Thermal deformation and stabilization annealing process and material of Al-Mg-Mn-Er-Zr alloy

A stabilized annealing and thermal deformation technology, which is applied in the field of metal materials, can solve the problems of corrosion resistance deterioration of alloys, and achieve the effect of improving corrosion resistance and good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1 (i.e. comparative example):

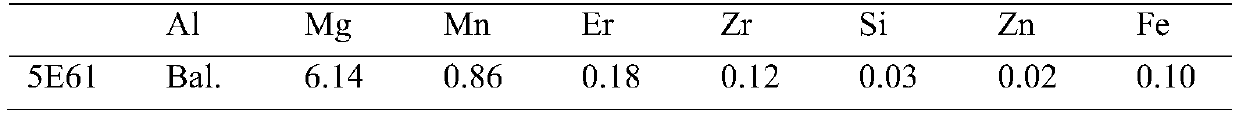

[0013] The Al-Mg-Mn-Er-Zr alloy ingot is subjected to hot deformation above 250°C. The composition of the alloy was analyzed by X-ray fluorescence (XRF), and the specific composition is shown in Table 1.

[0014] Table 1 The actual composition of the experimental alloy (wt.%)

[0015]

Embodiment 2

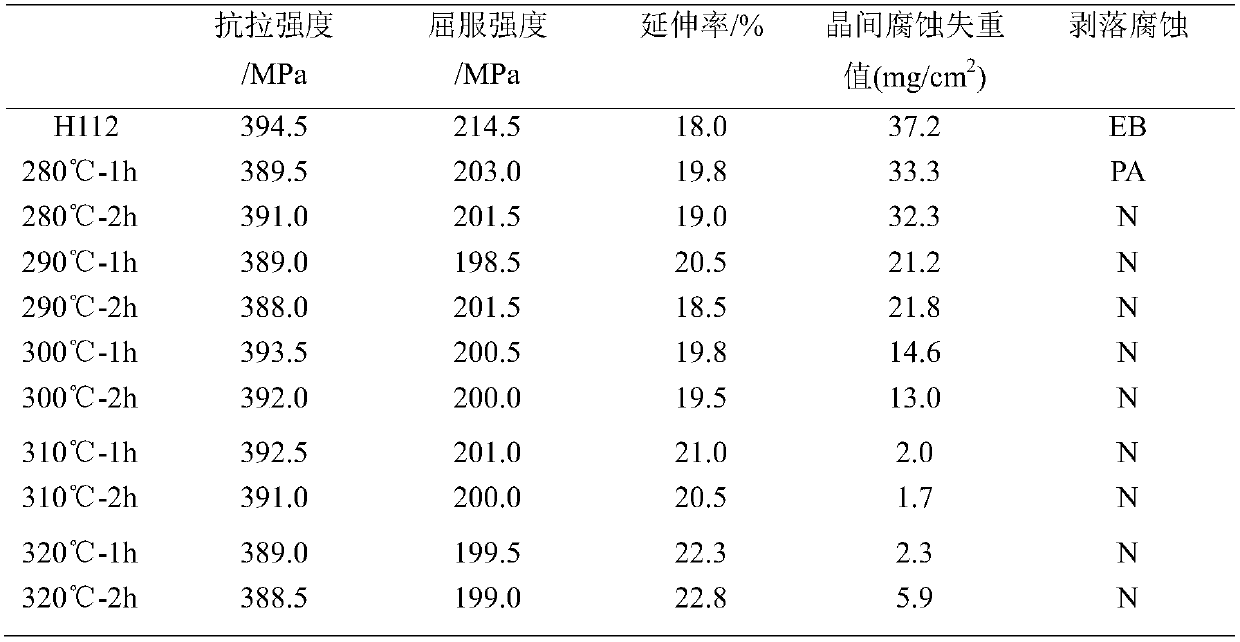

[0017] Perform stabilization annealing on the thermally deformed plates in Example 1 at 280°C, 290°C, 300°C, 310°C and 320°C respectively, the annealing time is 1-2h, and stretch the experimental alloy after stabilization annealing Performance test, intergranular corrosion weight loss test (American Society for Testing and Materials standard ASTM G67-04) and exfoliation corrosion test (American Society for Testing and Materials standard ASTM G66-99), the test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com