Patents

Literature

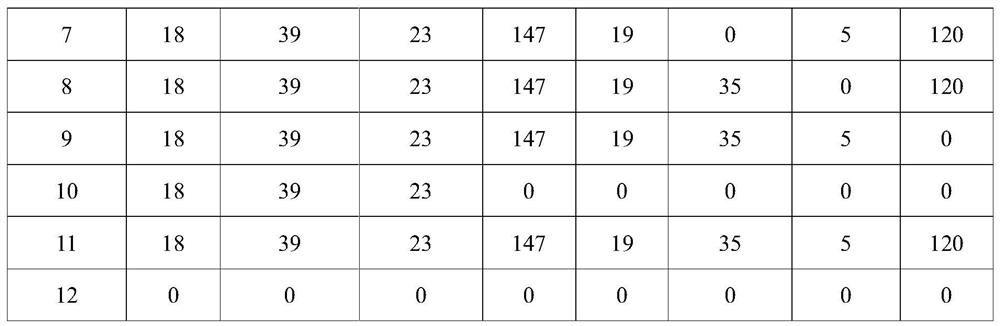

37results about How to "Improve self-healing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-network composite hydrogel, preparation method of double-network composite hydrogel and oil-water separator

ActiveCN108164643AGood tensile propertiesLow self-healing effectLiquid separationChemistryComposite hydrogels

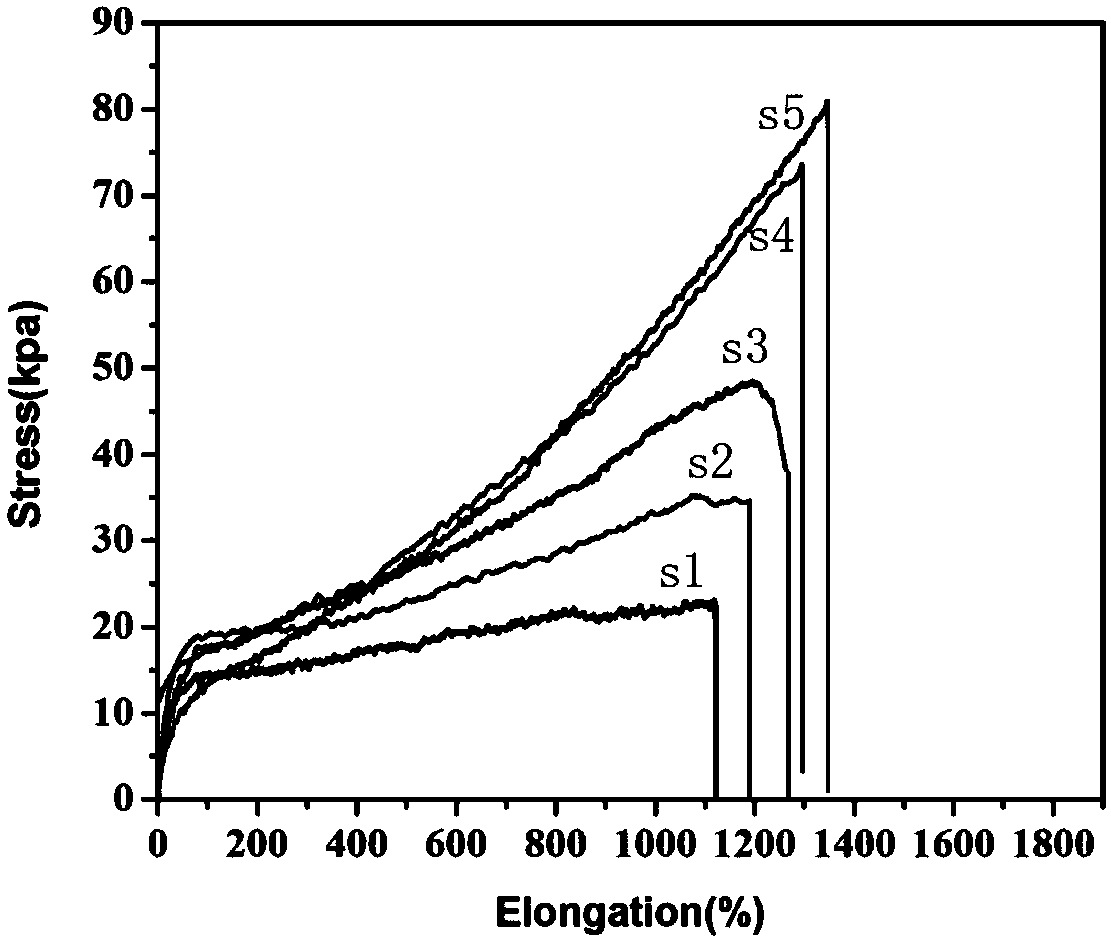

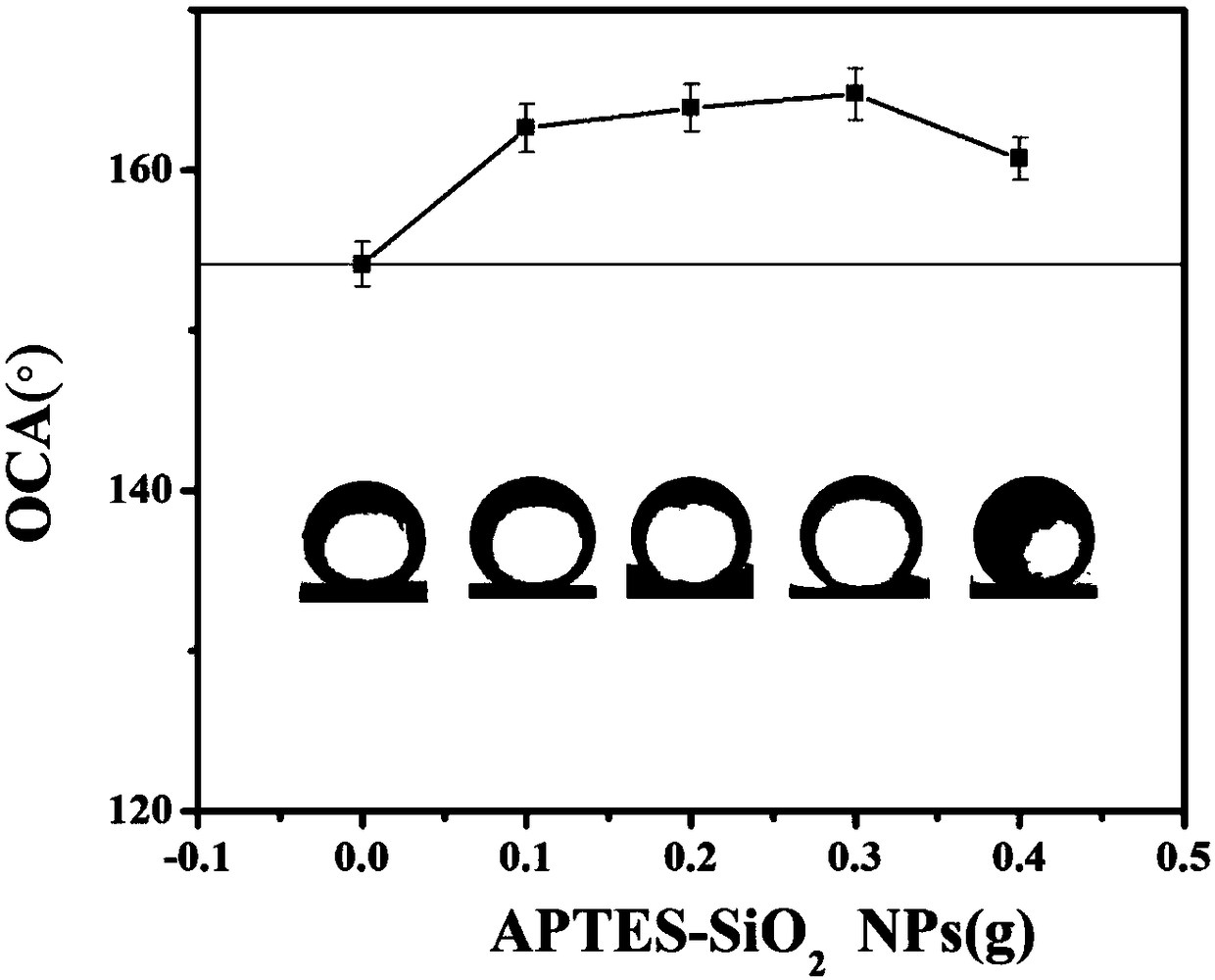

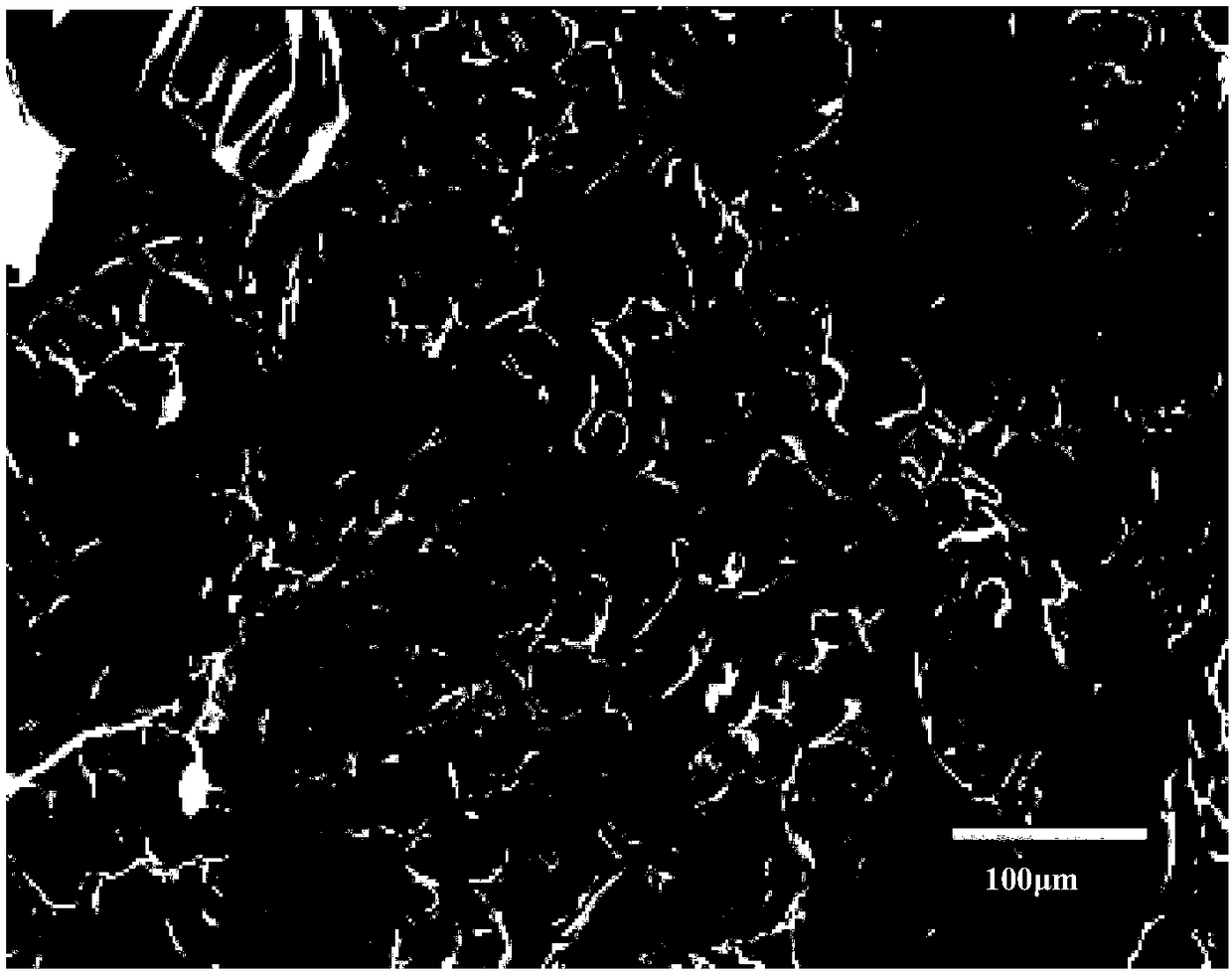

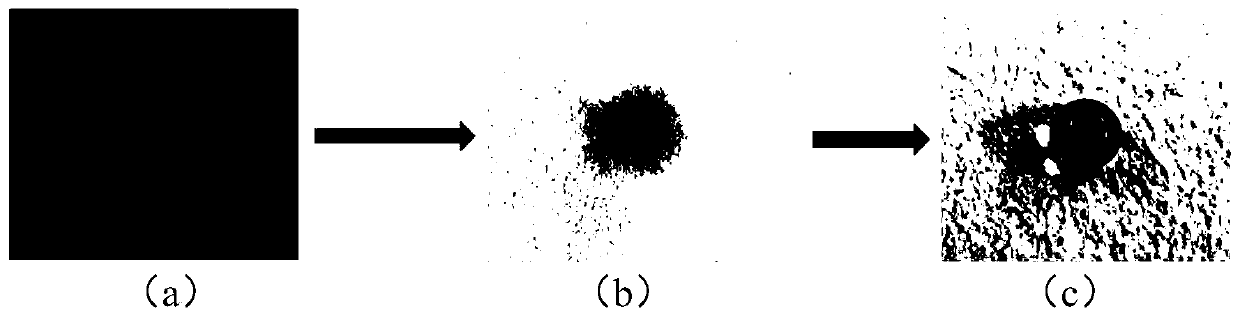

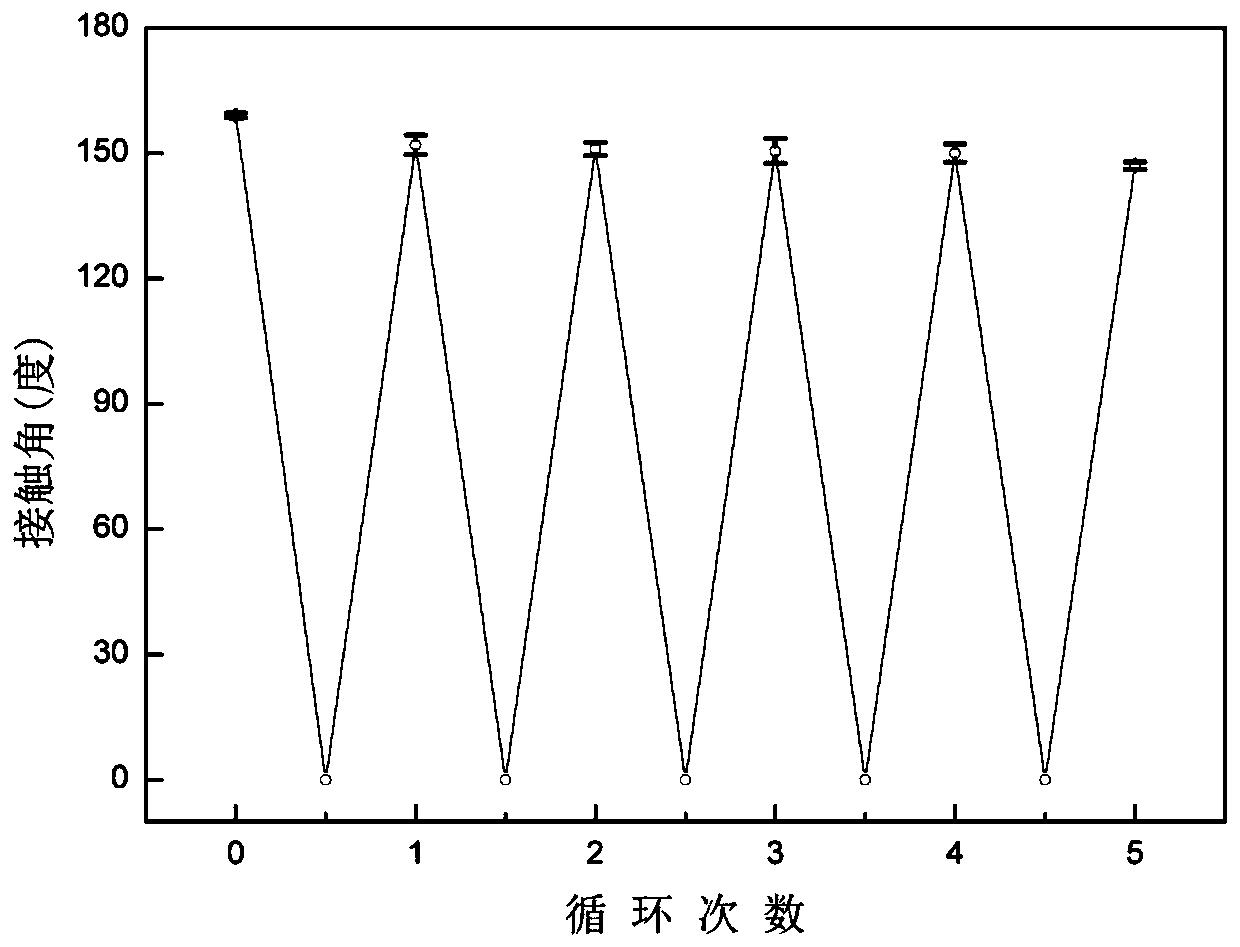

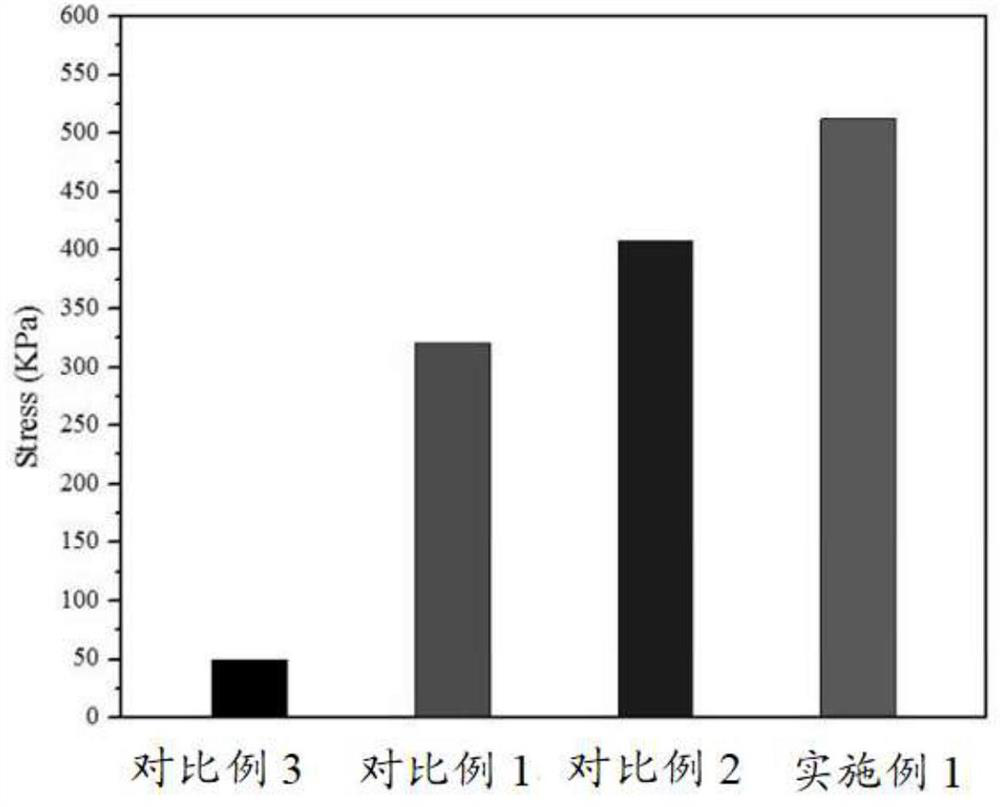

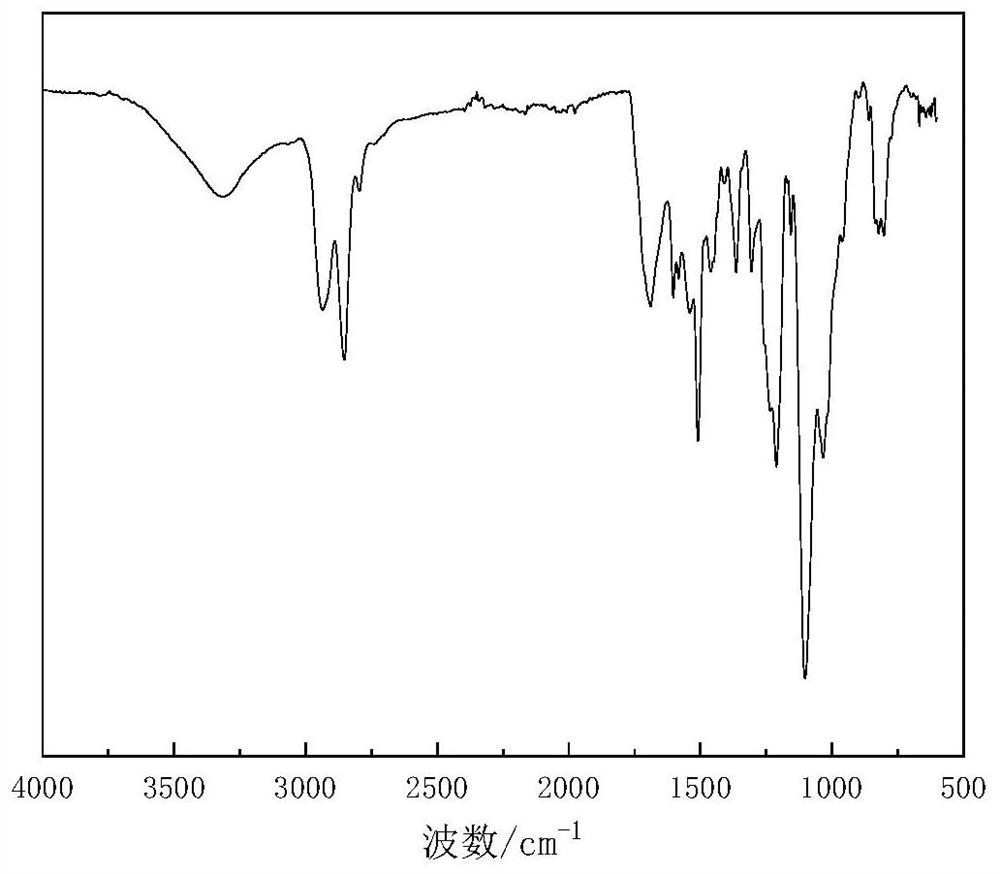

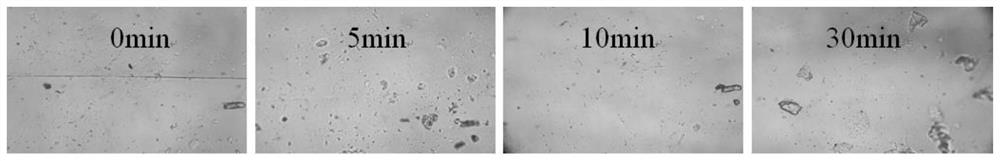

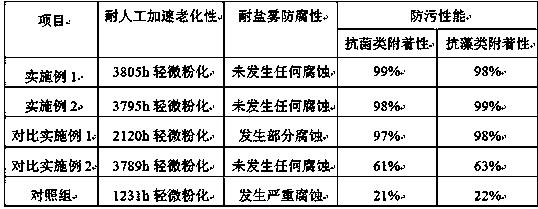

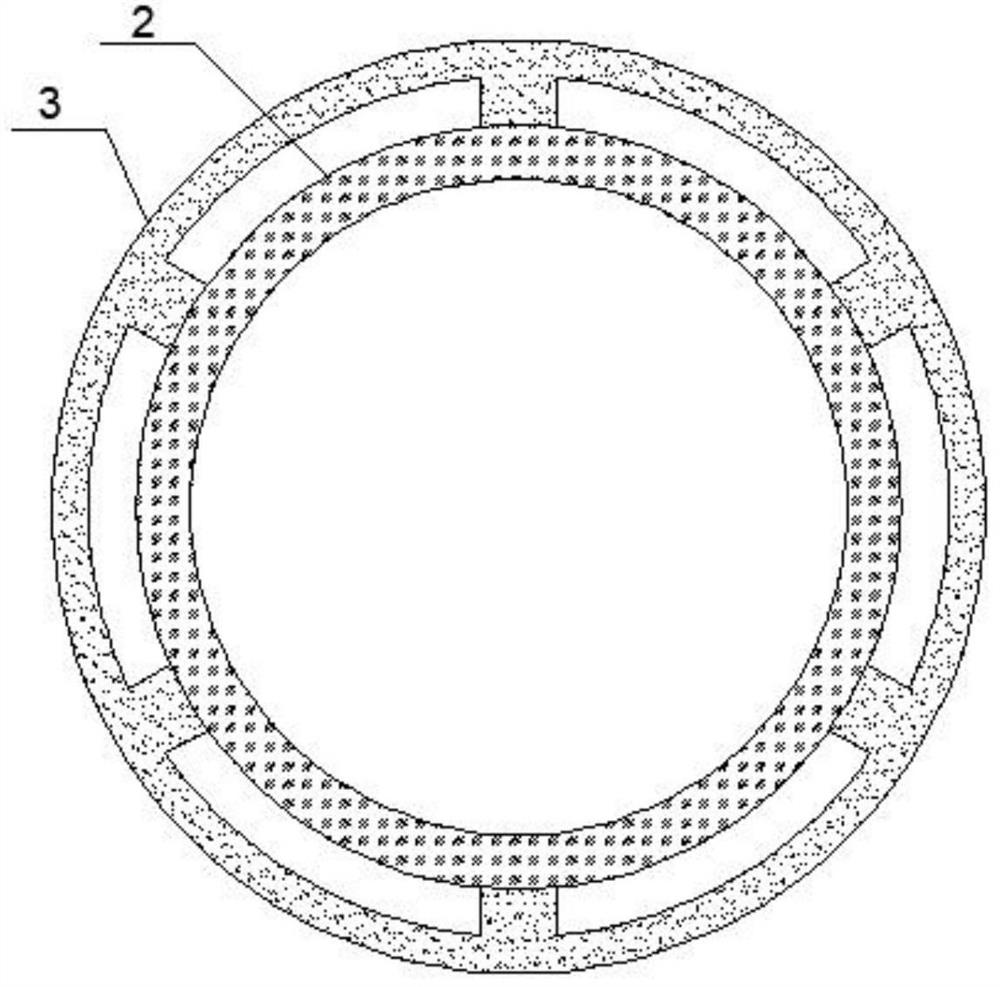

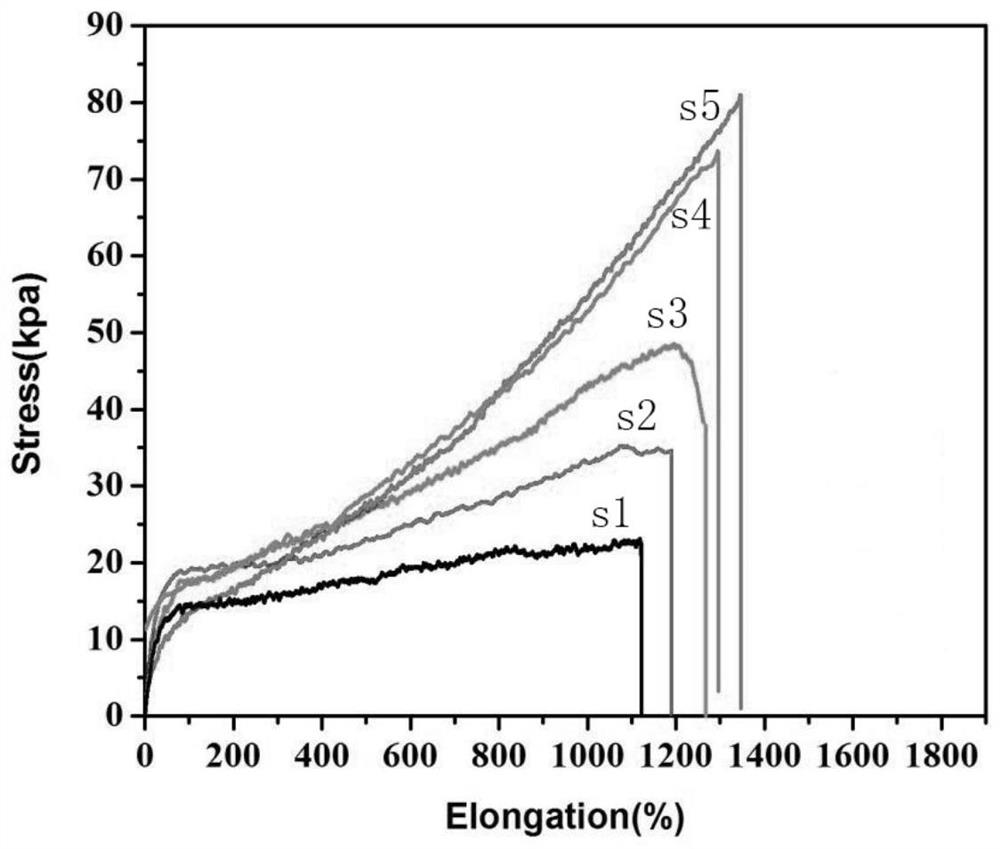

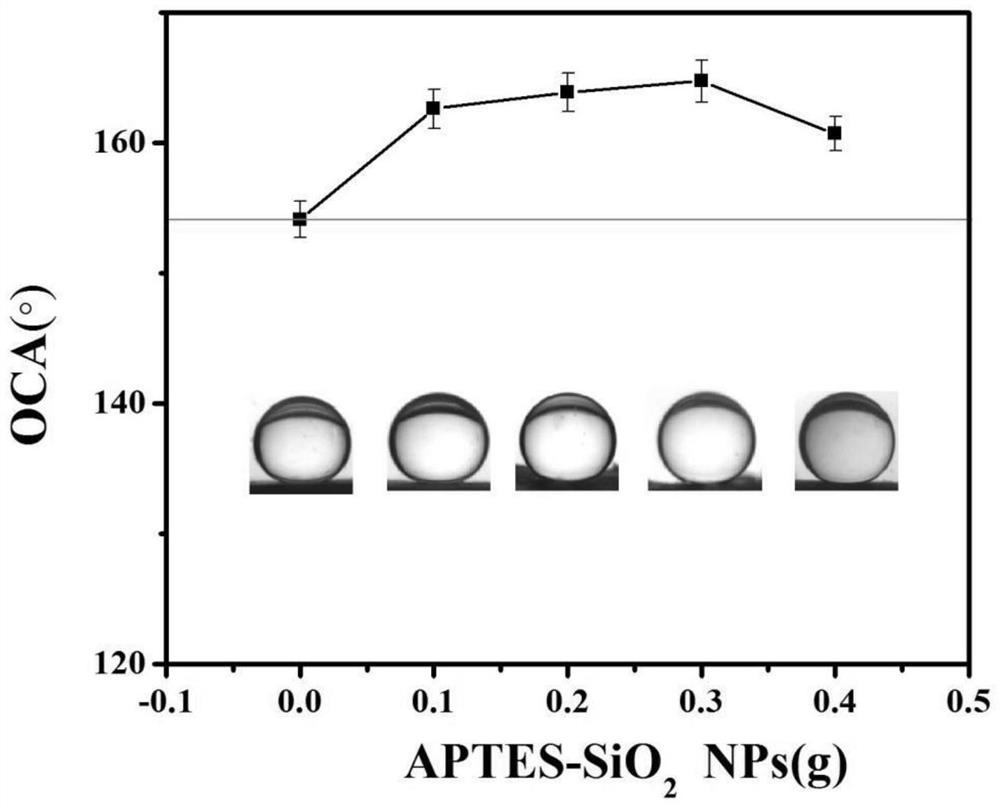

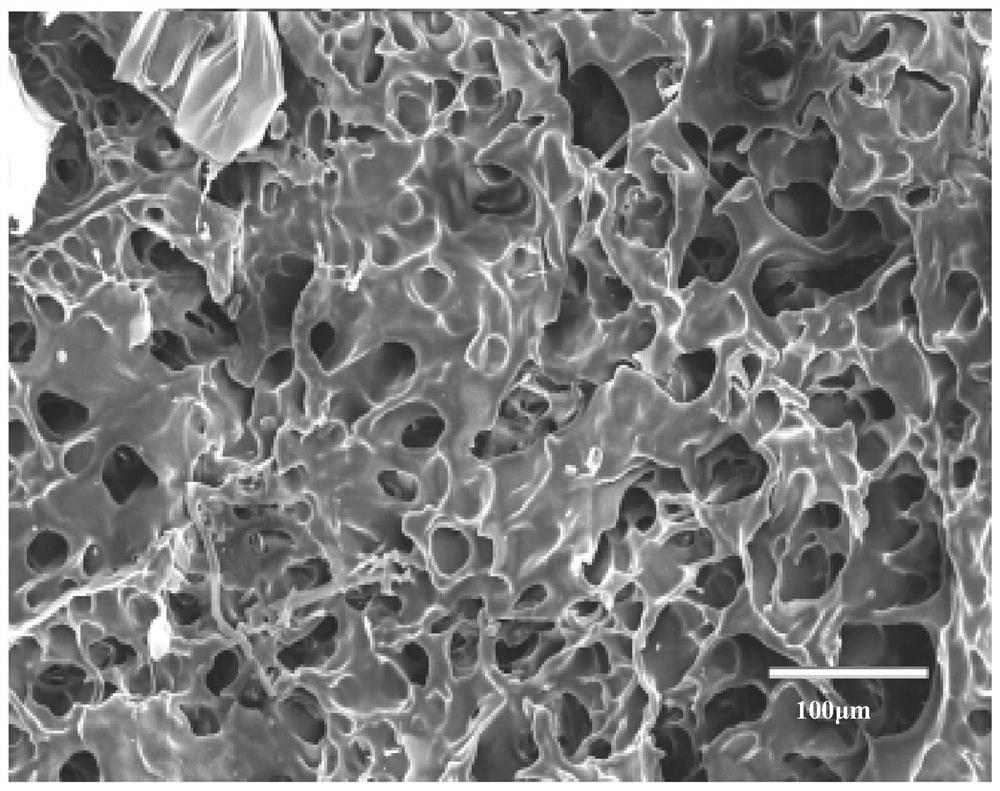

The invention relates to the field of materials, in particular to double-network composite hydrogel, a preparation method of the double-network composite hydrogel, and an oil-water separator. According to the method, an amino modified silicon dioxide nanoparticle, an acrylamide-acrylic acid copolymer and chitosan are cross-linked into a double-network structure by two pure physical effects of a hydrogen bond and an ionic bond; the double-network composite hydrogel has excellent tensile and underwater super-lipophobic properties, a certain self-repairing effect and a smaller swelling ratio; andthe oil-water separator prepared by coating a copper net with the double-network composite hydrogel is long in life and difficult to damage. The tensile strain of the double-network composite hydrogel is 1500-2000%; the tensile stress is 400-450kpa; a self-healing effect is obvious; the swelling ratio is smaller; and an underwater contact angle reaches 164 DEG. The separation efficiency of the oil-water separator on an oil-water mixture reaches 99.71%, and the hydrogel is an oil-water separation material with good development prospects.

Owner:HUBEI UNIV

Slurry for coating non-carbon metal-based anodes for metal production cells

InactiveUS6361681B1Reduce consumptionImprove responseMachining electrodesPretreated surfacesParticulatesOxygen ions

A method of coating an electronically conductive and heat resistant substrate of an anode of a cell for the electrowinning of metals, in particular a cell for the electrowinning of aluminium, to protect and make the surface of the anode active for the oxidation of the oxygen ions present in the electrolyte. The method comprises applying onto the substrate a slurry comprising at least one oxide or oxide precursor as a non-dispersed but suspended particulate in a colloidal and / or inorganic polymeric carrier. The applied-slurry is then solidified and made adherent to the substrate upon heat treatment to form an adherent, protective, predominantly oxide-containing coating. The colloidal and / or inorganic polymeric carrier may comprise at least one of alumina, ceria, lithia, magnesia, silica, thoria, yttria, zirconia, tin oxide and zinc oxide. The oxide of the coating may be a chromite or a ferrite, such as a ferrite selected from cobalt, copper, manganese, nickel and zinc.

Owner:MOLTECH INVENT

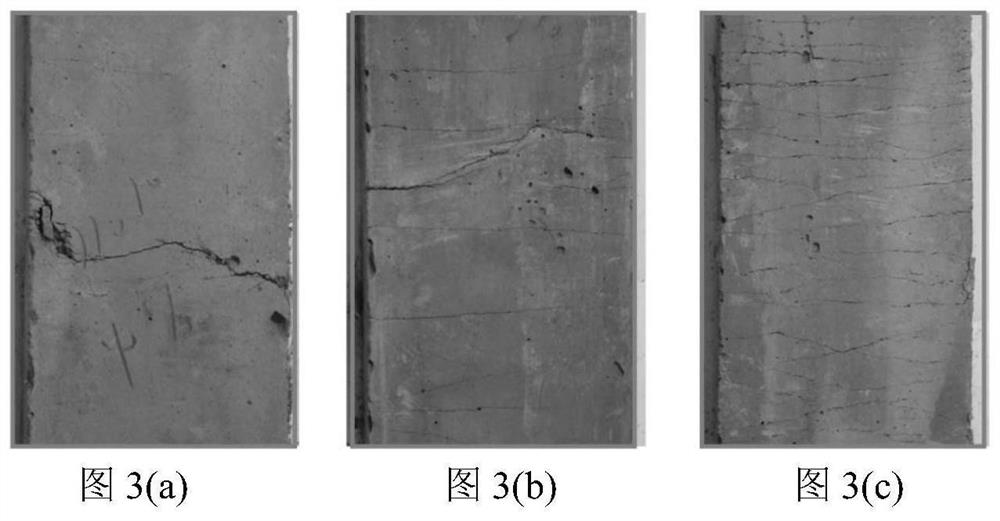

Self-repaired polyurethane waterproof coating and preparation method thereof

ActiveCN106010188AQuality is not affectedDoes not affect performancePolyurea/polyurethane coatingsSelf repairRapid construction

The invention discloses a self-repaired polyurethane waterproof coating and a preparation method thereof. The self-repaired polyurethane waterproof coating is a one-component or two-component coating and consists of 70-90% of polyurethane waterproof material and 10-30% of microcapsule material both by weight. In the invention, by adopting the technology, the base layer cracking and consequent pull crack of the waterproof layer are avoided, self-repairing is realized, and harsh requirements on the base layer are reduced; a perfect self-repairing effect is realized on the small cracks of the building concrete base layer caused by heat expansion and cold contraction and cement hydration, the efficacy of the waterproof material is greatly enhanced, and the self-repairing idea opens up a new thought for the building waterproofing; and moreover, the technology is simple and convenient, rapid construction can be realized, maintenance is not needed, the work efficiency is high, and the technology is the future development direction of building waterproofing.

Owner:浙江鲁班建筑防水有限公司

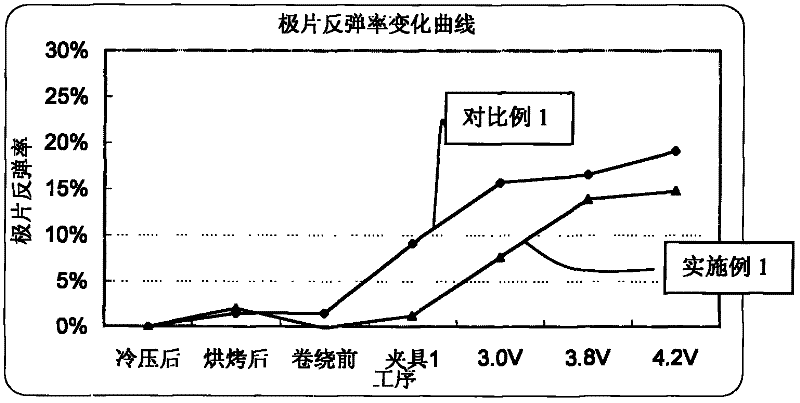

Lithium ion battery cathode and lithium ion battery therewith

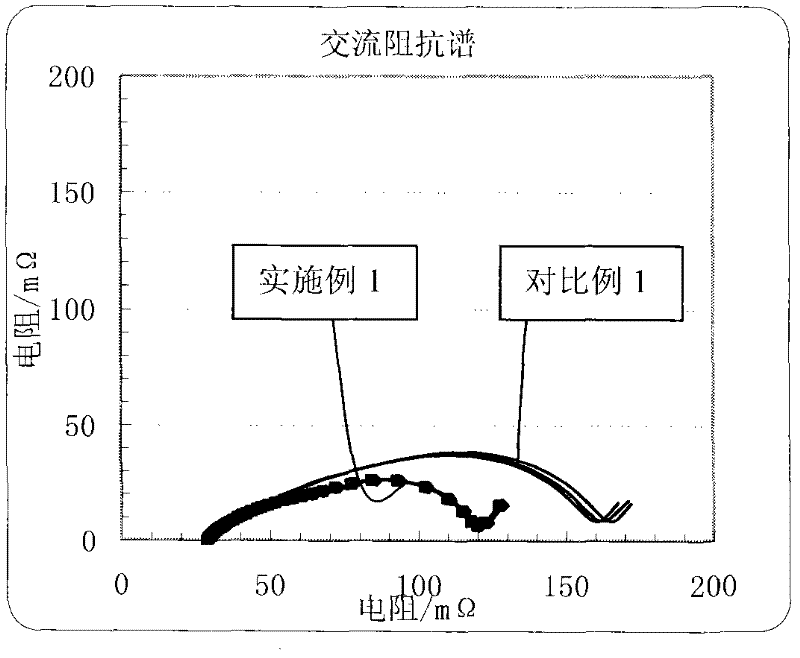

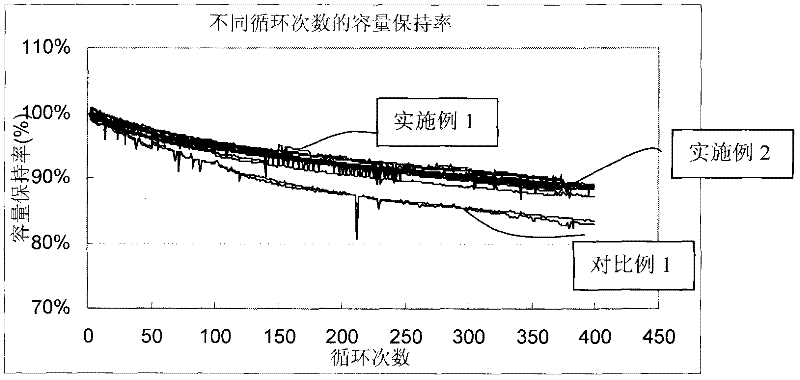

InactiveCN102368543AImprove convenienceImprove adhesionSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryAlloy

The invention belongs to the field of lithium ion battery materials, and provides a lithium ion battery cathode comprising a current collector and a cathode material coated on eth current collector. The cathode material comprises a carbon material or an alloy material. An adopted binder is carboxymethylcellulose sodium. The carboxymethylcellulose sodium has a substitution degree of 0.6 to 1.2, and a number-average molecular weight of 50 thousands to 1 million. The viscosity of a 1% aqueous solution of carboxymethylcellulose sodium under a temperature of 25 DEG C is 50-1200mPa*s. The mass percentage of carboxymethylcellulose sodium in the cathode material is 1% to 5%. With a lithium ion battery employing the cathode, a defect of over-expended thickness during a battery circulation process is solved. Also, the produced battery is safe, reliable, and has a long circulation life.

Owner:DONGGUAN AMPEREX TECH +1

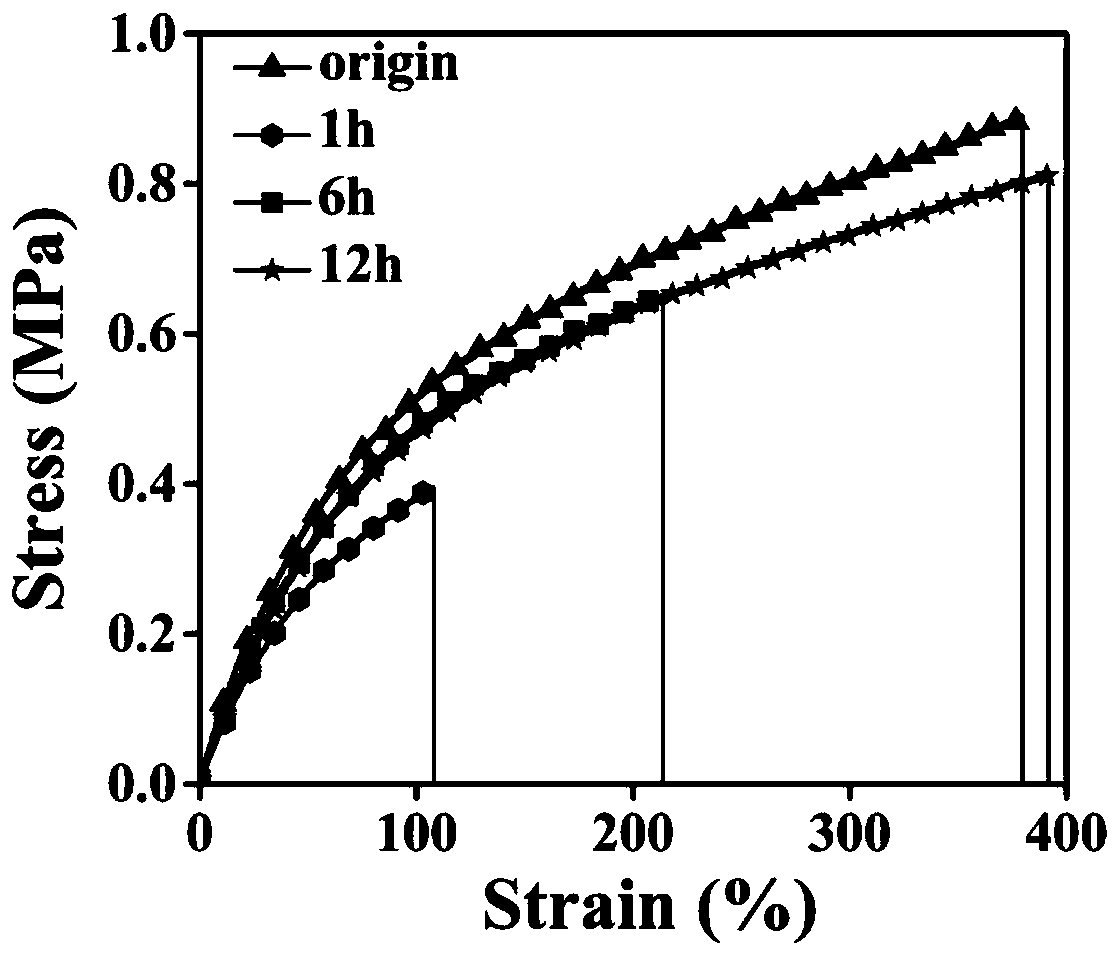

Aqueous polyurethane acrylate dispersion, preparation method thereof, and coating material with self repairing function

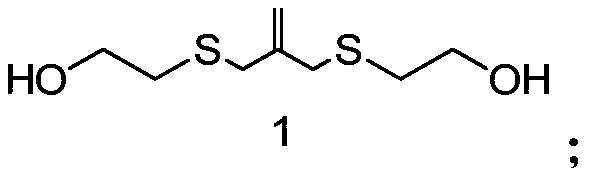

ActiveCN109970944APlay a superimposed effectImprove dynamic performancePolyurea/polyurethane coatingsPolyesterDouble bond

The invention relates to the technical field of coating materials, and provides a preparation method of an aqueous polyurethane acrylate dispersion. The preparation method comprises following steps: reacting diisocyanate with polyester polyol or polyether polyol to obtain a polyurethane prepolymer; mixing the polyurethane prepolymer with a viscosity reduced solvent, a hydrophilic chain extender, and a chain extender containing allyl thioether groups, carrying out reactions to obtain a first mixed solution; mixing the first mixed solution with hydroxyl containing acrylate monomers, carrying outreactions to obtain a double bond terminated polyurethane prepolymer; adding water into the double bond terminated polyurethane prepolymer, carrying out emulsification, removing the solvent, performing dilution until the solid content reaches 20 to 30% to obtain a second mixed solution; mixing the second mixed solution with acrylate monomers, carrying out emulsification, mixing the emulsion withan initiator solution, and carrying out reactions. The aqueous polyurethane acrylate dispersion is prepared by the method mentioned above. A coating material with a self repairing function comprises the aqueous polyurethane acrylate dispersion and a photo initiator. The coating material has a good self repairing performance under the irradiation of UV rays.

Owner:SICHUAN DOWELL SCI & TECH INC

Hydrogel, oil-water separator as well as preparation method and application of hydrogel

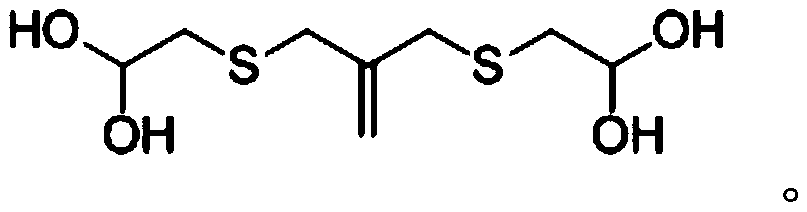

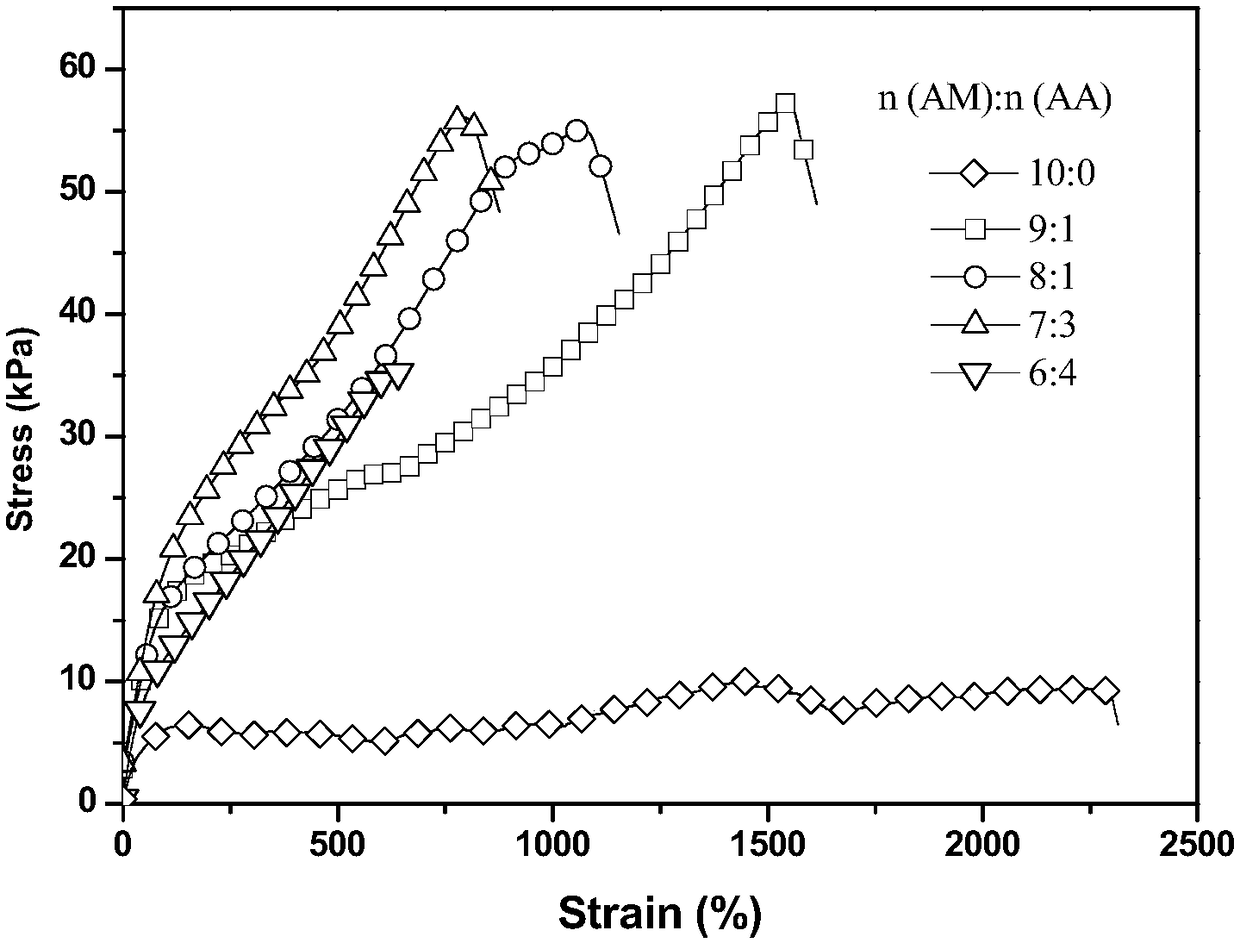

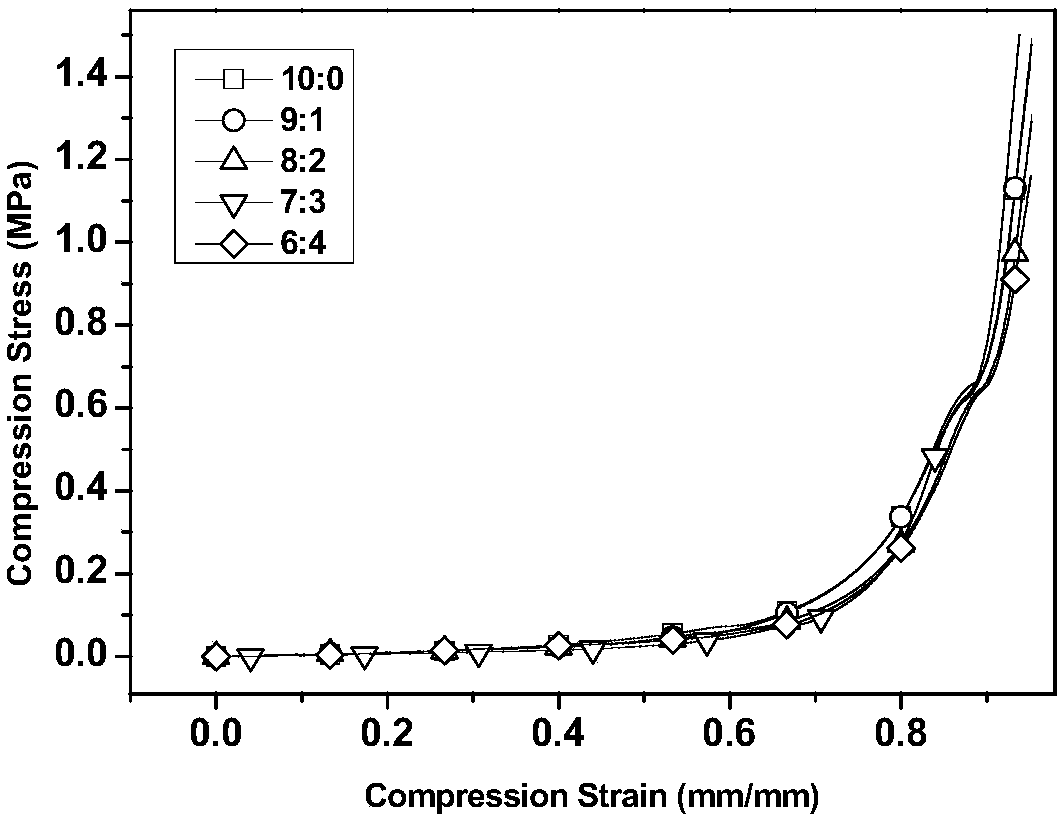

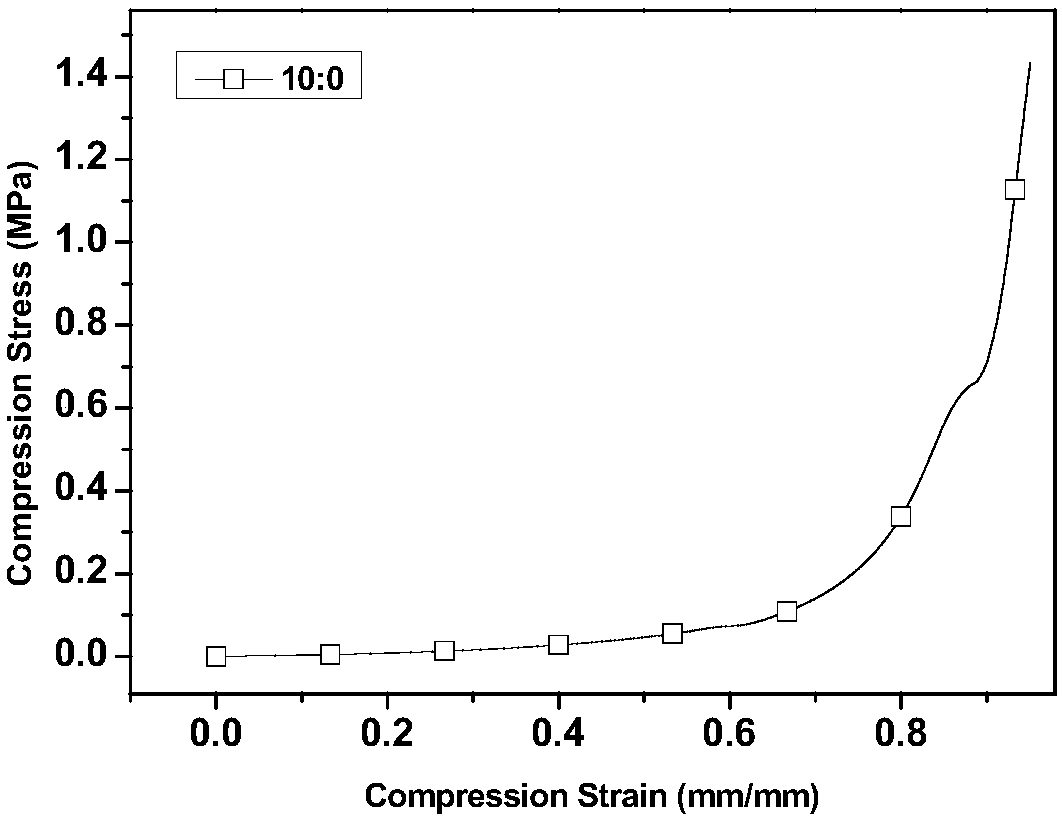

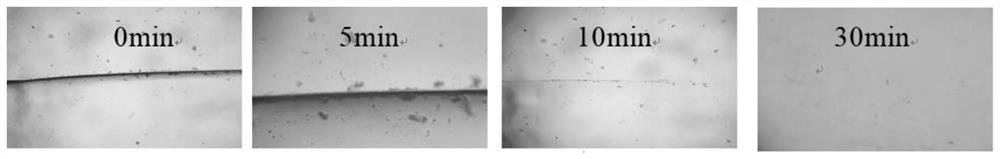

ActiveCN108503858AEasy to stretchImprove self-healing effectFatty/oily/floating substances removal devicesLiquid separationSilica particleDouble network

The invention provides hydrogel, an oil-water separator as well as a preparation method and application of the hydrogel and belongs to the field of environment protection. The hydrogel is of an organic and inorganic compound double-network crosslinking structure, wherein the double-network crosslinking structure is an organic polymer of an organic component; the organic polymer comprises an acrylamide and acrylic acid copolymer with a crosslinking form, and chitosan; an inorganic component is silicon dioxide particles, is dispersed in the double-network crosslinking structure and is chemicallybonded with the copolymer. The hydrogel has a good tensile property, is easy to process and has an excellent super-oleophobic capability. According to the oil-water separator based on the hydrogel, the separation efficiency on various oil-water mixtures commonly reaches 99 percent or more.

Owner:HUBEI UNIV

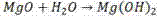

Magnesian concrete damage self-repairing additive and preparation method thereof

The invention relates to the field of building material additives. A magnesian concrete damage self-repairing additive comprises the following components in parts by weight: 30 to 60 parts of magnesium oxide, 15 to 40 parts of quartz powder, 10 to 20 parts of kaoline, 2 to 6 parts of sodium silicate, 2 to 10 parts of sodium hexametaphosphate and 5 to 10 parts of gypsum. The concrete damage self-repairing additive based on a light calcinesia magnesia expanding agent has rapid and excellent self-repairing effect on cracks and internal damage caused by various reasons while improving the mechanical property and the crack resistance of the concrete.

Owner:GUANGDONG YUESHENG SPECIAL BUILDING MATERIALS

Polymer wax powder with self-repairing function, and preparation method thereof

ActiveCN110885458AHigh surface hardnessImprove stain resistanceAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

The invention relates to a polymer wax powder with a self-repairing function, and a preparation method thereof. The polymer wax powder is prepared from, by weight, 55-75 parts of polyethylene wax, 1-20 parts of allyl bisphenol A epoxy resin, 0.5-2 parts of hydroxyalkylamide, 0.5-5 parts of a silane coupling agent, 5-25 parts of carboxyl-terminated saturated polyester and 0.5-5 parts of an accelerant. The preparation method comprises the steps of ingredient mixing, melt extrusion, micronization, electron irradiation crosslinking and the like. The composite polymer wax micro-powder with the average particle size of 1-75 [mu]m can be prepared, and the wax micro-powder can be used as a polyester or epoxy polyester powder coating self-repairing functional additive to improve the surface hardness of a powder coating, enhance the stain resistance and make the coating material have the self-repairing function.

Owner:NANJING TIANSHI NEW MATERIAL TECH

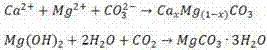

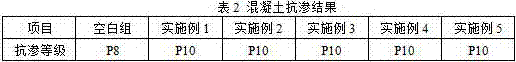

Environmental-friendly soundproof waterproof concrete wall brick and preparation method thereof

The invention relates to an environmental-friendly soundproof waterproof concrete wall brick and a preparation method thereof, and belongs to the technical field of a building material. The method comprises: firstly, carrying out processing of crushing, sorting and the like on building waste to obtain recycled coarse and fine aggregate; then carrying out batching on cement, the recycled coarse aggregate, haycite, the recycled fine aggregate, bamboo fibers, silica sol, a water reducing agent and water, and uniformly stirring; after sufficiently foaming a foaming agent by a foaming machine, mixing foam and slurry to prepare foam concrete; then carrying out pumping, injection molding and maintenance and demoulding to take the brick; finally, coating the surface with a modified polyurethane waterproof paint. The method is simple to operate; used raw materials are nonhazardous; the problem of the building waste can be effectively solved; the obtained concrete wall brick has the advantages of high intensity, good soundproof effect, excellent waterproof performance and the like.

Owner:龚家红

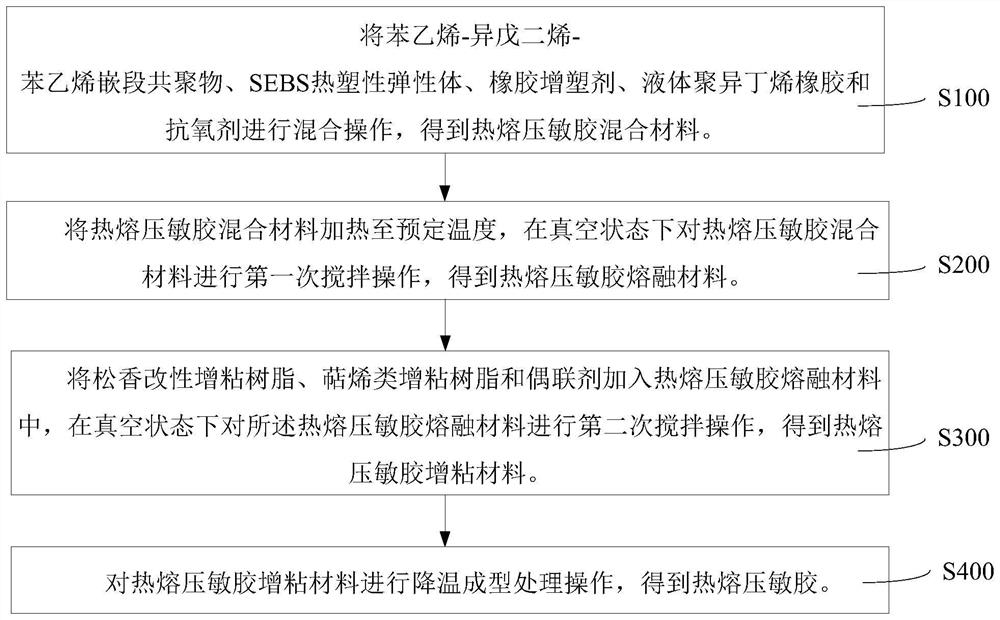

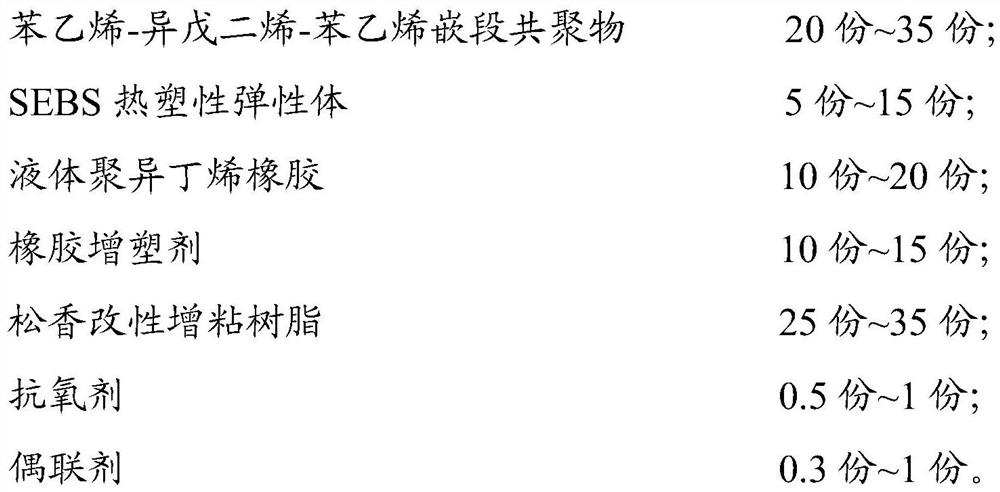

Hot-melt pressure-sensitive adhesive and preparation method thereof

ActiveCN112210328AImprove initial tackGuaranteed bonding effectMacromolecular adhesive additivesElastomerPolymer science

The invention provides a hot-melt pressure-sensitive adhesive and a preparation method thereof. The hot-melt pressure-sensitive adhesive is prepared from 20 to 35 parts of a styrene-isoprene-styrene block copolymer, 5 to 15 parts of an SEBS thermoplastic elastomer, 10 to 20 parts of a liquid polyisobutylene rubber, 10 to 15 parts of a rubber plasticizer, 25 to 35 parts of rosin modified tackifyingresin, 0.5 to 1 part of an antioxidant and 0.3 to 1 part of a coupling agent. The hot-melt pressure-sensitive adhesive is good in adhesion performance, good in high and low temperature resistance andgood in silencing effect and has a tire burst prevention effect on a tire.

Owner:广东凯盛新材料科技有限公司

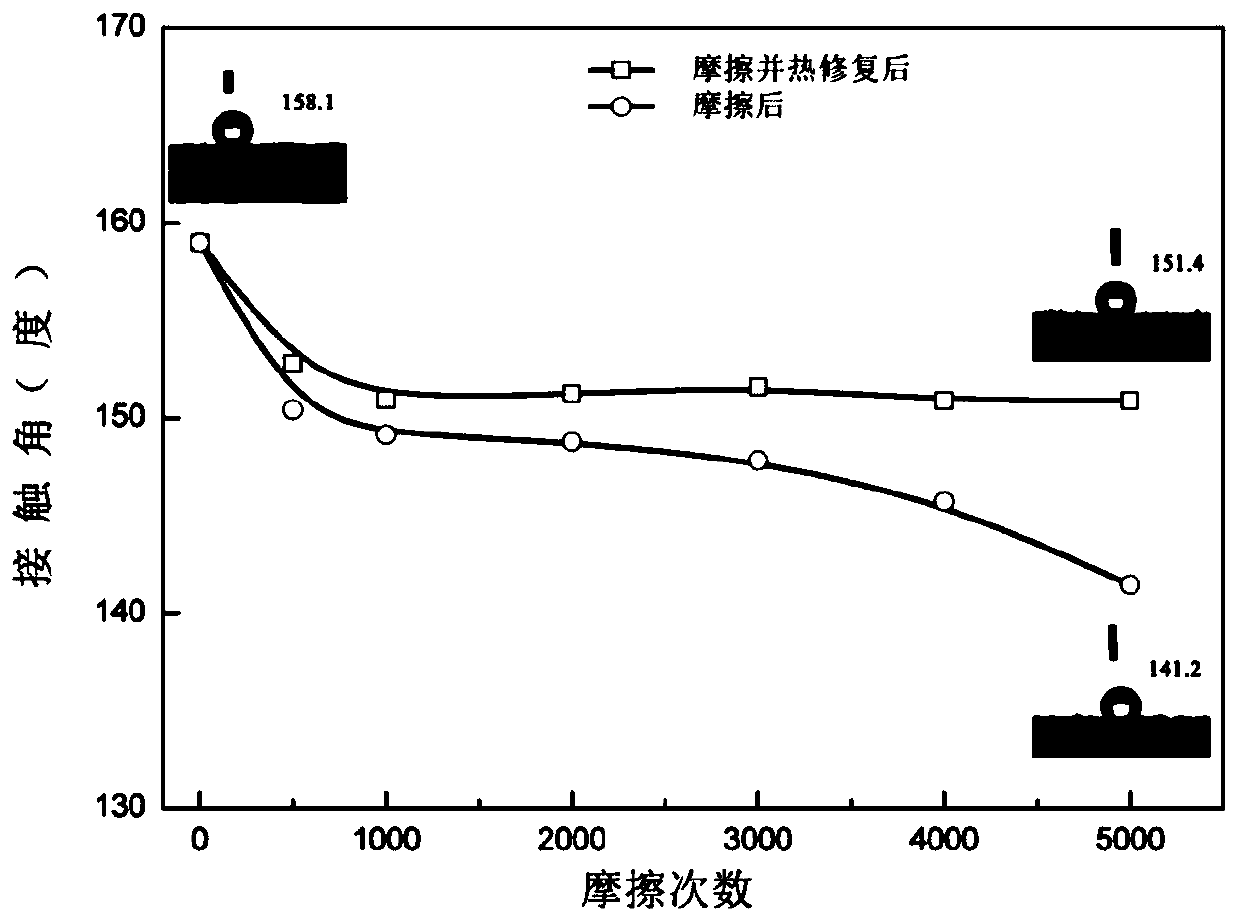

Manufacturing method of super-hydrophobic fabric and super-hydrophobic fabric

PendingCN111411512ASimple and fast operationIncrease productivityBiochemical fibre treatmentLiquid repellent fibresSilver ionHydrophobe

The invention provides a manufacturing method of super-hydrophobic fabric and the super-hydrophobic fabric. The manufacturing method comprises the following steps that tetrabutyl titanate is hydrolyzed, so that titanium dioxide sol is obtained; silver ions and amphiphilic polymers are subjected to a complex reaction, so that the amphiphilic polymers with the complex silver ions are obtained; the amphiphilic polymers with the complex silver ions are added to the titanium dioxide sol to form mixed sol, and siloxane is added to the mixed sol to conduct a reaction, so that siloxane modified sol isobtained; and the siloxane modified sol is adopted to neaten fabric, so that the nano titanium dioxide and nano-silver combined super-hydrophobic fabric is obtained. The manufacturing method is easyand convenient to operate, and is beneficial to improve the production efficiency and save the cost, the super-hydrophobic fabric has the lasting and efficient hydrophobic effect, the self repair of the hydrophobic performance of the fabric can be achieved, and the super-hydrophobic fabric has a good self repair effect on the surface breakage caused by mechanical friction and chemical oxidation and has the excellent antibacterial property.

Owner:HAITAI TEXTILE SUZHOU

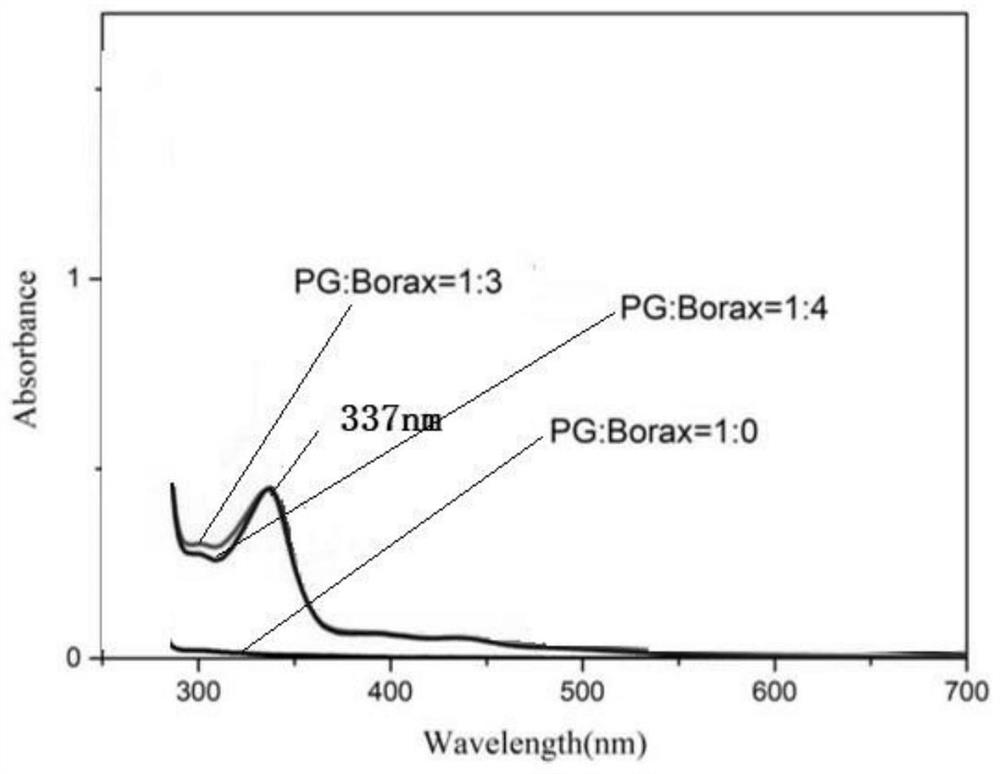

Self-repairing conductive hydrogel material and preparation method thereof

The invention provides a self-repairing conductive hydrogel material and a preparation method thereof. The method comprises the following steps: 1) adding pyrogallic acid into a dissolved borate solution, then adding polypyrrole powder after stirring, and conducting stirring until uniform dispersion is achieved so as to obtain a mixed solution; and 2) mixing the mixed solution with an acrylamide monomer, a cross-linking agent and tetramethylethylenediamine, conducting full stirring to completely dissolve the mixture to obtain a reaction system, adding glycerin and an initiator into the reaction system, and placing the reaction system at normal temperature to form gel. According to the invention, pyrogallic acid is oxidized under the action of oxygen and water to form dopaquinone substancesto provide a self-repairing capability, and carbon black-modified polypyrrole can be uniformly dispersed in water and provides conductive capability. The prepared hydrogel has the structural characteristics of good mechanical property, conductivity and self-repairability.

Owner:JIANGHAN UNIVERSITY

Preparation method of PAM/PVP/PAA triple-network hydrogel

InactiveCN111718445AGood mechanical propertiesGood self-healing effectCross linkerCrosslinked polymers

The invention relates to a preparation method of PAM / PVP / PAA triple-network hydrogel. The triple-network hydrogel is a cross-linked polymer interpenetrating network formed by three polymers, and the mechanical properties of gel are greatly enhanced. The preparation method of the hydrogel specifically comprises the following steps: 1) dissolving acrylamide (AM), acrylic acid (AA), ferric chloride hexahydrate and polyvinylpyrrolidone (PVP) in water in proportion, and carrying out uniform mixing; 2) sequentially adding a cross-linking agent and an initiator, carrying out argon oxygen displacementtreatment, and then adding an initiator and an accelerator, and 3) carrying out ultrasonic treatment on the obtained mixed solution, conducting reacting at 40 DEG C for 1 hour, and finally performingstanding at room temperature for 24 hours. The prepared triple-network composite hydrogel has high mechanical strength, good self-repairing performance and certain conductivity, the preparation process is simple, the raw materials are green, non-toxic and harmless, and the triple-network composite hydrogel can be applied to the aspects of medical instruments, bionic electronic skin, injectable hydrogel and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

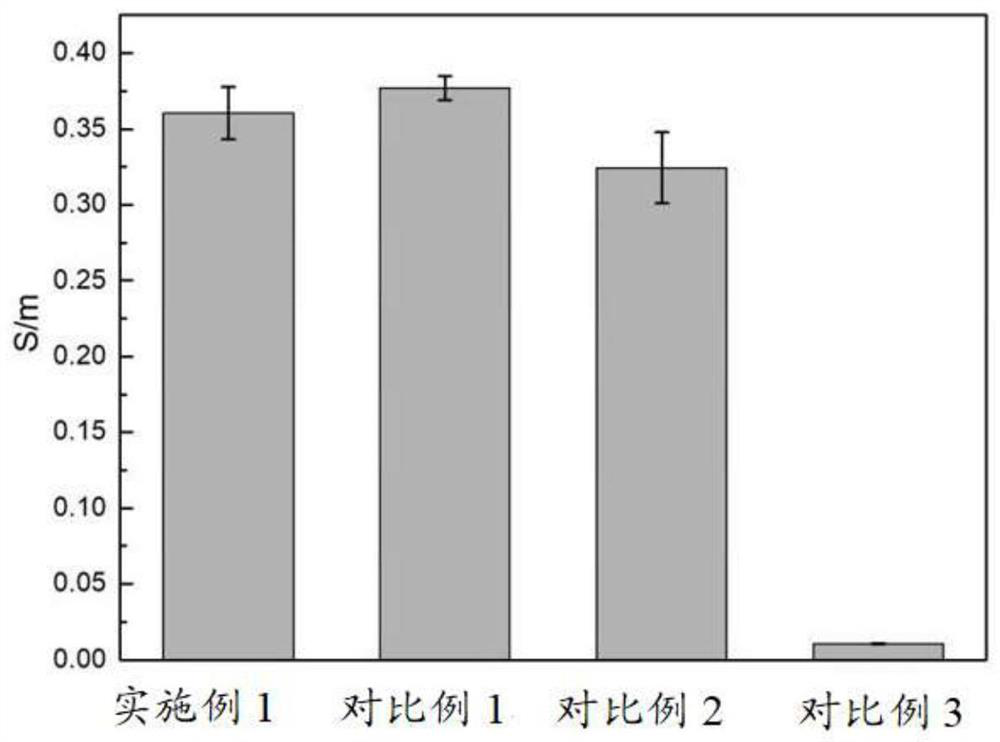

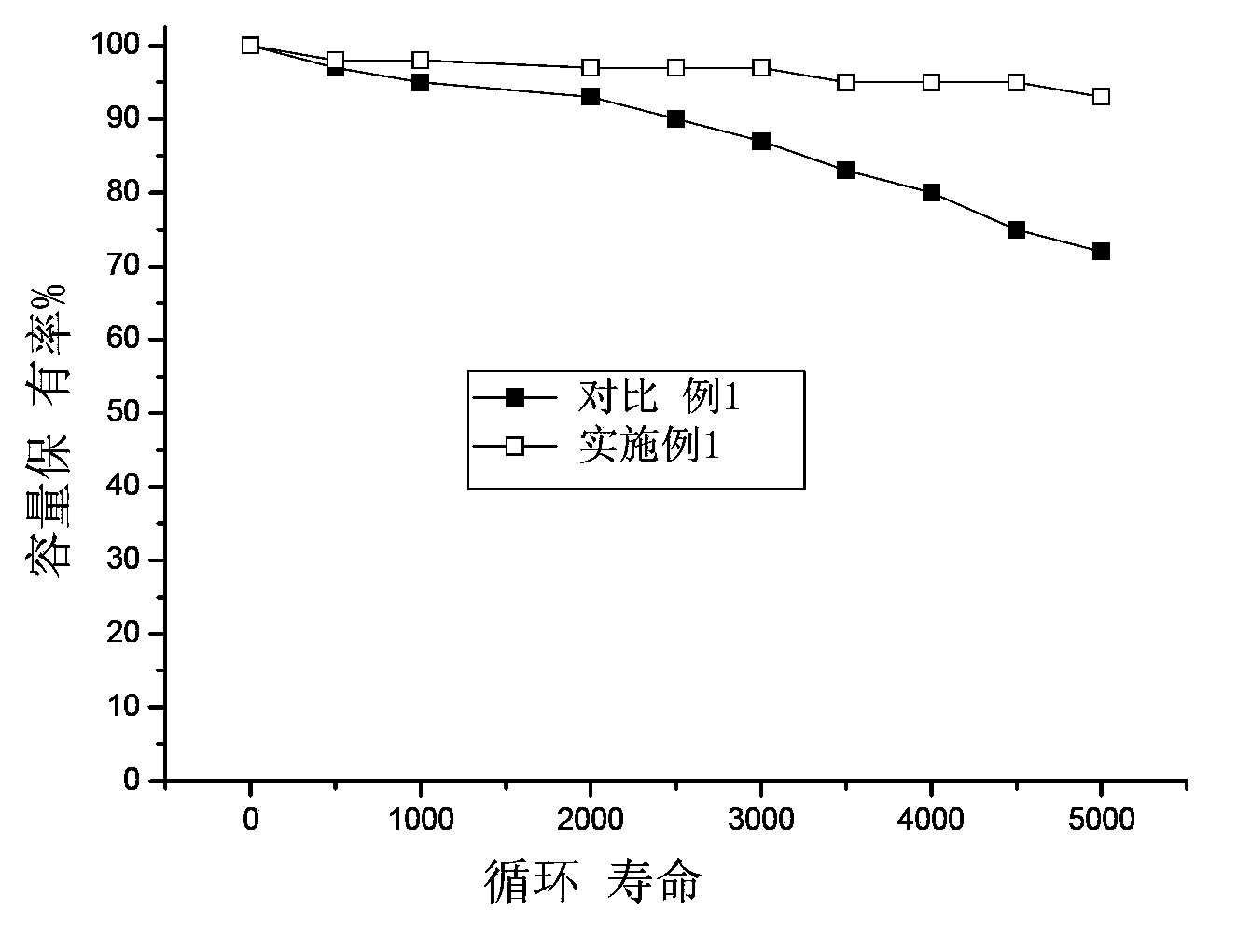

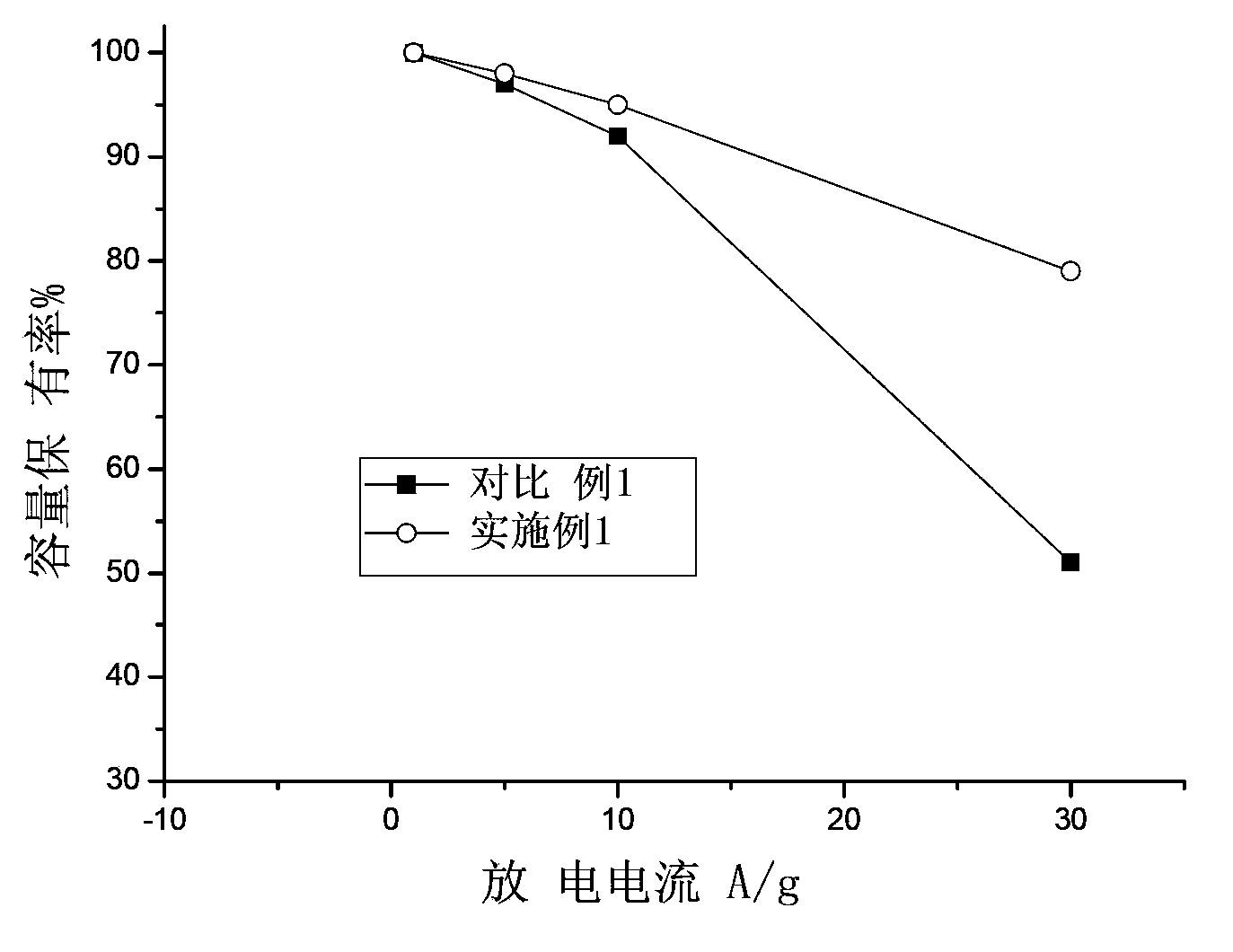

Graphene electrode plate, and preparation method and application thereof

InactiveCN103839696AHigh modulusLow elongationHybrid capacitor electrodesHybrid/EDL manufactureCvd grapheneGraphene electrode

The invention belongs to an electrochemical material and discloses a graphene electrode plate, and a preparation method and application thereof. The preparation method of the graphene electrode plate includes: preparing a graphene slurry through use of alginate, graphene and water and then coating a current collector with the slurry and drying and then obtaining the graphene electrode plate. In the preparation method for the graphene electrode plate, uniform carboxyl groups are distributed evenly on a chain structure of the alginate and the carboxyl groups in the alginate are capable of forming chemical bonds with hydroxyl groups on different graphene-plate layers so that a bonding force between the graphene plate layers is reinforced and conductivity between the graphene plate layers is improved and thus the rate performance is improved; and low reaction activity between the alginate and an electrolyte, and an excellent electrolyte resistance characteristic reduce irreversible consumption of the electrolyte on the surfaces of cathode active material particles in a cyclic process so that the long cyclic performance of a cell is ensured.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Self-repairing waterborne polyurethane coating containing imine bonds

PendingCN114561145ALong-term self-healingGood mechanical propertiesPolyurea/polyurethane coatingsPolymer sciencePolyurethane coating

The invention discloses a self-repairing waterborne polyurethane coating containing an imine bond, and relates to the technical field of coatings, a series of self-repairing waterborne polyurethane coatings containing the imine bond are prepared by synthesizing different types of polyurethane chain extenders containing the imine bond and reacting the polyurethane chain extenders with different polyurethane soft chain segments, isocyanate and hydrophilic chain extenders; a good self-repairing effect is achieved at the room temperature, and after repairing is conducted for 2 h at the temperature of 80 DEG C, the repairing rate reaches 99.2%. According to the prepared self-repairing waterborne polyurethane coating, the preparation technology is simple, the raw materials are cheap and easy to obtain, the coating has the high self-repairing rate, and maintenance of an industrial coating is facilitated.

Owner:ANHUI UNIVERSITY

Self-repairing rubber material and preparation method thereof

The invention discloses a self-repairing rubber material, which is characterized by being prepared from the following components in parts by weight: 40 to 50 parts of epoxidized natural rubber, 30 to 40 parts of methyl vinyl silicone rubber, 5-10 parts of benzophenone-4,4'-dicarboxylic acid / amino-terminated polyurethane polycondensate, 8-12 parts of a hyperbranched secondary thiol compound, 2-4 parts of hyperbranched polyamidoamine, 2-5 parts of pig hair fiber, 15-25 parts of an inorganic filler, 2-3 parts of a coupling agent, 1-3 parts of a vulcanizing agent and 1-2 parts of a photoinitiator. The invention also provides a preparation method of the self-repairing rubber material. The self-repairing rubber material provided by the invention is better in comprehensive performance and performance stability, better in self-repairing effect and more excellent in mechanical property, temperature resistance, impact resistance and aging resistance.

Owner:陈世玉

Method for preparing self-repairing concrete from egg shells

InactiveCN109265098AAchieve self-healingImprove self-healing effectFungiBuilding repairsUreaBuilding material

The invention relates to a method for preparing self-repairing concrete from egg shells, and belongs to the technical field of building material preparation. According to the method, firstly, the eggshells are ground into powder; then, peach gum is heated and melted; next, urea is coated for preparing a self-made functional filler; then, a liquid culture medium is used for culturing saccharomycetes; next, centrifugation is performed; centrifugal precipitation and vacuum freeze-drying are performed to prepare saccharomycete freeze-dried powder; finally, egg shell crushed matters, the self-madefunctional filler, the saccharomycete freeze-dried powder and other concrete raw materials are mixed to prepare the self-repairing concrete. The prepared self-repairing concrete has the advantages that the depth gap in the concrete can be fully repaired; a good self-repairing effect is achieved; the application prospects are wide.

Owner:王敏

Method for preparing anti-aging, anti-corrosion and anti-fouling lubricating oil

InactiveCN110791353AImprove anti-corrosion and anti-fouling performanceControl release speedAdditivesPolyaspartic acidActive agent

The invention discloses a method for preparing anti-aging, anti-corrosion and anti-fouling lubricating oil. The method includes dissolving polyaspartic acid into a buffer solution, adding sodium stearate organic modified hydrotalcite, performing ultrasonic dispersion, then performing magnetic stirring, centrifuging and washing, dispersing in a cerium nitrate aqueous solution, performing ultrasonicdispersion, performing magnetic stirring, centrifuging and washing to obtain cerium ion-sodium stearate compound modified hydrotalcite; adding copper chloride dehydrate and polyethylene glycol into deionized water for dissolving, dropwise adding a sodium hydroxide solution and a glucose solution, then adding modified nano-zinc oxide, stirring for reaction, dropwise adding a sodium chloride solution, stirring for reaction at constant temperature, filtering, washing, drying in vacuum and grinding to obtain antifouling microcapsules; mixing nano cerium dioxide and nano serpentine, adding a compound surfactant, carrying out ultrasonic dispersion to obtain a lubricating additive, adding the lubricating additive into lubricating oil base oil, and uniformly mixing with the cerium ion-sodium stearate compound modified hydrotalcite and the antifouling microcapsules to obtain the anti-aging, anti-corrosion and anti-fouling lubricating oil.

Owner:界首市鑫一龙机械设备购销有限公司

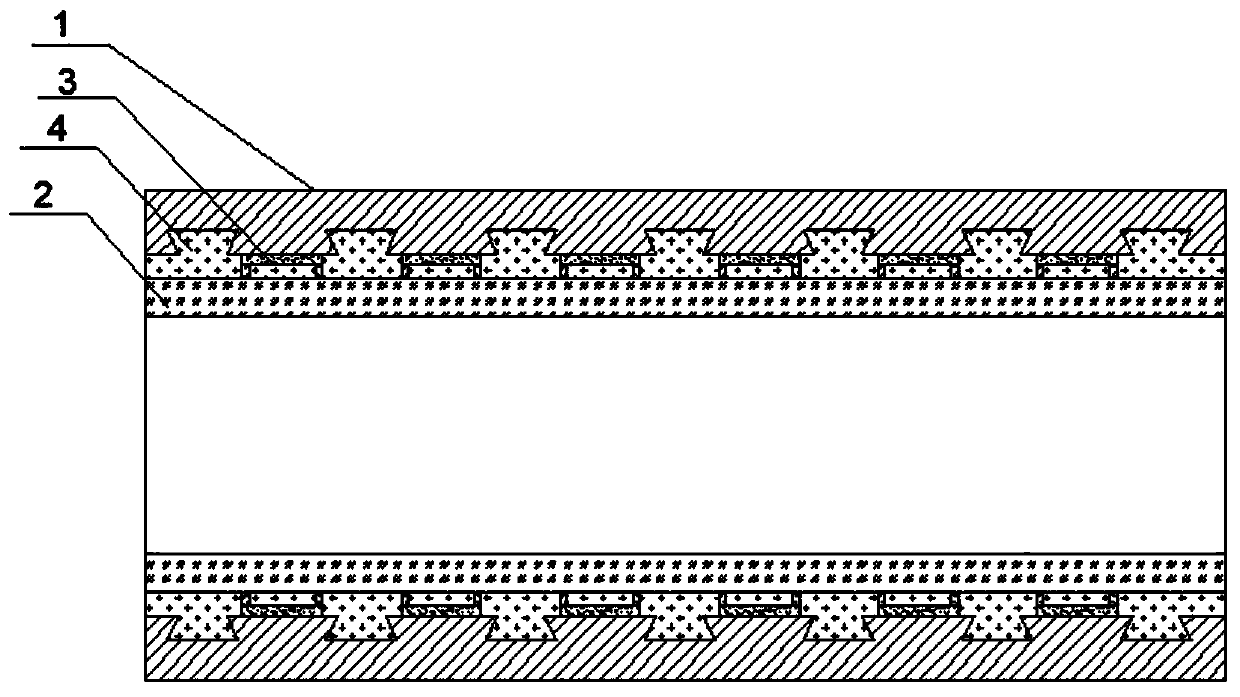

High-ductility self-recovery cement-based composite column

The invention discloses a high-ductility self-recovery cement-based composite column, which comprises a steel pipe and a self-recovery cement-based material poured in the steel pipe, wherein the self-recovery cement-based material comprises cement mortar, SMA fibers and carbon black, and the mass ratio of the SMA fibers to the carbon black is 32:5-96:10. The high-ductility self-recovery cement-based composite column can bear large deformation and is excellent in ductility and anti-seismic property; and carbon black is doped into a matrix and is combined with conductive SMA fibers, so that theconductivity of the matrix is improved, and the cracking condition can be sensitively detected by analyzing the change of resistivity after the material is cracked and recovered.

Owner:SOUTHEAST UNIV +1

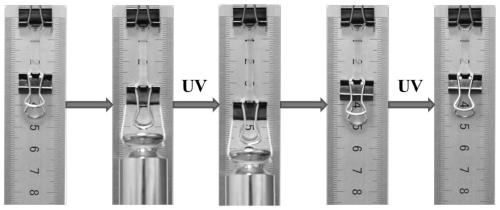

A self-healing light-controlled plastic polyurethane elastomer material, its preparation and application

The invention discloses a polyurethane elastomer material and a preparation method thereof. By taking hexaarylbiimidazole (HABI) photochromic molecules and polyhydric alcohol as cross-linking agents of an elastomer material, the polyurethane elastomer material with a double-cross-linking network structure is constructed, and an intelligent deformation polyurethane material having rapid response toultraviolet light is correspondingly obtained and has a self-healing function. A polyurethane elastomer has good mechanical and physical properties of tenacity, ductility, fatigue resistance and thelike, is taken as an intelligent material and has potential application markets in drivers, software robots, artificial biological organs, sensors, manufacturing industry, medical treatment, wearableequipment, medical treatment instructions and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

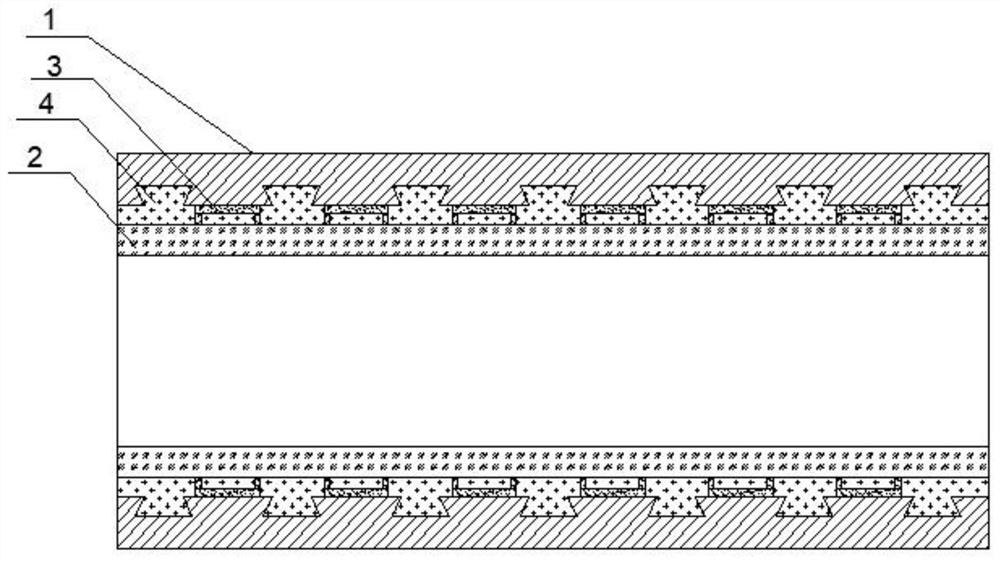

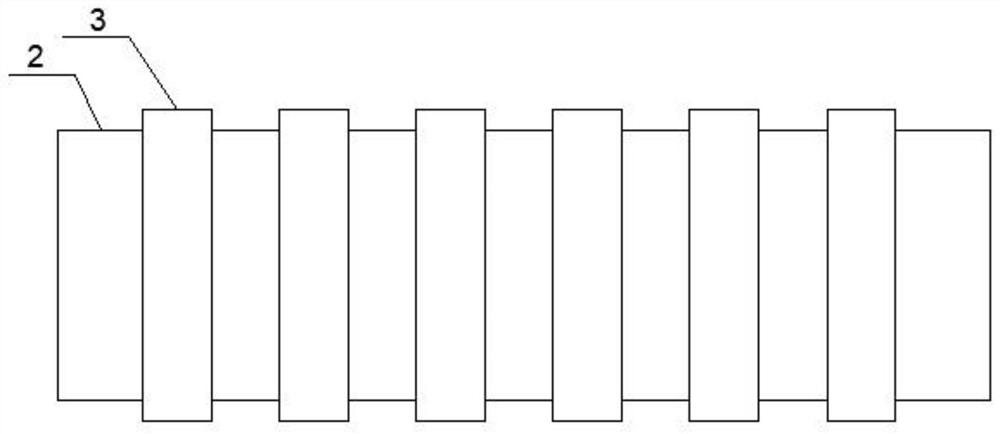

High-strength corrosion resisting titanium-steel composite pipe and production technology thereof

ActiveCN110270687AGuarantee interlayer compactnessImprove interfacial binding stabilityRigid pipesInterference fitAlloy

The invention provides a high-strength corrosion resisting titanium-steel composite pipe and a production technology thereof. The high-strength corrosion resisting titanium-steel composite pipe comprises an outer-side steel pipe and an inner-side titanium pipe, wherein the outer-side steel pipe and the inner-side titanium pipe are coaxially sleeved; the inner wall of the steel pipe is provided with a plurality of open slots; the outer wall of the titanium pipe is provided with a plurality of rib components; the outer walls of the rib components are in interference fit with the inner wall of the steel pipe; a part between the inner wall of the steel pipe and the outer wall of the titanium pipe is filled with an alloy layer. According to the high-strength corrosion resisting titanium-steel composite pipe disclosed by the invention, a composite surface structure of the titanium pipe and the steel pipe is specifically designed and is filled with the alloy layer, so that the interlayer compactness is effectively ensured, and the interface bonding stability is high; meanwhile, the filled alloy layer has a good guiding effect on infiltration of metal elements under the condition of high temperature; besides, the rib components have the effect of improving the hardness, good self-repairing effect, and an excellent compensating effect on high-temperature deformation of the titanium pipe; the deformation degree is reduced and comprehensive mechanical properties are obviously improved.

Owner:江苏众信绿色管业科技有限公司

Bioactive scaffold for controlling multistage release of drugs and manufacturing method of bioactive scaffold

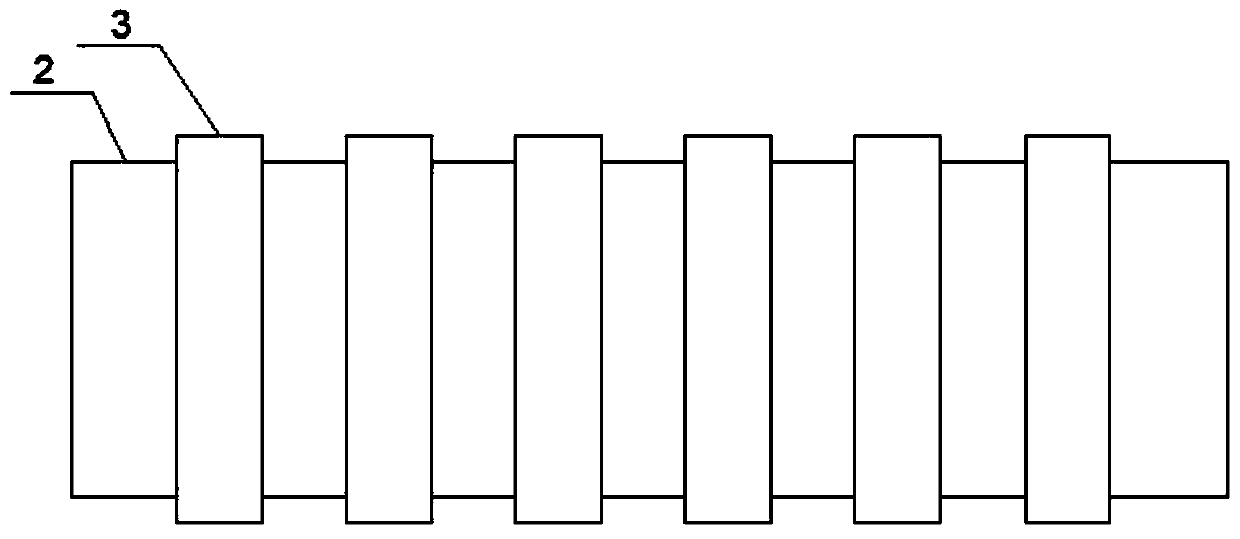

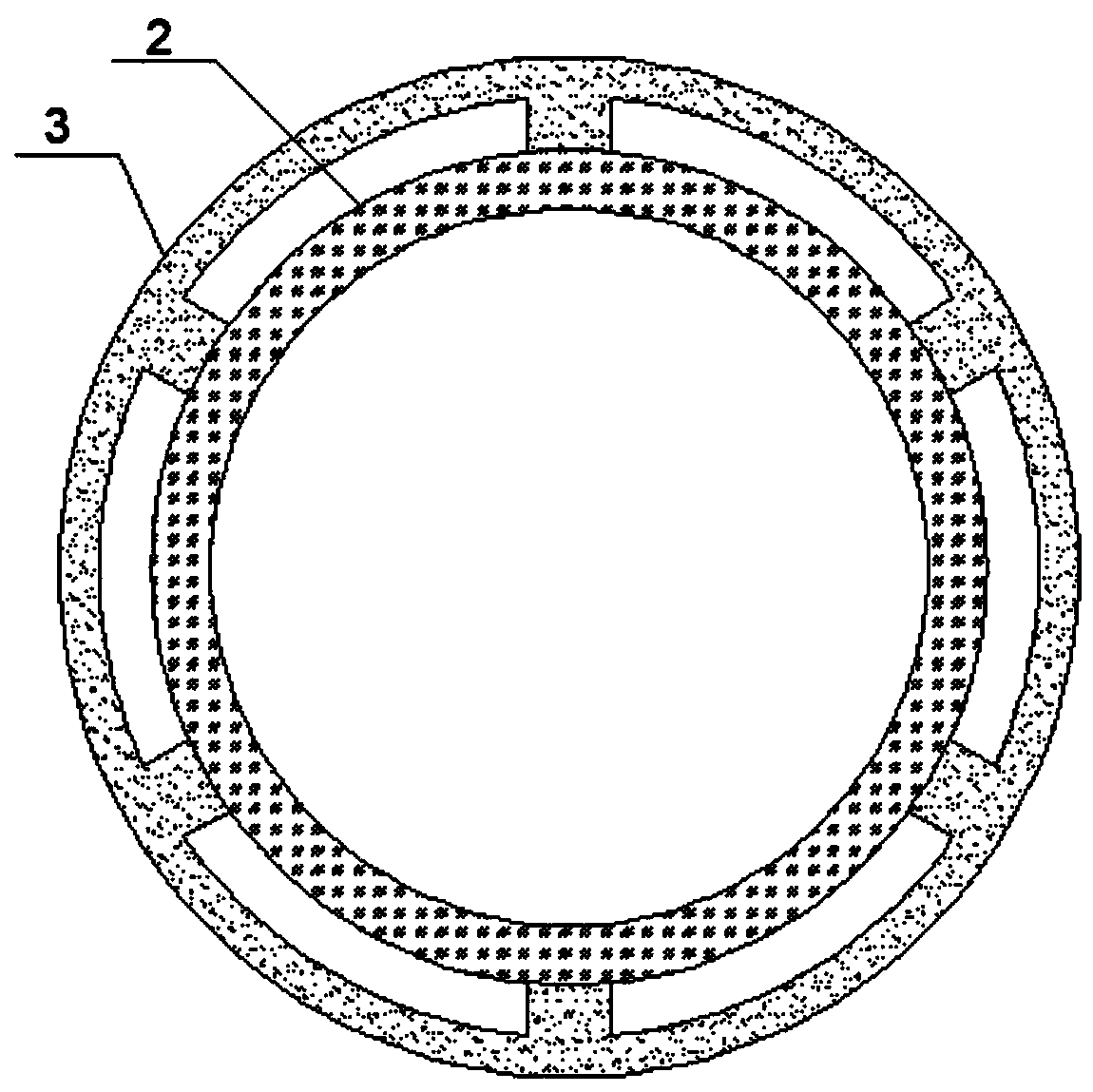

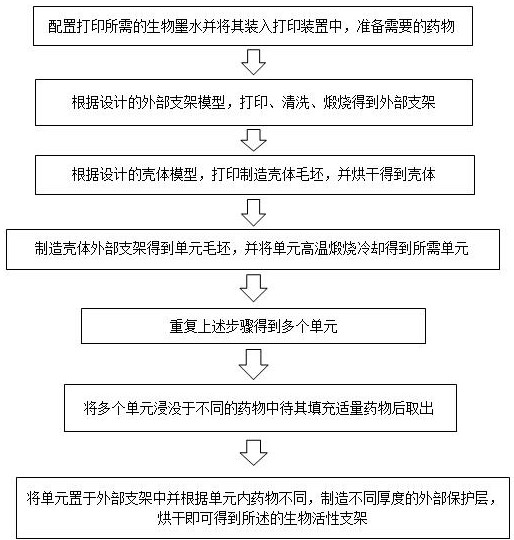

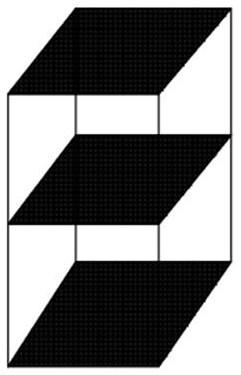

ActiveCN112451741AEasy to use in combinationPromotes the self-healing of bone injuriesAdditive manufacturing apparatusBone implantBioactive scaffoldEngineering

The invention discloses a bioactive scaffold for controlling multistage release of drugs and a manufacturing method of the bioactive scaffold. The scaffold is composed of two or more than two different scaffold units, each scaffold unit comprises an external scaffold, an external scaffold protective layer and an internal unit located in the external scaffold; each internal unit is composed of a shell, a porous scaffold wrapping the shell and drugs distributed in the shell and the porous scaffold; the pore diameter of each porous scaffold is 100-500 microns; and the outer scaffolds, the protective layers, the porous scaffolds and the shell are all made of bioactive materials. Various drugs required by bone self-healing can be carried into all the internal units, the release time of each drug is accurately controlled, the multistage release of the drugs in different time periods is realized, and the effects of each drug in different bone self-healing stages are fully exerted, so that thebone can be more effectively and quickly self-healed.

Owner:HANGZHOU DIANZI UNIV

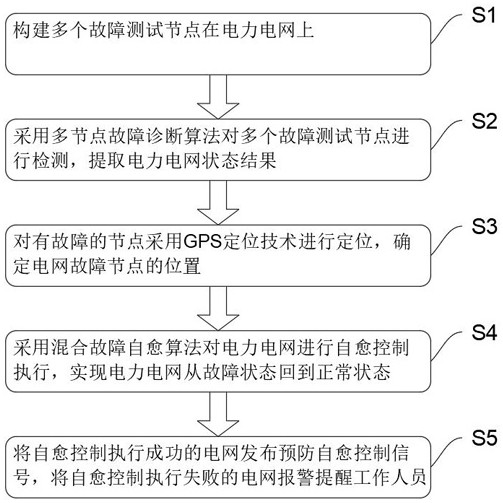

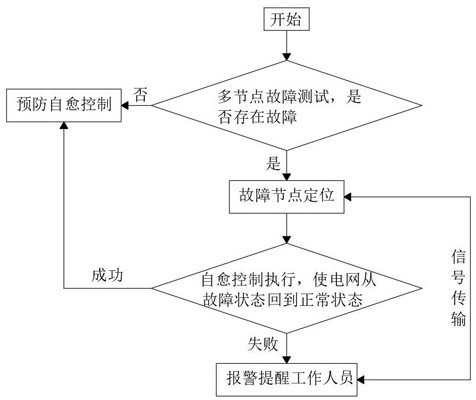

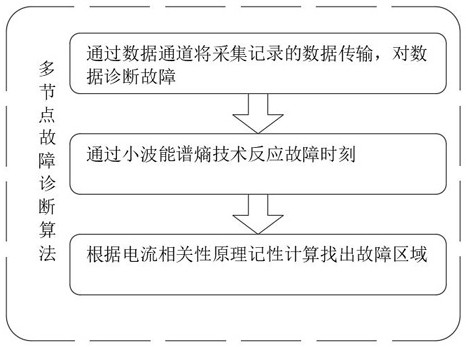

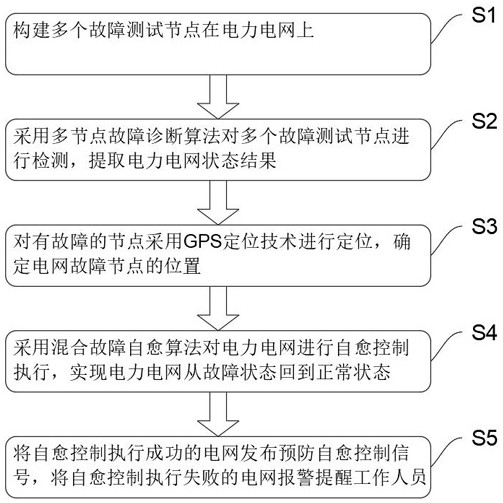

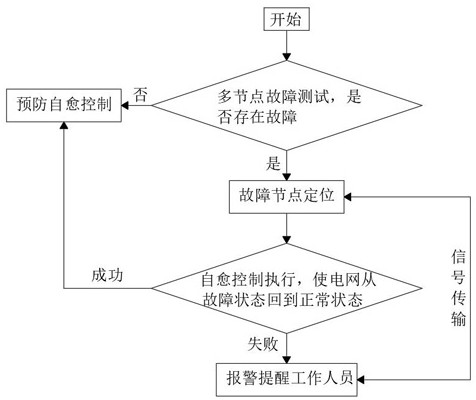

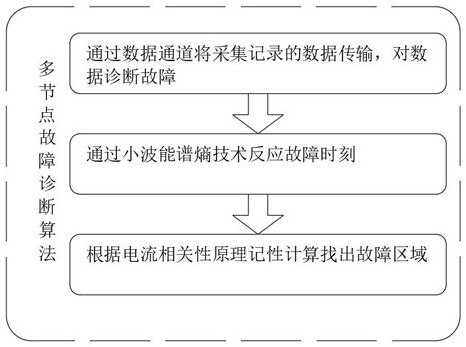

Power self-healing method for multi-node fault test

ActiveCN113612229AImprove recovery efficiencyGood self-healing effectFault location by conductor typesInformation technology support systemGrid faultControl signal

The invention relates to the technical field of electric power self-healing and particularly relates to an electric power self-healing method for a multi-node fault test. The method comprises the following steps of constructing a plurality of fault test nodes on a power grid; detecting a plurality of fault test nodes by adopting a multi-node fault diagnosis algorithm, and extracting a power grid state result; positioning the fault node by adopting a GPS positioning technology, and determining the position of the fault node of the power grid; performing self-healing control execution on the power grid by adopting a hybrid fault self-healing algorithm; the power grid successfully executing self-healing control issuing a self-healing prevention control signal, and the power grid failed in self-healing control execution being alarmed to remind a worker. The method is advantaged in that the node position of the power grid fault can be accurately obtained, recovery efficiency is improved, the self-healing effect is good, when self-healing control execution power grid recovery fails, an alarm is given to remind a worker in time, troubleshooting and maintenance are carried out according to a fault node positioning position, use safety of the power grid is improved, and practicability is higher.

Owner:深圳市景星天成科技有限公司

An electric power self-healing method for multi-node fault testing

ActiveCN113612229BImprove recovery efficiencyImprove self-healing effectFault location by conductor typesInformation technology support systemGrid faultControl signal

The invention relates to the technical field of electric power self-healing, in particular to a power self-healing method for multi-node fault testing. It includes the following steps: building multiple fault test nodes on the power grid; using a multi-node fault diagnosis algorithm to detect multiple fault test nodes, and extracting the status results of the power grid; using GPS positioning technology to locate faulty nodes and determining The position of the fault node of the power grid; the hybrid fault self-healing algorithm is used to perform self-healing control on the power grid; the power grid with successful self-healing control is issued a preventive self-healing control signal, and the power grid that fails to perform self-healing control is alarmed to remind the staff. The invention can accurately obtain the node position of the power grid fault, improve the recovery efficiency, and has a good self-healing effect. When the self-healing control fails to execute the power grid recovery, it will alarm and remind the staff in time, and check and repair according to the location of the faulty node to improve the use of the power grid. Safer and more practical.

Owner:深圳市景星天成科技有限公司

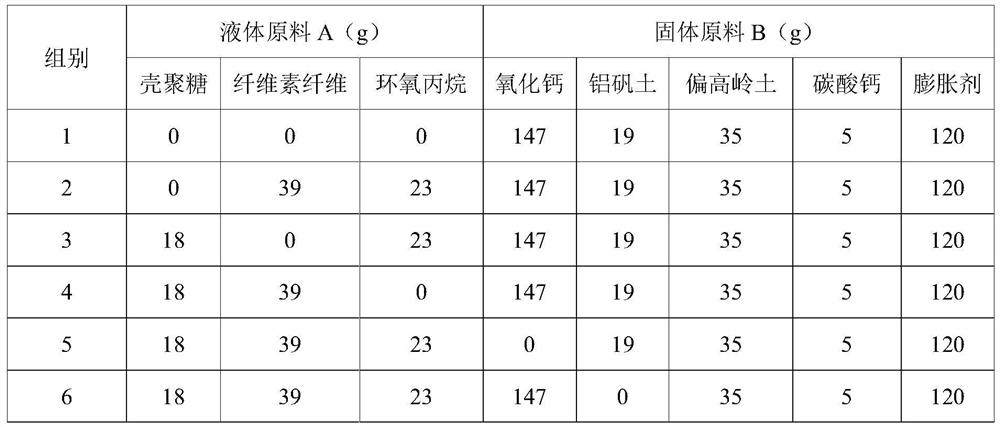

Concrete crack self-repairing agent as well as preparation method and application thereof

ActiveCN114751675AHigh compressive strengthHigh strength recoverySolid waste managementKaolin clayCellulose fiber

The invention discloses a concrete crack self-repairing agent which is mainly composed of a liquid raw material A and a solid raw material B. The liquid raw material A comprises the following specific components in parts by weight: 10-25 parts of chitosan, 20-50 parts of cellulose fiber and 10-25 parts of epoxypropane; the solid raw material B comprises the following specific components in parts by weight: 100-200 parts of calcium oxide, 10-25 parts of bauxite, 20-40 parts of metakaolin, 5-10 parts of calcium carbonate, 100-150 parts of an expanding agent and sufficient water. The concrete crack self-repairing agent provided by the invention is doped, so that the compressive strength of concrete is improved, the compressive strength after crack repairing is higher than that before crack prefabrication, the compressive strength after concrete crack repairing is improved, the strength recovery rate is relatively good and can reach 155%, the crack repairing effect is relatively good, and the cracks are completely healed; the self-repairing effect is good; and after being added into concrete, the anti-freezing agent can improve the compactness of slurry, reduce holes, has better compatibility with a matrix, is beneficial to crack repair, obviously improves the freezing resistance, has a good application prospect, and is suitable for wide popularization and application.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS +1

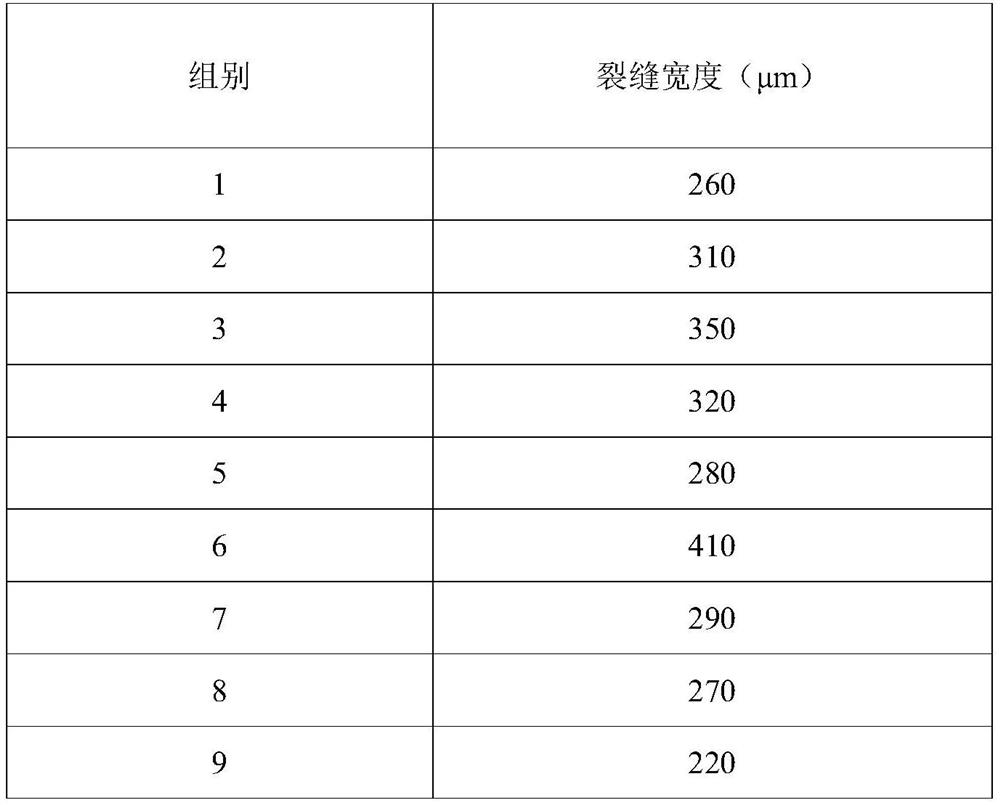

Self-repairing wear-resistant coating and preparation method thereof

The invention provides a self-repairing wear-resistant coating and a preparation method thereof. The coating is prepared from the following raw materials in parts by weight: 50 to 100 parts of modified phenolic resin, 10 to 20 parts of calcium naphthenate, 10 to 20 parts of methyltrimethoxysilane, 15 to 30 parts of self-repairing microcapsules and 8 to 15 parts of latent curing agent, the self-repairing microcapsule comprises a capsule core and a capsule wall; the capsule core comprises a catalyst and ethyl cellulose; the capsule wall is made of modified phenolic resin. When the coating is coated to form a coating, the coating has excellent wear resistance and stable self-repairing characteristic, the coating has high adhesive force with a pasted object, and in addition, the coating also has good mechanical strength and excellent water resistance.

Owner:GUANGDONG MAYDOS BUILDING MATERIALS LTD CO

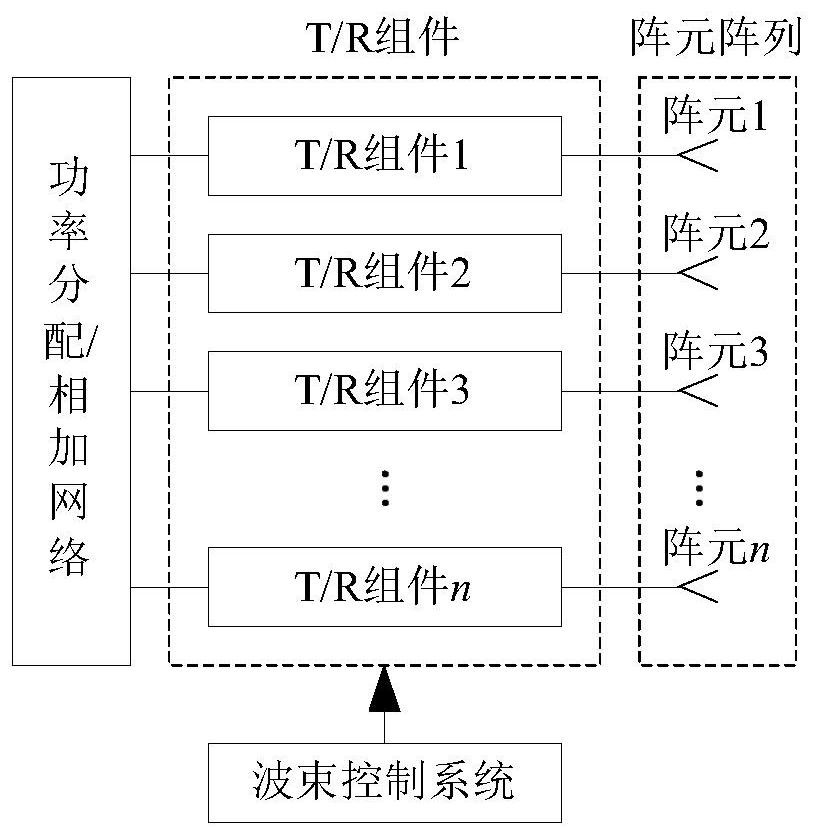

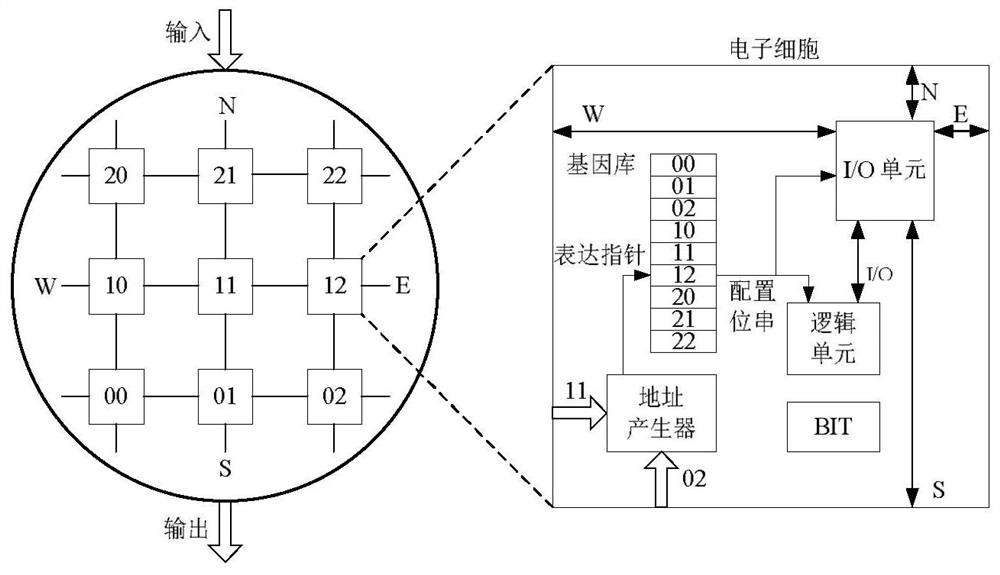

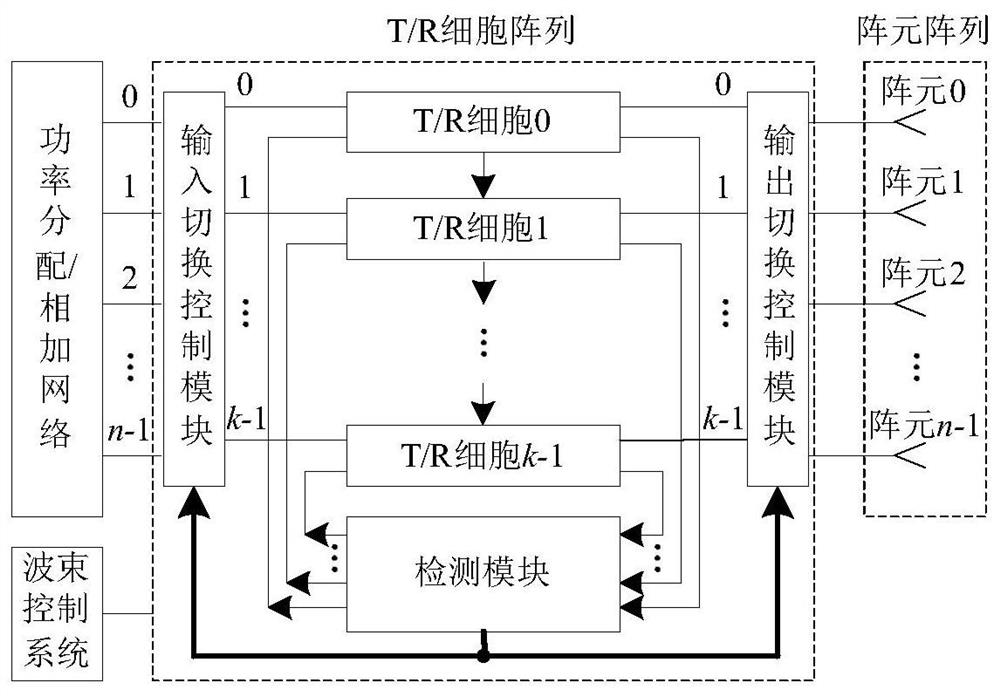

Array antenna with fast self-healing ability and its self-healing method

ActiveCN109980367BFast self-healingImprove self-healing effectAntenna arraysAntennas earthing switches associationMechanical engineeringSoftware engineering

The invention discloses an array antenna with a fast self-repairing ability and a self-repairing method thereof, and relates to the technical field of array antennas. The array antenna comprises an array element array, a T / R cell array, a power distribution / addition network and a beam control system, wherein the T / R cell array includes an input switching control module, k T / R cells, a detection module and an output switching control module. The array antenna can realize fast self-repairing thereof through fast switching of the T / R cells on the basis of fast self-detection, the original state of each radiation array element signal is maintained in the self-repairing process, the mutual coupling between the array elements does not change, and the self-repairing effect is improved.

Owner:ARMY ENG UNIV OF PLA

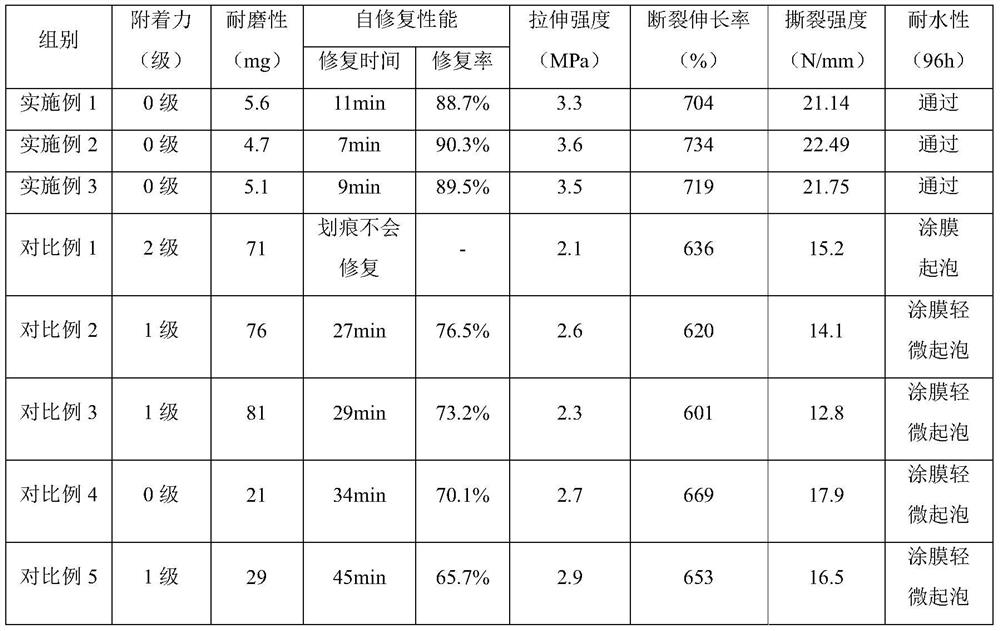

Self-healing polyurethane waterproof coating and preparation method thereof

ActiveCN106010188BQuality is not affectedRapid Response ExpansionPolyurea/polyurethane coatingsRapid constructionSelf repair

The invention discloses a self-repaired polyurethane waterproof coating and a preparation method thereof. The self-repaired polyurethane waterproof coating is a one-component or two-component coating and consists of 70-90% of polyurethane waterproof material and 10-30% of microcapsule material both by weight. In the invention, by adopting the technology, the base layer cracking and consequent pull crack of the waterproof layer are avoided, self-repairing is realized, and harsh requirements on the base layer are reduced; a perfect self-repairing effect is realized on the small cracks of the building concrete base layer caused by heat expansion and cold contraction and cement hydration, the efficacy of the waterproof material is greatly enhanced, and the self-repairing idea opens up a new thought for the building waterproofing; and moreover, the technology is simple and convenient, rapid construction can be realized, maintenance is not needed, the work efficiency is high, and the technology is the future development direction of building waterproofing.

Owner:浙江鲁班建筑防水有限公司

A high-strength corrosion-resistant titanium-steel composite pipe and its production process

ActiveCN110270687BGuarantee interlayer compactnessImprove interfacial binding stabilityRigid pipesAlloyTitanium

The present invention proposes a high-strength corrosion-resistant titanium-steel composite pipe and its production process, including an outer steel pipe and an inner titanium pipe, both of which are coaxially socketed, the inner wall of the steel pipe is provided with a number of slots, and the outer wall of the titanium pipe A number of rib assemblies are fixed, the outer wall of the rib assembly is in interference fit with the inner wall of the steel pipe, and the inner wall of the steel pipe and the outer wall of the titanium pipe are filled with an alloy layer; the present invention has a targeted design for the composite surface structure of titanium and steel pipes, And the alloy layer is filled, which effectively ensures the interlayer compactness and high interface bonding stability. At the same time, the filled alloy layer has a good guiding effect on the infiltration of metal elements under high temperature conditions. In addition, the rib component not only improves the strength but also has good The self-healing effect has an excellent compensation effect on the high-temperature deformation of the titanium tube, reduces the deformation rate, and significantly improves the comprehensive mechanical properties.

Owner:江苏众信绿色管业科技有限公司

Double network composite hydrogel and its preparation method and oil-water separator

ActiveCN108164643BImprove tensile propertiesImprove self-healing effectLiquid separationSilica nanoparticlesSwelling ratio

The invention relates to the field of materials, in particular to double-network composite hydrogel, a preparation method of the double-network composite hydrogel, and an oil-water separator. According to the method, an amino modified silicon dioxide nanoparticle, an acrylamide-acrylic acid copolymer and chitosan are cross-linked into a double-network structure by two pure physical effects of a hydrogen bond and an ionic bond; the double-network composite hydrogel has excellent tensile and underwater super-lipophobic properties, a certain self-repairing effect and a smaller swelling ratio; andthe oil-water separator prepared by coating a copper net with the double-network composite hydrogel is long in life and difficult to damage. The tensile strain of the double-network composite hydrogel is 1500-2000%; the tensile stress is 400-450kpa; a self-healing effect is obvious; the swelling ratio is smaller; and an underwater contact angle reaches 164 DEG. The separation efficiency of the oil-water separator on an oil-water mixture reaches 99.71%, and the hydrogel is an oil-water separation material with good development prospects.

Owner:合肥龙智机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com