Manufacturing method of super-hydrophobic fabric and super-hydrophobic fabric

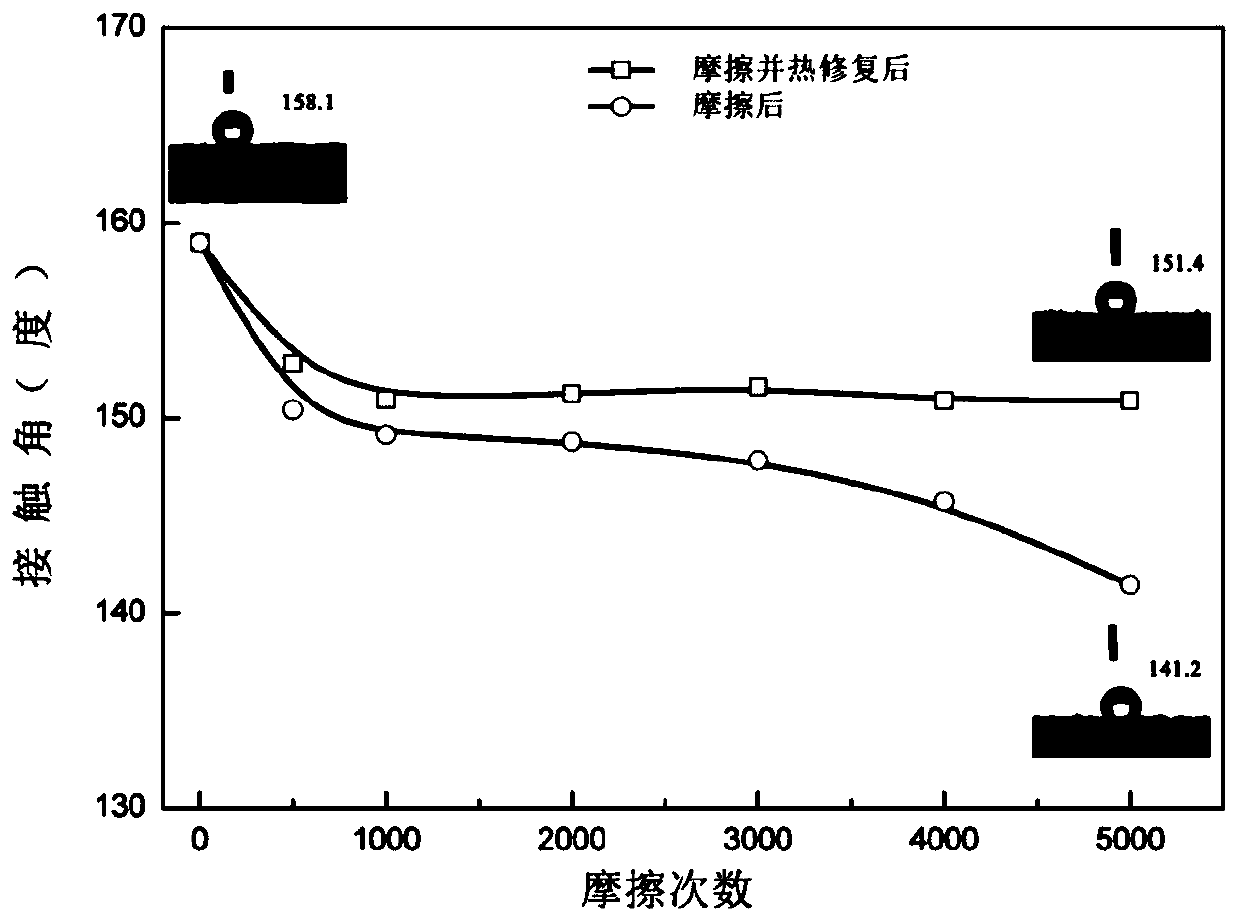

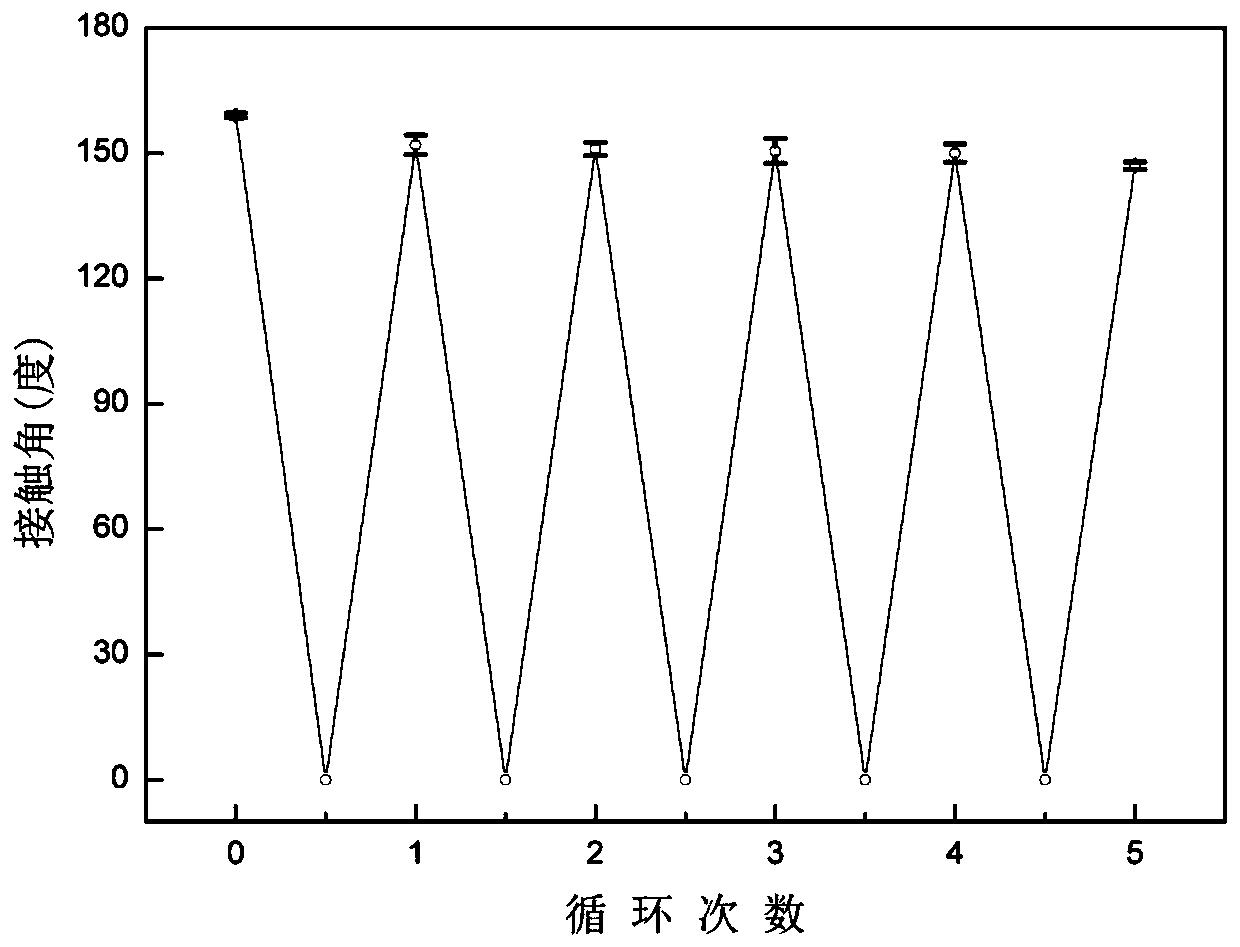

A super-hydrophobic and fabric technology, which is applied in the processing of textile materials, textiles and papermaking, and liquid-repellent fibers, etc., can solve the problems of aggravated hydrophobic structure damage, easy adhesion to other substances, and low durability, achieving excellent Antibacterial properties, maintenance of self-healing properties, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] S1. Hydrolyzing tetrabutyl titanate to obtain titanium dioxide sol.

[0041] S11, adding tetrabutyl titanate into the absolute ethanol solution to obtain a tetrabutyl titanate absolute ethanol solution.

[0042] S12. At room temperature, add 100ml of tetrabutyl titanate absolute ethanol solution with a concentration of 250g / L to a mixed solution consisting of 80ml of absolute ethanol, 20ml of glacial acetic acid and 20ml of deionized water dropwise. While stirring, continue to stir at room temperature after the dropwise addition until the solution appears light blue, and a titanium dioxide sol is prepared.

[0043] S2. Complexing silver ions and amphiphilic polymers to obtain amphiphilic polymers complexed with silver ions.

[0044] Add 1ml of silver nitrate aqueous solution with a concentration of 0.1mol / L dropwise to 10ml of an amphiphilic hyperbranched polymer ethanol solution with a concentration of 20g / L, and stir while adding to obtain the amphiphilic compound comp...

Embodiment 2

[0057] S1. Hydrolyzing tetrabutyl titanate to obtain titanium dioxide sol.

[0058] S11, adding tetrabutyl titanate into the absolute ethanol solution to obtain a tetrabutyl titanate absolute ethanol solution.

[0059] S12. At room temperature, add 100ml of tetrabutyl titanate absolute ethanol solution with a concentration of 250g / L to a mixed solution consisting of 80ml of absolute ethanol, 20ml of glacial acetic acid and 20ml of deionized water dropwise. While stirring, continue to stir at room temperature after the dropwise addition until the solution appears light blue, and a titanium dioxide sol is prepared.

[0060] S2. Complexing silver ions and amphiphilic polymers to obtain amphiphilic polymers complexed with silver ions.

[0061] Add 1ml of silver nitrate aqueous solution with a concentration of 0.1mol / L dropwise to 10ml of an amphiphilic hyperbranched polymer ethanol solution with a concentration of 20g / L, and stir while adding to obtain the amphiphilic compound co...

Embodiment 3

[0073] S1. Hydrolyzing tetrabutyl titanate to obtain titanium dioxide sol.

[0074] S11, adding tetrabutyl titanate into the absolute ethanol solution to obtain a tetrabutyl titanate absolute ethanol solution.

[0075] S12. At room temperature, add 100ml of tetrabutyl titanate absolute ethanol solution with a concentration of 250g / L to a mixed solution consisting of 80ml of absolute ethanol, 20ml of glacial acetic acid and 20ml of deionized water dropwise. While stirring, continue to stir at room temperature after the dropwise addition until the solution appears light blue, and a titanium dioxide sol is prepared.

[0076] S2. Complexing silver ions and amphiphilic polymers to obtain amphiphilic polymers complexed with silver ions.

[0077] Add 1ml of silver nitrate aqueous solution with a concentration of 0.1mol / L dropwise to 10ml of an amphiphilic hyperbranched polymer ethanol solution with a concentration of 20g / L, and stir while adding to obtain the amphiphilic compound co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com