, 10 parts by mass of Portland cement and 20 parts by mass of fly ash and mix them. A single admixture aqueous solution with a mass ratio of 0.1 wt.% of acetic acid was prepared. Utilize the granulator to add admixture aqueous solution to the mixture with a mass water-cement ratio of 0.18 to form balls to obtain spherical artificial steel slag aggregates of 9-31.5mm; Spherical steel slag aggregate pre-curing 3d. After the curing is completed, put the spherical steel slag aggregate with carbonized pre-structure into the carbonization kettle, introduce carbon dioxide with a concentration of 99.9vol.%, and carbonize under the pressure of 0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com