Double-network composite hydrogel, preparation method of double-network composite hydrogel and oil-water separator

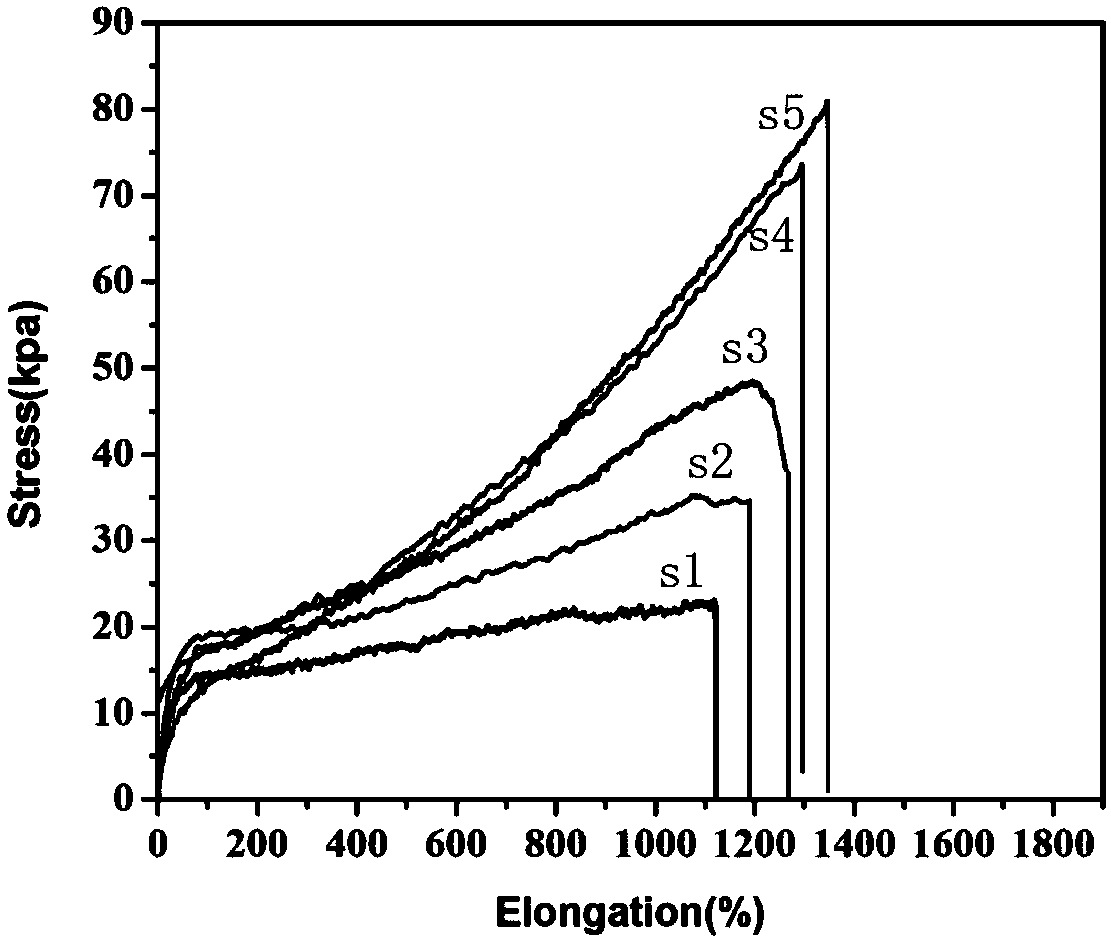

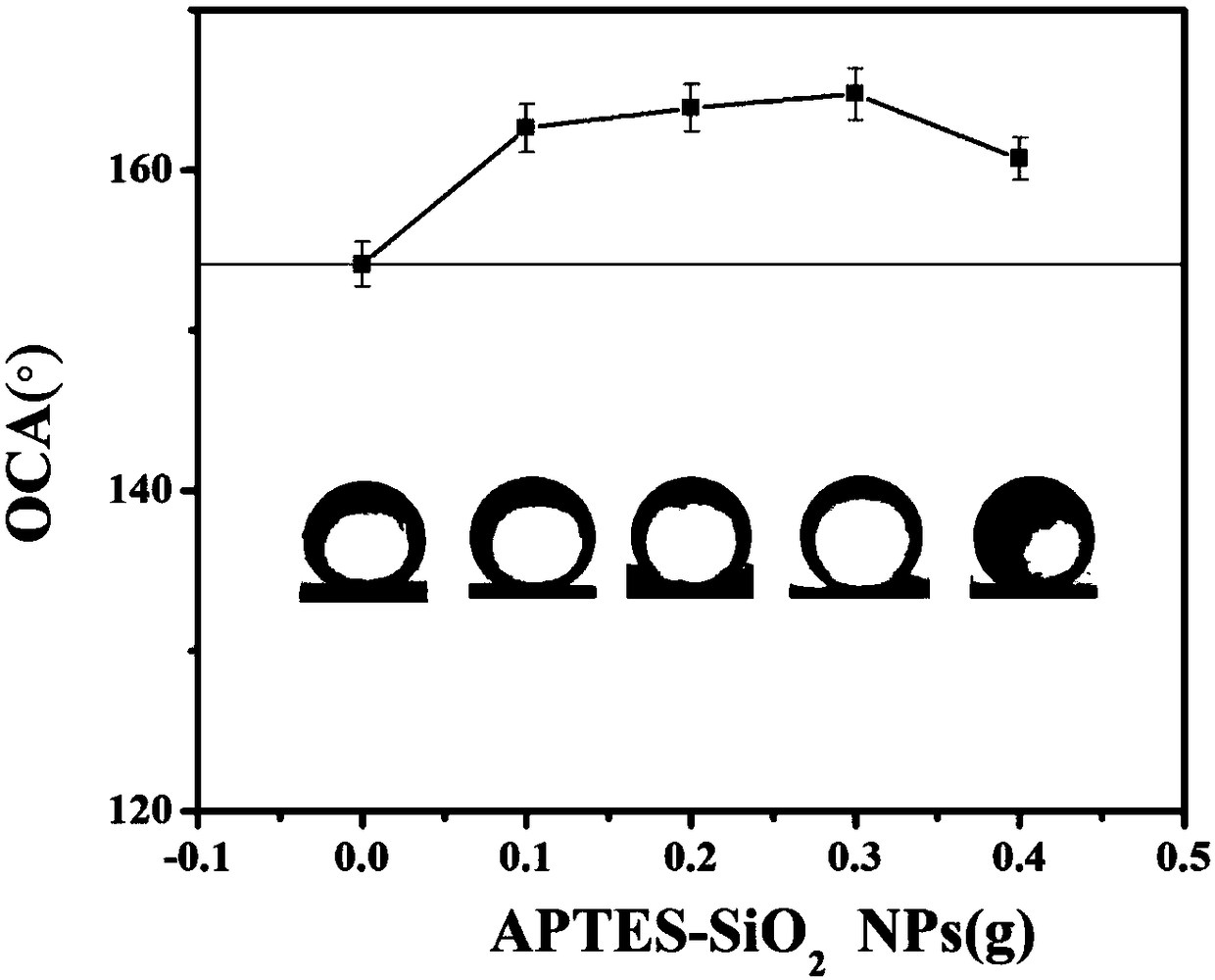

A composite hydrogel and double network technology, applied in the field of materials, can solve the problems of irreparable, high swelling rate of hydrogel coatings, and achieve the effects of excellent tensile properties, low self-healing effect and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a double-network composite hydrogel provided in an embodiment of the present invention includes:

[0030] S1. After mixing acrylamide, acrylic acid, silica nanoparticles and deionized water, stir the mixed solution until it is uniform and transparent to obtain the first solution.

[0031] Further, after mixing the acrylamide, acrylic acid, silica nanoparticles and deionized water, the mixed solution is stirred until uniform and transparent, using ultrasonic stirring.

[0032] Further, ultrasonically stir for 5-20 minutes.

[0033] Further, the amount of acrylamide is 5-20g, the amount of acrylic acid is 5-10g, the mass of deionized water is 5-20g, and the mass of silica nanoparticles is 0.5%-5% of the total amount of acrylamide and acrylic acid.

[0034] Specifically, acrylamide, acrylic acid, silicon dioxide nanoparticles and deionized water were mixed and stirred evenly, then added to a 50ml round bottom flask, ultrasonically stirred for 5 to 2...

Embodiment 1

[0054] A kind of double-network composite hydrogel provided in this embodiment is prepared by the following method:

[0055] Weigh 5g of acrylamide and 3.33g of acrylic acid; dissolve them in 5g of deionized water and add them to a 50ml round bottom flask, then add 0.5% of the total mass of acrylamide and acrylic acid to amino-modified silica nanoparticles under ultrasonic conditions Under full stirring and dispersion for 5 minutes, a uniform and transparent first solution was obtained.

[0056] Then measure 0.01 g of glacial acetic acid, add it to the first solution, adjust its pH to be acidic, add 0.1 g of chitosan therein, and ultrasonically stir for 0.5 hour, so that all the chitosan is dissolved to obtain a viscous second solution.

[0057] After passing nitrogen gas under magnetic stirring, 2-hydroxy-2-methylpropiophenone was added as a photoinitiator, sealed in a transparent mold and placed under sunlight for one day, and then polymerized to form a double-network compos...

Embodiment 2

[0061] A kind of double-network composite hydrogel provided in this embodiment is prepared by the following method:

[0062] Weigh 20g of acrylamide and 8.57g of acrylic acid; dissolve them in 20g of deionized water and add them to a 50ml round bottom flask, then add amino-modified silica nanoparticles with 5% of the total mass of acrylamide and acrylic acid under ultrasonic conditions Under full stirring and dispersion for 20 minutes, a uniform and transparent first solution was obtained.

[0063] Then measure 0.5 g of glacial acetic acid, add it to the first solution, adjust its pH to be acidic, add 1 g of chitosan therein, and ultrasonically stir for 3 hours, so that all the chitosan is dissolved to obtain a viscous second solution.

[0064] After passing nitrogen gas under magnetic stirring, add 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone as a photoinitiator, seal it in a transparent mold and place it under sunlight for one day, and polymerize to form Double netwo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com