Concrete crack self-repairing agent as well as preparation method and application thereof

A concrete and self-repairing technology, which is applied in the field of concrete crack repair, can solve the problems of non-destructive micro-cracks, relatively little research on the evaluation method of self-repair effect of electrodeposition method, and creep, so as to improve the density of slurry and self-repair Good repair effect and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a concrete crack self-healing agent, which is mainly composed of a liquid raw material A and a solid raw material B. The specific components of the liquid raw material A are 18 g of chitosan, 39 g of cellulose fibers, and 23 g of propylene oxide; The specific components of the solid raw material B are 147 g of calcium oxide, 19 g of bauxite, 35 g of metakaolin, 5 g of calcium carbonate, 120 g of swelling agent, and sufficient water.

[0031] Its specific preparation method comprises the following steps:

[0032] (1) adding cellulose fiber, chitosan, and propylene oxide by weight in water successively, stirring to make turbid liquid, and packing it into a light-proof sealed tank to obtain liquid raw material A;

[0033] (2) adding calcium oxide, bauxite, metakaolin, calcium carbonate, and swelling agent to mixed calcium oxide, bauxite, metakaolin, calcium carbonate, and swelling agent successively by weight, and then adding the mixture to water, ...

Embodiment 2

[0040] On the basis of the above-mentioned embodiments, this embodiment provides a specific application of the above-mentioned concrete crack self-healing agent, which is specifically applied in the preparation of concrete capable of automatically repairing cracks. The specific preparation process of the concrete is specifically as follows: avoiding the In the environment of direct sunlight, stir and mix the solid raw material B in the cement, sand, water, and concrete crack self-healing agent, and finally add the liquid raw material A, stir and mix evenly, wherein the mass ratio of cement, sand and water is 2:5 : 1, the quality of the concrete crack self-healing agent is 7.5% of the added cement quality. The other parts of this embodiment are the same as the above-mentioned embodiments, and are not repeated here.

Embodiment 3

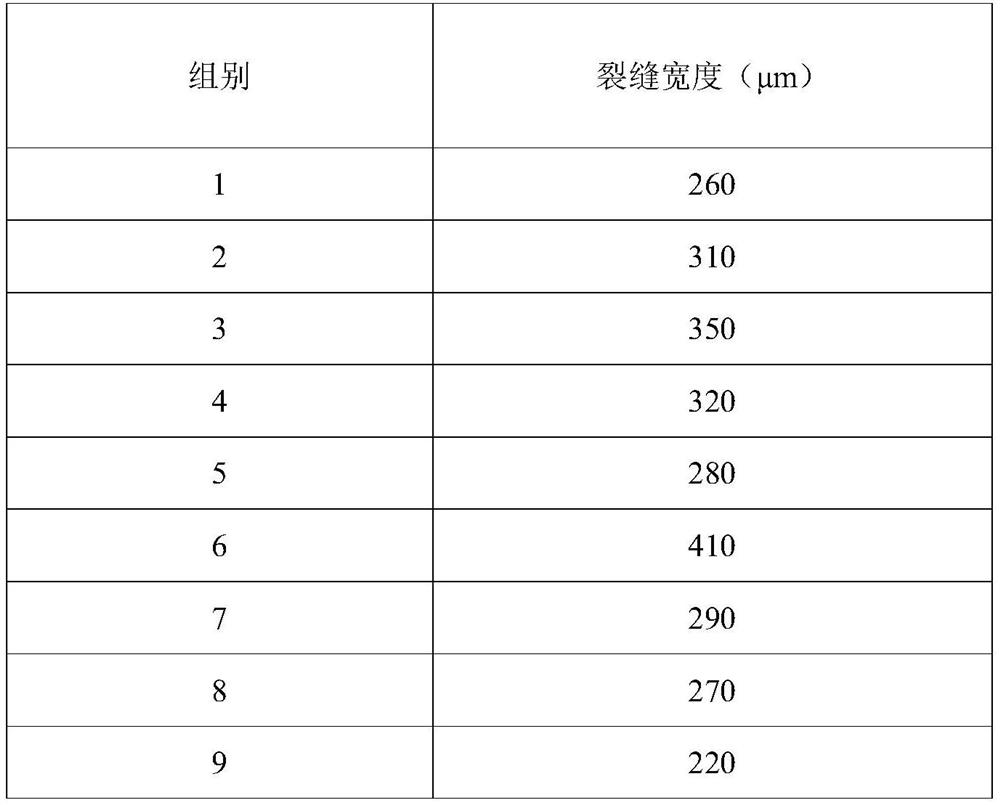

[0042] The present embodiment is directed to the concrete crack self-healing agent provided by the above-mentioned embodiment, and carries out a concrete crack repair experiment:

[0043] (1) Preparation of concrete self-healing agent:

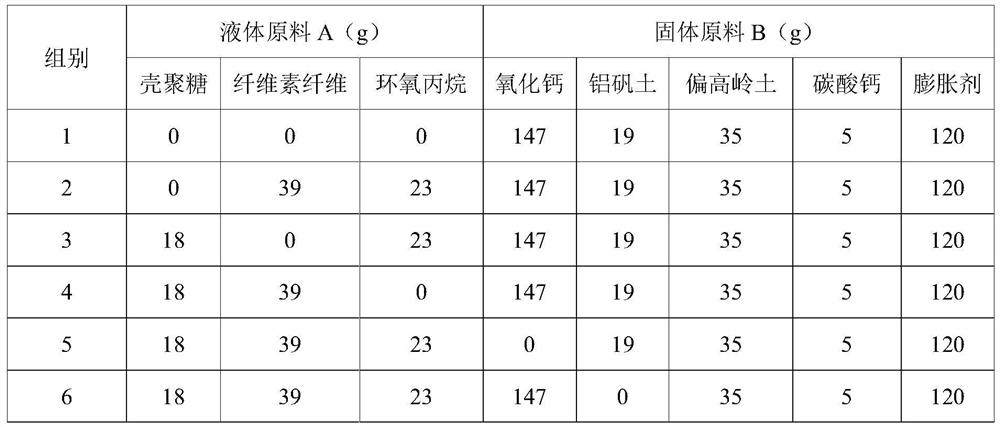

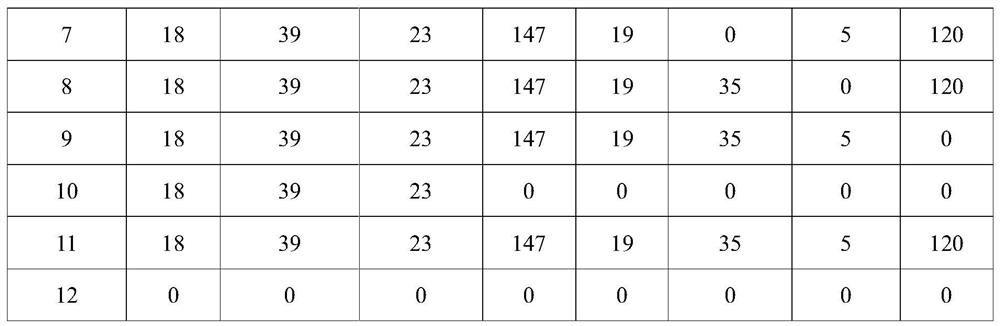

[0044] The concrete self-healing agent is composed of liquid raw material A and solid raw material B, wherein the liquid raw material A contains three components of chitosan, cellulose fiber and propylene oxide, and the solid raw material B contains calcium oxide, bauxite, metakaolin, carbonic acid There are five components of calcium and expansion agent, and the experiment is designed by the uniform design method. Each component (eight components), liquid raw material A, and solid raw material B are used as influencing factors. There are a total of ten influencing factors, and 10 kinds of ratios are obtained. The concrete crack repairing agent was used as the control group, and the concrete crack self-healing agent prepared in the above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com